- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high-pressure pumps

Results for

High-pressure pumps - Import export

KELLER PRESSURE

Switzerland

This high-pressure pump generates pressures of up to 700 bar with ease, with fine control for precise adjustment. It is perfect for testing manometers and pressure transmitters. The pump must be filled with 100 cm3 of hydraulic oil or water and can therefore fill up even relatively large dead volumes. An additional manometer (not supplied) is needed for reference measurement of the configured pressure. KELLER recommends manometers in the LEX1 series with a suitable pressure range.

Request for a quote

KAMAT GMBH & CO. KG

Germany

customer-specific unit design incl. powerful high-pressure pump easy maintenance cavitation-free central drainage according to the latest global emission laws optionally fully automatic control own software with best support optional extreme sound absorption optionally all explosion protection classes

Request for a quote

KAMAT GMBH & CO. KG

Germany

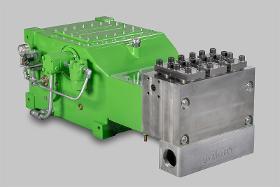

Performance in a small space Our compact K100-3 high-pressure three-plunger pump boasts impressive performance data: With only 15 kW of input power, it delivers a pressure of 2000 bar, making it one of the most powerful pumps in its size class. The K100-3 triplex plunger pump really comes into its own when it comes to water jetting for industrial high-pressure cleaning.

Request for a quote

KAMAT GMBH & CO. KG

Germany

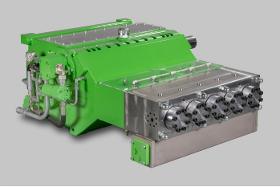

K25000-3G high-pressure triplex plunger pump for 24/7 operation, pipeline tensioning and leak testing of tanks and various pipelines. The K25000-3G is used internationally hundreds of times as a high-pressure pump in hydraulic face construction. With a power of 250 kW, a gearbox with forced lubrication and an optional oil cooler, the pump is perfectly suited to the demands of 24/7 mining operations. SPECIAL FEATURES - Capacity data at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on pumped liquid - Speed range 10-100% depending on rod load - Dynamically balanced gearbox - Forced lubrication gearbox (> 160 kW with oil cooler) - Standard gear ratios i = 3.33 - 3.50 - 4.04 - 4.62 - 5.44 - Can also be operated vertically - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc. on request

Request for a quote

KAMAT GMBH & CO. KG

Germany

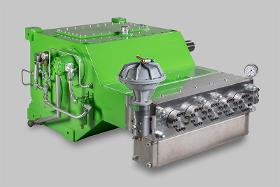

With 110 kW, the K11000-3G high-pressure pump is a powerful plunger pump that is mostly used in intermittent operation. The reason for this is that this KAMAT high pressure pump has splash lubrication and not oil pressure lubrication. This makes the pump more suitable for intermittent operation, but it is extremely robust and can therefore be used in continuous operation even at 110 kW. Classic applications for this pump are industrial cleaning, blasting and process engineering. SPECIAL FEATURES - Capacity data at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on pumped liquid - Speed range 10-100% depending on rod force - Dynamically balanced gearbox - Splash lubricated gearbox - Standard gear ratios i = 3,00 - 3,14 - 3,39 - 3,76 - 4,13 - 4,50 - 4,93 - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils etc. on request, oils etc. on request

Request for a quote

KAMAT GMBH & CO. KG

Germany

The KamJet is our solution for trouble-free extreme high pressure blasting on a mobile platform. The trailer mounted high pressure unit is powered by a 175kW Volvo diesel engine and produces pressures up to 3,000 bar for up to eight hours on a full tank of fuel. The KamJet mobile high-pressure unit with advanced control unit, optionally suitable for powering the Gekko system. Only high quality parts used - Our KamJet is a complete solution and comes mounted on a twin axle trailer that can travel at speeds of up to 100km/h. All parts and pipework on our units are made from stainless steel. Most importantly, it is equipped with a state of the art control system with touch screen or remote control that fully automatically controls the output pressure and speed. This makes it easy for the user to operate the machine and ensures uninterrupted operation. The KamJet can also be used with two users.

Request for a quote

KAMAT GMBH & CO. KG

Germany

For special applications, individual high-pressure systems are required, which KAMAT can provide from the initial project idea to the turnkey installation, with 100% of the production taking place in-house. This also applies to electric high-pressure pumping units. Depending on the application, our customers can choose between different drives, power transmission components, PLC controls, measuring systems, data transmission, remote controls, pneumatic and electric valve controls, chassis and sound insulation equipment. Even the electrical units supplied on the base frame are fully operational and can be used directly by the customer. Electric units have the advantage of emission-free operation at extremely low noise levels. ATEX certified high pressure electric units can also be used in ATEX hazardous areas.

