- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wear-resistant steel

Results for

Wear-resistant steel - Import export

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

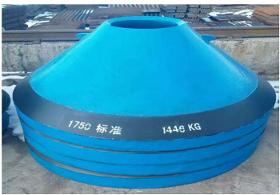

Xian Huan-Tai has been specialized in Custom heavy castings with machining include mantle, bowl liner, jaw plates, cone castings etc since 1996. Material options are carbon steel, stainless steel, gray iron, ductile iron, copper etc. to accommodate with different environment. Process include sand castings and vacuum castings. Our inspection: 1.Metal testing and analysis, mechanical properties, microstructure, spectrometer and furnace chemical composition analysis. 2.Non-destruction inspection: MPE, LPE, UE and RE 3.Dimension inspection: well experienced inspector team 4.Quality control 5.3rd party inspection 6.Special inspection method agreed by customers like hydraulic, pneumatic test, water tight test etc.

Request for a quote

A J MARSHALL (SPECIAL STEELS) LTD

United Kingdom

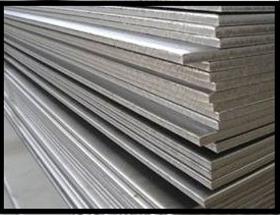

Stocked steel grades: 12/14% Manganese, X120 Mn12, X120 Mn13, Creusabro M, ASTM A128 Grade B2, DIN W1.3401. A high manganese, fully austenitic, quench annealed, non-magnetic, work hardening steel with an exceptionally high level of wear resistance when subjected to work hardening by shock or high impact pressure in service. The underlayers not work-hardened maintain an excellent resistance to shock and a very high ductility. TYPICAL APPLICATIONS: Earth moving crusher jaw, grizzly, screen, stone chutes, chain guide, shredder plates, shovel buckets, bucket blade of loader, chain conveyor parts, sprocket wheel, various armouring elements. Guiding and shifting plates, scraps container, liner of shot blasting unit, wear liner, shot blasting equipment. All steel is supplied with full mill test certificates to DIN EN 10204-3.1. Payment: L/C, T/T, Cheque, Transfer, Cash, VISA.

A J MARSHALL (SPECIAL STEELS) LTD

United Kingdom

Stocked steel grades: RAEX 400, RAEX 500, BRINAR 400, AR400, 20MnCr6-5. RAEX 400360-440HB3mm - 100mm+ RAEX 500450-540HB6mm - 50mm RAEX STEELS RAEX is a hot rolled hardened steel grade with excellent hardness and strength properties and is resistant to abrasion and extreme surface pressure. RAEX 400 extends the lifespan of machinery, decreases the impacts of wear in structural components and saves costs. Thanks to its high strength properties, RAEX allows innovative and environmentally sound product development. RAEX is easy to weld, cut and has reasonably good formability. TYPICAL APPLICATIONS: Buckets and cutting edges of earth-moving machines, wearing parts of mining machines, wearing parts of concrete mixing plants and wood processing machines, platform structures, feeders and funnels. All steel is supplied with full mill test certificates to DIN EN 10204-3.1. Payment: L/C, T/T, Cheque, Transfer, Cash, VISA.

