- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- screen filters

Results for

Screen filters - Import export

HEBMÜLLER GMBH

Germany

Sieves, strainers and filter elements are manufactured by injection molding Either a plastic mesh or a metal mesh is placed inside the mold and overmolded with plastic. We focus on small and medium quantities from manual to semiautomatic series production.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

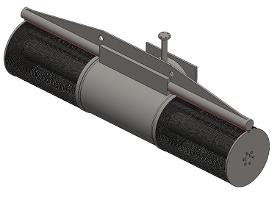

The dust filter is located at the front of the blower, which allows efficient filtration of the air emitted. The filter is equipped with an air purge system that automatically cleans and keeps the filter screen unclogged. The filter area can be manufactured according to customer requirements and is equipped with different types of filters, suitable for different industries and conditions. A manual butterfly valve and a dust container are located under the machine to facilitate cleaning. It is suitable for food, chemical and plastic powders.

Request for a quoteEUROQUARTZ LTD

United Kingdom

Custom crystal filters, overview of Euroquartz design and oproduction capability: Band Pass Crystal Filters, Linear Phase Filters, Comb Filter Banks, Band Reject Filters stc. Custom designed and manufactured Wide range of filter models Speedy design and development

Request for a quote

SIGA FILTRATION

United Kingdom

SF-IL Inline Screen Filters Heavy duty industrial inline screen filters for coarse applications. Standard units are supplied with inline connections for easy istallation. Industrial design Range of screen sizes Hinged closure Stainless Steel Construction PN16 flange 10 bar pressure rating PED compliant F-SF Inline Bulk Transfer Filter Designed for product transfers from holding tanks to tankers. Ideal for product transfers from tankers to tanks Industrial or hygienic design Camlock couplings for quick connections Clamp closure for easy maintenance Basket in range of mesh sizes PED 10 bar -10 / 80 °C

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The flat screen also called panel screen is a rectangular type wedge wire screen for filtration. Thus, the shape of the flat screen helps the filtration process complete accurately by vibration or flow. Panel wedge screen panels provide efficient filtration for different applications with suitable geometry. With the portable design of the panel wedge wire screen, it adapts to a wide range of applications with straight geometry. Advantages Special surface treatment Suitable & customizable design Long service life High durability – less maintenance Effective filtration The most popular usage of the panel filter screen is eliminating the big particles over the screen with vibration. Applications Food and Mineral Processing Water Cleaning Mining Applications Vibrational Separation Fermentation Water Treatment Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

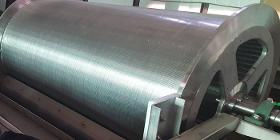

The rotary screen is a portable cylindrical wedge wire screen that can be used for filtration. Rotary screens are also called drum screen, operates with rotational movement. Drum screen filters using the open gap between the Vwires of the cylindrical wedge wire screen. Rotary drum screen is most effective for water filtration applications. Therefore, it is called rotary screen wastewater as well. With the rotation around the cylindrical axis, efficient filtration is achieved with the drum screen. Rotary screen is easytouse and easy to clean compared to the other wedge wire types Advantages: Special surface treatment Portable customizable design Corrosion resistance Efficient filtration Suited for many applications Applications: Water Treatment Water intake Food processing Mineral processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The basket screen consists of cylindrical and tubular wedge wire screen which is suitable for centrifugal applications. Therefore, the conical or tubular shape of the screen basket helps the filtration process complete accurately. Centrifugal screen provides efficient filtration for unique applications with conical geometry. Advantages 1-Special surface treatment 2-Centrifugal customizable basket design 3-Corrosion resistance 4-Durable and long service life 5-Precise filtration 6-Strong mechanical properties Applications 1-Different applications are possible for the wedge wire screen basket such as vibratory centrifuge applications. 2-Mining Applications 3-Water Treatment 4-Chemical Fertilization 5-Food Processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The flat screen also called panel screen is a rectangular type wedge wire screen for filtration. Thus, the shape of the flat screen helps the filtration process complete accurately by vibration or flow. Panel wedge screen panels provide efficient filtration for different applications with suitable geometry. With the portable design of the panel wedge wire screen, it adapts to a wide range of applications with straight geometry. Advantages 1-Special surface treatment 2-Suitable & customizable design 3-Long service life 4-High durability – less maintenance 5-Effective filtration Applications 1-Food and Mineral Processing 2-Water Cleaning 3-Mining Applications 4-Vibrational Separation 5-Fermentation 6-Water Treatment Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

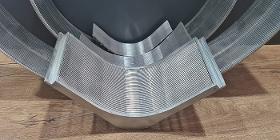

The sieve bend screen – also called bend screen – comprises a curved screen for filtration. The bend screen filters by guiding the particles along with the curved sieve filter screen. The shape of the sieve bend screen offers high filtration because of the forces exerted from the particles in the flow over the sieve bend. Thus, it is used for different applications by benefiting from the bend screen geometry. Advantages: 1-High filtration performance 2-Customized bend screen design 3-Corrosion resistance 4-Durable – long service life 5-Precise open gap 6-High capacity compared to panel wedge wire screen Applications: 1-Mining process 2-Water treatment 3-Food processing 4-Particle filtration 5-Coal removal Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The basket screen consists of cylindrical and tubular wedge wire screen which is suitable for centrifugal applications. Therefore, the conical or tubular shape of the screen basket helps the filtration process complete accurately. Centrifugal screen provides efficient filtration for unique applications with conical geometry. Thus, centrifugal wedge wire screen is suitable for the different kinds of applications where accurate filtration is required. Advantages Special surface treatment Centrifugal customizable basket design Corrosion resistance Durable and long service life Precise filtration Strong mechanical properties Applications Different applications are possible for the wedge wire screen basket such as vibratory centrifuge applications. Mining Applications Water Treatment Chemical Fertilization Food Processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The sieve bend screen – also called bend screen – comprises a curved screen for filtration. The bend screen filters by guiding the particles along with the curved sieve filter screen. The shape of the sieve bend screen offers high filtration because of the forces exerted from the particles in the flow over the sieve bend. Thus, it is used for different applications by benefiting from the bend screen geometry. Advantages: High filtration performance Customized bend screen design Corrosion resistance Durable – long service life Precise open gap High capacity compared to panel wedge wire screen Applications With the advantages of the bend screen geometry, they are used in different applications as a filtering element. Mining process Water treatment Food processing Particle filtration Coal removal Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The water well screen V or wedge shaped wires around an internal array of longitudinal support rods. It is designed for the well intakes. It is also called ‘V’ wire screens in some applications. These efficient screens ensure a long well life by minimizing clogging. Water Well screen also called Johnson Screen provides different advantages for filtration as a type of filter screen. The main advantages of the water well screen are listed below as: Special surface treatment Modular and customizable design Corrosion resistance Durable – long service life Precise open gap Suited for many applications

