- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- paint spray guns and accessories

Results for

Paint spray guns and accessories - Import export

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our wet painting booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts. In our wet painting booth with solid filter, the air is sucked through the filters by exhaust fans while the unused wet paint is held by paper or fiber filters. And the clean and healthy environment is created by supplying the fresh air to the environment. Teflon (non-stick), solvent based and water based paint applications can be applied in our wet painting booths. We also design Flash off and Positive Pressure rooms for our wet paint plants. In flash off rooms, solvent separation process of painted parts is done. The solvent that released in these rooms is removed by exhaust fans and a healthy working environment is obtained.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Conveyors that we use for painting plants and various transfer lines are the most important parts of the automatic systems. Commonly used Webb, Kardan and Power & Free type conveyors are projected and put into used by us. Semi-automatic conveyor lines are also produced for lower production capacities.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

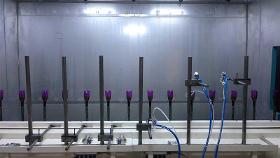

Powder and Wet paint equipment must be determined and selected carefully according to the properties of the parts to be painted. In our systems, we use the highest quality, most efficient and most reliable, manual and automatic powder and wet paint guns, single and multi-axis robots.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Penetrant non-destructive testing method is a system that is used for the detection of cracks in the surfaces of parts. After the material which is going to be subjected to penetrant test is pre-cleaned, it is subjected to penetrant application as dipping or spray. After this process, the material is rinsed and dried. Powder “developer” is applied electrostatically on the dried material. Finally, possible cracks and faults on the material are detected by checking under the UV lamp.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

It is the furnaces where the hardening process of various aluminum profiles is happened, in other words, the aging process. Aluminum profiles are loaded into the furnace with the help of loading cars. The profiles which are kept in the oven at about 185 °C for 6-8 hours will be harden with the aging process. The whole operation is programmed with the PLC control unit. Thanks to its safe guillotine doors, they contribute to the air circulation in the interior and provide security with the locking mechanisms.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our wet painting booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts. In our wet painting booth with water curtain, the air is sucked through the water curtain by exhaust fans while the unused wet paint is held by water. And the clean and healthy environment is created by supplying the fresh air to the environment. Teflon (non-stick), solvent based and water based paint applications can be applied in our wet painting booths. We also design Flash off and Positive Pressure rooms for our wet paint plants. In flash off rooms, solvent separation process of painted parts is done. The solvent that released in these rooms is removed by exhaust fans and a healthy working environment is obtained.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

The main part of the wet painting lines that we have produced is wet painting booths. Wet painting booths are used to apply wet paint on the material under the most ideal conditions after the surface cleaning process and to prevent the paint that can not hold onto the work piece from being escaped to the environment. The wet paint is atomized by high pressure air and applied on the part that is going to be painted. It is preferred because it is easy to apply and gives good results. As Rota Makine, we design lines with conveyor and robots to offer our esteemed customers who want to make production with high capacity, automation and untouched. Our wet painting booths are categorized as With Water Curtain and With Solid Filter because of their different advantages. Wet enameling cabinets for enamel applications are also available in our scope of production.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our powder paint booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts to easy disassembling. Recycling is done with the cyclones in our powder coating booths with cyclone. It is preferred because it allows easy and fast color change. The powder particles which are not used passes through the cyclone unit before the filter unit. While the particles go down through cyclones with centrifugal effect, the particle that cannot be reused is sent to the filter unit and filtered there. The parts which are suitable for recycling are recycled to the system for reuse. Multi and mono type cyclone units are used in our booths. Both types offer efficiency with recycling systems, practicality with easy color changing. In filter cabins, it is necessary to change

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our powder paint booths are manufactured as standard or custom design according to the customer’s needs. For the cabin selection, the dimensions of the parts and the targeted capacity are the determining elements. Our booths are made of stainless steel or galvanized sheet and fully assembled with bolts to easy disassembling. In our powder paint booths with filter, the air is sucked through the filters while the unused powder particles are held by filters. The filters are automatically and periodically pumped air in reverse direction to direct the powder paint that held by filters to the sieve tanks which is under the cabinet for reusing. As a result of this process, the unused powder paint is recycled. Polyester-Teflon and Sinter-Lamellar type filters are used in our booths. Polyester-Teflon filters are preferred due to their low cost and Sinter-Lamellar filters are preferred due to their long filter life. Both types offer efficiency with recycling systems, economical solution