IGUS® GMBH

Germany

iglidur® PEP, metric d1 [mm]: d2 [mm]: iglidur® PEP, inch d1 [inch]: d2 [inch]: When to use iglidur® PEP plain bearings? When a low-priced plastic plain bearing system is required When freedom is required from shaft material and shaft surface For the protection of expensive and sensitive shafts For extraordinary wear resistance with rare and slow movements. For constantly low coefficients of friction When freedom from corrosion is desired When not to use them? For high surface speeds iglidur® J For high loads iglidur® G iglidur® Q For high temperatures iglidur® V400 iglidur® X iglidur® Z When low-clearance bearings are required iglidur® P iglidur® X Maintenance-free plain bearings usually distinguish themselves by their ability to glide free of lubricants without any further additional layer on the shaft. In these systems it is obvious that shaft materials are as important as the bushings. igus® blazes a new trail with an enclosed and maintenance-free plain bearing concept. iglidur® PEP is an entirely novel lubricant-free plastic plain bearing system with an inner and outer ring. Special feature: The running partner is determined by the inner ring and for the first time, the material and surface finish of the shaft are insignificant. Even thread, rust or scratches do not affect the long-term reliable function. By the specification of the gliding partner and extensive series of tests, the long-term behavior of the bearing system can be precisely forecast. With the PEP polymer plain bearing, the inner ring rotates with the shaft like in ball bearings Relative movements of the shaft to the bearing are dispensed with. This protects the shaft surface from wear and saves costs. Another plus point: Even the most sensitive or unusual materials for the rotating shaft can be used with these new polymer bearings. The PEP polymer bearings are thereby absolutely free from material-dependent corrosion. Wear resistance The wear test results are absolutely convincing with loads up to 5 N/mm². Here the PEP polymer bearings attain values that are virtually comparable with those of the most wear-resistant plastic-steel bearing systems. An exceedingly satisfying result when you consider the costs saved by dispensing with the otherwise essential surface treatment of the shaft. The constantly low friction-coefficient level is also an advantage for the user. As the glide partners are fixed by the defined system, their tribological data too are accurately predictable. The coefficients of friction of the lubricant-free bearing are not determined any more by the shaft materials or surface conditions. If necessary, the coefficients of friction can be further lowered by additional minimum lubrication. Detailed test information with a wide range of lubricants are available and can be had from igus® on request. iglidur® PEP bearings operate independent of the shaft material. iglidur® PEP bearings consists of an inner and outer bearing. X = Load [MPa] Y = Wear [μm/km] A = PEP B = Combination 1 C = Comb. 2 D = Comb. 3 E = Comb. 4 F = Comb. 5 G = Comb. 6 H = Comb. 7 A1 = Wear of the outer bearing B2 = Wear of the inner bearing Fig. 02: Wear tests of various material combinations, p = 0.75 MPa, v = 0.3 m/s X = Load [MPa] Y = Wear [μm/km] A = iglidur® J B = iglidur® PEP Fig. 03: Wear of the iglidur® PEP bearing dependent on the load, v = 0.3 m/s iglidur® PEP, metric d1 [mm]: d2 [mm]: iglidur® PEP, inch d1 [inch]: d2 [inch]: Dimensions according to ISO 3547-1 and special dimensions

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC machining high carbon Steel parts

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

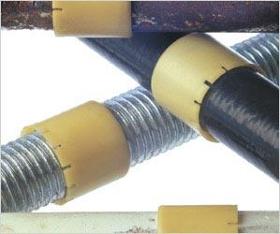

Along with highly wear-resistant stainless steel pipe bends of type HVA NIRO® we offer suitably highly wear-resistant branch pipes. They are available in in all sizes, diameters and angle degrees.

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

We can supply you with highly wear-resistant stainless steel pipe bends which have a service life 10 to 20 times longer than that of standard stainless steel pipe bends. This high degree of wear protection is required, for example for conveying fibreglass-reinforced plastic granules or similarly abrasive media. suitable for use of highly abrasive products easy installation no stepped pipe couplings and no flange connections required safe for use with food

