- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cnc machines

Results for

Cnc machines - Import export

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

The C 22 ensures the precise, cost effective and efficient production of parts. The numerous automation solutions enhance its range of application; individual configuration is easy thanks to the modular design. The Hermle engineers have essentially designed and created this machine with space in mind. With the most efficient footprint possible, the C 22 offers maximum efficiency. And it goes without saying that large components can be machined, too. Nonetheless, the C 22 is ultra compact and ensures the necessary clearance for 5-side/5-axis machining. Short process cycles, quick workflows and the highest possible machine dynamics: The C 22 is designed to machine complex geometries with high accuracy and small tolerances. The circular tool magazine is integrated into the base body of the machining centre and can house up to 65 cutters; additionally, it is possible – as with almost all HERMLE machining centres – to adjust the operating system to the user.

Request for a quote

FÖHRENBACH GMBH

Germany

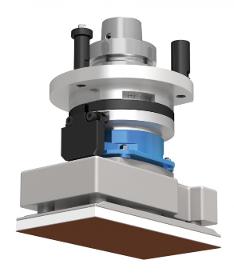

The directly driven dividing apparatus of the TA3 series are excellent suited for the exact positioning of workpieces or, due to the high speeds, also for round machining of workpieces. The direct drive is absolutely backlash-free and ensures highest dynamics. All dividing apparatus are equipped with an automatic, pneumatically actuated clamping system. The dividing apparatus TA3G180 can be optionally equipped with an automatic hydrodehn clamping system (hydraulic expansion technology). Field of applications Rotation axis for angle positioning of work piece carriers in: Processing centers CNC - grinding machines Tool machines Laser processing machines, etc.

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Absolute exposed linear encoder for CNC machine tools with Siemens (DRIVE-CLIQ) , Fanuc and Mitsubishi CNC. Due to the magnetic operating principle of the SQ47, the measuring system is extremely insensitive to contamination, e.g. oil, water and dust, while at the same time providing maximum accuracy and resolution. Contactless read head design without ball bearing guide Measuring lengths: 90mm - 3.740mm Accuracy: 3+3ML/1,000 µm(p-p) Max. Resolution: 5nm Max. Response speed: 200m/min Protection class: IP67 without supplied air Interface: Siemens DriveCliQ, Fanuc, Mitsubshi Thermal expansion like steel Easy installation

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC controlled machine with rotary indexing table and tool magazine. Automatic tool changer with HSK spindle tools. Mosts common tools used are tampico and sisal fibre brushes for bottom, bottom radius and side wall polishing.

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

High resolution magnetic absolute linear encoder system for CNC machine tools with robust design. The read head is guided contactless without ball bearing Measuring lengths: 70mm - 3.770mm Accuracy: 3+3ML/1.000 µm(p-p) Max. Resolution: 5nm Max. Response speed: 200m/min Extremely robust against vibration and shock Insensitive to contamination such as oil, water, moisture and dust due to the magnetic operating principle Same thermal expansion behavior as steel or cast iron machine bed Compatible with serial protocols from Fanuc, Mitsubishi and Siemens Siemens DriveCliQ version is Functional Safety certified

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC controlled machine for belt grinding and polishing stainless steel weld seams. Belt grinding on the contact wheel or slack belt unit is possible for edge profiling.

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Highly accurate magnetic absolute linear encoder with slim design for machine tools with Siemens, Fanuc, and Mitsubishi CNCs Easy integration in cramped installation conditions due to the slim design Insensitive to contamination such as oil, water, moisture and dust due to the magnetic operating principle Same thermal expansion behavior as steel or cast iron. Compatible with serial protocols from Fanuc, Mitsubishi and Siemens Siemens DRIVE-CLIQ version is Functional Safety certified

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

Designed for machining cubic parts up to 100 kg in weight, the C12 works in the most diverse applications compactly, precisely and dynamically. The C 12 is more than a match for larger models. Aside from its compact size, the main focus is on HERMLE's core competences precision, durability and dynamics. Designed as a 5-axis machining centre featuring the different spindle speeds and different interfaces, the ideal speed is available for almost every area of application. The C 12 can be equipped with two-piece ore compact spindles. All tool spindles can be replaced quickly and easily in case of failure. Thanks to the respective HERMLE set-ups, the C 12 also meets the ever increasing requirements placed on speed and precision. The C 12 machining centre additionally provides extensive options for more intricate applications.

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

Within the HERMLE range of models, the C 250 is an entry-level model into the world of 5-axis & 5-sided machining. Nevertheless, the “large” models are in no way inferior. Thanks to the large swivelling range of the workpieces in the working area, the utilisation of the complete traverse range and the large collision circle between the table side walls, the C 250 offers the largest working area relative to the installation area. The C 250 is designed for daily use – maximum user-friendliness thanks to pivotable control panel and minimum table distance from the operator and optimum loading height with option ofloading by crane. Maximum precision thanks to the HERMLE swivelling rotary table concept. The table variants of the C 250 therefore stand for the highest quality and optimum use of material – from the cast housing to the installed gear motors: Made in Germany – made in Gosheim.

