- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wear-resistant steel

Results for

Wear-resistant steel - Import export

IGUS® GMBH

Germany

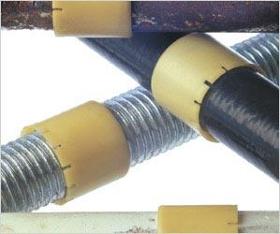

iglidur® PEP, metric d1 [mm]: d2 [mm]: iglidur® PEP, inch d1 [inch]: d2 [inch]: When to use iglidur® PEP plain bearings? When a low-priced plastic plain bearing system is required When freedom is required from shaft material and shaft surface For the protection of expensive and sensitive shafts For extraordinary wear resistance with rare and slow movements. For constantly low coefficients of friction When freedom from corrosion is desired When not to use them? For high surface speeds iglidur® J For high loads iglidur® G iglidur® Q For high temperatures iglidur® V400 iglidur® X iglidur® Z When low-clearance bearings are required iglidur® P iglidur® X Maintenance-free plain bearings usually distinguish themselves by their ability to glide free of lubricants without any further additional layer on the shaft. In these systems it is obvious that shaft materials are as important as the bushings. igus® blazes a new trail with an enclosed and maintenance-free plain bearing concept. iglidur® PEP is an entirely novel lubricant-free plastic plain bearing system with an inner and outer ring. Special feature: The running partner is determined by the inner ring and for the first time, the material and surface finish of the shaft are insignificant. Even thread, rust or scratches do not affect the long-term reliable function. By the specification of the gliding partner and extensive series of tests, the long-term behavior of the bearing system can be precisely forecast. With the PEP polymer plain bearing, the inner ring rotates with the shaft like in ball bearings Relative movements of the shaft to the bearing are dispensed with. This protects the shaft surface from wear and saves costs. Another plus point: Even the most sensitive or unusual materials for the rotating shaft can be used with these new polymer bearings. The PEP polymer bearings are thereby absolutely free from material-dependent corrosion. Wear resistance The wear test results are absolutely convincing with loads up to 5 N/mm². Here the PEP polymer bearings attain values that are virtually comparable with those of the most wear-resistant plastic-steel bearing systems. An exceedingly satisfying result when you consider the costs saved by dispensing with the otherwise essential surface treatment of the shaft. The constantly low friction-coefficient level is also an advantage for the user. As the glide partners are fixed by the defined system, their tribological data too are accurately predictable. The coefficients of friction of the lubricant-free bearing are not determined any more by the shaft materials or surface conditions. If necessary, the coefficients of friction can be further lowered by additional minimum lubrication. Detailed test information with a wide range of lubricants are available and can be had from igus® on request. iglidur® PEP bearings operate independent of the shaft material. iglidur® PEP bearings consists of an inner and outer bearing. X = Load [MPa] Y = Wear [μm/km] A = PEP B = Combination 1 C = Comb. 2 D = Comb. 3 E = Comb. 4 F = Comb. 5 G = Comb. 6 H = Comb. 7 A1 = Wear of the outer bearing B2 = Wear of the inner bearing Fig. 02: Wear tests of various material combinations, p = 0.75 MPa, v = 0.3 m/s X = Load [MPa] Y = Wear [μm/km] A = iglidur® J B = iglidur® PEP Fig. 03: Wear of the iglidur® PEP bearing dependent on the load, v = 0.3 m/s iglidur® PEP, metric d1 [mm]: d2 [mm]: iglidur® PEP, inch d1 [inch]: d2 [inch]: Dimensions according to ISO 3547-1 and special dimensions

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

Along with highly wear-resistant stainless steel pipe bends of type HVA NIRO® we offer suitably highly wear-resistant branch pipes. They are available in in all sizes, diameters and angle degrees.

