- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- watering systems

Results for

Watering systems - Import export

ANTHERMO GMBH

Germany

Universal use for a wide range of applications Ice stores are used in more and more areas of technology. In addition to the classic areas of application in refrigeration, air conditioning and commercial kitchen technology, ice storage systems and cold water systems are increasingly being used in process engineering systems. Cold water for subsequent production processes is generated with ice storage tanks. Ice storage systems thus provide stored cold. Use of cheap night electricity tariffs With the help of ice storage technology, cheap nighttime electricity tariffs can be used. During the night, ice is continuously built up on the plates or on the pipe coils. This ice is then available during the day as stored cooling capacity. This can significantly reduce energy costs. The cooling units can also be made smaller when using ice storage systems.

Request for a quote

IGUS® GMBH

Germany

- Low-maintenance system for travel up to 100 m - Other sizes and versions available, travel up to 200 m and more with E2 roller e-chains® - Protection against weather and dirt exposure - Cost-effective and fully enclosed complete solution - Standardized and modular design - Simple wall assembly or optional floor mounting - Cable lengths up to 50% shorter than festooning, low-profile installation and no cable junction - Cables are at all times guided with a defined bending radius, and tensile forces are absorbed by the e-chain® - Cables cannot hook, jam, or tear - No slip ring contacts (as is the case on motor drums) -Cables or hoses can easily be retrofitted at any time Reduce electricity costs - direct drive due to scraper, no additional drives needed (as is the case on motor drums) Scraper arm (e.g. as mechanical connection to the scraper carriage) optionally available - we document the situation on-site and will propose a customised solution

Request for a quote

FLOTTWEG SE

Germany

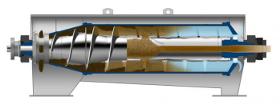

The demands on the quality and efficiency of sewage treatment plants are growing from year to year, not least due to rising energy and disposal costs. As a result, using decanters to dewater sludge means using state-of-the-art technology. The C-series decanters from Flottweg achieve high performance with reduced energy consumption. Flottweg Wastewater Decanters offer advantages over other processes and competitors' machines: ► High dry solids values in the discharged material ► Higher power density within a small footprint ► Powerful Flottweg Simp Drive® drive ► Reduction of operating costs due to reduced need for flocculant ► Additional energy recovery with the Flottweg Recuvane® system ► Economical bowl and scroll drive ► duces the energy consumption of your decanter by 10 to 30 percent

Request for a quote

BURRE HYDRAULIK GMBH

Germany

Application: watergate technology

Request for a quote

BURRE HYDRAULIK GMBH

Germany

Application: Ro-Ro Landing Systems

Request for a quote

BURRE HYDRAULIK GMBH

Germany

Piston rod with ceramic coating With integrated position measuring system Application: floodgate and bridge lifting technology

Request for a quote

HOPPECKE BATTERIEN GMBH & CO. KG

Germany

The trak | uplift save battery is a lead-acid traction battery optimized for use in dusty and harsh environments. It has a robust battery trough with cover, which protects the battery from contamination and violent damage. The water refill system trak | aquafill and the electrolyte level indicator trak | aquacheck, which are fitted as standard, can significantly reduce water refill intervals and costs. In combination with a HOPPECKE trak | charger HF premium charger, virtually maintenance-free operation can be achieved. trak | uplift save is particularly suitable for rental stores and tough operating conditions.

Request for a quote

BEKO TECHNOLOGIES GMBH

Germany

A more economic solution for an environmentally sound condensate management is the decentralised oil-water separation directly at the source. Condensate which was processed with ÖWAMAT can be directly introduced as cleaned water into the sewerage system. The devices have a national technical approval and do not require a permit according to the law on water. In addition, the ÖWAMAT oil-water separators do not create any energy costs, boast enormous filter service lives and can be retrofitted into older systems without difficulty.

Request for a quote

FLOTTWEG SE

Germany

In the process of treating waste water, fine biological sludge is constantly produced during the decomposition process at a sewage treatment plant. For a stable decomposition process in the biological treatment phase, the sludge produced in the secondary sedimentation pond, also known as excess sludge, is removed and fed into the digestion tower. Flottweg's OSE decanters thicken the sludge before it enters the digestion tower. Sewage treatment plants benefit from an even feeding of the digestion tower and can thus optimally use the volume of the digestion tower. The Flottweg OSE decanter is specially designed for sludge thickening. ► Highest gas yield through constant feeding of the digestion tower ► Best possible thickening even with changing feed conditions ► Larger sedimentation volume (due to deep pond and steep cone) enables highest power density (10 - 20 percent) with minimum space requirement

Request for a quote

FLOTTWEG SE

Germany

Innovationen sind Flottweg Spezialität. Unsere Xelltorbaureihe spiegelt Erfindergeist, langjährige Erfahrung und technisches Know-How in einer Maschine wieder. Auf Kläranlagen ausgelegt ist die X5E für mittelgroße Kläranlagen die optimale Lösung, wenn es um Schlammentwässerung und Schlammeindickung geht. Die Kosteneinsparung hinsichtlich Entsorgung und Transport ist für viele Kläranlagenbetreiber der ausschlaggebende Punkt, sich für den Flottweg Xelletor zu entscheiden.

