- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drying equipment

Results for

Drying equipment - Import export

RULOMATIK

Turkey

It is a vending machine that give microfiber car drying towels and is equipped with high-tech features such as a continuous operation system. The addition of high-tech features has made the vending machine more reliable and easy to use. Rulomatik car drying towel vending machine is used in a variety of settings such as car washes, gas stations and other places where people may need to dry their cars quickly and conveniently. The 24/7 operation of the Rulomatik vending machine makes it more convenient for customers to get towels when they need them. The use of reflective material on the outside of the advertising space makes the vending machine more visible and easy to find, even in low light conditions.

Request for a quote

BÜRKLE GMBH

Germany

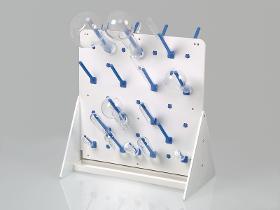

The draining rack is easy and flexible to set down on a table or working surface. Two large supports with wide bases ensure sufficient stability. Since both sides of the draining board can be used, it provides twice the hanging space. The collecting pan can simply be removed for emptying. The stable rods are individually placed into the holes of the draining rack and are clicked into place. Their positions can be changed at any time. Using a combination of rods of three different lengths (60 mm, 100 mm and extension to 150 mm), the draining rack can be adapted to any apparatus which is to be dried.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of highly stressed and relatively slowly running gears where due to leakage a grease must be used instead of oil For drives under high and shock load Chain lubrication of e.g. hollow pins, chains in the conveyor and transport field, under the influence of water and vapour and at higher operation temperatures Bearing lubrication of roller and plain bearings at annealing furnaces and drying equipments, manipulators and robots, conveyor and cooling systems, machines of preserve industry, steam sterilizers, etc. Advantages and benefits Best use in corrosive operation conditions with high operation temperatures and high pressure and shock load Economically due to optimum formulation Reduces wear and thereby downtime and enables long-term lubrication Ropy, strongly adhesive, temperature and water resistant, noise dampening, high-load and shock absorbing

Request for a quote

SICHUAN ODOT AUTOMATION

China

CT-623F: 8-channel digital input /24VDC/ source or sink type & 8-channel digital output /24VDC/ source type Module features The module supports 8-channel digital input, and supports source type and sink type two-way input. The input voltage is 0V/24VDC. The module supports 8-channel digital output, Output high level valid, and the output voltage is 24VDC. Module input channel can collect digital output signal of field equipment. (dry contact or active output) The module input channel can be connected to the 2-wire or 3-wire digital sensor. Module input channel supports 32-bit counter for each channel, the counting frequency < 200Hz. The input channel of the module supports the signal maintenance function, and the maintenance time can be set. The input channel of the module can set the digital signal input filtering time and the byte transfer order of the counter. The input channel of the module can set the counting mode and counting direction independently.

Request for a quote

SICHUAN ODOT AUTOMATION

China

CT-122F 16 channels digital input/0VDC/Source type/Input 0V, the input low level is valid Module features the Module supports 16 channels digital input, supports source input, the input voltage is 0V and the input low level is valid. the module could collect the digital output signal of field equipment (dry contact or active output). the module can be connected to a 2-wire or 3-wire digital sensor. the internal bus of the module and field input are isolated by optocoupler. the module supports input signal holding function, holding time can be set. the module carries with 16 digital input channel LED indicator. after adding counting submodule, the counting function is effective. each input channel of the module supports 32-bit counter with counting frequency <200Hz. the module could set the digital signal input filter time and counter byte transmission sequence.

Request for a quote

SICHUAN ODOT AUTOMATION

China

CT-121F:16 channel digital input/24VDC/ Sink type/The input high level is valid Module features the module supports 16 channels digital input, supports sink input, and input voltage is 24VDC. the module can collect digital output signal of field equipment (dry contact or active output). the module can be accessed to 2-wire or 3-wire digital sensor. the internal bus and field input of the module use opto-isolator. the module supports the input signal holding function, and the holding time can be set. the module carries 16 digigtal input channels with LED indicator on each channel. supports counting function, by adding counting sub-module. each input channel of the module supports a 32-bit counter with the counting frequency <200Hz. the module can set the digital signal input filtering time and the byte transmission order of the counter. each channel of the module can set the counting mode and counting direction independently.

