- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamping systems

Results for

Clamping systems - Import export

GSW SCHWABE AG

Germany

Paper Unwinder with a mechanical drag brake and conical clamping system, available in different sizes and versions for all types of coil reels and for all material widths Paper Recoiler, for all types of coil reels and for all material widths, with air motor or with electromotor

Request for a quote

NORELEM FRANCE

France

Flange plate, piston and body rust-resistant, bright. Screws electro zinc-plated. Collet red or clear anodised. Note: Machinable collet system with base plate for mounting on 50mm pitch grid plates. The flange plate can be used for external or internal clamping collets. The contour of the workpiece to be clamped is machined into the collet. Free-form and asymmetrical contours can be clamped. The integrated spring package generates a clamping force of 5.8 kN. The clamping force can be raised to 43.5 kN by pneumatic post-clamping. The clamp is released by blowing compressed air onto the lower piston surface pushing the piston upwards and releasing the clamping force on the collet. Clamping travel 0.2 mm. Repeat accuracy < 0.01 mm. Accessory: Collet for external or internal clamping 03179

Request for a quote

NORELEM FRANCE

France

The easy operability and rapid adjustment using a scale means that the clamping jaws can be quickly and surely adapted to new workpieces The workpiece is always centred through the systematic construction of the 5-axis compact clamping system. The optimal accessibility to the workpiece allows short, standard tooling to be used. Tooling costs are significantly reduced. Positive down force by a clamping depth of >5 mm. Clamping widths of 20 mm to 320 mm are possible. Assembly: The 5-axis clamping system compact can be mounted on T-slot tables, grid systems or, using an adapter flange on conventional zero-point clamping systems. Accessory: Seating ledge 41345 Jaw plates 41320 Pendulum jaws 41325 Centre jaws 41335 Coupling for cross-clamping 41365 Order the seating ledges and jaw plates with pins separately.

Request for a quote

FÖHRENBACH GMBH

Germany

Automatic clamping takes place over disc springs, which are adjustable in the pre-loading and are solved pneumatically to the workpiece change. Manual clamping is made by a knurled knob on the opposite side of the collet. Due to the integration into the existing through-hole of the rotary table, the rotary table with the clamping system remains very compactly. Compact High run-out accuracy Easy to operate Retrofit possible

Request for a quote

BCL INVENT

France

Our EasyGel Protect® coring solutions guarantee you a dusting <to 10f / L. This performance is achieved in compliance with the product instructions, in a regulatory operations and adequate staff training. The solution is suitable for all types of dust harmful or not (Asbestos / Lead / Silica / Dusts,…). SPECIFICATIONS • Transparent core tube with decontaminable accessories and its equipment. BENEFITS • Cheap Solution • Easy to use • Reproducible operating mode • Clean Site • Protection of operators and their environment

Request for a quote

ENIGMA TOGGLE CLAMPS

Turkey

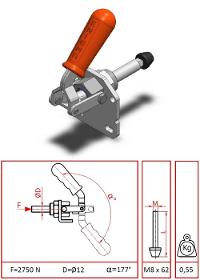

There are three different options for mounting type: horizontal, vertical, and baseless. It is made of Steel Sheet Plate and body. Black is produced upon request. It has a non-reflective feature for measuring laboratories.

Request for a quote

ENIGMA TOGGLE CLAMPS

Turkey

Heavy-duty clamps are extremely robust, handle heavy-duty clamping tasks with ease. Heavy duty to the alloy steel forging structure does not cause problems. For this reason, forged steel clamps are particularly preferred for welding and milling applications and more. Compact design, Hardened and ground surface stepped suspension bolts, hardened and H7 tolerance machined inner diameter bushings, weldable thrust arm, weldable action arm, 146 degree opening action arm to relieve workspace, Mounting base options.

Request for a quote

ENIGMA TOGGLE CLAMPS

Turkey

Made of Steel Forged body. It is produced as a black coating. It has a non-reflective feature for measuring laboratories. It is preferred in heavy work, part clamping and welding fixtures.

