- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamping parts

Results for

Clamping parts - Import export

MAROVT D.O.O.

Slovenia

The advantage of the Marovt company is that forged parts are machined in our own forge. This is why we are able to ensure forged parts with characteristics defined together. The machining of forged parts is mostly automated; therefore, the human factor is decreased and permanently the same technological process can assure all parts to be machined in the same way and being controlled and tested according to the same procedures.The machining of forged parts is carried out on technologically advanced 3 and 4-axe machines. Our machining centres have the possibility of using up to 40 changeable cutting tools. The tool can be up to 300 mm long and up to 10 kg heavy.The machining center spindle can rotate up to 20,000 rpm. Changing the cutting tool at our centers only takes 1.7 s, which greatly shortens the machining time. All our machining centers have a pallet system that eliminates the time of mounting the forging parts into the clamping device.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

OEM milling machining anodized aluminum clamp parts for industrial use

Request for a quote

NORELEM FRANCE

France

Enter the desired lever colour here. The standard colours are: Black grey clamping lever, traffic red push button. Orange clamping lever, black grey push button. Traffic red clamping lever, black grey push button. Where L ≥ 60 mm the thread length is 60 mm. On request: Other threads, screw lengths and special versions. Dimension “H1” available in other lengths at extra charge. Drawing reference: 1) flat point DIN 78

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Stampling device for welding work ■ positioning, centering & clamping of metal part, with integrated part scanning The individuel customized solution will be performed according to customer specification!

Request for a quote

NORELEM FRANCE

France

Sliding carriage Base structure in extruded section, aluminium EN AW6060. Sliding elements Maintenance free plain bearing iglidur® J. Version Eloxalcoated E6/EV1. Black thermoplastic Note With a low rate of inerita, high accelerations and short term extreme speeds up to 30 m/s are possible. DryLin® T linear glide guides are resistant to dirt and corrosion and are adjustable, maintenancefree and quiet. Application temperature max. 80 °C. As no lubricants are used they are recommended for use in food, medical, and clean room technologies. Manual clamping was developed for simple functions. Polymer under constant pressure has a tendency to creep which causes a decrease in clamping force over time (up to 70%), which means that no safetyrelevant parts should be clamped. Suitable guide rails see 21200. Drawing reference 1) manual clamping

Request for a quote

FLUX-GERÄTE GMBH

Germany

The pump-kit MINIFLUX is designed for emptying IBCs via their floor-level outlet. Designed as an alternative to a vertical pump, the MINIFLUX can be used when an IBC is not accessible from the top. It is suitable for applications when gravity draining via the outlet tap is insufficient e.g. rapid dispensing or transfer to another container in a higher location. Power can ideally be provided by a commutator or compressed air motor. Product attributes: - For pumping out of IBCs directly from the outlet (with standard S60 x 6 thread) - Simple connection of the pump to the outlet by union nut - Compact design - Can be dismantled into two parts via clamp - Low overall weight of 1.2 kg - No need to mount pump to top of container - Does not require access to the container from above - Ideally combined with commutator motor or compressed-air motor Benefits: - Can be used where ceilings are low - Allows pumping directly from floor-level outlets, even when containers are stacked

Request for a quote

NORELEM FRANCE

France

The workholding magnets 090602010 to 090602030 consist of a permanent magnetic system with fine pole divisions (4 mm) which are effective on two or three faces. To clamp extremely thin steel parts we recommend the magnet 090602040 with the finest pole division of 1.3 mm. The magnetic lifespan of the workholding magnets under conditions prevailant in industrial machining is unlimited. Approximately half the height of the workholding magnets can be ground down or polished away with no significant impairment of the magnetic strength.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

Based on its many years of experience in the development and production of high-quality machine components, GMN has chosen to specialize in the production of efficient, long-life sprag type freewheel clutches. The standardized model series offer a large selection of feature options to furnish effective freewheel clutch solutions for almost any field of application. The functional principle of sprag type freewheel clutches is based on static friction. A certain number of sprags are in constant friction contact with the connecting parts. Sprags are components with variable height. They are uprighted when the connecting parts are rotated and clamped between the connecting parts while there is static friction between sprags and connecting parts. The static friction is guaranteed by a specific geometry (clamping angle) of the sprags to the connecting parts. GMN sprag type freewheel clutches can be used as indexing clutches, backstops or as overrunning clutches.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

2-spindle solution with a 4-part clamping device Editing the OP 20 after the turning process Piece time less than 90s possible