Request for a quote

ASTRA LT AB

Lithuania

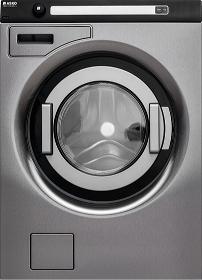

Astra represents the largest manufacturers of industrial laundry equipment in the Baltic States, such as: Primus, Alliance Laundry Systems UniMac, Union, Sidi. We can offer a wide range of industrial laundry equipment: washing, drying, ironing, dry cleaning machines. We will help you meet your needs and provide the best technical service.

Request for a quote

FRIGORTEC GMBH

Germany

The POWDRYER™ PD08 metal powder dryer is used to dry inorganic metal powder for the complex additive manufacturing (3D printing) process. It corrects the manufacturer’s fluctuating metal powder qualities, thus optimizing the metal powder’s flowability. It also reduces the number of air inclusions in finished workpieces. Significantly higher material densities are the result. Fields of application > Particularly for metal printing products where maximum strength is required > For the printing of alloys of aluminium, titanium, tool steel, etc. > Special tools for the metal-processing industry, machine and system engineering, prototype development, and more > Aviation, aerospace, and automotive industries, plus medical and dental technology

Request for a quote

TEMIS ITALY

Italy

Thirty years of expertise in Dry Ice blasting and production, with cooperation at university level and applications in a wide range of business areas: we put all of this at your service. Extend the lifespan of tire molds with non-abrasive blasting methods to preserve the external appearance of new or retreaded tires – curing after curing. Ultra-sonic nozzles are custom engineered for complex patterns, including spring vent inserts. Blast away vulcanized rubber using 100% pneumatic or electropneumatic Dry Ice blasting units, manual or robot-operated. Produce Dry Ice blocks, pellets, micropellets, flakes or dust; store and transport them; protect your workers: we can offer you everything you need for Dry Ice. Dry ice blaster Dry ice accessories Dry ice accessories Dry ice pelletizers (micro pellets); Dry ice pallets storage boxes; Ultrasonic dry ice blasting nozzles (custom design and development); Standard dry ice blasting nozzles (bi-tube)

Request for a quote

VICTORY LIGHTING (UK) LTD.

United Kingdom

Victory Lighting mobile infrared paint curing systems offer one of the most cost-effective answers to automotive paint drying presently available. All dryers incorporate the latest technology in short-wave quartz lamps, allowing quick, economical and convenient drying of primers, sealers, top coats, clear lacquers and all water based products. There are several models available, from hand-held units up to a fully automatic temperature feed back large paint dryer covering an area of 2 x 1 metres.

Request for a quote

DC PRODUCTS

United Kingdom

Maximum spin speed: 1400rpm Finish: Light grey 28 programmes including three custom programmes Anti-leakage system and child lock ECO cold and hot water connection – saves up to 70% of electrical consumption and 20% of the programme time Connection: 400V / 3ph / 16A / 50Hz / Max effect: 4.6kW Can be reconfigured to: 230V / 1ph / 13A / 50Hz / Max effect: 2.4kW Available with pump or valve drain system

Request for a quote

DC PRODUCTS

United Kingdom

Finish: Light grey Seven auto programmes; four timed programmes Sensor-controlled auto programmes stop drying when clothes are dry Dryer can be mounted on washing machine LCD display and interface on local language (13 languages) Reversible door (right/left) Manual or automatic drainage of condensation water – drain hose included Stacking brackets for column installation included Connection: 230V / 1ph / 13A / 50Hz / Max effect: 2.8kW Can be reconfigured to: 230V / 1ph / 10A / 50Hz / Max effect: 2.25kW Condenser dryer