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

The main part of the powder coating lines that we have produced is powder coating booths. Powder coating booths are used to apply powder coating on the material under the most ideal conditions after the surface cleaning process and to prevent the paint particles that cannot hold onto the work piece from being escaped to the environment. Electrostatically charged dye particles adhere to the surface with maximum efficiency and homogeneous spread. The system is preferred because; non-adherent powder is reusable with the recycling system in the booths. As Rota Makine, we design lines with conveyor and robots to offer our esteemed customers who want to make production with high capacity, automation and untouched. Our powder coating booths are categorized as With Filter and With Cyclone because of their different advantages. Powder enameling cabinets for enamel applications are also available in our scope of production. Our powder enamel booths are produced

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our Infrared ovens can be produced as conveyor belt tunnel or internal return (U) type. Our ovens have andirect heating system with radiation heat transfer. They are used due to the cure flat shaped parts after wet or powder coating paint applications. They are preferred because they can cure the paint three times faster than the convectional type ovens. They can be produced with natural gas or lamp type infrareds. The inner surfaces of our ovens’ panels are produced with a galvanizedor stainless steel sheets and the outer surfaces are produced with galvanized sheet steel coated with electrostatic powder paint. Considering the application temperature, the required thicknesses determined and rock wool or glass wool is used for insulation.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our continuous type ovens can be produced as belt tunnel type, internal return (U) type or with span conveyor. Our ovens have the indirect heating thermo-block system with convection heat transfer. It can be manufactured according to power supply sources like electricity, gas or liquid fuel. The inner surfaces of our ovens’ panels are produced with galvanized sheet and the outer surfaces are produced with galvanized sheet steel coated with electrostatic powder paint. Considering the application temperature, the required thickness (usually 160 mm) is determined and only rock wool is used for insulation. Air curtains in the furnace are placed inlet and outlet of the oven to minimize heat loss while increasing the efficiency.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Our box type ovens have the indirect heating thermo-block system with convection heat transfer. It can be manufactured according to power supply sources like electricity, gas or liquid fuel. The inner surfaces of our ovens’ panels are produced with galvanized sheet and the outer surfaces are produced with galvanized sheet steel coated with electrostatic powder paint. Considering the application temperature, the required thickness (usually 160mm) is determined and only rock wool is used for insulation. For paint applications up to 220 °C, for special purposes up to 400 °C ovens can be produced by our company. The doors of our box type furnaces can be produced as double-sided, top opening or as guillotine door according to needs.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

The dipping system which is one of the other methods is produced with a robot or crane controlled. The systems are equipped with the most efficient heating, ventilating and PLC control equipment. In our dipping lines manufacturing, AISI 304- AISI 316 stainless sheets of steel and polypropylene are used. The system should be selected according to the shape of the part, the area to be used and the corrosion resistance. Some chemicals which are used for surface cleaning must be applied hot. Due to this situation, our company produces cold dipping lines as well as natural gas heated, electric heated, liquid fuel heated and water heated dipping pre-treatment lines according to the energy source that is planning to be used.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

In the spraying pre-treatment method, applying chemicals with a certain pressure on the parts creates big positive differences on paint quality and life span. By cleaning and coating the surface of the part before painting, the paint will retain its first-day quality with out any degradation for long years by strong adhesive forces. Our spray tunnels, with the help of automation systems, allow you to be able to produce automatically and continuously with out any touch. Tunnel type spray surface cleaning lines consist of parts like spray nozzles, heat exchangers, dosing pumps and ventilating systems. In our spray lines, the AISI 304 – AISI 316 stainless sheets of steel and polypropylene are used. According to needs of our esteemed customers, horizontal belt type conveyor, compact type, and rotary table type automatic plc controlled washing machines can be produced by us. Some chemicals which are used for surface cleaning must be applied hot. Due to this situation

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

Pre-treatment is the first step of the painting process. This is why it has crucial importance. By cleaning and coating the surface of the part before painting, the paint will retain its first-day quality with out any degradation for long years by strong adhesive forces. A quality product is possible with a quality surface pre-treatment.

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

The industrial ovens we produce are used to dry the water and chemical particles remaining on the material after the surface cleaning, moreover to finish the chemical reaction of the paint, after painting process. Our ovens are renowned in the sector for their heat homogenization, give the opportunity to long term usage with trust and designed for maximum efficiency in a frame of our respect for nature policy.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HFP BANDSTAHL GMBH & CO KG

Germany

We have successfully adapted many of the adhesion promoters (developed for the Coil Coating process) for spray and brush application. Various adhesion promoters for NR, NBR, HNBR, EPDM, SBR, FPM, PVC, PP, ABS, PA, PU, TPE... are available.