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 4 spindles OP 10 with 4 part clamping on workpiece carrier unit OP 20 with 4 workpieces on 2 rotary tables (5-axis machining

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

2-spindle solution with 4 parts clamping Processing in one setup Machining time less than 82s per workpiece Machining with 4 spindles Tool monitoring for all tools takes place parallel to production time

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

CLAMPING DEVICES FROM THE EXPERTS. SAMAG OFFERS PROCESS-OPTIMIZED SOLUTIONS AND A COMPLETE ALL-ROUND SERVICE WHEN IT COMES TO DEVICE CONSTRUCTION. Complete machining of workpieces begins with the right clamping concept. Our engineers develop innovative solutions and clamping devices at the highest technical level. Processing complicated workpieces in efficient cycle times requires process-optimized clamping. We deliver technological solutions with longevity and all-round service. The workpieces are aligned, fixed and clamped hydraulically, pneumatically or mechanically. If several parts are processed at the same time, depending on the number of motor spindles, high-precision fixing, positioning and clamping of the parts is necessary. This is only possible with automated tensioning (e.g. hydraulic) and precise alignment of the devices.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Railway Parts Railway Clamp Bronze Clamp Bronze casting

Request for a quote

AVM AUTOMATION

France

Handling pneumatic gripper with parallel clamping with 3 concentric fingers. The guide is prismatic and mechanism is completely protected Benefits of 3finger parallel tightening Although most handling applications are using parallel grippers with 2 fingers, because even in the case of cylindrical parts, Vshaped jaws allow a good grip. The use of a gripper with 3 fingers is preferred in 2 case – refocusing of the part along 2 axes during tightening – stability of a long cylindrical part clamped by its end In the particular case of screwing, we have a range of 3jaw grippers specifically dedicated to screwing Type 2913 grippers. Reliability and robustness of Type 24 parallel grippers With a hard anodized body and cylinder, prismatic steel guide, fully protected mechanism, these pneumatic parallel grippers are robust and reliable. The positions are detected by magnetic detectors (delivered separately) thanks to 2 Tgrooves on the upper face of the cylinder.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Ming Xiao Mfg is specialize in sheet metal Stamping services more than 20 years,have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching, bending, cutting, shearing, riveting, spinning, welding, deep drawing, etc. We are also have 6 sets different sizes progressive die stamping machines, can produce small metal stampings with high speed and low prices. suitable to high volume metal stamping components. Metal Stamping Parts Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper Finishs: Anodize,painting,powder coating,blackening,electroplatings of chrome/zinc/nickel /tin/silver...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Permanent magnetic chucks type PMNM are high precision plates for clamping small and thin parts for precision grinding and eroding. The low magnetic field height prevents magnetization of the processing tools. The chipboard is activated via a removable hex shifter. Structure: — Neodymium magnet system, steel body — transverse pole pitch 1.4 + 0.5mm — Holding power 100 N/cm2 — Magnetic field height 5mm — Pole plate wearing limit 6mm Recommendation: High-precision chuck for grinding and eroding

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Permanent magnetic chucks type PMNM are high precision plates for clamping small and thin parts for precision grinding and eroding. The low magnetic field height prevents magnetization of processing tools. The chipboard is activated via a removable hex shifter. PMNM palletising clamping plates are available in 3 versions: Structure: — Neodymium magnet system, steel body, — Transverse pole pitch 1.4+0.5 mm — Holding power 100N/cm² — Magnetic field height about 5 mm — Pole plate wearing limit 6 mm Recommendation: High-precision plate for grinding and eroding

Request for a quote

MAXRAY KIMYA SANAYI VE TICARET LIMITED SIRKETI

Turkey

It cleans calipers and linings, discs, drums, brake center cylinder, clamps, springs and clutch parts in the brake system and increases the holding feature. Thanks to its special formula, it provides cleaning of grease, tar and other oils that have formed layers by combining with dust without much effort. You can also use the package by turning it 180 ° upside down.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

▪ Compact and light-weight design for applications in which space is limited ▪ Available in 3 different sizes and covering all standard metric and imperial diameters between 4 mm and 32 mm / .16 inch and 1.26 inch ▪ Vibration/noise-reducing clamp body material with UV, ozone and weathering-resistant characteristics ▪ Advanced design with a film hinge allows the top part of the clamp body to open up and insert or replace the pipe, tube or hose without the use of force ▪ Embedded metal sleeve to ensure stability of the clamp assembly Please also ask for the Anti-Twist Feature to prevent turning of the components.

