- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wind machine

Results for

Wind machine - Import export

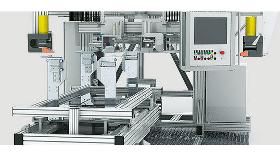

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

CLAremontage Automatic station which wind the movement by the rotor - Loading/unloading unit inserts - Independent station or integrated in an SMS line - Multi-calibers - Winding mechanical watches

Request for a quote

KABELMAT WICKELTECHNIK GMBH

Germany

This motorized ring and drum winding machine is designed for winding coilable material such as cables, pipes, hoses, steel ropes, plastic profiles etc. either as rings or on spools and drums. With the appropriate components such as length measuring device and material cutter, the material can be measured and cut to length. The winding speed is adjustable at the operating desk by means of a rotary potentiometer. The frequency-controlled winding drive allows a smooth winding of the material. * other coiler heads and winding spools available on request

Request for a quote

KABELMAT WICKELTECHNIK GMBH

Germany

This motorized ring and drum winding machine is designed for winding coilable material such as cables, pipes, hoses, steel ropes, plastic profiles etc. either as rings or on spools and drums. With the appropriate components such as length measuring device and material cutter, the material can be measured and cut to length. The winding speed is adjustable at the operating desk by means of a rotary potentiometer. The frequency-controlled winding drive allows a smooth winding of the material. * other coiler heads and winding spools available on request

Request for a quote

SHANGHAI DURA INDUSTRIAL CO., LTD.

China

Our factory produce automatic and semi automatic bobbin winding machine, this is automatic type 2 position PLC control system bobbin winding machine can be used to wind the different size bobbin automatically. One time wind two bobbins and no need worker to change the bobbin after the bobbin winded full. Specification: Model: DR-2 1, Two heads; high speed of 3200RPM 2, Advanced design with space saving and easy operation 3, Highly automatic to save labor 4, Auto-stop for yarn breaking and auto-counting 5, Suitable for all high speed bobbins and some low speed ones. 6. Voltage: 220/380 VAC, 50/60HZ 7. Power: 0.75kw Quality Control: All the machines will be inspected carefully before delivery. Oversea service: We have agent in different countries, so oversea service is available. Certificate: CE Packing: The quantity under 10 sets packed in single wooden case, over 10 sets order will load in full container.

Request for a quote

FERPLAST SNC

Italy

Place the pallets (EPAL) using a simple hand pallet truck, attach the film to the base of the pallet, select the wrapping program and press the start button. The machine automatically winding and stops. Cut the film manually. Attention: the pallet must not have the inner crosspieces on the side of the transpallet. STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport. The type of films supplied by us is of premium quality and is suitable to be used on our machines. We recommend using only top quality film in that it significantly reduces packaging waste and failures due to the use of an unsuitable product.

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

Wound filter-cartridges Type: PP, PPW (washed) Wound filter-cartridges are depth-filter-elements, produced in a special way of winding. Newest winding-machines guarantee a constant and high quality for filter-cartridges up to 60”. The PPW filter-element is wound with a special washed yarn. Washed yarn is free of wetting agents and prevents foaming.

Request for a quote

FERPLAST SNC

Italy

Place the pallet on the platform and hook the stretch film to the base then press the start button. The platform begins to rotate, after 2-3 turns operate the button for coil ascent. After reaching the desired height, stop the lifting of the reel and after 2-3 turns stop the machine or operate the descent of the reel and carry out the winding up to the base of the pallet. At the end of wrapping, press the stop button and cut the film. On request we can produce wrapping machines with: Rotary table diameter mm. 1800 - 2000 Electronic scale integrated STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport.

