- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- kneading machines

Results for

Kneading machines - Import export

PKO-SURA COMPANY

Russia

The machine is intended to knead various types of high viscosity dough at confectionery and bakery enterprises: •gingerbread dough; •dough for doughnut products; •dough for sugar cookies; •dumpling dough, etc. The dough dish overturns through 120 degrees to unload the dough. All dangerous points of the machine are guarded. When the cover is open, the vane drive motor is automatically shut off. The feature of the dough-mixer is its powerful Z-shaped blades of stainless steel that enable to knead the tight dough gently. A variable frequency drive is used for smooth change of the blade rotation speed that makes it possible to use the machine for kneading crumpet dough.

Request for a quote

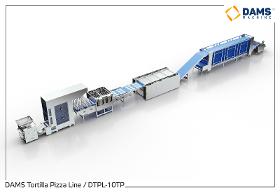

DAMS MACHINE

Turkey

It is used in splitting (cutting/ slicing) the sandwich and hamburger breads before packaging. Circular blade is used, this blade is easy to remove and install. 304 Cr-Ni is manufactured on the surfaces that the product touches. The bands used are suitable for food. Product feeding is done manually. There are three adjustment arms; First Setting Arm It is top pressing setting. The top band is adjusted according to the thickness of the bread to be split and the bread is prevented from flying during cutting.

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 11000 pcs/hour capacity Weigh trange 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI TouchPanel , PLC control.

Request for a quote

DAMS MACHINE

Turkey

The settings are made easily from the PLC-controlled touch screen. Mechanical settings are simple to use and easy to learn. Information on usage can be stored in memory and used continuously. Daily cleaning is easy. It is easy to disassemble, install and replace belts and running parts. The speeds of all belts can be adjusted to the desired level. Electrical and electronic faults that may occur are displayed on the PLC screen with pic and text.

Request for a quote

DAMS MACHINE

Turkey

Our machine is used in bagel, roll, sandwich and hamburger breads. Machine settings can be made on PLC and digital display. These settings are saved in the recipe and do not want to be re-adjusted in product change. Machine chassis is made of 304 Cr-Ni sheet metal. It has the feature of spraying the desired amount of water, eggs, slurry and molasses on top of the products in the flat tray or molded tray. At the same time, it can sprinkle the desired amount of granular materials such as sesame, bran, kernel, rye on the products on the flat tray or molded tray. It is simple to use and clean.

Request for a quote

DAMS MACHINE

Turkey

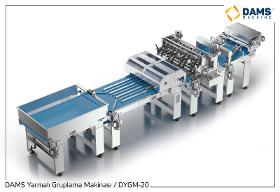

Sandwich and hamburgers coming from the cooling tower or in bulk are placed manually between the product sorting slides with the help of two personnel. When the products are divided into groups, the numbers are checked with the sensors, and if there are missing rows, they wait until the order is completed. The queues are divided into groups by the help of two flaps, and the number of packages depends on desired grouping (sandwich 4, 5, 6, Hamburger 4, 6, 8). Here, the products are placed between the product pushers of the packaging machine with the help of a push rod. Product pushers take products to the enveloping unit and allow them to be packaged.

Request for a quote

DAMS MACHINE

Turkey

GENERAL CHARACTERISTICS Sandwich and hamburgers coming from the cooling tower or in bulk are placed manually between the product sorting slides with the help of two personnel. When the products are divided into groups, the numbers are checked with the sensors, and if there are missing rows, they wait until the order is completed. The queues are divided into groups by the help of two flaps, and the number of packages depends on desired grouping (sandwich 4, 5, 6, Hamburger 4, 6, 8).

Request for a quote

DAMS MACHINE

Turkey

It can cut sandwiches and hamburgers, flatbread, bagels, baguettes and similar products. It is used in the slicing (cutting) process of sandwich and hamburger breads before packaging. The slicing machine has wheels and can be taken anywhere easily. The chassis is completely chrome nickel. Used strip blade, easy to disassemble and install. The surfaces that the product comes into contact with are made of tape suitable for food. Product feeding is done manually.

