- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding materials

Results for

Welding materials - Import export

BDP MECHANICAL COMPONENTS DEUTSCHLAND GMBH

Germany

Made by cold forging, machining and welding, material stainless steel, sizes 250mm x 50mm x 15mm, weight 0,5kg, annual demand 800pcs

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

They have the following specifications: widened and welded material no. AISI 304 / 304L other lengths are possible at request

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

Highly wear-resistant reducers of type HVA NIRO® stainless steel are also available in all sizes and diameters. They have the following specifications: widened and welded material no. AISI 304 / 304L other lengths are possible at request

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

close tolerances and longitudinally welded carrying roller tubes made of S235JR steel in accordance with DIN 2458; deep drawn steel bearing retainers with calibrated bearing seats pressed in from the side and circularly welded, material thickness min. s = 2.00 mm; RAL 3000 red powder coated sheath, coating thickness min. 60 U; 20 mm Ø round steel in accordance with ISO h9; single row radial steel ball bearings in accordance with DIN625 type 6204 with suitable grease filling and cover plates on both sides made of sheet steel C3 bearing clearance. The calculated service life of the ball bearings, assuming belt speed 2m/sec. delivery capacity 200 t/he bulk weight 0.75 t/m³ temperature range 0° C 50° C is 30,000 hours. Steel circlip in accordance with DIN 471 Sealing using double labyrinth seal, incl. suitable grease filling, galvanized, sheet steel sealing cap and plastic rain cap

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP drinking water tanks for water supply companies are offered together with our project partner Kurz Leitungsbau GmbH. In doing so, we meet the highest standards applicable to the supply of drinking water, from planning and conception up to construction. Our automated welding process for high alloy stainless steels based on the LIPP System enables us to offer tanks with a maximum volume of 10,000 m3. In addition, on site production “off the production line” enables construction to be completed within the shortest possible time. Optimum quality thanks to automated welding process Material savings and additional stability thanks to circumferential profile Short construction times thanks to mechanised production Easy to maintain and clean Low investment and maintenance costs Can be set up indoors or in the open air Turnkey complete solution or components

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Ensure sample purity for microfluidic diagnostic systems POREX ® microfluidic media and filters provide sample filtration and absorption, particulate capture, debubbling, venting, fluid metering, and separation for real-time, PCR and molecular diagnostics systems. Our highly specialized, pure materials and media are critical to the function of lab-on-a-chip, molecular diagnostics, and POC analysis solutions by: Minimizing interference with critical samples and assays – Certified Pure POREX® materials certified by independent test labs ensure optimal performance, accuracy and reproducibility. Making manufacturing easier – Our components can be easily inserted into your device using common manufacturing techniques including press fitting, heat staking and ultrasonic welding. Providing customized material solutions – Our proprietary material technology expertise can help find the right material solution for any microfluidic component need. Applications Sample...

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

Schnelldorfer CORNERWELD seam welding machines have been designed to weld sheet metal plates in a 90° joint. The precision clamping system with inert gas coverage and advanced OEM control package precisely controls the welding sequence and weld parameters, resulting in the perfect weld for your corners. CORNERWELD applications include welded corners for food, medical equipment, HVAC drip pans, electrical enclosures, and laboratory furniture. Complex inward and outward flanges can be accommodated with custom made tooling pieces. A wide range of materials can be welded, including Stainless Steel, Carbon Steel and Aluminium. Complete welded parts do not require any costly grinding, polishing or blending thus greatly saving on manufacturing costs.

Request for a quote

ALPHA LASER GMBH

Germany

Suitable also for welding precision mechanical parts and medical technology components as well as for the manufacture of sensors and electrical components The ALS 100 is an ergonomic workplace The spacious work chamber offers a very brightly lit work area and is loaded via two side doors. The average power of 100 W enables a fast pulse sequence (up to 25 Hz) and thus fast work even at high energy settings. The homogeneous fusion of the materials results in welding results of the highest quality. The laser is used in the manufacture and repair of jewelry, in precision engineering or when welding sensors

Request for a quote

SFS GROUP GERMANY GMBH - GESIPA

Germany

As a combination of blind rivet nut and screw, blind rivet nut studs offer an alternative or replacement for welding studs. The following applications are particularly suitable for the use of GESIPA® blind rivet nut studs: • Accessibility from one side only • Thin carrier materials (sheet metal, plastics, etc.) • Necessary pre-centering • On heat sensitive application materials (e.g. welding not possible) • Surface coatings must not be damaged • Production of electrically conductive joints • Fast replacement of welding studs (repairs) GESIPA® blind rivet nut studs can be set without any problem with the GESIPA® blind rivet nut setting tools FireBird®, GBM 95 and FireFox® using corresponding adapters (see tool description) for blind rivet nut studs