Request for a quote

GRÜNING & LOSKE GMBH

Germany

Short description: The solid nozzle for everyday use The sewer nozzle is best suitable for a heavy everyday operation. With its 10 to 12 nozzle inserts and two different jet angles it is primarily used for the all-round cleaning of pipes up to 800 mm in diameter. The sewer nozzle has patented fluid mechanics (patent no.: DE 19516780) and is made of highly wear-resistant special steel. This universal nozzle of heavy construction is characterized by high efficiency and absolute reliability. It is an efficient and low-cost alternative to the conventional standard products.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconium oxide jars 60 times the hardness of regular steel, highly wear-resistant and resistant to acid and solvents. The grinding jars are extensively applied to in the fields of Paint, Ink, Geology, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry, Medicine, Environmental Protection and so on. Each jar set includes grinding jar, jar lid, rubber sealing gasket and different sizes of mixed zirconium oxide grinding balls. Specification: .High cost-effective, low wear and long lifetime. .High specific gravity, high efficiency. .Highly wear resistant to acid and solvents. .Highly polished, smooth, easy to clean, low abrasion to the equipment. .High mechanical strength, good toughness, impact resistance, no broken beads. .Mainly used for lab planetary ball mill machines.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Xian Huan-tai Technology and Development Corp., Ltd Specializes in manufacturing and exporting investment castings and sand casting. Our company founded in1995 Covering 30000 square meters, with the annual output capacity of 1200 tons. The company has production capabilities of tool making, investment casting with all silica sol process, machining and heat treatment. Huan-tai has become a leading metal parts manufacturer in south of China, Relying on the integrated superiority in advanced equipments and professional team. The company offers OEM service of investment castings& sand casting and other metal parts. The castings are exported to USA, Germany, France, Canada, Italy, Spain and many other countries. Customers at home and abroad are warmly welcome to hold business talks with us. APPLICATION FIELDS: Crusher equipment, Machinery parts and components, Mobile parts, Pipe couplings, Tools hardware, Kitchen hardware, Shower hardware,Lamps hardware, Marine hardware, Building hardware,

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Xian Huan-tai Technology and Development Corp., Ltd Specializes in manufacturing and exporting investment castings and sand casting. Our company founded in1995 Covering 30000 square meters, with the annual output capacity of 1200 tons. The company has production capabilities of tool making, investment casting with all silica sol process, machining and heat treatment. Huan-tai has become a leading metal parts manufacturer in south of China, Relying on the integrated superiority in advanced equipments and professional team. The company offers OEM service of investment castings& sand casting and other metal parts. The castings are exported to USA, Germany, France, Canada, Italy, Spain and many other countries. Customers at home and abroad are warmly welcome to hold business talks with us. APPLICATION FIELDS: Crusher equipment, Machinery parts and components, Mobile parts, Pipe couplings, Tools hardware, Kitchen hardware, Shower hardware,Lamps hardware, Marine hardware, Building hardware,

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Xian Huan-tai Technology and Development Corp., Ltd Specializes in manufacturing and exporting investment castings and sand casting. Our company founded in1995 Covering 30000 square meters, with the annual output capacity of 1200 tons. The company has production capabilities of tool making, investment casting with all silica sol process, machining and heat treatment. Huan-tai has become a leading metal parts manufacturer in south of China, Relying on the integrated superiority in advanced equipments and professional team. The company offers OEM service of investment castings& sand casting and other metal parts. The castings are exported to USA, Germany, France, Canada, Italy, Spain and many other countries. Customers at home and abroad are warmly welcome to hold business talks with us. APPLICATION FIELDS: Crusher equipment, Machinery parts and components, Mobile parts, Pipe couplings, Tools hardware, Kitchen hardware, Shower hardware,Lamps hardware, Marine hardware, Building hardware,

Request for a quote

CL MACHINERY GMBH

Germany

With its full stainless steal and modular construction, Closure Systems International's Series 5000 Combi Capping Machine is recognized in the industry for its reliability, low maintenance, and flexibility. This durable and versatile capper allows bottlers to effectively apply a wide variety of closures, especially aluminum caps, including: TSROPP, ROPP, screw caps, lug caps, Ring Pulls, and T-Corks for glass, aluminum, and PET bottles. In fact, Series 5000 Combi, allows plastic closures (CIH) and metal roll-on caps to be applied on the same capper using the same spindle. Reliable & Robust Robust, durable construction for long-lasting performance Full stainless steel construction to prevent corrosion Stainless steel turret Stainless steel spindles with wear-resistant plastics Stainless steel headsets New modular spindle assembly Proven headset designs for highly consistent closure application and torque control High throughput Plastic: 42 BPM / 2,520 BPH per head Roll On: 50 BPM.