Request for a quote

KAMAT GMBH & CO. KG

Germany

With a maximum drive power of 1000 kW, the K100000-5G high pressure pump is an extremely powerful pump. As a five-cylinder pump (quintuplex), it offers the possibility of pumping without inlet pressure in many applications. Its special five-cylinder design allows high flow rates without cavitation in the pump. Like its smaller counterpart, the K55000-5G, it is used for larger jetting or hydraulic applications. Special Features Flow rate based on 100% volumetric efficiency and 20°C ambient temperature Min. inlet pressure dependent on fluid Speed range 10-100% depending on rod force dynamically balanced gear Gear unit with forced lubrication and oil cooling gear ratios i = 3.40 - 4.10 - 4.69 - 5.19 - 6.03 Also available to API 674, including vertical operation Filtration up to 350 µm Special media such as seawater, glycol, methanol, oils etc. on request

Request for a quote

KAMAT GMBH & CO. KG

Germany

Pumps without upstream pressure: The Quintuplex K55000-5G plunger pump as a 550 kW high-pressure pump with five cylinders for direct as well as indirect hydromechanical descaling, mining and concrete rehabilitation. With five cylinders, the K55000-5G is one of our extremely powerful high-pressure pumps. Its special feature is that it has five cylinders that are precisely calculated and matched to each other: Thus, the K55000-5G achieves high performance without cavitation and with very low residual pulsation. It is even capable of pumping up to 640 l/min without upstream pressure. SPECIAL FEATURES Flow rate based on 100% volumetric efficiency and 20°C ambient temperature Min. inlet pressure dependent on fluid Speed range 10-100% depending on rod force Gear dynamically balanced Gearbox with forced lubrication and oil cooling gear ratios i = 3.30 - 3.95 - 4.66 - 5.63 Also available to API 674, including vertical operation Special fluids such as seawater, glycol, methan

Request for a quote

POFI-ENGINEERING

Luxembourg

High Pressure Metering Pump, DMP is applied DUT KOREA’s innovative technology with perfect compati-bility from previous models and stable shipment gives you to help building your polyurethane machine on time. Do not hesitate to contact us for more information Compatibility ‘DMP’ gives you perfect compatibility with your previous models. Light weight Using ‘Duralumin’ case and Simplification of parts inside of ‘DMP’ make amazing lightweight to help metering for operators Maintenance Simplification of ‘DMP’ gives operators to help easy maintenance and repair. Economical Price ■ To prevent flowing backward, it is controlled by actuator (Not by Hydraulic) ■ Semi-permanent product life by super-precision machine ■ High metering accuracy and repeatability ■ Operating pressure up to 220bar ■ Very little pulsation of flow ■ Quite operation ■ Optimum volumetric available ■ Low suction pressure, even when pumping highly viscosity materials ■ It can be used all parts together with Rexroth...

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Screw spindle pumps with their silicon carbide spindle housing and highly wear resistant spindles are capable of achieving extremely high pressures. Brinkmann high pressure screw pumps are designed for pumping filtered and lubricating fluids such as coolant oils andwatersoluble coolants. High pressure screw pumps are NOT designed for dry-running. Screw spindle pumps are positive displacement pumps which always require the installation of a pressure relief valve in order to prevent bursting. Volumetric delivery: up to 878 l/min Delivery pressure: up to 200 bar Please contact us for delivery quantity

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Screw spindle pumps with their silicon carbide spindle housing and highly wear resistant spindles are capable of achieving extremely high pressures.Brinkmann high pressure screw pumps are designed for pumping filtered and lubricating fluids such as coolant oils andwatersoluble coolants. High pressure screw pumps are NOT designed for dry-running. Screw spindle pumps are positive displacement pumps which always require the installation of a pressure relief valve in order to prevent bursting. Volumetric delivery: up to 878 l/min Delivery pressure: up to 200 bar Please contact us for delivery quantity

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for building up pressure in the polymer process. The series is the result of a complete revision of the core components used. The BOOSTER-AT is available with flange connections according to EN1092-1 and ANSI B16.5. Thanks to the new gear wheel geometries, differential pressures of up to 320 bar are possible with selected pump sizes. The new design is rounded off by the usual variety of different material combinations. Advantages: Higher efficiency, therefore Less temperature input into the polymer Wider viscosity range possible Larger volume flow range possible Increased safety against shaft breakage in case of overload due to new design

Request for a quote

ZBKIT LLC

Russia

One-plunger pumping units PT 1.1 with capacity up to 8 m3/h and pressure up to 40 MPa Three-plunger pump units according to API 674 (3-d edition) PT 1.3 and PT 2.3 with a capacity of 0.2 m3/h to 60 m3/h and pressure up to 80 MPa Five-plunger pumping units Pumping units are designed for pumping various liquids, including chemically active ones, with temperatures from -15 ° С to + 450 ° С, kinematic viscosity of not more than 8 cm / s, with the content of solid non-abrasive particles up to 0.2% by weight and size up to 0.2 mm.