Request for a quote

WIGTEC FISCHEREDER KG

Germany

New employees are first introduced to TIG welding in a basic training lasting several months. Only then are the first products manufactured for customers, whereby the following topics are handled in a multi-year development process, which includes the welding test for the tube welder CrNi relatively early: Material requisition Additional materials Gas protection Interpass temperature and welding temperature Maximum material temperature during welding Cleaning the weld seam Welding distortion Mechanical seam load

Request for a quote

ORBITEC GMBH

Germany

Measuring devices are the first step to the perfect weld. Precise purging is essential for controlling weld quality, particularly when welding high-alloy, corrosion-resistant materials that are highly sensitive to oxygen in the welding process. Oxy Smart: — Battery powered device — For inert gases — For mixed gases with hydrogen (max. 10%) — Measuring cell made of zirconium oxide (maintenance free), long lifetime through intelligent software — Robust for use at site (protective frame out of rubber) — Dust- and moisture-proof, also for use around high humidity — Intuitive operator guidance through symbols — Coloured enlighten display — Battery indicator — Fault indication in case of error Package includes: — Oxygen analyser — Charging cable with various adapter plugs for worldwide use — Hose set, 1m, incl. filter and stainless steel probe — Calibration certificate — Plastic case with inlay

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The all-round solution for process industries The OPTIFLUX 4000 has a field proven and unsurpassed lifetime. This is assured by the fully welded construction, full bore pipe construction, absence of moving parts and wear resistant liner materials. Even for demanding applications in harsh environments or with aggressive and abrasive media KROHNE’s OPTIFLUX 4000 can offer a solution. Examples include water injection under high pressures (2500lbs), subsea installations, slurries with very high solids contents, alkaline solutions and acids, up to chemical dosing, bleaching, coloring, and black liquor in the paper industry. If required, a solution beyond our standard scope can be engineered. KROHNE has in house specialized know how on constructions, welding and exotic materials

Request for a quote

JINTIAN COPPER

Germany

Main products: Leaded brass, brass, lead-free free-cutting brass, copper, tin bronze, chrome-zirconium copper Product characteristics: High electrical conductivity, thermal conductivity, good strength and hardness, heat resistant, wear resistant and deformation resistant Applications: Aerospace, automobile manufacturing, communication technology, precision processing, household appliances, hardware, welding materials Production capacity: 207,000 tons Honorary titles: China's Top 10 Copper Wire & Rod Company, Zhejiang Famous Brand Product

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The EASYBOND product line has been designed for simple, continuous welding applications for nonwoven materials and web material. The features of the ultrasonic modules are precisely adapted to customer requirements. Its flexible design allows for upgrade to MICROBOND technology.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The most simple way of welding thermoplastic materials is to use the ultrasonic manual welding device. This is particularly well suited for applications in prototype design, for processing of single products, small series and repairs. Regardless of caulking, swaging, staking, cutting, or spot welding, the HSG ultrasonic manual welding device is easy to use, provides variable power rating, and can be equipped with all types of conventional sonotrodes (35 kHz).

Request for a quote

IPR GMBH

Germany

The used head protection textile resists liquide metal, sparks and slag. With these characteristics, it is the perfect addtion to our security cutting. in order to keep visual, thermal and dynamic effects of an arc when cutting under voltage cables to a minimum as possible . The heat protective cover protects flammable and temperature sensitive materials for welding- and shringking work. - Asbestos-free, free from hazardous substances - tissue from sicilia fiber, about 96% share of silica (amorphus Si02) - Suitable for temperatures up to 1300&°;C short term, continuous exposure to bis 1100&°;C - The product is not toxic. There is no ecologcially harmful effects known.

Request for a quote

EWM AG

Germany

The Welding 4.0 quality management system ewm Xnet was specifically developed for the welding production and effectively supports all the employees involved in the welding process (welding coordinator, welder, production manager, manager, etc.). The services provided by ewm Xnet include, on the one hand, the monitoring and the documentation of all welding parameters from any number of networked welding machines. On the other hand, it creates and manages the welding documentation (WPQR, WPS, welding certificates) digitally and opens up numerous evaluation options. Additionally, the Xnet welding management system can take over the management of components including all the information associated with it, such as component identification via bar code, material consumption, welding parameters, etc. Thanks to the modular structure, the Xnet welding management system can be used in small, medium and large companies.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OTC DAIHEN EUROPE GMBH