Request for a quote

DC PRODUCTS

United Kingdom

Maximum spin speed: 1400rpm Finish: Touch Proof™ Stainless steel 28 programmes including three custom programmes Relay card for auto dosing with three signals Anti-leakage system and child lock ECO cold and hot water connection – saves up to 70% of electrical consumption and 20% of the programme time Connection: 230V / 1ph / 16A / 50Hz / Max effect: 3.2kW Can be reconfigured to: 230V / 1ph / 10A / 50Hz / Max effect: 2.2kW or 400V / 3ph / 10A / 50Hz / Max effect: 3.2kW Available with pump or valve drain system

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

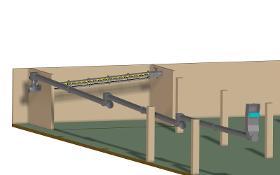

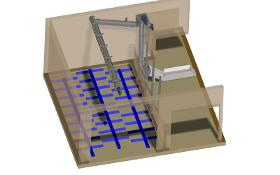

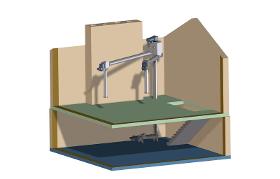

Standard advantages: RTS-Rotation – low-maintenance dry spray booth Overspray dry separation demonstrates its strengths in practice above all when relatively large quantities of paint have to be processed and the overspray portion cannot be reduced any further. Spray booth with dry separation are usually equipped with disposable filters or manually regenerative filters. These cause costs for spare filters, maintenance and disposal. In addition to that, operation has to be interrupted in order to exchange the filters. The ‘RTS rotation’ system was developed by Rippert in order to reduce these costs and tooling times. Maintenance intervals and filter service lives are prolonged significantly in comparison with conventional systems due to the new brush pre-filtration. How the ‘RTS-Rotation’ system works Overspray separation in the RTS-Rotation system takes place by means of a pre-filter and a fine filter stage. The pre-filter stage is formed by vertical, slowly rotating brush rollers. The bristles present a very large total surface area and absorb the adhesive particles from the overspray. During the slow rotation, the paint particles can dry on the tips of the bristles. This results in slowly growing cakings on the bristles. Scrapers are mounted in the area behind the brush rollers that continuously remove these cakings from the bristles. The dislodged, hardened material falls into the drawers arranged under the brushes and can thus be simply disposed of. The dry paint dust may often be disposed of as ‘commercial waste’. The brushes otherwise require little maintenance and do not need to be exchanged or renewed. The fine filter stage is formed by a special fleece filter, which is arranged above the brush rollers and must be manually maintained or exchanged in the standard version. The maintenance intervals depend on the paint material used. Automatic cleaning or an external fine filter with automatic cleaning is also possible as an option. Over 10 years of operational experience shows that around 75 to 95% of the overspray is separated out by the pre-filter stage and the rest by the fine filter stage. The degree of separation depends strongly on the type of paint and the drying reactivity during the flying phase. Use of the RTS-Rotation with the following paints Before practical use, the paints are tested and approved in Rippert’s own pilot plant. Stove enamels and 100% UV paint systems cannot be used. The horizontal version Furthermore, it is possible to use the system as a horizontal underfloor extraction system. This version is used, for example, by a machine manufacturer for large parts. In addition, a drag conveyor with gulley extraction is used there in order to automatically transport the particles cleaned off the brushes out of the pit. Conclusion The RTS-Rotation system is particularly useful when relatively large quantities of paint with an unavoidable overspray portion have to be processed, as otherwise a great deal of residual waste would result using conventional technology. Compared to water-sprinkled spray walls and normal dry spray booths the amortisation period is shorter; it is frequently less than two years.

Request for a quote

TURKEYRAF

Turkey

Maximizes heat transfer with D Form aluminum pipe winding, provides extraordinary performance with 71mm insulation thickness. Dust-proof condenser does not require maintenance, it is long-lasting thanks to its aluminum frame and electrostatic powder painted and galvanized coated inner and outer body. Apple Series with its negative (Static), positive (dynamic) or dual regime options and large volume, provides minimum energy consumption. Apple is suitable for installation types such as singular, block and land, and allows you to create different layouts in the Market.

