- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- oil separator

Results for

Oil separator - Import export

ERDEM REFRIGERATION

Turkey

The main task of helical oil separators is to separate the high volume of oil coming from the discharge of compressor and return it in the most effective and efficient way. It is to increase the efficiency of the system by minimizing the excess oil rate that may occur. Helical oil separators are also suitable for multiple systems. Using the flator system to ensure high performance by closing the oil return line when there is not enough oil volume in the oil seperator. By having the flange type connection model, it can be cleaned during the system maintenance. Using special materials (stainless steel and brass), flawless and long life-span design. PROPERTIES: It has a working pressure of 45, Flator system providing high performance, Compatibilty with Group I (Ashrae 34 A2L, A2) and Group II (Ashrae 34 A1) refrigerants

Request for a quote

ERDEM REFRIGERATION

Turkey

ESSOSC130 Series Oil Seperators has Coalescent Filter providing highest performance and efficiency of seperation. ESSOSC130 series is the best solution for the high capacity systems. ESSOSC130 Series Oil Seperators are designed with Solder type connections as a standart. The oil return connection is SAE 1/4″. PROPERTIES: Having special design, long life-span without any problems, 130 bars working pressure – Compatibility with R744 refrigerant

Request for a quote

ERDEM REFRIGERATION

Turkey

The main task of helical oil separators is to separate the high volume of oil coming from the discharge of compressor and return it in the most effective and efficient way. It is to increase the efficiency of the system by minimizing the excess oil rate that may occur. Helical oil separators are also suitable for multiple systems. Using the flator system to ensure high performance by closing the oil return line when there is not enough oil volume in the oil seperator. Using special materials (stainless steel and brass), flawless and long life-span design. PROPERTIES: It has a working pressure of 45, Flator system providing high performance, Compatibilty with Group I (Ashrae 34 A2L, A2) and Group II (Ashrae 34 A1) refrigerants

Request for a quote

ERDEM REFRIGERATION

Turkey

ESSOSFF Series Oil Seperators are designed to seperate the mixture of the oil and refrigerant which caused by the compressors’ discharge. By the return of the discharged oil to the compressor, the life-span of the compressor and system is extended. Using the flator system to ensure high performance by closing the oil return line when there is not enough oil volume in the oil seperator. By having the flange type connection model, it can be cleaned during the system maintenance. Using special materials (stainless steel and brass), flawless and long life-span design. ESSOSFF Series Oil Seperators are designed with Solder type connections as a standart. The oil return connection is SAE 1/4″. PROPERTIES: Having special design, long life-span without any problems, Flator system providing high performance, Compatibilty with Group I (Ashrae 34 A2L, A2) and Group II (Ashrae 34 A1) refrigerants

Request for a quote

ERDEM REFRIGERATION

Turkey

ESSOSF Series Oil Seperators are designed to seperate the mixture of the oil and refrigerant which caused by the compressors’ discharge. By the return of the discharged oil to the compressor, the life-span of the compressor and system is extended. Using the flator system to ensure high performance by closing the oil return line when there is not enough oil volume in the oil seperator. Using special materials (stainless steel and brass), flawless and long life-span design. ESSOSF Series Oil Seperators are designed with Solder type connections as a standart. The oil return connection is SAE 1/4″. PROPERTIES: Having special design, long life-span without any problems, Flator system providing high performance, Compatibilty with Group I (Ashrae 34 A2L, A2) and Group II (Ashrae 34 A1) refrigerants

Request for a quote

ERDEM REFRIGERATION

Turkey

ESSOSC Series Oil Seperators has Coalescent Filter providing highest performance and efficiency of seperation. ESSOSC series is the best solution for the high capacity systems. ESSOSC Series Oil Seperators are designed with Solder type connections as a standart. The oil return connection is SAE 1/4″. PROPERTIES: Having special design, long life-span without any problems, – Compatibilty with Group I (Ashrae 34 A2L, A2) and Group II (Ashrae 34 A1) refrigerants

Request for a quote

ERDEMLER COOLING COMPANY

Turkey

The central screwed devices are compatible with high capacity installations and are produced by connecting 2 to 5 compressors in parallel. Separately economizers are used for each compressor. Oil control is carried out in screw type devices. Electrostatic paint is applied on a galvanized sheet according to device size from 2 mm thickness to 4 mm thickness. Electrical panel and all automatic control elements are shipped as ready for assembly. It is manufactured in accordance with European Union norms and CE certificate. It is manufactured in accordance with hot gas or electric defrosting device. Easy installation and maintenance opportunity. European equipment. Energy consumption at minimum level. Perfectly compatible with market and supermarket applications. Oil separator.