Request for a quote

FERPLAST SNC

Italy

Place the pallets (EPAL) using a simple hand pallet truck, attach the film to the pallet base and press the start button. The table starts to turn, after a few turns, press the coil rise button and hold it. When the coil of film reaches the top of the load stop the machine or press the down button to perform the double winding. Attention: the pallet must not have the inner crosspieces on the side of the transpallet. STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport. The type of films supplied by us is of premium quality and is suitable to be used on our machines. We recommend using only top quality film

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). We can wind onto any desired coil form using many different press-in ferrite and metallic cores. Multiple tap coils are also possible. Pins are automatically applied to the coil connections during the winding process, with wire drawing electrically controlled. Our winding machines handle single-chamber and multi-chamber coils with wire thicknesses from 0.045 to 0.71 millimetres.

Request for a quote

FERPLAST SNC

Italy

Place the pallets (EPAL) using a simple hand pallet truck, attach the film to the base of the pallet, select the wrapping program and press the start button.The machine automatically winding and stops. Cut the film manually. Attention: the pallet must not have the inner crosspieces on the side of the transpallet. STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport. The type of films supplied by us is of premium quality and is suitable to be used on our machines. We recommend using only top quality film in that it significantly reduces packaging waste and failures due to the use of an unsuitable product.

Request for a quote

FERPLAST SNC

Italy

Place the pallet on the platform, attach the film to the base, select the wrapping program and press the start button.The machine automatically winding and stops. Cut the film manually. On requrest we can produce wrapping machines with: Rotary table diameter mm. 1800 - 2000 Electronic balance with load cells Load/ Unload rollers STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport. The type of films supplied by us is of premium quality and is suitable to be used on our machines. We recommend using only top quality film in that it significantly reduces packaging waste and failures due to the use of an unsuitable product

Request for a quote

JOSEF MACK GMBH & CO.KG

Germany

Our brush rockers are oriented to your system requirements. When you are looking for long term quality: You have come to the right place here at MACK. The MACK brush rockers are available in many different dimensions, designs, and pole numbers, and depending on the application can be combined with flange holders or multiple shaft holder lines. From small motors to large direct-current machines or wind turbines: Our brush rockers are in use in numerous fields of application.

Request for a quote

FERPLAST SNC

Italy

Wrapping Machine Mod. FP 15 SE/T with table cut for loading and unloading with pallet, and safety photocell, photocell height sensing pallet, digital panel with 3 programs winding, inverter for soft start, manual lock/cut of the film and automatic wrapping cycle (machine CE). NOTE: the machine is loaded from the side. When ordering, with a surcharge, it is possible to obtain the modification for the front load. UPON REQUEST WE CAN MAKE WITH WRAPPING MACHINES: Rotary table diameter mm. 1800 (pallets up to 1300x1300 mm)Place the pallets (EPAL) using a simple hand pallet truck, attach the film to the base of the pallet, select the wrapping program and press the start button. The machine automatically winding and stops. Cut the film manually. Attention: the pallet must not have the inner crosspieces on the side of the transpallet.

Request for a quote

VERPET S.R.O.

Czech Rep.

Cable harnesses, toroidal transformers, coils, chokes, connecting cabling and other components from the field of electrical engineering are our main activity. During their production, we perform micro-soldering, tinning, winding using winding machines – vertical and horizontal, assembly of joints, connections and more.

Request for a quote

MARTIN GROUP SRL

Italy

double heating system with pre-heating that concurs to fuse with very low temperature respect to the standard temperature pressure system with “OUT” function for very delicate woven inside and outside belts cleaning devices carbon/graphite lower belt separation blade automatic turn ON and turn OFF by digital timer COUPLING, LAMINATION, TRANSFER, APPLICATIONS - COMPLETE LAMINATION LINE THAT CONCURS THE COUPLING OF 2 OR MORE LAYERS OF WOVEN WITH INTERLININGS, WEB GLUE OR FILM GLUE DIAGNOSTIC ON THE CONTROL PANEL introducion of the several rolls of wovens, interlinings, web glue or film glue by engine rolls perfect syncrony between fusing machine winding module and rewinding unit by inverter automatic cut machine availabilty for worked parts winding unit with vertical and horizontal control for a perfect alignment of the woven rolls during the winding fusing machine connected to the winding and rewinding module by inverter exit zone with rewinding unit equipped