Request for a quote

DAMS MACHINE

Turkey

It is used in splitting (cutting/ slicing) the sandwich and hamburger breads before packaging. Circular blade is used, this blade is easy to remove and install. 304 Cr-Ni is manufactured on the surfaces that the product touches. The bands used are suitable for food. Product feeding is done manually. There are three adjustment arms; First Setting Arm It is top pressing setting. The top band is adjusted according to the thickness of the bread to be split and the bread is prevented from flying during cutting.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DAMS MACHINE

Turkey

DSPM series are standard mixers. It has a double-speed motor and belt-pulley equipment. The dough mixing process is completed in 18 minutes. It can be used in making dough, meatballs, butter, minced meat, cream, tobacco, cookies and similar products. PRODUCT SPECIFICATIONS Time setting Reinforced body Double-speed motor Parts in contact with food are made of 304 quality stainless steel. Electrostatic oven painted surface

Request for a quote

DAMS MACHINE

Turkey

DMOM series are new generation mobile bowl mixers. It has a fast and practical system that allows kneading without losing time thanks to the spare mobile bowl.It has a double-speed motor and belt pulley equipment. The anchor lifting and bowl locking systems are hydraulic. Slow and fast cycle times can be determined by setting the time with the automatic operation mode.It has a faster kneading feature than standard dough kneading machines and the dough kneading process is completed in 15 minutes.It is aimed at meeting fast mass production needs. It can be used in the production of dough, raw meatballs, butter, minced meat, cream, tobacco, snacks and similar products. PRODUCT SPECIFICATIONS Touch Screen PLC Control Panel Hydraulic bowl locking and anchor lifting Differential-free system Water dosing Time setting Double-speed and powerful motor All surfaces in contact with food are made of 304 quality stainless steel

Request for a quote

COSTRUZIONI METALMECCANICHE VALENTE

Italy

Our staff, who are specially trained and kept constantly up-to-date with the latest developments, produce special and automatic machines, production lines and industrial plants, automation and handling systems, prototypes and newly developed machines, material handling and automation systems, equipment and lines. The on-site engineering department at the Nole plant provides specialist consulting on the production of ad hoc industrial machines and systems, which are designed according to customer requirements using advanced 3D design software. Below are some examples of machinery produced : Equipment for the production of foam rubber Automatic cutting lines for rubber Industrial washing facilities Drying ovens Inspection machines Newspaper sorting plants Polymer tempering plants Rolling mills for pasta and kneading machines

Request for a quote

ALFA BREAD

Turkey

Full set of Arabic pita bakery equipment that you need to start producing perfect Arabic pita bread Fully automatic Lebanese bread production line Arabic pita bread machines include dough kneading machine dough proofer x 2 dough sheeter Oven Cooling conveyor belt Arabic pita bakery production capacities can range from 2000 to 12.500 pcs /h Lebanese bread line warranty 100% Automatic Arabic pita bread production line is designed to fit big and small production spaces Free training on how to make Arabic bread and free installation Full after-sales service for more details about Arabic pita bakery equipment www.alfabread.net 00905527066558

Request for a quote

TURKIYE MACHINES BAKERY MACHINES

Turkey

Spiral kneading machines are commonly preferred by bakery and pastry shops in order to shorten the usual kneading time. Also homogenous dough mixture is obtained thus volume of bread becomes even bigger. Machine can be worked as manual and automatic cycle with two programmable timers. The bowl, spiral arm, bar are made of stainless steel. The bowl can be rotated in reverse motion. Machine works as silent via belt transmissions of main power. It is a mobile machine and the wheels have locking system. Optionally, the temperature measuring unit may be added. process and allows to remove the bowl by user. The bowl is fasten to the mixer`s body with a locking system. By the way kneading standardization is always assured. The other specifications of removable bowl mixer are as follow: stainless steel bowl, knife and spiral hook, automatic and manual control, silence in mechanical system and power transfer, mechan-ical system and security system according to CE standards.