Request for a quote

BEKO TECHNOLOGIES GMBH

Germany

A more economic solution for an environmentally sound condensate management is the decentralised oil-water separation directly at the source. Condensate which was processed with ÖWAMAT can be directly introduced as cleaned water into the sewerage system. The devices have a national technical approval and do not require a permit according to the law on water. In addition, the ÖWAMAT oil-water separators do not create any energy costs, boast enormous filter service lives and can be retrofitted into older systems without difficulty.

Request for a quote

SAMSYS GMBH

Germany

The PFOS oil separator as an alternative to oil skimmer The Profluid oil separator clean the cooling water of cutting machines in approx. 2 hours. Due to their well thought-out design they are very easy to operate and maintain. The oil separator separates oil and cooling water by means of a porous filter. This porous filter has an effective resolution and works without clogging. By the difference of the specific weight the oil drives the surface. The result is an easy separation and removal of the oil. Regular cleaning and separation of oil and emulsion prevents health problems for your employees. Another positive aspect is the increase in the service life of the cooling water. Cooling channels can become clogged due to contamination of the cooling water. This can be prevented by cleaning the cooling water. Excessive wear of machine parts and corrosion on workpieces can also be the result of contaminated cooling water.

Request for a quote

SAMSYS GMBH

Germany

Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%. Health hazards Oil mist and emulsion mist

Request for a quote

SAMSYS GMBH

Germany

Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%. Health hazards Oil mist and emulsion mist

Request for a quote

SAMSYS GMBH

Germany

Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%. Health hazards Oil mist and emulsion mist

Request for a quote

SAMSYS GMBH

Germany

Oil mist separator – extraction systems for vapours Oil mist separators are a must in order to ensure the extraction of oil mist from machine tools. With AOF filters we offer a whole series of extraction systems for effective extraction and filtration. The separator can filter emulsion mist, oil mist, smoke and odours. Oil mist filters can be installed on almost all turning machines– and milling machines and BAZ. In this way you can offer a healthy working environment for you and your employees. Heat and odours are effectively filtered and the emulsion separated from the exhaust air can be reused. The filters of the oil mist separators are equipped with multi-stage filtration. The elements are cleanable and reusable. Harmful emissions, dust and aerosols are removed from the air at almost 100%.

Request for a quote

MIKROPOR

Turkey

The revolutionary Mikropor "3S" Separator is designed to fit the smaller separator housings without sacrificing operating performance. The "3S" separator has double to tripled capacity when compared to a conventional separator with the same dimensions. The "3S" separator has 1/2 - 1/3 of the volume of a conventional separator functioning in the same operating conditions. This increased capacity is achieved with specially designed progressive type, deep bed, coalescing media using an increased number of wraps.

Request for a quote

ROTORSTECH

Slovakia

Plants of these types are intended: - for the separation of liquid mixtures, which consist of two liquids, with the simultaneous removal of solid particles contained in liquids - to remove solid particles from a liquid (clarification) - for purification of mineral oils having a viscosity at a temperature of 50°C not more than 65 mm2/s - for use in power plants, substations, other energy facilities and at enterprises involved in the regeneration of technical oils