CL MACHINERY GMBH

Germany

With its full stainless steel and modular construction, Closure Systems International’s Series 5000 capping machine is recognized in the industry for its reliability, low maintenance and flexibility. This durable and versatile capper allows bottlers to effectively apply a wide variety of closures, especially aluminum caps, including: TSROPP, ROPP, screw caps, lug caps, Ring Pulls, and T-Corks for glass, aluminum and PET bottles. Reliable & Robust Robust, durable construction for long-lasting performance Full stainless steel construction to prevent corrosion Stainless steel turret Stainless steel spindles with wear-resistant plastics Stainless steel headsets New modular spindle assembly Proven headset designs for highly consistent closure application and torque control High throughput Plastic: 42 BPM / 2,520 BPH per head Roll On: 50 BPM / 3,000 BPH per head CSI Cap-in-Head technology assures proper closure placement at high speeds for optimized cap application Direct integration.

IPR GMBH

Germany

The resilient guide sleeve FFH-M stainless, wear resistant steel for work not performend under voltage ! - For precise centering head screws - Suitable for Bit-pick-up and Battery screwdriver - Centering sleeve replaceable Technial Data: ► wear resistant, stainless steel X 6 Cr 13 ► mit ¼“ (6,3mm) – Hexagon Bit ► Available in size 5,5 x 0,8 x 6,0 for screw heads up to Ø 6,0 mm ► Centering available single ► With the AuS-versions 5,5 x 0,8 x 6,0 und 5,5 x 1,0 x 8,0 combined

Request for a quote

CRAFTMACH ENGINEERED SOLUTIONS INC.

Canada

Hello, let's improve the company performance and profitability with our committed help, products and solutions by 10-25%. We can manufacture and supply high quality standard and custom injection molding nozzle tips with guaranteed quality and unbeatable price. Please get in touch with more details and attractive pricing. CRAFTMACH Tool Steel Tips are made from High Quality Wear Resistant H-13 Alloy Tool Steel. All Nozzle Tips are as per Industry Standards and Fit All Competing Adaptor Bodies. The Hardness Is 46-48 RC. Other Alloy Tool Steel Materials and Sizes Nozzle Tips are also available as per Customer Requirement. WHY CRAFTMACH NOZZLE TIPS? •Guaranteed Performance & Work Life •High Quality Wear Resistant Tool Steel •Industry Standard and Compatible Fit •Super Finished and Highly Polished •Hardened and Tempered as Per Requirement •Custom Nozzle Tips are Available On Request

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

b.dry chains are made from corrossion-free, maintenance-free CF stainless steel with an optimized articulated link that represents a masterpiece of high precision. The secret of the b.dry range is to consign the old notions of „steel on steel“ to the past! The fact that no lubricants are needed is thanks to our b.dry bushes, which are made from a special, high-performance polymer. The capabilities of this material are absolutely unparalleled. b.dry products run completely dry, but are still more resistant to wear and corrosion, stronger and have a longer service life than comparable chains.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METZEN INDUSTRIES GMBH

Germany

Bulk handling of any kind in sea and inland ports or storage facilities. For ship-to-ship, ship-to-storage/wagon/silo handling. For various types of handling machinery (mobile, stationary, crawler or portal) designed to be connected to hydraulic attachments. Technical design Half-closed or closed grip; with 2 or 4 cylinders Optimisation of machine load capacity thanks to its lightweight design which can hold maximum loads Grab drive: Hydraulic hoses connect the materials handling machine to the grab Closing and opening movements are controlled by the materials handling machine Closing and opening movements controlled by directly connected hydraulic cylinders Grab connection bearing Re-greaseable, robust steel bushing bearing Stable, torsion-resistant shells adapted to material flow: Shell plates made of S355J2+N Cutting edges made of special, highly wear-resistant steel

