- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wind machine

Results for

Wind machine - Import export

KABELMAT WICKELTECHNIK GMBH

Germany

This motorized ring and drum winding machine is designed for winding coilable material such as cables, pipes, hoses, steel ropes, plastic profiles etc. either as rings or on spools and drums. With the appropriate components such as length measuring device and material cutter, the material can be measured and cut to length. The winding speed is adjustable at the operating desk by means of a rotary potentiometer. The frequency-controlled winding drive allows a smooth winding of the material. * other coiler heads and winding spools available on request

Request for a quote

KABELMAT WICKELTECHNIK GMBH

Germany

This motorized ring and drum winding machine is designed for winding coilable material such as cables, pipes, hoses, steel ropes, plastic profiles etc. either as rings or on spools and drums. With the appropriate components such as length measuring device and material cutter, the material can be measured and cut to length. The winding speed is adjustable at the operating desk by means of a rotary potentiometer. The frequency-controlled winding drive allows a smooth winding of the material. * other coiler heads and winding spools available on request

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

Wound filter-cartridges Type: PP, PPW (washed) Wound filter-cartridges are depth-filter-elements, produced in a special way of winding. Newest winding-machines guarantee a constant and high quality for filter-cartridges up to 60”. The PPW filter-element is wound with a special washed yarn. Washed yarn is free of wetting agents and prevents foaming.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). We can wind onto any desired coil form using many different press-in ferrite and metallic cores. Multiple tap coils are also possible. Pins are automatically applied to the coil connections during the winding process, with wire drawing electrically controlled. Our winding machines handle single-chamber and multi-chamber coils with wire thicknesses from 0.045 to 0.71 millimetres.

Request for a quote

JOSEF MACK GMBH & CO.KG

Germany

Our brush rockers are oriented to your system requirements. When you are looking for long term quality: You have come to the right place here at MACK. The MACK brush rockers are available in many different dimensions, designs, and pole numbers, and depending on the application can be combined with flange holders or multiple shaft holder lines. From small motors to large direct-current machines or wind turbines: Our brush rockers are in use in numerous fields of application.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

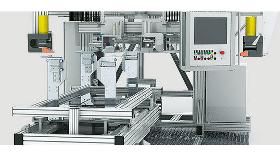

METZNER MASCHINENBAU GMBH

Germany

The specially developed production line can unwind, label, roughen, cut to length, strip, wind, bind and automatically deposit the cable wires. The material to be processed is unwound by a motorised unwinder and fed to a thermal transfer printer via a straightener. The latter prints the cable with two QR codes and a serial number. This ensures that each cable can be identified throughout the entire processing and manufacturing process and assigned to the stations which have already passed through. This traceability offers great advantages – for example in the diagnosis of faults. The cable then passes through a roughening station, which lightly roughens the material surface so that the connector overmoulding adheres better later on. An AM 3550 from Metzner Maschinenbau cuts to length and strips the cable, which is then transported to the winding station and onwards by a gripper to the binding machine. The latter winds the cable to form a cable ring.

Request for a quote

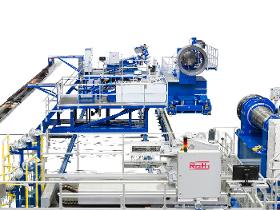

ROTH COMPOSITE MACHINERY GMBH

Germany

•Serial production for large-scale parts •Carriage with maximum precision movable •Several carriages can be realized for additional materials •Highest precision and winding quality

Request for a quote

ROTH COMPOSITE MACHINERY GMBH

Germany

•Product development and small-scale production •Small footprint •Enables direct transfer of process parameters to automated capabilities •Highest precision and winding quality

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

eldec brazing systems: automatic induction brazing of pole coils The semi-automatic equipment is designed for manufacturing pole coils of hydro and wind power generators. The machine is based on the experience of the previous manufactured equipments. The machine is designed as a sturdy, high quality and low maintenance machine. The operating is very simple, on automatic mode by 2-hand operation with step by step program and on manual mode by touch-panel.

Request for a quote

ARNO FUCHS GMBH

Germany

Combined with almost all cutting machines. Winding diameter of 150 - 600 mm

Request for a quoteResults for

Wind machine - Import exportNumber of results

11 ProductsCountries

Company type