Request for a quote

ERDEM REFRIGERATION

Turkey

ESSOS Series Oil Seperators are designed to seperate the mixture of the oil and refrigerant which caused by the compressors’ discharge. By the return of the discharged oil to the compressor, the life-span of the compressor and system is extended. Application of special design in ESSOS Series Oil Seperators, seperation efficiency of oil is higher. Using special filters and regulator, the ESSOS has high performance. ESSOS1 and ESSOS2 Series Oil Seperators are designed with O-Ring Flare type connections as a standart. The oil return connection is SAE 1/4″. ESSOS1R and ESSOS2R Series Oil Seperators are designed with Flare type connections as a standart. The oil return connection is SAE 1/4″. ESSOS1S and ESSOS2S Series Oil Seperators are designed with Solder type connections as a standart. The oil return connection is SAE 1/4″. PROPERTIES: Having special design, long life-span without any problems, Compatibilty with Group I (Ashrae 34 A2L, A2) and Group II (Ashrae 34 A1) refrigerants

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Greater efficiency high performance separation media Our oil separation media feature a unique bonded fiber technology that can perform the function of multiple layers of traditional filter media, efficiently separating oil mist from the air stream. Our bonded fiber can also separate water from diesel and other fuels. With its gradient density structure, our reliable, efficient media can replace several layers of traditional media used in water separation. Specifically designed to reduce vehicle emissions and to improve performance, our powertrain filters come in two different types of solutions that can be provided in both custom and standard options: Our unique bonded fiber structure can efficiently separate over 95% of oil mist from oil reservoir fumes. Efficiently removes water from fuel streams that can cause issues with injectors and engines Increase efficiency, as POREX ® media can perform the function of multiple layers of traditional separation filter media request...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POREX TECHNOLOGIES GMBH

Germany

Greater efficiency high performance separation media Our oil separation media feature a unique bonded fiber technology that can perform the function of multiple layers of traditional filter media, efficiently separating oil mist from the air stream. Our bonded fiber can also separate water from diesel and other fuels. With its gradient density structure, our reliable, efficient media can replace several layers of traditional media used in water separation. Specifically designed to reduce vehicle emissions and to improve performance, our powertrain filters come in two different types of solutions that can be provided in both custom and standard options: Our unique bonded fiber structure can efficiently separate over 95% of oil mist from oil reservoir fumes. Efficiently removes water from fuel streams that can cause issues with injectors and engines Increase efficiency, as POREX ® media can perform the function of multiple layers of traditional separation filter media request...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Greater efficiency high performance separation media Our oil separation media feature a unique bonded fiber technology that can perform the function of multiple layers of traditional filter media, efficiently separating oil mist from the air stream. Our bonded fiber can also separate water from diesel and other fuels. With its gradient density structure, our reliable, efficient media can replace several layers of traditional media used in water separation. Specifically designed to reduce vehicle emissions and to improve performance, our powertrain filters come in two different types of solutions that can be provided in both custom and standard options: Our unique bonded fiber structure can efficiently separate over 95% of oil mist from oil reservoir fumes. Efficiently removes water from fuel streams that can cause issues with injectors and engines Increase efficiency, as POREX ® media can perform the function of multiple layers of traditional separation filter media request...

Request for a quote

FLOTTWEG SE

Germany

The Flottweg AC1700 separator – the newest member of the Flottweg family Separators are used to separate the finest solid particles from liquids. Separators are available from Flottweg for a wide range of applications, from the production of beverages to the production of vegetable oil. Our separators are subject to different requirements depending on the application and size of the respective plant. To be able to offer our customers more options and the optimum solution, we have expanded our separator portfolio with a new machine size: the Flottweg AC1700 separator. The Flottweg AC1700 separator fits between our popular AC1500 and AC2000 series and completes our product portfolio for the food and beverage industry. With over 70,000 m² / 753,474 ft² of clarification area and an acceleration of 11,000 g, the compact separator ensures an optimally clarified final product with a high throughput.