Request for a quote

FLOTTWEG SE

Germany

Flottweg C series decanters around the world process 25 million liters of sewage sludge per hour. The dewatering and thickening of sewage sludge plays a decisive role in the wastewater treatment process. Requirements for the quality and efficiency of sewage treatment plants increase year after year, not least driven by the increasing costs of energy and disposal. As a result, the state of the art is now to use decanter centrifuges to dewater and/or thicken the incoming sludge. Flottweg developed the decanters of the C series especially for this purpose. The C7E represents the largest of all the C machines. The C7E increases the proportion of dry substance in the sludge, thereby reducing its volume and weight (due to loss of water). That means that operators need to dispose of, recycle, or burn less sludge. The result: enormous potential savings for the operators of sewage treatment plants.

Request for a quote

FLOTTWEG SE

Germany

Proven know-how meets state-of-the-art technology. This is the best way to describe the new Flottweg decanter C series. We also have the optimal solution for the very large wastewater treatment plants. The combination of our own Simp Drive® drive system, which has been in use since 1994, and Recuvane®, which allows flexible and simple retrofitting as well as targeted discharge of the centrate water, sets new standards for Flottweg in separation technology.

Request for a quote

FLOTTWEG SE

Germany

Flottweg has developed a unique centrifuge concept especially for the high-level dewatering of sewage sludge: The Flottweg Xelletor series. For the wastewater treatment plant operator, dewatering offers enormous savings potential. The costs for transport and disposal of dewatered sewage sludge often account for 80% of the operating costs of mechanical dewatering. The dewatering performance of the Xelletor machine is significantly better than that of our predecessor models. And it's setting new standards in terms of throughput, dry substance, and polymer and energy consumption.

Request for a quote

FLOTTWEG SE

Germany

Honored with the German Innovation Award 2019, the Xelletor series is one of the greatest achievements in the field of sewage sludge. Dewatering sewage sludge is standard for wastewater treatment plants and since it usually has to be transported away, operators have an interest in separating as much water as possible from the sludge. This saves weight and thus reduces costs. Savings of up to 10% in sludge volume and 34% in energy consumption are possible. Our Xelletor high-performance centrifuge inspires customers all over the world with the many years of technical know-how and innovative spirit behind it.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

We know the requirements and wishes of our customers and business partners very well. For this reason, apart from high product quality, great importance is attached to professional project management in particular. Only in this way can construction schedules and completion dates be complied with and projects completed to the full satisfaction of the customer. FLEXIBILITY AND PROFESSIONALISM, WORLDWIDE Lipp understands the requirements of this industry through countless projects in cooperation with German and international engineering offices and plant engineering companies. In addition to professional management of a project, customers pay particular attention to the flexibility of the system and timely execution. These include not only the individual design and assembly but also leak tests that are requested for acceptance. Our professional project management, and technical process expertise, which goes beyond pure container construction

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This automatic washing & drying system provides high efficient cleaning of elastomers in through-feed method (on option washing with de-ionized, de-mineralized or ultra-pure water possible). Starting from the loading station, the washing drums are conveyed automatically to each washing station (→ station pre-washing → station rinsing → station high pressure cleaning → station high pressure drying) and are finally conveyed to the unloading station after treatment. The dimensions of this system depend on the drum dimensions desired (perforation from 3 - 15 mm possible by choice). Set as our default, the models WD3, WD5 and WD9 are available with different sizes. For industry 4.0 demands, this system is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control of the machine via OPC-UA server can be installed additionally. Siliconisation or other coating of elastomers is possible on option.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OPTIGRÜN INTERNATIONAL AG

Germany

L-section for separation of gravel and substrate. Simple installation due to click-connection system. Installed on protection membrane, drainage elements or filter fleeces; connectable to water conduit systems. For roof pitches of up to 5°.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

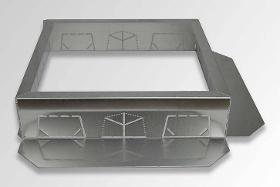

Optigrun Triangle Water Conduit WLP Plus is used as water conduit system to support the discharge of excess water from drainage and substrate layers. Profiles may be interconnected by means of simple click-locks to any desired length.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Triangle Maxi Inspection Chamber TMK suitable for negative pressure drainage. Combinable with Triangle and TSK water discharge systems. Drainage capacity for 2 % roof pitch and profiles connected to all four sides: 24 l/s. Extendable in 50 and 100 mm increments.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

L-section for separation of gravel and substrate. Simple installation due to click-connection system. Installed on protection membrane, drainage elements or filter fleeces; connectable to water conduit systems. For roof pitches of up to 5°.

Request for a quoteINOX VERTRIEBS GMBH

Germany

INOX cooling system tight can be used in vehicles, motorcycles and boats. The product seals the water-cooling circuit system in the event of leaks and cracks.