Request for a quote

ÇAGAN PASLANMAZ

Turkey

.Spiral Hamur Karıştırıcı Genel Özellikler 0.5 kg ile 10 kg arası. Ayarlanabilir hızı ile her türlü hamur için idealdir. Spiral kazan kolu paslanmaz çelik. Potansiyometre tek fazlı motor ve hız regülasyonu için bir seri invertör mevcuttur. Elektrostatik epoksi boya. LED ışıklar. Kayış buluşmaları. Sessiz şalma. 12 litre Minimum %50 içerik. Otomatik ve manuel seçim. Temizlemesi kolay. Modlar taşınabilirdir. CE standardına uygun olarak erütimekedir. 1 yıl garanti. Aksesuarlar: Zamanlayıcı 15 saniye. 10 kilo Un kapasite Dilleksi renk taferlerinde 2 yıl garanti. GENİŞLETİLMİŞ BİR SERVİS AĞI MEVCUTTUR. MARKA HİÇ BU KADAR UYUMLU OLMADI Mütüşler sözteği aklımızın ön seralarında yer alımın. Ürünlerimiz tamamen orijinal ve yerli üretimdir. En iyi fiyat ve kaliteli hizmet önceliğimizdir. Tüm ürünlerde ücretsiz ve hızlı kargo imkanı sunuyoruz. BİLGİ 0090541 8017150 WATSAPP VE WİBER

PIMAK PROFESSIONAL KITCHEN EQUIPMENTS

Turkey

Product Code BHY.10K Capacity (Flour/Dough Kg) 25/35 Voltage (Volt/Hz) 220-380 / 50-60 Power(kW/hp) 0,37 / 0,5 Weight (Kg.)65 Dimensions(mm) 700x460x600

Request for a quote

MIXACO MASCHINENBAU

Germany

MIXACO Container Mixer Vortex™ It is suitable for any industry where different recipes need to be mixed in quick succession, resulting in frequent mixer cleaning. As the transport container and mixer head are separate units, products can be conveyed to the next processing station without loss of time. The design of the MIXACO Vortex™ mixer, which was robust from the outset, is continuously being improved and updated. The system and its individual components are also configured for multi-level operation, with corresponding connectors to allow dust-free, airtight discharging of the transport container directly into extrusion, kneading, weighing and bagging machines. The MIXACO Vortex™ is more than simply a classic among container mixers; it also offers modern technology with numerous advantages for your in-house material logistics and work processes.

Request for a quote

DIRMAK MAKINA SAN. TIC. LTD. ŞTI.

Turkey

Dirmak Machinery ISM Series appeal many sectors to cater with a wide range of products from 10 litre up to 350 litre. Our machines provide to knead very short time thanks to excellent bowl and spiral apparatus design. Spiral mixer yields very quick preparation without warming and tiring products such as dough, mincemeat, cigkofte etc. ISM Series give power to your business with quite and smooth operation, durable and long-lasting.

Request for a quote

LEVANT RUS LLC

Russia

High-quality construction made entirely of stainless steel, heat exchanger made of heat-resistant stainless steel AISI 310S rotary platform drive without frame two independent steam generators - a tray in the hot air stream and a high-temperature one, built into the heat exchanger and heated by exhaust gases highly efficient heat block with air movement from the least hot output stage to the hottest zone of the furnace thermal insulation with a thickness of 150 mm 3 years warranty, 24-hour customer service the height of the baking chamber in the serial version is 2000 mm, an increase in productivity by 22% with the same occupied area two circulation fans, air supply from both sides – a large volume of heated air at low speed reduced baking time, reduced baking loss thermal efficiency is more than 93%, which is the best indicator best price-quality ratio, the minimum payback period.

Request for a quote

STANCMETAL

Serbia

Thermowell is used to protect the temperature probe for boilers. What’s important is the tube closing, not by welding and kneading, but with machine that closes the tube by friction. This method of closing copper probes turned out to be very successful, and it can be performed on customer’s request. In Stancmetal, copper probes with dia 6mm 8 mm, 9.5 mm, 10 mm, 15 mm and 16 mm can be closed.

Request for a quoteResults for

Kneading machines - Import exportNumber of results

29 ProductsCountries

Company type

Category

- Kneading machines for bread- and pastry-making (20)

- Bakery and confectionery industry - machinery and equipment (17)

- Bakery - machinery and equipment (4)

- Bakery - machinery and equipment (4)

- Bakery ovens (1)

- Cement-making - machinery and equipment (1)

- Food extracts - machines and equipment (1)

- Hotels and restaurants (1)

- Pipes and tubes, copper (1)

- Rolling mills - machinery and installations (1)