Request for a quote

MERZ & BENTELI AG

Switzerland

Professional sealant gun with strong drive plate Rotary carriage and ladder hoak Rubbercoated handle and trigger Corrosion protected driving parts with special blackened alloy Trigger ratio 171 For cartridges up to 310ml

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

Airless Spray Gun, Paint Sprayer

Request for a quote

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

Combined spraybooths are designed for manual painting application for automotive industry with downdraft ventilation and drying system. It is manufactured from insulated panel body. Installed to the factory ground or to an metal basement, extraction air ducts are placed at the ground, Fresh air plenum and filtering system is located at the ceiling that creates clean environment inside the spray booth during the painting and drying application. Painting or drying option are selected manually from the control panel, flash-off and cooling positions are automatically controlled. Includes standard type illumination system and optionally Ex-zone, electrical control panel and wiring to the control panel is done. The spray booth is fully controlled by PLC control system and a touch panel. Control system indicates when filters gets contamnated. Filters are easy replaceable. The spraybooth is CE certificated and conforms to the European Norms.

Request for a quote

VOGAMAKINA INDUSTRIAL PLANTS LTD. CO.

Turkey

The spraybooth is designed for manual painting application, with sidedraft ventilation and dry cardboard filtration system. The benefit of the retractable liquid spray booth is that it is an extendeable and saves space in the workshop at folded position during it is not used. The spray booth is environmentally friendly.

Request for a quote

PNEUFLEX PNEUMATIC CO., LTD

China

Pneuflex air blow guns (air dust guns, pneumatic blow guns, metal air blow guns, air blower), including metal air blow guns and metal air blow guns, which are often used to clean the dust , water and crumb.

Request for a quote

GEHEIT GMBH

Germany

HVLP Spray Gun ABAC PN 1A for ABAC SG2000 and SG2500 HVLP Paint Spraying Units, with Intermittent Air Supply, 3 Nozzles 1,0- 1,5 -2,0mm Dia, 0.7 l Aluminium Paint Container, Nozzle Spanner Professional and reliable equipment of high quality. Made in Germany, components only from European manufacturers. 2-year warranty. Minimal overspray, "low-misty" spray, minimal material loss, paint transfer coefficient up to 90% possible. Reduced set up and cleaning times, reduced maintenance costs. Plenty of additional nozzles from 0.2 (NANO) to 3.0 mm in diameter Technical Data: Maximum permissible operating pressure: 0.45 bar; Size: 180 x 110 x 350 mm; Weight: 0.76 kg.

Request for a quote

GEHEIT GMBH

Germany

"Made in Germany" ABAC HVLP Paint Spraying System SG 2000: Motor Blower ABAC SG 2000, Spray Gun ABAC PN 1A, Air Hose 6 m., Dipper for Viscosity Checks, 2 Spare Intake Filters. Scope of Supply: Adjustable low-pressure motor blower SG 2000 with continuous pressure regulation and 5 m connecting cable. Spray gun PN 1A with intermittent air supply, with 3 nozzles 1 - 1,5 - 2 mm and 0,7 I aluminium paint container. Nozzle spanner. Special air hose 6 m. Dipper for viscosity checks. 2 spare intake filter. Manufacturer: Geheit GmbH (ex CHIRON) Motor power: 1200 Watt Voltage 230 volts or 115V Flow Rate 2800 Litres Per Minute Air Flow Capacity 2.8 Cubic Meters per Minute Maximum Pressure 0.31 Bars Sound Level 81 dB Hose Length 6 Metres Cord Length 5 Metres Spray gun- anodized aluminum 0,7L

Request for a quote

GEHEIT GMBH

Germany

"Made in Germany" HVLP Spray Gun ABAC PN 2A for ABAC SG90, SG2000 and SG2500 HVLP Paint Spraying Units, with Continuous Air Supply, 3 Nozzles 1, 1.5 and 2 mm Dia, 0.7 l Anodized Aluminum Paint Container, Nozzle Spanner Manufacturer: Geheit GmbH (ex CHIRON) Box Size: 37x17x12cm Weight:1,2 kg

Request for a quote

GEHEIT GMBH

Germany

" Made in Germany" ABAC HVLP SET - HVLP turbine ABAC SG90 electronic, HVLP spray gun ABAC PN2A (nozzle 1,0-1,5-2,0mm); air hose 6m, shoulder strap, viscosity measuring cup, 1pc. reserve filter for turbine. Manufacturer:Geheit GmbH (ex CHIRON) Voltage230 volts or 115V Flow Rate2300 Liter Per Minute Air Flow Capacity2.3 Cubic Meters per Minute Maximum Pressure0.22 Bars Sound Level80 dB Hose Length6 m Cord Length5 m Spray gun- anodized aluminum 0,7L

Request for a quoteResults for

Paint spray guns and accessories - Import exportNumber of results

29 ProductsCountries

Company type