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

We can supply you with highly wear-resistant stainless steel pipe bends which have a service life 10 to 20 times longer than that of standard stainless steel pipe bends. This high degree of wear protection is required, for example for conveying fibreglass-reinforced plastic granules or similarly abrasive media. suitable for use of highly abrasive products easy installation no stepped pipe couplings and no flange connections required safe for use with food

Request for a quote

GRÜNING & LOSKE GMBH

Germany

Short description: The solid nozzle for everyday use The sewer nozzle is best suitable for a heavy everyday operation. With its 10 to 12 nozzle inserts and two different jet angles it is primarily used for the all-round cleaning of pipes up to 800 mm in diameter. The sewer nozzle has patented fluid mechanics (patent no.: DE 19516780) and is made of highly wear-resistant special steel. This universal nozzle of heavy construction is characterized by high efficiency and absolute reliability. It is an efficient and low-cost alternative to the conventional standard products.

Request for a quote

CL MACHINERY GMBH

Germany

With its full stainless steal and modular construction, Closure Systems International's Series 5000 Combi Capping Machine is recognized in the industry for its reliability, low maintenance, and flexibility. This durable and versatile capper allows bottlers to effectively apply a wide variety of closures, especially aluminum caps, including: TSROPP, ROPP, screw caps, lug caps, Ring Pulls, and T-Corks for glass, aluminum, and PET bottles. In fact, Series 5000 Combi, allows plastic closures (CIH) and metal roll-on caps to be applied on the same capper using the same spindle. Reliable & Robust Robust, durable construction for long-lasting performance Full stainless steel construction to prevent corrosion Stainless steel turret Stainless steel spindles with wear-resistant plastics Stainless steel headsets New modular spindle assembly Proven headset designs for highly consistent closure application and torque control High throughput Plastic: 42 BPM / 2,520 BPH per head Roll On: 50 BPM.

CL MACHINERY GMBH

Germany

With its full stainless steel and modular construction, Closure Systems International’s Series 5000 capping machine is recognized in the industry for its reliability, low maintenance and flexibility. This durable and versatile capper allows bottlers to effectively apply a wide variety of closures, especially aluminum caps, including: TSROPP, ROPP, screw caps, lug caps, Ring Pulls, and T-Corks for glass, aluminum and PET bottles. Reliable & Robust Robust, durable construction for long-lasting performance Full stainless steel construction to prevent corrosion Stainless steel turret Stainless steel spindles with wear-resistant plastics Stainless steel headsets New modular spindle assembly Proven headset designs for highly consistent closure application and torque control High throughput Plastic: 42 BPM / 2,520 BPH per head Roll On: 50 BPM / 3,000 BPH per head CSI Cap-in-Head technology assures proper closure placement at high speeds for optimized cap application Direct integration.

IPR GMBH

Germany

The resilient guide sleeve FFH-M stainless, wear resistant steel for work not performend under voltage ! - For precise centering head screws - Suitable for Bit-pick-up and Battery screwdriver - Centering sleeve replaceable Technial Data: ► wear resistant, stainless steel X 6 Cr 13 ► mit ¼“ (6,3mm) – Hexagon Bit ► Available in size 5,5 x 0,8 x 6,0 for screw heads up to Ø 6,0 mm ► Centering available single ► With the AuS-versions 5,5 x 0,8 x 6,0 und 5,5 x 1,0 x 8,0 combined

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

b.dry chains are made from corrossion-free, maintenance-free CF stainless steel with an optimized articulated link that represents a masterpiece of high precision. The secret of the b.dry range is to consign the old notions of „steel on steel“ to the past! The fact that no lubricants are needed is thanks to our b.dry bushes, which are made from a special, high-performance polymer. The capabilities of this material are absolutely unparalleled. b.dry products run completely dry, but are still more resistant to wear and corrosion, stronger and have a longer service life than comparable chains.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Handling general scrap, steel chips, shredder scrap, wood chippings and much more, in sea and inland ports and at storage facilities. For various types of handling machinery (mobile, stationary, crawler or portal) designed to be connected to hydraulic attachments. Technical design Open, half-closed or closed grip; with 2, 4 or 5 shells Optimisation of machine load capacity thanks to its lightweight design which can hold maximum loads Grab drive: Hydraulic hoses connect the materials handling machine to the grab Closing and opening movements are controlled by the materials handling machine Closing and opening movements controlled by directly connected hydraulic cylinders Grab connection bearing Re-greaseable, robust steel bushing bearing Stable, torsion-resistant shells made of: Shell plates made of S355J2+N Welded shell tips made of special highly wear-resistant steel