Request for a quote

ENIGMA TOGGLE CLAMPS

Turkey

There are four different options for mounting type: horizontal, vertical, butt base and butt vertical. It is made of Steel Sheet Plate. Black is produced upon request. Black models have a non-reflective feature for measuring labs.

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Product features: -Excellent ease of operation guarantees optimal handling for every application -Fast adjustment for clamping range presetting -Reproducible clamping forces are achieved using a torque wrench -Integrated scrapers ensure functional reliability and minimise cleaning -Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base -Optional centre jaw allows two or more workpieces to be clamped Scope of application: -Conventional and CNC-controlled milling machines – for efficient, precision machining -Horizontal installation – great variability and flexibility

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability -Particularly suitable for single-piece production if you wish to make your vice rotatable -Can be removed at any time -Swivel base supporting edge larger than the vice‘s maximum clamping range -Swivels 360° without indexing -Alignment on the machine with T-keys in slots in the swivel base -Clamping slots arranged in the form of a ring for machines with different slot spacings

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Product features: -Excellent ease of operation guarantees optimal handling for every application -Fast adjustment for clamping range presetting -Reproducible clamping forces are achieved using a torque wrench Integrated scrapers ensure functional reliability and minimise cleaning Fixing on the machine table by means of mounting holes in the vice base. Additional holes can be made in the soft middle section of the vice base Optional centre jaw allows two or more workpieces to be clamped Scope of application: -Conventional and CNC-controlled milling machines – for efficient, precision machining -Horizontal installation – great variability and flexibility

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

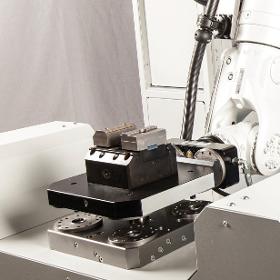

You are short of personnel, but have to process your orders, preferably 24/7? Then the DockLock AC zero-point clamping system for automated fixture change-over, in either the hydraulic or pneumatic version, is perfect for you. The clamping device quick change-over system for stationary applications allows automated change-over of your clamping devices in two minutes. And with repeatability of ≤ 0.005 mm, without alignment. The design of the form fit clamping and power transmission is identical to the DockLock for manual set-up. In addition, it is equipped with a closure at the clamping position as protection against contamination and chips. That ensures even less wear and reduces maintenance expenses. In addition, standard features include an air sensing control, air-blast support isles and a piston position control for a safe and reliable automated process.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Are you tired of losing so much time due to change-over on your machining center? Then we have something for you. The DockLock zero-point clamping system in the hydraulic or pneumatic version. One clamping device quick change-over system for stationary applications. It allows you to change your clamping devices in two minutes. And with repeatability of ≤0.005 mm, without alignment. A special feature: form fit clamping with a collet or clamping segments. That means a rigid clamping set-up and higher repeatability. This also prevents clamping marks on the clamping bolt as opposed to zero-point clamping systems with balls or sliders, which lead to inaccuracies and consequently to replacement of the clamping bolts. Likewise, no contamination and chips can get through, which ensures low-wear operation and reduces maintenance expenses.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TECHNOMARK

France

Graphix Plus is an all-in-one laser marking station equipped with an electrical door (manual control) with an opening of up to 580mm. It has a large loading capacity and can be used to mark small to medium-sized parts. The X-axis is motorised, allowing the head to move vertically, giving a marking zone 475mm long. The marking head with on-board camera allows you to view the rendering and position the marking on-screen, thanks to the Smart View function. There's no need to move the part to ensure that the marking is correctly positioned; it adapts to the part, as everything can be controlled from the screen. Its ergonomic software developed by Technomark is very easy to use. It has a materials database, enabling marking to be done in just a few clicks. The station has a 250x225mm opening on the left-hand side for marking long parts. Its aluminium plate with universal T-slot allows various clamping systems to be fitted, such as a rotating D-axis for marking cylindrical parts.