Request for a quote

BFT GMBH

Austria

INCREASE THE PRODUCTIVITY OF YOUR EXISTING WATERJET CUTTING SYSTEMS BY AT LEAST 30 % With HYPERTRON®, you can reach a 30 to 50 % higher cutting speed and energy efficiency combining servo technology with ultra-high pressure. The HYPERTRON® provides flow rates of 3.5 l per minute with 6,000 bar or 4.6 l per minute with 4,000 bar. Whether you want to work with two cutting heads or only with one cutting head, HYPERTRON® provides the right pressure – from 100 to 6,000 bar. Flexibility and high performance in one. Customers buy European products… because they are adjusted to the requirements of European companies. because they are designed taking into consideration a responsible treatment of our resources. because they are easy to service and all common metrical tools match. because they meet European standards and quality expectations.

Request for a quote

BFT GMBH

Austria

THE PROFESSIONAL PUMP WITH A HIGH VOLUME FLOW FOR MULTIPLE-HEAD APPLICATIONS. EVEN PRESSURE SIGNAL FOR HIGH PRODUCTIVITY. Proven 4,000 bar technology combined with high flow rates – greatly appreciated by the professionals. Especially for multiple-head applications, HYTRON® always ensures the required volume of high-pressure water. HYTRON® provides 6.0 or 7.6 l per minute with 4,000 bar. Whether you are using two or four abrasive cutting heads simultaneously, HYTRON® provides continuously adjustable pressure from ten to 4,000 bar. The two chamfered pressure intensifiers create an optimal cut. Customers buy European products because they are adjusted to the requirements of European companies. because they are designed taking into consideration a responsible treatment of our resources. because they are easy to service and all common metrical tools match. because they meet European standards and quality CONVENTIONAL WORKING PRINCIPLE WITH EVEN PRESSURE

Request for a quote

BFT GMBH

Austria

THE NEXT STEP IN PUMP TECHNOLOGY EVOLUTION: ENERGY-SAVING, HIGHLY EFFICIENT AND PROFESSIONAL. SERVOTRON® is available in the power classes 37 kW and 45 kW. Its operating pressure of 4,000 bar has been considered to be the optimum in the professional waterjet cutting sector for years. The Austrian technical control board has confirmed that up to 24% energy can be saved with SERVOTRON® in a comparison with conventional pumps. It is available with a flow rate of 3.8 l per minute and 4.6 l per minute. Customers buy European products… because they are adjusted to the requirements of European companies. because they are designed taking into consideration a responsible treatment of our resources. because they are easy to service and all common metrical tools match. because they meet European standards and quality expectations.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MERTSAN PUMPS

Turkey

Flow (LT. / M.) : 71 Speed (R.P.M) : 540 Power (HP) : 7.3 Pistons : Pressure (Bar) : 45 Oil Type : 20W50 Dimension (CM) : 26 x 34 x 34 Weight (kg) : 17.15

Request for a quote

MERTSAN PUMPS

Turkey

Flow (LT. / M.) : 30 Speed (R.P.M) : 540 Power (HP) : 2.7 Pistons : 2 Pressure (Bar) : 35 Oil Type : 20W50 Dimension (CM) : 22 x 30 x 38 Weight (kg) : 13.15

Request for a quote

MERTSAN PUMPS

Turkey

Flow (LT. / M.) : 71 Speed (R.P.M) : 540 Power (HP) : 7.3 Pistons : 3 Pressure (Bar) : 45 Oil Type : 20W50 Dimension (CM) : 26 x 34 x 34 Weight (kg) : 18.45

Request for a quote

HIPRUN POMPA VE CNC EKIPMANLARI

Turkey

Double filtration system is used in our high pressure coolant sytems. They are easily removable and cleanable. On the other hand, especially the main feature of this system is not to be obligated to stop machine during cleaning and changing filter. One filter can be operated with machine while another is been cleaning. This will provide you the time saving during filter change Multiple Manifold Block with 4 outlets is provided as standart in this model. However, it can be manufactured over 4 outlets depending on your requirements at your machining process. HP2 High Pressure Coolant Units are used as mobile station. They have wheels under units and you may easily move it where you prefer them to be placed at your workshop.