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Bulk handling of any kind in sea and inland ports or storage facilities. For ship-to-ship, ship-to-storage/wagon/silo handling. For various types of handling machinery (mobile, stationary, crawler or portal) designed to be connected to hydraulic attachments. Technical design Half-closed or closed grip; with 2 or 4 cylinders Optimisation of machine load capacity thanks to its lightweight design which can hold maximum loads Grab drive: Hydraulic hoses connect the materials handling machine to the grab Closing and opening movements are controlled by the materials handling machine Closing and opening movements controlled by directly connected hydraulic cylinders Grab connection bearing Re-greaseable, robust steel bushing bearing Stable, torsion-resistant shells adapted to material flow: Shell plates made of S355J2+N Cutting edges made of special, highly wear-resistant steel

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Slag handling in waste incineration plants or incineration plants of any kind. For various types of cranes with internal or external holding ropes. Technical design Low-maintenance or maintenance-free for increased profitability Transverse or longitudinal suspension with 4-fold, 5-fold and 7-fold rope reeving; as a 4-rope grab High load capacity thanks to its lightweight design Smooth grab thanks to its low centre of gravity and because the rope’s diameter matches that of the pulley Closing rope devices: Rope nozzles KROGER MAINTENANCE-FREE, rope-protecting, roller-bearing pulley system Lower pulley block unrestrained on the crossbeam Rope pulley bearing: Re-greaseable plain bearing KROGER MAINTENANCE-FREE pulley block system Grab shells: Material: S355J2+N Cutting edge material: special, highly wear-resistant steel Grab connection bearing: Re-greaseable steel bushing bearing KRÖGER MAINTENANCE-FREE bearing system

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Underwater gravel and sand extraction using dredgers with 2-cable or 4-cable winches. Suitable for use in all river and lake dredging areas with difficult ground conditions and deep dredging depths. Technical design MAINTENANCE-FREE design, which benefits both the environment and your profitability High load capacity thanks to its lightweight design Robust, torsion-resistant grab design for maximum loads Grab shells made of wear-resistant fine-grain steel Tooth tips are interchangeable depending on ground conditions KROGER MAINTENANCE-FREE bearing system in the shell pivots and cylinder rod bearings KROGER power unit is easy to service, the crosshead engine is separate from the hydraulic tank, hydraulic units are in the tank Environmentally friendly hydraulic fluid using organic oil

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Underwater gravel and sand extraction using dredgers and rope excavators with 2 or 4 ropes. Suitable for use in all river and lake dredging areas with difficult ground conditions and at dredging depths of over 100m. Technical design MAINTENANCE-FREE design, which benefits both the environment and your profitability 5-rope or 7-rope reeving design in all sizes Larger capacity for increased output Lightweight design, optimised grip Closing rope infeed in star form on the grab head with the KRÖGER MAINTENANCE-FREE, rope-protecting pulley system Fixed linkage steering on one side of the grab head KRÖGER MAINTENANCE-FREE pulley block system Grab shells made of wear-resistant fine-grain steel Grab connection bearing with the KRÖGER MAINTENANCE-FREE bearing system Tooth tips are interchangeable depending on ground conditions

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quote

FÖRDERTEC GMBH

Germany

Screw conveyors primarily comprise a U-shaped trough and the worm shaft with blades. They are primarily used for internal transportation of bulk goods (filter cake, pellets, wood). Our standard screw conveyors are manufactured with pedestal bearings and gland seals. The construction forms for material transport can be selected with a pitch of between 0° and 90°. The construction length can be varied depending on requirements. The materials for the screw conveyors can be supplied in normal steel and wear-resistant steel; plastic panels are also possible.

Request for a quoteResults for

Wear-resistant steel - Import exportNumber of results

21 ProductsCountries