Request for a quote

SITEMA GMBH & CO KG

Germany

KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electric Locking Unit The electric Locking Unit KFE is used as a stepless locking device on round rods and holds axial forces in both load directions without axial play. It is used where hydraulic or pneumatic solutions are not possible. The holding force is created by the proven spring-operated clamping system as it is used in SITEMA’s hydraulically or pneumatically operated Locking Units. At a drop of the control voltage or in case of failure of the electric supply, the Locking Unit KFE clamps automatically. Therefore, it is also suitable for use in safety relevant applications. To operate the Locking Unit KFE, a supply voltage of 24 V and a control signal for the input command “clamp/release” are sufficient. The Locking Unit is self-monitoring and provides output signals...

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Driven tools form a further core area of EWS. More than 8,000 different tools are available at short notice. In addition to standard products like axial and angular heads, EWS offers swivel units, slot broaching tools, multiform tools and multi-spindle machines. There is just no limit. The tool clamping systems range from the classic collet chuck holder to Weldon and hydro extension to Capto, KM, ABS and HSK. The applications range from classic CNC lathes to highly complex turning milling centers. The rapid change system EWS-Varia has set a standard for a flexible modular system. With its safe handling and short change-over times, EWS-Varia ranks among the most successful systems in the market. This was impressively confirmed by the Innovation Award awarded by the German state of Baden-Württemberg in 2006. "Made in Germany" is of course guaranteed by EWS also for these tool systems.