Request for a quote

KAMAT GMBH & CO. KG

Germany

Versatile, turnkey diesel high-pressure pumping units Special applications require customised high-pressure systems, which KAMAT can provide from the initial project idea through to turnkey installation, with 100% of the manufacture taking place in-house. Depending on the application, our customers can choose from a range of drives, power transmission components, PLC controls, measuring systems, data transmission, remote controls, pneumatic and electric valve controls, chassis and sound insulation. However, the units are ready for use on the base frame on which they are delivered. KAMAT diesel-powered units are traditionally used in industrial cleaning and pressure testing, mining and water hydraulics, but special solutions for special fluids or to meet explosion protection requirements are also part of the KAMAT range. It makes no difference whether the customer requires a mobile or stationary unit.

Request for a quote

KAMAT GMBH & CO. KG

Germany

customer-specific unit design incl. powerful high-pressure pump easy maintenance cavitation-free central drainage according to the latest global emission laws optionally fully automatic control own software with best support optional extreme sound absorption optionally all explosion protection classes

Request for a quote

KAMAT GMBH & CO. KG

Germany

For special applications, individual high-pressure systems are required, which KAMAT can provide from the initial project idea to the turnkey installation, with 100% of the production taking place in-house. This also applies to electric high-pressure pumping units. Depending on the application, our customers can choose between different drives, power transmission components, PLC controls, measuring systems, data transmission, remote controls, pneumatic and electric valve controls, chassis and sound insulation equipment. Even the electrical units supplied on the base frame are fully operational and can be used directly by the customer. Electric units have the advantage of emission-free operation at extremely low noise levels. ATEX certified high pressure electric units can also be used in ATEX hazardous areas.

Request for a quote

MERECS ENGINEERING GMBH

Germany

Merecs develops individual test systems for heat pumps, gas, fluid and water systems. Our engineers & fitters for electronics, installation technology and mechanics build the systems completely from one source at our location in Steinfurt. The systems are then delivered and commissioned at home and abroad. Our range of products includes - Development test benches - Life time test benches - End-of-line test benches (production) - Retrofit of existing systems (software / hardware) - Climate & temperature test systems - Leakage test benches - Software development LabVIEW, TestStand, Python, C/C++ (Embedded), Microsoft PowerBI, SQL - Electronics development - Mechanical 3D CAD design

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Water treatment for steam boiler systems — Prevention of corrosion in the boiler — Outstanding deaeration efficiency and reduced consumption of chemicals with WSM-V complete deaeration system — Partial deaeration module WSM-T for small systems — Fast and easy planning, installation and acceptance appropriate to the steam boiler in question — Requirement for positive suction head allows for ground-level installation and easy commissioning

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

The multiple water quantity control system in modular design that is available in several versions fulfils not less than three requirements at the same time. It combines the advantages of the conventional water distributors, the impulse cooling systems and the continuously operating temperature control units while eliminating the disadvantages of each of these systems. The temperature control system disposes of up to 128 individually adjustable circuits and is suitable for the processing of polyolefins and technical thermoplastic materials. In case of the basic execution (itd B) the requested flow rate is adjusted manually and is then monitored by a flow meter and presented digitally and graphically on the central display of the control unit. In the standard execution (itd R) the water quantity is individually set for each circuit at the central operating unit and - if necessary - is readjusted automatically via a water quantity regulation valve within adjustable limit values.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

CLEAN PROCESS WATER WITH GWK KU-PLANTS Water is one of the key elements in our daily life. It is a supplier of the most various requirements, also in the area of technical and mechanical production. Water is an excellent cooling medium. ku-plants from gwk utilise the cooling energy provided by water to carry away heat from production machines in the most troublefree and cost effective way possible. Removing side effects Fresh water from a well, from rivers and from other surface reservoirs is always saturated with oxygen and includes a large number of minerals and suspended particles which can block up the cooling channels in production units through corrosion or by producing deposits. ku-plants from gwk do not allow such problems to arise. A plate-type heat exchanger made of stainless steel separates the clean closed circuit that is used to cool the production from the natural fresh water circuit that is contaminated with all kinds of impurities.

Request for a quoteResults for

Watering systems - Import exportNumber of results

79 ProductsCountries

Category

- Water extraction - systems and equipment (21)

- Water purification - systems and equipment (14)

- Water treatment, industrial - systems and equipment (10)

- Heating, domestic - installations and equipment (7)

- Water treatment products (3)

- Pumps (2)

- Laboratory equipment and instruments (2)

- Plastics - machines and material for industry (2)

- Steel, special (2)

- Tanks, metal (2)

- Water - production and distribution (1)

- Centrifugal pumps (1)

- Fountains, street and park (1)

- Heating, industrial - installations and equipment (1)

- Accumulators and batteries (1)

- Cleaning of stables and stalls - machinery and equipment (1)

- Detergents and soaps - professional (1)

- Diesel engines (1)

- Fittings, metal (1)

- Grinding - steels and metals (1)