Request for a quote

F. ZIMMERMANN GMBH

Germany

The 5-axis portal milling machine FZ 25 is a universal solution for the machining of highly complex and at the same time voluminous components. Model materials as well as composites through to light alloys can all be machined with this HSC gantry machine. This machine range fulfils the specific requirements of many sectors: - In the automobile design where large models need to be produced (e. g. cars on a scale of 1:1). - In pattern and tool making, especially in connection with very large workpieces with deep contours need to be machined (e. g. large rotation-symmetric moulds such as tanks and pools, etc.). - In the boatbuilding and shipbuilding industries, where huge work areas are required in all three axes, since the components are often elongated in shape. - In the aircraft industry, e. g. for milling panels, other large parts and components with extreme contours. In the wind energy industry with its long thin blades and bulbous hubs.

Request for a quote

F. ZIMMERMANN GMBH

Germany

The FZ 35 Portal Milling Machine is the economical solution for a vast variety of tasks. For finishing and roughing of steel and cast alloys, light alloys and plastics, these machines can be used for all types of materials*. This model range satisfies the sector-specific requirements of many industries. - In pattern and mold making for machining patterns, molds, injection-molding dies and sheet-metal forming tools in all their variety. - Outstanding capacity utilization, because different parts can be set-up at the same time and then machined in succession – of course in unmanned shifts as well. - In aircraft production for the trimming of panels, stretchforming parts, rudders etc., or for special applications of acrylic sheet, cockpit canopies for example. - In ship and boatbuilding for the manufacture of laminating forms, deck structures etc.

Request for a quote

F. ZIMMERMANN GMBH

Germany

The FZ 30 and FZ 35 Portal Milling Machines are the economical solution for a vast variety of tasks. For finishing, and with the FZ 35 even roughing of steel and cast alloys, light alloys and plastics, these machines can be used for all types of materials*. This model range satisfies the sector-specific requirements of many industries. - In pattern and mold making for machining patterns, molds, injection-molding dies and sheet-metal forming tools in all their variety. - Outstanding capacity utilization, because different parts can be set-up at the same time and then machined in succession – of course in unmanned shifts as well. - In aircraft production for the trimming of panels, stretchforming parts, rudders etc., or for special applications of acrylic sheet, cockpit canopies for example. - In ship and boatbuilding for the manufacture of laminating forms, deck structures etc.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Angle head 0-100° - with flexible angle / stepless adjustment Machining: in any variable position Optional: with IC

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Angle head 90° Machining: without spatial constraint Optional: with EC

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

It is annoying when you have to reclamp individual workpieces. Why not just produce workpieces entirely in a single set-up? Products can be planed in one clamping process using a moulder head on your CNC machine and can be finished using additional units. Moulder heads are suitable for processing products made of solid wood, sheet products such as MDF, plastic or similar materials. Not even large cutting volumes can push the unit to its limits.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Chiseling – Square. Practical. Precise. Typical applications for chiseling processes are stake holes on steps for mounting a handrail or inserting fiche hinges in window processing. Whether hard or soft wood, CNC chiseling units help you achieve precise, square cutouts.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

It‘s a situation you know. You run your hand over a piece of furniture and appreciate its shape under your fingertips. One surface feels rough, another feels fine and smooth. There‘s only one thing that can deliver this distinctive feeling: the perfect sanding pattern. BENZ sanding units make sure that your workpiece gets the exactly right surface, for every shape and surface. Your benefit from machine CNC sanding: no more need for time-consuming clamping for further processing or manual rework. Your production process is streamlined and your production costs are reduced as a result.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cutting - Many different materials, one unit Where wood previously dominated, today you see materials like leather or textiles moving into the production process. Leather-covered seating, foamed-lined instrument cases or lampshades made of pieced-together veneer parts – the list of application examples is long. Despite this new mix of materials, nothing changes for you in production. Thanks to the BENZ SECO cutting unit, you do not need any special machines. Rather, you are able to cut these materials easily on your CNC machine – and without any splintering.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Sanding of surfaces with internal corners ≥90 °: ZUCCO vibrating sanding unit With the SIMOLO eccentric sanding unit, BENZ already has a range with high sanding performance and surface quality, especially for machining small to medium-sized surfaces. With the new ZUCCO vibratory sanding unit sanding surfaces with internal corners ≥ 90 ° is possible. The eccentric movement of the unit ensures uniform workpiece surfaces. As abrasives, commercially available products can be used. Abrasive blanks can be attached to the sanding plate via a hook and loop fastener. These options provide the user with the greatest possible flexibility.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Angle head ≠ 90° - with fixed angle Machining: special machining at fixed angle Optional: with IC

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Angle head 90° - output spindle on both sides Machining: in opposite direction / with different tools Optional: with EC

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

It is annoying when you have to reclamp individual workpieces. Why not just produce workpieces entirely in a single set-up? Products can be planed in one clamping process using a moulder head on your CNC machine and can be finished using additional units. Moulder heads are suitable for processing products made of solid wood, sheet products such as MDF, plastic or similar materials. Not even large cutting volumes can push the unit to its limits.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Chiseling – Square. Practical. Precise. Typical applications for chiseling processes are stake holes on steps for mounting a handrail or inserting fiche hinges in window processing. Whether hard or soft wood, CNC chiseling units help you achieve precise, square cutouts.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Angle head 90° - narrow or extremely narrow design Machining: for extreme spatial constraint / maximum useable tool length Optional: with EC

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quoteResults for

Cnc machines - Import exportNumber of results

41 ProductsCompany type