Request for a quote

IGUS® GMBH

Germany

drylin® W - Advantages Dirt-resistant Weight saving Lubrication-free High speed Silent and light weight drylin® W - Advantages drylin® W - technical properties The technical properties of the drylin® W profile guide system Technical properties drylin® W - configuration Find the right profile guide system in 4 simple steps with the system and life calculation. drylin® W - configuration Single rail and housing bearing - round Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W single rail and housing bearing - round Single rail and housing bearing - angular Sizes: 6 mm, 10 mm, 16 mm and 20 mm DryLin® W single rail and housing bearing - angular double rail, round Sizes: 10 mm (rail width 40 mm, 74 mm and 120 mm), 16 mm (rail width 58 mm), 20 mm (rail width 82 mm) and 25 mm (rail width 120 mm) DryLin® W double rail Guide carriage, assembled Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W guide carriage, assembled double rail, square Sizes: 06 mm (rail width 30 mm), 10 mm (rail width 40 mm and 74 mm) and 16 mm (rail width 58 mm) drylin® W double rail, square Mono-slide guide carriage Size: 10 mm Mono-Slide guide Single rail and housing bearing - round, adjustable Sizes: 10 mm, 16 mm and 20 mm Linear Guides with “Turn-To-Fit” Hybrid bearing WJRM drylin® roller bearings - Roll and glide for easy movement. drylin® W hybrid bearing | roller bearing hybrid bearing double WJRM drylin® double roller bearing - Roll and glide for easy movement. drylin® W hybrid bearing double Double rail, reduced weight Sizes: 6 mm (rail width 30 mm), 10 mm (rail width 40 mm and 80 mm) DryLin® W double rail, reduced weight Hybrid carriage with rollers Size: 10, 16 mm DryLin® W hybrid carriage with rollers Stainless steel guide V4A, individual Size: 20 mm DryLin® W stainless steel guide V4A - individual Stainless steel guide V4A - double DryLin® W stainless steel guide V4A - double drylin® W slider rails/carriages drylin® W rail profiles with 3/8" threads, complete rails with Ø 10 mm through bore, with/without hand clamps DryLin® W double rail, square Gliding elements For round and angular rails. DryLin® W - Gliding elements Manual clamp Developed for simple positioning tasks. DryLin® W - Manual clamp Digital measuring system With immediate digital indication of position. DryLin® W - Digital measuring system Hand clamp for higher forces Designed for positioning tasks with higher forces. DryLin® W hand clamp for higher forces DryLin® WKMEX digital measuring system with external output drylin® WKMEX measuring system with external output DryLin® SLW - the compact* Spindle-lift tables The extremely thin unit is based on a DryLin® W profile system, and its entire length is supported. This design offers an extremely high torsional stiffening simultaneously with compact dimensions. DryLin® SLW - Compact DryLin® ZLW Toothed belt axis For quick positioning of small loads. DryLin® ZLW - Toothed belt axis Single rail and housing bearing - round Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W single rail and housing bearing - round Single rail and housing bearing - angular Sizes: 6 mm, 10 mm, 16 mm and 20 mm DryLin® W single rail and housing bearing - angular double rail, round Sizes: 10 mm (rail width 40 mm, 74 mm and 120 mm), 16 mm (rail width 58 mm), 20 mm (rail width 82 mm) and 25 mm (rail width 120 mm) DryLin® W double rail Guide carriage, assembled Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W guide carriage, assembled double rail, square Sizes: 06 mm (rail width 30 mm), 10 mm (rail width 40 mm and 74 mm) and 16 mm (rail width 58 mm) drylin® W double rail, square Mono-slide guide carriage Size: 10 mm Mono-Slide guide Single rail and housing bearing - round, adjustable Sizes: 10 mm, 16 mm and 20 mm Linear Guides with “Turn-To-Fit” Hybrid bearing WJRM drylin® roller bearings - Roll and glide for easy movement. drylin® W hybrid bearing | roller bearing hybrid bearing double WJRM drylin® double roller bearing - Roll and glide for easy movement. drylin® W hybrid bearing double Double rail, reduced weight Sizes: 6 mm (rail width 30 mm), 10 mm (rail width 40 mm and 80 mm) DryLin® W double rail, reduced weight Hybrid carriage with rollers Size: 10, 16 mm DryLin® W hybrid carriage with rollers Stainless steel guide V4A, individual Size: 20 mm DryLin® W stainless steel guide V4A - individual Stainless steel guide V4A - double DryLin® W stainless steel guide V4A - double drylin® W slider rails/carriages drylin® W rail profiles with 3/8" threads, complete rails with Ø 10 mm through bore, with/without hand clamps DryLin® W double rail, square Gliding elements For round and angular rails. DryLin® W - Gliding elements Manual clamp Developed for simple positioning tasks. DryLin® W - Manual clamp Digital measuring system With immediate digital indication of position. DryLin® W - Digital measuring system Hand clamp for higher forces Designed for positioning tasks with higher forces. DryLin® W hand clamp for higher forces DryLin® WKMEX digital measuring system with external output drylin® WKMEX measuring system with external output DryLin® SLW - the compact* Spindle-lift tables The extremely thin unit is based on a DryLin® W profile system, and its entire length is supported. This design offers an extremely high torsional stiffening simultaneously with compact dimensions. DryLin® SLW - Compact DryLin® ZLW Toothed belt axis For quick positioning of small loads. DryLin® ZLW - Toothed belt axis drylin® W - Advantages Dirt-resistant Weight saving Lubrication-free High speed Silent and light weight drylin® W - Advantages drylin® W - technical properties The technical properties of the drylin® W profile guide system Technical properties drylin® W - configuration Find the right profile guide system in 4 simple steps with the system and life calculation. drylin® W - configuration

Request for a quote

ZIMMER GMBH KUNSTSTOFFTECHNIK

Germany

SHORTENED CHANGEOVER PROCESS In modern production processes, factors such as efficiency and flexibility play an increasingly important role. For injection moulding companies, this demand for flexibility means there is a constant challenge posed by increasingly smaller lot sizes, the desire to achieve lower inventories and just-in-time deliveries.

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

Bolt clamp with rubber inlay

Request for a quote

NORELEM FRANCE

France

Locating cylinder tempered, black oxidised. Balls hardened, bright. Note: Locating cylinder with quick-clamp system for extra timesaving during setups. Insert the locating cylinder into the receiving hole and press the button. The three balls are pushed out and position the components. By tightening the set screw a 1/4 turn using an hexagonal key, the components are positively and securely held.