Request for a quote

OCV ITALIA

Italy

SE1200 singleend Type 30™ roving is a compelling solution designed specifically for knitting and weaving with versatility to work well in filament winding, pultrusion, and LFTP applications. EXCELLENT PROCESSING Smooth runout from lower drag across contact points produces less fuzz, resulting in smoother parts, less cleanup, and improved machine efficiencies. MULTIPROCESS & MULTIRESIN COMPATIBLE Flexibility for use with standard weaving looms, multiaxial knitting machines, filament winding, and pultrusion. FAST WETOUT WITH REDUCED COST Fast, uniform strand wetout leads to higher glass loading and good adhesion, resulting in optimized part production speed which supports increased productivity and betterquality finished parts. ENHANCED SERVICE LIFE Compared to standard Eglass, Advantex® glass provides longer service life in applications facing corrosion and possesses high fatigue properties to help qualify for wind energy.

Request for a quote

FLEXPLAS

Turkey

FLEXPLAS DRIVEN CONVEYORS are designed to your specifications and adapted to your specific extrusion line and manufacturing requirements for maximum efficiency Flexplas take-away conveyors are designed with tilt/dump tables to be used when cutting flexible hoses and tubing. Typically located directly after cutting devices, Driven Conveyors enhance the cut length tolerance and cut quality by supporting and transporting the hose away from the cutter bushing at adjustable speeds typically more than line speed, eliminating accumulation and sorting confusion. The hose can then be optionally ejected by a pneumatic ejector system into a collection tray for operator removal or for coiling by a winding machine. The driven conveyor automatically discharges parts to a collection tray for this purpose. Our conveyors can be optionally configured for one side or dual side collection which is for double extrusion of the hose on the same extrusion line.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KARL SCHUPP AG

Switzerland

Devices and machines for dismantling and transport, for cleaning, for mounting or fixing aiming, for insulating, for winding, forming, ligaturing and closing, for stripping, for marking, for measuring and testing of electrical motors and for collector maintenance as well.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Use your AirWave1 and the AirWave2 air cushion machine with the mobile coiler unit. Ideal for the production of wide type 8 air cushion mats at an ideal height for grabbing. By activating a side button, the air cushion machine and the winding unit are activated. The mobile winding unit has an integrated sensor which stops winding once the maximum coiler size has been reached. The coiler unit has a separate power connector for the AirWave1 or AirWave2. Only a single power connection is needed for the roll coiler. Package Contents: Mobile coiler unit including power connection for the AirWave1 / AirWave2 Electronic winding unit incl. Start / stop function Dimension (without air cushion machine or air cushions): 106x50x121 cm (LxWxH)

Request for a quote

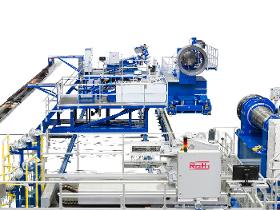

ROTH COMPOSITE MACHINERY GMBH

Germany

•Serial production for large-scale parts •Carriage with maximum precision movable •Several carriages can be realized for additional materials •Highest precision and winding quality

Request for a quote

ROTH COMPOSITE MACHINERY GMBH

Germany

•Product development and small-scale production •Small footprint •Enables direct transfer of process parameters to automated capabilities •Highest precision and winding quality

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

eldec brazing systems: automatic induction brazing of pole coils The semi-automatic equipment is designed for manufacturing pole coils of hydro and wind power generators. The machine is based on the experience of the previous manufactured equipments. The machine is designed as a sturdy, high quality and low maintenance machine. The operating is very simple, on automatic mode by 2-hand operation with step by step program and on manual mode by touch-panel.