Request for a quote

KAMAT GMBH & CO. KG

Germany

Versatile, turnkey diesel high-pressure pumping units Special applications require customised high-pressure systems, which KAMAT can provide from the initial project idea through to turnkey installation, with 100% of the manufacture taking place in-house. Depending on the application, our customers can choose from a range of drives, power transmission components, PLC controls, measuring systems, data transmission, remote controls, pneumatic and electric valve controls, chassis and sound insulation. However, the units are ready for use on the base frame on which they are delivered. KAMAT diesel-powered units are traditionally used in industrial cleaning and pressure testing, mining and water hydraulics, but special solutions for special fluids or to meet explosion protection requirements are also part of the KAMAT range. It makes no difference whether the customer requires a mobile or stationary unit.

Request for a quote

KAMAT GMBH & CO. KG

Germany

High-Pressure Cleaning, Load Change Systems and Pressure Test Systems If your application requires forced lubrication and an oil cooler may be required, the powerful K9000-3G three-plunger high-pressure pump is an alternative to the smaller K8000-3G three-plunger high-pressure pump. Like the compact K8000 model, this 90 kW high-pressure pump is suitable for smaller industrial applications such as industrial cleaning, jetting or process engineering. SPECIAL FEATURES - Capacities at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on fluid - Speed range 10-100% depending on rod force - Forced lubrication gearbox (> 75 kW with oil cooler) - Standard gear ratios i = 2.75 - 3.22 - 3.68 - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc. on request - Vertical operation possible

Request for a quote

KAMAT GMBH & CO. KG

Germany

Working at high pressure and high volume flow with the KAMAT Triplex plunger pump K45000-3G: particularly suitable for pressure tests of containers, pipeline stressing and pipeline testing. The K45000-3G focuses on hydraulic applications and jetting. In jetting, the 450 kW high-pressure plunger pump is often installed in large mobile systems. The K45000-3G plunger pump is particularly suitable when high litre capacities are to be realised at high pressure. SPECIAL FEATURES - Flow rates with 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on fluid - Speed range 10-100% depending on rod force - Dynamically balanced gearbox - Forced lubrication gearbox with oil cooler - Standard gear ratios: i = 3.39 - 4.05 - 4.76 - 5.25 - Also available according to API 674, can also be operated vertically - Special media such as seawater, glycol, methanol, oils, etc. on request

Request for a quote

DOREY

France

You can work many formats with or without contact with high quality and suitable for lamination of contact and contactless plastic cards BENEFITS Heating and cooling presses are independent, so the costly heating up and cooling down of the hot platens during each production cycle is totally avoided. The main frame of the heating and cooling presses are constructed of rigid welded steel. The main hydraulic cylinders are hardened, ground and hard chromium plated. The platens are guided by frictionless material. Heating and cooling presses are operated by a separate hydraulic system. A low pressure pump is used to lift the platen at a quick speed, while a high pressure pump is used to keep the heating and cooling presses at a high pressure. The pressure settings at the different stages of heating and cooling are programmable. The closed loop transport system significantly reduces material cassette loading and transfer time, resulting in much reduced consumption of energy.

Request for a quote

DOREY

France

Heating and cooling presses are independent and operated by separate hydraulic system. A low pressure pump is used to lift the platen at a quick speed, while a high pressure pump is used to keep the heating and cooling presses at a high pressure. Heating and cooling presses are built from two solid welded frames, with all platens securely guided, allowing for a tremendously high rigidity of construction and thus , excellent parallelism of platens. This eliminates the undesirable effects of heat expansion. The pressure settings at the different stages of heating and cooling are programmable. High precision temperature control ( 1.5℃) is achieved through excellent circulation and monitoring of thermal heating oil. Manual transfer the material cassette from table stand to stand by stand. Uniform application of pressure thereby avoids discoloration. The heating temperature is evenly and accurately distributed across the total hot platen area.

Request for a quoteResults for

High-pressure pumps - Import exportNumber of results

149 ProductsCountries

Category

- Pumps (13)

- Connectors, plumbing (10)

- Milling - machine tools (10)

- Pumps, hydraulic (7)

- Diesel engines (6)

- Gear pumps (6)

- High-pressure cleaning machines (6)

- Hydraulic equipment (6)

- Dosing pumps (5)

- Industrial sprayers for surface treatment (5)

- Agriculture - Machines & Equipment (4)

- Cement-making - machinery and equipment (3)

- Cooling and lubrication pumps (3)

- Industrial valves, operating equipment (3)

- Oil-fired power stations, installations and equipment (3)

- Piston pumps (3)

- Shearing machine tools (3)

- Additives, cement and mortar (2)

- Bottling and filling - machinery and equipment (2)

- Centrifugal pumps (2)