Request for a quote

NORELEM FRANCE

France

The 5-axis vice features excellent stability and flexibility, and is extremely easy to use. The 5-axis vice can be used as a positive-down force vice or normal vice. When the positive down force function is used, the workpiece can be held with a repeat accuracy of ±0.01 mm. A workpiece clamping height of 180 mm enables easy access during machining. The clamping width is preset using the crank handle, cutting down on setup times. Additionally, the closed geometries and the resistance to dirt that they provide keep maintenance and repair times to a minimum.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Besides its own systems Freek also manufactures original Rosemount-systems that can also be used as "Husky-replacement heater" (see spare part cross-reference list). For example the two screw clamp band (FB) and the axial clamp band (FE). Both systems can be supplied with MicroCoils in "Rosemount style" (Ø 1,4 mm) as well as MicroCoils in "Freek style" (1,3 x 2,3 mm).

Request for a quote

NORELEM FRANCE

France

The screw is tightened or the clamping lever is turned to expand the two wedges in the hole. The infinitely adjustable shaft collar enables one or more stop elements with various thicknesses to be securely fixated. Application: These clamping pins are perfect for fixing standard stop elements with various thicknesses to hole grid boards / welding tables with hole Ø 16 mm or 28 mm. Advantages: Infinitely adjustable clamping range of 0-36 mm and 0-75 mm. Not affected by the diameter or surface quality of the bore (up to H12). Clamping range can be easily preset using the scale. Gentle clamping in the bore. Pull-down effect even with thin table material (≥8 mm or ≥4 mm). Compatible with conventional stop elements.

Request for a quote

FÖHRENBACH GMBH

Germany

The directly driven dividing apparatus of the TA3 series are excellent suited for the exact positioning of workpieces or, due to the high speeds, also for round machining of workpieces. The direct drive is absolutely backlash-free and ensures highest dynamics. All dividing apparatus are equipped with an automatic, pneumatically actuated clamping system. The dividing apparatus TA3G180 can be optionally equipped with an automatic hydrodehn clamping system (hydraulic expansion technology). Field of applications Rotation axis for angle positioning of work piece carriers in: Processing centers CNC - grinding machines Tool machines Laser processing machines, etc.

Request for a quote

NORELEM FRANCE

France

It is recommended that the cam lever is in a vertical position when the collet is positioned in the bore. The function of the clamping system was tested in bores with tolerance H7. All values for retaining force are guide values and are given without safety factor. The suitability for the respective application must be checked by the user. Advantages: Two components can be joined together without tools. The components are perfectly centred in the clamped state. The compact design means that the mandrel collet with cam lever can even be used in blind holes. There are no specific dimensional requirements for the holes. Additionally, the surfaces and design do not need to have any specific properties. Functional principle: The clamping system is inserted in the hole in the open state. At the beginning of the locking process, the mandrel collet expands and clamps itself in the lower component. The integrated disc spring assembly creates a positive down force

Request for a quoteResults for

Clamping systems - Import exportNumber of results

143 ProductsCountries

Company type

Category

- Machine tools - metal machining (18)

- Clamp collars, plastic (10)

- Machine tools, metal machining - parts and accessories (10)

- Fasteners, metal (4)

- Sawing machine tools (4)

- Chemical and pharmaceutical industry - machinery and equipment (2)

- Conveyor belts (2)

- Cutting - machine tools (2)

- Disks, magnetic (2)

- Electroheat - machines and equipment (2)

- Laser - cutting and welding machines (2)

- Marking machines (2)

- Transport, indoor - rolling equipment (2)

- Vacuum cleaners - industrial (2)

- Automation - systems and equipment (1)

- Bearings, ball (1)

- Bedroom furniture (1)

- Buckets and grabs, crane (1)

- Components and parts for small household appliances (1)

- Cutting - steels and metals (1)