Request for a quote

SERVOLIFT GMBH

Germany

The SERVOLIFT drying station completes the cleaning steps in the SERVOLIFT semi-automatic wash station. The still-damp containers are placed in the drying station, which is placed in a separate drying area. The work is done nearby in the same room. The system can be used as a compact unit separated in an equipment area. The drying station takes up very little space. The complete system ensures a successful drying process in the shortest time with very low energy use. Fast and efficient Technical description Drying using air circulation with approximately 60% fresh air input Heat exchanger, electric, approx. 9KW Drying temperature up to 80° C Control - microcontroller with digital display Adapter for drums Vertical or horizontal construction

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

The COMPACT swift dryers are designed with flexibility in mind. They offer an integrated solution, combining the drying and conveying of the raw material in one unit. The dryers are available in two versions and are each equipped with one drying bin of the size 80 or 150 litres and up to 2 hopper loaders with a capacity of 4 litres each. The COMPACT swift A dryer is provided with advanced functions such as dew point control and dry air conveying function with line purging. Thanks to a modern 7-inch colour display with touch screen, all conveying and drying functions can be shown and monitored in a user-friendly way. 16 user languages can easily be selected.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

This method allows extremely fast workpiece cooling. When it is necessary to pack or stack workpieces immediately, VEN DRY COOL modules can be installed in all Venjakob drying equipment at any time. Perfect surface results are guaranteed by the drying technique of these individual machine line solutions.

Request for a quote

STEINER GMBH & CO. KG

Germany

The planning and development of our systems are always made according to customer requirements. Whether in combination with container, drying equipment, conveyors, pellet production, saw mills, particle board / furniture industry or in other areas of application. Conveying vertical Low rotational speeds Standard execution Low noise Planning according to the customer

Request for a quote

STEINER GMBH & CO. KG

Germany

The planning and development of our systems are always made according to customer requirements. Whether in combination with container, drying equipment, conveyors, pellet production, saw mills, particle board / furniture industry or in other areas of application. Conveying vertical Low rotational speeds Standard execution Low noise Planning according to the customer

Request for a quote

STEINER GMBH & CO. KG

Germany

The planning and development of our systems are always made according to customer requirements. Whether in combination with container, drying equipment, conveyors, pellet production, saw mills, particle board / furniture industry or in other areas of application. Conveying vertical Low rotational speeds Standard execution Low noise Planning according to the customer

Request for a quote

STEINER GMBH & CO. KG

Germany

The planning and development of our systems are always made according to customer requirements. Whether in combination with container, drying equipment, conveyors, pellet production, saw mills, particle board / furniture industry or in other areas of application. Conveying vertical Low rotational speeds Standard execution Low noise Planning according to the customer

Request for a quote

STEINER GMBH & CO. KG

Germany

The planning and development of our systems are always made according to customer requirements. Whether in combination with container, drying equipment, conveyors, pellet production, saw mills, particle board / furniture industry or in other areas of application. Conveying vertical Low rotational speeds Standard execution Low noise Planning according to the customer

Request for a quoteResults for

Drying equipment - Import exportNumber of results

52 ProductsCountries

Company type

Category

- Laundry and dry cleaning machinery and equipment (16)

- Infrared tubes (6)

- Freeze drying - machinery and equipment (3)

- Networks - installation and maintenance (3)

- Plastics - machines and material for industry (2)

- Tumble dryers and spin dryers, industrial (1)

- Bakery and confectionery industry - machinery and equipment (1)

- Carwash systems (1)

- Dry-cleaning machines (1)

- ELECTRIC EQUIPMENT (1)

- Food Industry - Machines & Equipment (1)

- Gasification - bioenergy systems (1)

- Heat exchangers (1)

- Home automation (1)

- Industrial washing facilities (1)

- Laboratory equipment and instruments (1)

- Mining and quarrying - machinery and equipment (1)

- Moulding, rubber - machinery (1)

- Planing lathes, automatic (1)

- Plastic packaging (1)