Request for a quote

FLOTTWEG SE

Germany

Flottweg Sedicanter separates solids from liquids. Its special feature: the solids consist of a sediment with properties ranging between soft and fluid. Typical applications of the Sedicanter are "soft products": ► Biomass, yeast and protein suspensions. ► Fermentation broths and UF retentate ► CIP cleaning liquids and coarse matter-free live sludge ► Fruit juice byproducts and plant-derived raw materials ► Soap separation from oil refining processes The special technical features of the Flottweg Sedicanter: ► Separation of extremely difficult-to-sediment solids by acceleration up to 10,000 gee. ► Hygienic design, thus usable for applications in biotechnology ► Flexibility with fluctuating composition of the feed product by the adjustable impeller ► Gas-tight operation is possible by sealing the separation space off from the ambient air using inert gas

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Separate water easily from your oil and gas streams From bonded fiber to sintered porous media, Porex creates media to separate or filter water from oil and gas streams. Specifically designed for your oil and gas application, our water separation media: Reduce material usage - Porex bonded fiber material products can replace the need for multiple medi layers commonly found in oil/water separation filters. Self support - Filters can be self-supporting and customized into various shapes and sizes. request sample ask an engineer

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

Cora®Oil is an oleophilic polyster fleece and a unique technical innovation! Cora®Oil is a high quality thermally bonded polyester nonwoven and capable of separating oil and water. This allows oils to be completely filtered out of water. Another advantage: Cora®Oil can be used in all common band filters.

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The CCX is the most advanced, sophisticated and versatile laboratory corrosion testing cabinet. With installed options, it can replicate up to 15 environmental conditions, placing powerful capability in the hands of the user. Advanced cyclic tests are used to qualify a specific coating or material for a wide range of end uses, to quickly qualify a coating or material on a pass-fail basis, to predict service life or determine the probability of corrosion of a specific material. Applications include: Aerospace, Automotive, Research, Electronics, Government, Military, Paints/Coatings, Robotics, and Telecommunications. Reinforced fiberglas cabinet - Exposure zone lined with gel coat Solution reservoir - 60 gallon (227 l) Exposure zone heated by titanium rod heater Polypropylene cover with water seal - CCX9000 only Peaked cover prevents dripping of condensation onto samples Clear cover with dual magnetic Santoprene gaskets Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 160 °F (71 °C) - high temperature option up to 194 °F (90 °C) Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) CCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 2.4 x 0.9 x 1.4 m CCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 3 x 0.9 x 1.4 m CCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 3 x 1.1 x 1.4 m CCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 3.05 x 1.3 x 2.16 m CCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 3.12 x 2.59 x 2.13 m Standard Controls Features Programmable Logic Controller with Operator Interface Panel Five Pre-loaded Test Methods for Immediate Operation Storage of up to 15 Test Profiles with up to 18 Steps Pressure Gauge for Bubble Tower Premium Controls Features Notebook Computer with Color Screen, PC-compatible Seven Pre-loaded Test Methods for Immediate Operation Display of up to 50 Test Profiles with up to 100 Steps Display Graphing on Notebook Monitor Operator Interface/Datalogging Software Pressure Transducer for Bubble Tower Solution Reservoir Fill with Automatic Shut-off SO2 Injection System High voltage kit High capacity oil: water separator External condensate collection system(to check collection rate of fog with cover closed) Air actuated cover, automatic ambient Solution spray (direct impingement) Power exhaust kit Water fog, automatic Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Cabinet options choices: Standard controls. Two pen circular chart recorder with digital display (wet bulb and dry bulb), recorder/6 channel strip chart (4 temperatures, air pressure), modem for remote trouble shooting / Premium controls Controlled, Adjustable RH with direct RH Sensor; required for SAE J2334 Color Touchscreen Upgrade Data Recording PC Software; output to customer's computer- DB/WB/BT temps Immersion Option, Automated - CCX2000/3000/4000; recommended for SAE J2334 Immersion Option, Automated - CCX9000; recommended for SAE J2334- 1250 Immersion Set-up Kit; required for future addition of Immersion Option LN2 Freezing/Cooling System; using customer-supplied liquid nitrogen; to 30ºC Mechanical Freezing/Cooling System; to 30ºC; includes Controlled RH Automatic Retractable Housing; for RH sensor Very High Temperature 90ºC; for Dry Cycle operation, CCX2000/3000/4000 Very High Temperature 90ºC; for Dry Cycle operation, CCX9000/11000 Solution Spray; multiple nozzles (8, 12 or 16) w/ separate shut-off valves Volume Marker and Overflow Protection; for Solution Reservoir CCX Exhaust Recirculation System; for Salt Fog and Water Humidity steps only - not for use during Freezing/Cooling or Very High Temp 90ºC options