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

These flange type units is made of stainless steel and fix the hub positively against their extended flange preventing axial movement during tightening. Applied wherever self-centering action and good concentricity of mounted components are essential and hubs with straight-thru bores are used. Available sizes: Metric series shafts from 20 mm to 150 mm dia. and Inch series for shafts from 1” to 4” diameter. Excellent concentricity and very easy to dismantle – these Locking Assemblies provide particularly good concentricity between the clamped parts. The flange is reinforced at the critical point, preventing bending or lifting of the inner ring during assembly and thereby ensuring easy dismantling. High rotation speed – the dimensional accuracy of the RfN 7013 Locking Assemblies allows their use in applications with higher rotational speeds. High radial loads – the material strength of the RfN 7013 Locking Assemblies makes them especially suitable for applications with high radial...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

These flange type units fix the hub positively against their extended flange preventing axial movement during tightening. Applied wherever self-centering action and good concentricity of mounted components are essential and hubs with straight-thru bores are used. Available sizes: Metric series shafts from 20 mm to 150 mm dia. and Inch series for shafts from 1” to 4” diameter. Excellent concentricity and very easy to dismantle – these Locking Assemblies provide particularly good concentricity between the clamped parts. The flange is reinforced at the critical point, preventing bending or lifting of the inner ring during assembly and thereby ensuring easy dismantling. High rotation speed – the dimensional accuracy of the RfN 7013 Locking Assemblies allows their use in applications with higher rotational speeds. High radial loads – the material strength of the RfN 7013 Locking Assemblies makes them especially suitable for applications with high radial loads. Axial hub positioning –...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

These Locking Assemblies are of single-taper design with a self-locking taper providing good self-centering action and concentricity, as well as increased torque capacity. A pre-centering hub section is not required. Integral push-off screws for disassembly are provided. This unit can be placed deep inside a bore due to it’s design. Available sizes: Metric series shafts from 20 mm to 150 mm dia. and Inch series for shafts from 1” to 4” diameter. Excellent concentricity and very easy to dismantle – these Locking Assemblies provide particularly good concentricity between the clamped parts. The flange is reinforced at the critical point. This prevents a bending and lifting of the inner ring during installation and therefore a good dismantling is ensured. Higher Rotation Speed – the Locking Assemblies remain true-to-form during assembly and so they are suitable in applications with higher rotational speeds. High radial loads – the material strength of the RfN 7013 Locking Assemblies...

Request for a quote

TAS SCHÄFER GMBH

Germany

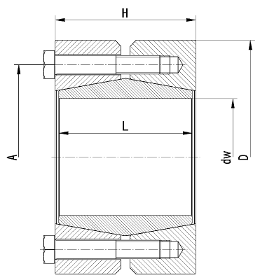

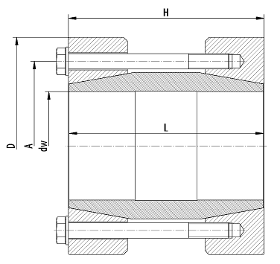

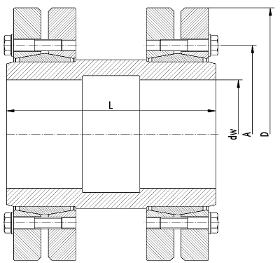

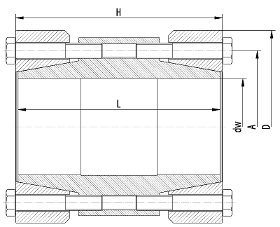

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. The external clamping system does not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean....

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quoteResults for

Clamping parts - Import exportNumber of results

52 ProductsCompany type

Category

- Machine tools - metal machining (15)

- Mechanical engineering - custom work (4)

- Paint mixers and grinding machines (4)

- Disks, magnetic (3)

- Aluminium and aluminium alloys (1)

- Chemicals - Basic Products & Derivatives (1)

- Clamp collars, plastic (1)

- Fasteners, metal (1)

- Foundries - copper, bronze and brass (1)

- Joints, pneumatic (1)

- Laser - cutting and welding machines (1)

- Metals - Machines & Equipment (1)

- Moulds and patterns (1)

- Pipes and tubes, stainless steel (1)

- Pneumatic systems and tools (1)

- Portable electrical pumps (1)

- Stamping - steels and metals (1)

- Welding work - steels and metal (1)

- Welding, soldering and brazing - equipment and supplies (1)