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Slag handling in waste incineration plants or incineration plants of any kind. For various types of cranes with internal or external holding ropes. Technical design Low-maintenance or maintenance-free for increased profitability Transverse or longitudinal suspension with 4-fold, 5-fold and 7-fold rope reeving; as a 4-rope grab High load capacity thanks to its lightweight design Smooth grab thanks to its low centre of gravity and because the rope’s diameter matches that of the pulley Closing rope devices: Rope nozzles KROGER MAINTENANCE-FREE, rope-protecting, roller-bearing pulley system Lower pulley block unrestrained on the crossbeam Rope pulley bearing: Re-greaseable plain bearing KROGER MAINTENANCE-FREE pulley block system Grab shells: Material: S355J2+N Cutting edge material: special, highly wear-resistant steel Grab connection bearing: Re-greaseable steel bushing bearing KRÖGER MAINTENANCE-FREE bearing system

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

The microstructures inside duplex stainless steels are approximately 50 per cent austenite and 50 per cent ferrite, and consequently duplex products share the physical properties of both ferritic and austenitic grades. Duplex stainless steels are resistant to the cracking caused by chloride stress corrosion in austenitic grades, and have improved resistance to localised corrosion. This family of stainless steels has roughly twice the yield strength of their counterpart austenitic grades . Higher hardness values provide better wear resistance for high precision tubes. Duplex stainless steel tubes have high hardness and wear resistance propertiesDuplex steels are easily welded and formed, similar to austenitic grades. Depending on chromium, nickel and molybdenum content, duplex stainless steels are divided into four main categories: lean duplex, duplex, super duplex and hyper duplex. Please note that we have a minimum order value of £10,000.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Underwater gravel and sand extraction using dredgers with 2-cable or 4-cable winches. Suitable for use in all river and lake dredging areas with difficult ground conditions and deep dredging depths. Technical design MAINTENANCE-FREE design, which benefits both the environment and your profitability High load capacity thanks to its lightweight design Robust, torsion-resistant grab design for maximum loads Grab shells made of wear-resistant fine-grain steel Tooth tips are interchangeable depending on ground conditions KROGER MAINTENANCE-FREE bearing system in the shell pivots and cylinder rod bearings KROGER power unit is easy to service, the crosshead engine is separate from the hydraulic tank, hydraulic units are in the tank Environmentally friendly hydraulic fluid using organic oil

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Underwater gravel and sand extraction using dredgers and rope excavators with 2 or 4 ropes. Suitable for use in all river and lake dredging areas with difficult ground conditions and at dredging depths of over 100m. Technical design MAINTENANCE-FREE design, which benefits both the environment and your profitability 5-rope or 7-rope reeving design in all sizes Larger capacity for increased output Lightweight design, optimised grip Closing rope infeed in star form on the grab head with the KRÖGER MAINTENANCE-FREE, rope-protecting pulley system Fixed linkage steering on one side of the grab head KRÖGER MAINTENANCE-FREE pulley block system Grab shells made of wear-resistant fine-grain steel Grab connection bearing with the KRÖGER MAINTENANCE-FREE bearing system Tooth tips are interchangeable depending on ground conditions

Request for a quote

HAN SONG M&T

South Korea

[Product Description] H-PRO series can be used in a wide range from general steel to high-hardness steel, and it is designed for high-hardness and high-speed milling. It is suitable for cutting carbon steel, alloy steel series, molds and mold parts, and is useful for ultra-precision machining by applying high-precision tolerances. [Product Specification] Flat end mill : D0.05 ~ D25 + Various effective length / total length Ball end mill : D0.1 ~ D20 + (same as above) C/R end mill : D0.2 ~ D20 + (same as above) Inner C/R end mill : D0.5 ~ D5.9 + (same as above) High speed milling end mill : D0.8 ~ D12 + (same as above) [Product Model] Flat : 2HRE, 2HPE, 2HLE, 4HRE, 4HPE, 4HLE, 4HHE, 6HPE Ball : 2HRB, 2HSB, 2HPB, 3HPB, 4HPB, C/R : 2HRR, 2HCR, 4HRR, 4HCR, 4HIT Inner C/R : 2IRC, 4IRC [Product Use] H pro series is suitable for High hardened steels (HRC 45~55) and pre-hardened steel. Strong wear-resistance and minimizing chipping by adapting H-pro coating.