Request for a quote

ENGINEERING TECHNOLOGY CORPORATION

United States

Engineering Technology Corporation’s team of engineers, material specialists, and process technicians allows the manufacturing of customized filament winding machinery, production lines, automated work cells, and other auxiliary equipment for a complete production cycle. The company develops and supplies all kinds of equipment for filament winding and provides consulting, process integration, automation, installation, training, and maintenance support.

Request for a quote

ASPEL ELEKTRIK ELEKTRONIK SAN. VE TIC. LTD. STI.

Turkey

- Full automatic - Soft start of winding thanks to motor drive - Detachable reel carrier an rotator - Need only 220Vac standart mono-phase supply - Settable the language to English or Turkish

Request for a quote

ENGINEERING TECHNOLOGY CORPORATION

United States

Cost-effective, reliable machinery with capabilities beyond the standards: from desktop filament winders to multi-spindle high-speed automated pressure vessel winders with industry-leading fiber payout. The portfolio includes everything from filament winding machines to fiber placement systems: polar winders, pipe winders, tape wrappers, gantry systems, and production lines of any complexity. Additionally, process equipment for filament winding such as curing ovens, tensioning creels, mandrel preheaters and extractors, thread grinders, hydraulic testers.

Request for a quote

KSK-GRUPP

Russia

PET films are used for electroinsulation of cables and wires, winding of electric machines and electric devices, for slot insulation in stators of electric motors with a broad range of power levels, and in wireless devices.

Request for a quote

ARNO FUCHS GMBH

Germany

Combined with almost all cutting machines. Winding diameter of 150 - 600 mm

Request for a quote

GIESSE

Italy

OPTIMA wrap is a machine designed and built to produce wrap chenille yarn. The OPTIMA wrap is the only chenille machine that direct take up in cone the chenille yarn and check it during the manufacturing process. Quality control of the yarn is made by optical sensors (CMC – link CMC ) mounted on the machine. The advantages of this machine are countless and chenille here below there list the most importants: - Total elimination of the winding department, is no longer necessary to wind chenille yarn produced by the winding machine!!! - Control of yarn quality by optical sensors (CMC) during the manufacturing process of the chenille. - Production speed about double compared to a traditional chenille machine. - Reduced manpower almost 50%. - Greater resistance of the yarn produced, which results to be particularly suitable for weaving.

Request for a quote

CRB CUSCINETTI VOLVENTI

Italy

Angular contact bearings are designed so that the contact angle between the raceways and the balls is formed while the bearing is in use. The ability of angular contact ball bearings to withstand axial loads increases proportionally as the contact angle increases. Features of angular contact ball bearings: high stiffness ideal for high-precision performance at high speed able to withstand heavy axial loads and moderate radial loads available with a single or double row, in the open or shielded / sealed versions Series Single row: 7200, 7300 Double row: 3200, 3300, 5200, 5300 APPLICATIONS: Agricultural Machinery Metal processing Oil Industry Paper making machines Wind sector Gearboxes Pumps and Compressors Ventilators /Fans Semiconductors Motorcycle Industry Machine tools Electromechanics Textile machinery Injection molding machines

Request for a quoteResults for

Wind machine - Import exportNumber of results

30 ProductsCountries

Category

- Packing and packaging - machinery and equipment (6)

- Spooling and reeling machines (3)

- Coil winders (2)

- Import-export - mechanical engineering (2)

- Wrapping machines (2)

- Automation - systems and equipment (1)

- Bearings - ball, needle and roller (1)

- Electrical & Electronic Components (1)

- Extrusion, plastics - machinery (1)

- Fabrics for technical use (1)

- Fallout shelters, construction (1)

- Filtering equipment and supplies (1)

- Induction heating systems (1)

- Laminating machines and equipment (1)

- Mechanical engineering - custom work (1)

- PVC, polyvinyl chloride (1)

- Textiles - Machines & Equipment (1)

- Trolleys and trucks (1)

- Twisting and spinning - machinery and equipment (1)