Germany

The Welbee P502L is the top model for perfect welding of steel, stainless steel and aluminum. It combines all the new features and functions of the M400 / 500, M400L and P402, making it the perfect choice for all applications. • High-speed welding on thin stainless steel sheets • Unique appearance of the seams due to OTC aluminum welding characteristics • High speed pulse mode • Increased gap-bridging ability • Low spatter: maximum spatter reduction for the entire current range, spatter reduction up to 80%

Request for a quote

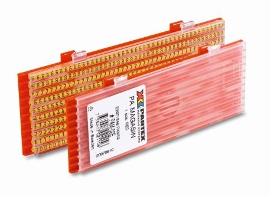

PARTEX MARKING SYSTEMS GMBH

Germany

Has 10 grooves for storing PA-marking strips and a transparent protective lid which is welded in place. Material ABS Colors Red for PA02 and blue for PA1. Temperature range From –30°C to +60°C.

Request for a quote

NORA SYSTEMS GMBH

Germany

Individual requirements for stairwells are best fulfilled from our extensive system programme, from the tailored norament® stairtread with integrated preformed stair nosing, riser, and tread to individual combinations of stair angles, stair nosings, and integrated safety stripes. Our system range is rounded off with colour-matched skirting solutions, joint-sealing compounds, hot welding rods, and installation materials.

Request for a quote

NORA SYSTEMS GMBH

Germany

Individual requirements for stairwells are best fulfilled from our extensive system programme, from the tailored norament® stairtread with integrated preformed stair nosing, riser, and tread to individual combinations of stair angles, stair nosings, and integrated safety stripes. Our system range is rounded off with colour-matched skirting solutions, joint-sealing compounds, hot welding rods, and installation materials.

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

Welbee W400: Precise adjustment and arc stability – even in the lower welding area* Precise adjustment of energy input due to AC pulse welding process * High-speed AC pulse welding due to improved features for the respective material * Welding shape looks like TIG welding process due to AC wave pulse technology * High melting rate, weld penetration control * Extended application scope due to 400 A at 40% rated duty cycle

Request for a quote

NORA SYSTEMS GMBH

Germany

Individual requirements for stairwells are best fulfilled from our extensive system programme, from the tailored norament® stairtread with integrated preformed stair nosing, riser, and tread to individual combinations of stair angles, stair nosings, and integrated safety stripes. Our system range is rounded off with colour-matched skirting solutions, joint-sealing compounds, hot welding rods, and installation materials.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Procurement of all materials Welding Full dimension check Mechanical engineering Pressure testing Leak testing with vacuum Surface treatment Documentation Acceptance

Request for a quote

METZEN INDUSTRIES GMBH

Germany

For example, casing made of nickel-chromium steel 1.4571 Procurement of materials Welding Mechanical engineering Surface treatment

Request for a quote

METZEN INDUSTRIES GMBH

Germany

For example, pressure vessels in accordance with the category IV DGRL97/23 EG Design support according to technical welding requirements Procurement of all materials Welding Mechanical engineering Pressure/leak testing Non-destructive testing Surface treatment Documentation

Request for a quote

KTW TECHNOLOGY GMBH

Germany

Economical metal welding (especially reactive metals, mixed materials) with the highest quality standards in high vacuum (10-5 mbar)

Request for a quote

KTW TECHNOLOGY GMBH

Germany

Economical metal welding (especially reactive metals, mixed materials) with the highest quality standards in high vacuum (10-5 mbar)

Request for a quote

METZEN INDUSTRIES GMBH

Germany

We support you throughout your design process and consider all the necessary technical requirements for welding. We can also produce components and assemblies from scratch. METZEN supports you with everything from purchasing materials to welding, mechanics, required checks and authorisations, surface treatment and, finally, documentation. Our product range includes normal steel vessel construction, stainless steel vessel construction/stainless steel pressurised vessel construction and aluminium vessel construction.

Request for a quoteResults for

Welding materials - Import exportNumber of results

42 ProductsCountries

Company type

Category

- Automation - systems and equipment (8)

- Laser - cutting and welding machines (3)

- Welding, soldering and brazing - equipment and supplies (3)

- Rubber flooring - industrial (3)

- Supply vessels (3)

- Industrial robots (2)

- Reducers (2)

- Steels and metals - welding and brazing (1)

- Welding, electric - equipment and supplies (1)

- Brass (1)

- Casting, steel (1)

- Copper and copper alloys (1)

- Electronic document interchange (1)

- Fasteners, metal (1)

- Flowmeters (1)

- Marking - diverse products (1)

- Rolling machines (1)

- Software (1)

- Tanks, metal (1)

- Vacuum cleaners - industrial (1)