Request for a quote

HAN SONG M&T

South Korea

[Product Description] H-PRO series can be used in a wide range from general steel to high-hardness steel, and it is designed for high-hardness and high-speed milling. It is suitable for cutting carbon steel, alloy steel series, molds and mold parts, and is useful for ultra-precision machining by applying high-precision tolerances. [Product Specification] Flat end mill : D0.05 ~ D25 + Various effective length / total length Ball end mill : D0.1 ~ D20 + (same as above) C/R end mill : D0.2 ~ D20 + (same as above) Inner C/R end mill : D0.5 ~ D5.9 + (same as above) High speed milling end mill : D0.8 ~ D12 + (same as above) [Product Model] Flat : 2HRE, 2HPE, 2HLE, 4HRE, 4HPE, 4HLE, 4HHE, 6HPE Ball : 2HRB, 2HSB, 2HPB, 3HPB, 4HPB, C/R : 2HRR, 2HCR, 4HRR, 4HCR, 4HIT Inner C/R : 2IRC, 4IRC [Product Use] H pro series is suitable for High hardened steels (HRC 45~55) and pre-hardened steel. Strong wear-resistance and minimizing chipping by adapting H-pro coating.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK offers a range of wear resistant tool steel powers used in P/M, MIM, and metal additive manufacturing. Tool steels use a combination of C, Cr, Mo, V, and W in an Fe based alloy to generate a carbide microstructure in the metal alloy. Powder Metallurgy (P/M) tool steels offer the highest grade of performance, especially in respect to toughness, due to the extremely fine and uniform distribution of carbides resulting from the atomization process. AMETEK offers multiple grades in the M, D, and T series of tool steels including M3-5, D-2, and T-15 among others. Each tool steel is optimized for its respective purpose to give exceptional properties. Some tool steels, such as our premium T-15 grade, can result in hardness near 70 HRC when appropriately processed and heat treated. Materials that have been routinely produced include M-2, M3-2, M3-5, M4-2, D2, and T15.

Request for a quote

HAN SONG M&T

South Korea

[Product Description] R-PRO series is specialized for cutting super-hardened & heat-treated steel (HRC 52 to HRC 72). It has excellent wear resistance and a shape design for increasing machinability. In addition, we have taper end mills that can be customized to customers. [Product Specification] Flat end mill : D0.1 ~ D12 + Various effective length / total length Ball end mill : D0.1 ~ D12 + Various effective length / total length C/R end mill : D1 ~ D12 + Various effective length / total length Taper end mill : D1 ~ D12 + Various effective length / total length [Product Model] Flat : 2RRE, 4RRE, 4RPE, 4RLE Ball : 2RRB, 2RSB, 2RPB, 3RSB C/R : 4RRR, 4RCR, 6RCR Taper: 2RTB, 3RTB, 2RTR, 4RTR [Product Use] * R pro series is suitable for Super hardened steels (HRC 52~70) and pre-hardened steel * Strong wear-resistance and minimizing chipping by adapting R-pro coating.(Si based PVD coating) * Excellent surface roughness of work pieces due to optimized cutting edge design