FLOTTWEG SE

Germany

The Flottweg Tricanter® For Three-Phase Separation In three-phase separation, it is possible to separated two liquid phases from one solid phase at the same time. The Flottweg Tricanter® is the perfect partner for separating these three phases. Tricanter® - Typical Applications For Three-Phase Separation - Processing of sludges containing oil from refineries, oil ponds, etc. - Extracting animal/vegetable fats and oils - Starch manufacture for separating wheat starch and gluten Tricanter® - Advantages And Customer Benefits - Greatest possible purity of the liquids to be separated, by using the impeller - Other processing steps/separating stages can be dispensed with, or are no longer required, thereby offering cost savings for the plant owner - Adaptation to changing conditions (product in the feed) possible at any time - Automation is possible - Produced, manufactured and developed in Germany, for the highest possible production quality

Request for a quote

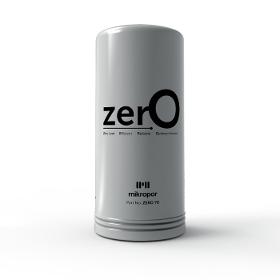

MIKROPOR

Turkey

Mikropor Spin-On Type Air/Oil Separators are manufactured as exchangeable elements. Because Spin-Ons do not require a compressor housing, they permit uncomplicated and quick replacement without dismantling the compressor. Spin-On Type Air/Oil Separators are available for 0,5 to 7 m³/min flow rates operating at 7 bar.

Request for a quote

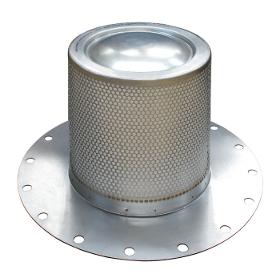

MIKROPOR

Turkey

"Pleated separators increase the media surface area to reach higher capacities while maintaining the dimensions. Mikropor manufactures dozens of pleated separator designs."

Request for a quote

MIKROPOR

Turkey

Mikropor ""Conwrap"" Separators are standard wrapped style separators. Theseseparators are designed for outside to inside flow and can be used with all oil injectionRotary Vane and Rotary Screw Compressors. Conwrap separators operate between1 to 60 m³/min flow rate at 7 bar with 1 to 3 mg/m³ oil carry over.

Request for a quote

MIKROPOR

Turkey

Our Compressed air filters are the first line of defence for any air compressor and have a significant impact on the service life of the compressor, lubricant, air/oil separators, and oil filters. We offer the highest efficiency air intake filters in the market, outperforming the competition and delivering more value to customers. With over 3000 Air/Oil Separator designs for compressors, we offer multiple options for the full range of airflow and performance requirements. Our water separators have been designed for the removal of bulk liquid water and particulate from compressed air and gases. Unique centrifugal action removes contaminants at low-pressure drop for maximum energy saving. You can download our product catalogue and brochures on the left panel in order to see our wide variety of products below.

Request for a quoteResults for

Oil separator - Import exportNumber of results

70 ProductsCountries

Company type

Category

- Electric motors and parts (7)

- Filtering equipment and supplies (7)

- Refrigeration plants and equipment, commercial and industrial (7)

- Air treatment - equipment and systems (3)

- Filters, liquid (3)

- Industrial washing facilities (3)

- Olive oil (2)

- Air conditioning equipment (2)

- Automation - systems and equipment (2)

- Import-export - mechanical engineering (2)

- Pumps (2)

- Air compressors (1)

- Cleaning machines, industrial (1)

- Cooling and lubrication pumps (1)

- Electricity generators (1)

- Environmental clean-up - machines and equipment (1)

- Food industry - machinery and equipment (1)

- Grinding - steels and metals (1)

- Hydraulic tools (1)

- Industrial sheet metal work (1)