Request for a quote

HAN SONG M&T

South Korea

[Product Description] R-PRO series is specialized for cutting super-hardened & heat-treated steel (HRC 52 to HRC 72). It has excellent wear resistance and a shape design for increasing machinability. In addition, we have taper end mills that can be customized to customers. [Product Specification] Flat end mill : D0.1 ~ D12 + Various effective length / total length Ball end mill : D0.1 ~ D12 + Various effective length / total length C/R end mill : D1 ~ D12 + Various effective length / total length Taper end mill : D1 ~ D12 + Various effective length / total length [Product Model] Flat : 2RRE, 4RRE, 4RPE, 4RLE Ball : 2RRB, 2RSB, 2RPB, 3RSB C/R : 4RRR, 4RCR, 6RCR Taper: 2RTB, 3RTB, 2RTR, 4RTR [Product Use] * R pro series is suitable for Super hardened steels (HRC 52~70) and pre-hardened steel * Strong wear-resistance and minimizing chipping by adapting R-pro coating.(Si based PVD coating) * Excellent surface roughness of work pieces due to optimized cutting edge design

Request for a quote

HAN SONG M&T

South Korea

[Product Description] R-PRO series is specialized for cutting super-hardened & heat-treated steel (HRC 52 to HRC 72). It has excellent wear resistance and a shape design for increasing machinability. In addition, we have taper end mills that can be customized to customers. [Product Specification] Flat end mill : D0.1 ~ D12 + Various effective length / total length Ball end mill : D0.1 ~ D12 + Various effective length / total length C/R end mill : D1 ~ D12 + Various effective length / total length Taper end mill : D1 ~ D12 + Various effective length / total length [Product Model] Flat : 2RRE, 4RRE, 4RPE, 4RLE Ball : 2RRB, 2RSB, 2RPB, 3RSB C/R : 4RRR, 4RCR, 6RCR Taper: 2RTB, 3RTB, 2RTR, 4RTR [Product Use] * R pro series is suitable for Super hardened steels (HRC 52~70) and pre-hardened steel * Strong wear-resistance and minimizing chipping by adapting R-pro coating.(Si based PVD coating) * Excellent surface roughness of work pieces due to optimized cutting edge design

Request for a quote

HAN SONG M&T

South Korea

[Product Description] H-PRO series can be used in a wide range from general steel to high-hardness steel, and it is designed for high-hardness and high-speed milling. It is suitable for cutting carbon steel, alloy steel series, molds and mold parts, and is useful for ultra-precision machining by applying high-precision tolerances. [Product Specification] Flat end mill : D0.05 ~ D25 + Various effective length / total length Ball end mill : D0.1 ~ D20 + (same as above) C/R end mill : D0.2 ~ D20 + (same as above) Inner C/R end mill : D0.5 ~ D5.9 + (same as above) High speed milling end mill : D0.8 ~ D12 + (same as above) [Product Model] Flat : 2HRE, 2HPE, 2HLE, 4HRE, 4HPE, 4HLE, 4HHE, 6HPE Ball : 2HRB, 2HSB, 2HPB, 3HPB, 4HPB, C/R : 2HRR, 2HCR, 4HRR, 4HCR, 4HIT Inner C/R : 2IRC, 4IRC [Product Use] H pro series is suitable for High hardened steels (HRC 45~55) and pre-hardened steel. Strong wear-resistance and minimizing chipping by adapting H-pro coating.

Request for a quoteResults for

Wear-resistant steel - Import exportNumber of results

43 ProductsCountries

Category

- Cutting - machine tools (9)

- Hydraulic equipment (5)

- Casting of special and high-grade steels (3)

- Pipes and tubes, stainless steel (2)

- Blades for saws and cutting machines (1)

- Casting, steel (1)

- Ceramics, industrial (1)

- Cutting - steels and metals (1)

- Goods handling systems, continuous (1)

- Injection moulding of rubber and plastic (1)

- Laser printing (1)

- Mechanical transmission systems and components (1)

- Metal powders (1)

- Stainless steels (1)

- Steel (1)

- Steel sheets and strips (1)

- Valves for sanitary fittings (1)