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The gap between the looped wires defines the filtration performance of the welded wedge wire screen. Welded wedge wires are used as a filter to eliminate bigger sizes or types of materials above the wedge wire screen. Special manufacturing is required to create equal loops between the welded wires. Welded wedge wire screen is used in heavy applications for high filtration performance. The main advantages of welded filter screen are Advantages Special surface treatment Modular and customizable design High durability Suitable for heavy applications Superior filtering with unique screen Long service life & less maintenance Looped wedge wire screen is adaptable for many applications including Applications Coal and Gold Mining Filtration Mineral Processing Water Treatment Petrochemical Applications Food Processing Stainless steel with different grades and different materials can be used. Also, special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The wedge wire cylinder screen is the most popular screen that can be adapted to many applications. The shape of the cylindrical screen helps the filtration process complete accurately. It is also called Johnson Screen in some applications. With the modular design of the cylindrical screen, it provides efficient filtration performance for many applications. In addition, cylinder wedge wire screens can rotate or remain static depending on your application. Advantages: Cylinder screen also called Johnson Screen provides different advantages for filtration as a type of filter screen. The main advantages of the cylindrical screen are listed below as Special surface treatment Modular and customizable design Corrosion resistance Durable – long service life Precise open gap Suited for many applications Applications: Water Treatment Mine, coal, mineral Processing Food and Beverage Petrochemical and oil

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with highefficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths.Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages The bicylindrical perforated screen provides different advantages for filtration as a type of special filter screen in different industries. The main advantages of the bicylindrical drilled screen are listed below as Special filtration Counterbore and customized filtration holes Corrosion resistance High durability – long service life Precisely drilled holes Special surface treatment Applications Typical industries and applications of bicylindrical screens are Sugar Pulp Pressing Water Filtration Paper Mills Pressing Processing of Chemicals Seperation Process

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The water well screen V or wedge shaped wires around an internal array of longitudinal support rods. It is designed for the well intakes. It is also called ‘V’ wire screens in some applications. These efficient screens ensure a long well life by minimizing clogging. Water Well screen also called Johnson Screen provides different advantages for filtration as a type of filter screen. The main advantages of the water well screen are listed below as: Special surface treatment Modular and customizable design Corrosion resistance Durable – long service life Precise open gap Suited for many applications

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with high efficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths. Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages 1-Special filtration 2-Counterbore and customized filtration holes 3-Corrosion resistance 4-High durability – long service life 5-Precisely drilled holes 6-Special surface treatment Applications 1-Sugar Pulp Pressing 2-Water Filtration 3-Paper Mills 4-Pressing 5-Processing of Chemicals 6-Seperation Process

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The rotary screen is a portable cylindrical wedge wire screen that can be used for filtration. Rotary screens are also called drum screen, operates with rotational movement. Drum screen filters using the open gap between the V-wires of the cylindrical wedge wire screen. Rotary drum screen is most effective for water filtration applications. Therefore, it is called rotary screen wastewater as well. With the rotation around the cylindrical axis, efficient filtration is achieved with the drum screen. Rotary screen is easy to use and easy to clean compared to the other wedge wire types Advantages 1-Special surface treatment 2-Portable customizable design 3-Corrosion resistance 4-Efficient filtration Applications 1-Water Treatment 2-Water intake 3-Food processing 4-Mineral processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The wedge wire cylinder screen is the most popular screen that can be adapted to many applications. The shape of the cylindrical screen helps the filtration process complete accurately. It is also called Johnson Screen in some applications. With the modular design of the cylindrical screen, it provides efficient filtration performance for many applications. In addition, cylinder wedge wire screens can rotate or remain static depending on your application. Advantages: Cylinder screen also called Johnson Screen provides different advantages for filtration as a type of filter screen. The main advantages of the cylindrical screen are listed below as: 1-Special surface treatment 2-Modular and customizable design 3-Corrosion resistance 4-Durable – long service life 5-Precise open gap Applications: 1-Water Treatment 2-Mine, coal, mineral Processing 3-Food and Beverage 4-Petrochemical and oil

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

Intake screen also called T-screen is used to intake and clear water in many industrial areas. They are commonly used in hydroelectric, agricultural, drinking applications to prevent dirty materials from the water. Intake screen is commonly used in lakes known as lake pump intake screen. Intake water works as passive intake screen to intake of water for generating electricity for hydropower. Water intake filter screens can intake clean water by eliminating unwanted materials. Because of its simple cleaning, major maintenance is not required for the operational time. Advantages: 1-High performance water filtration 2-Fish friendly 3-Corrosion resistance 4-Passive intaking water 5-High durability – less maintenance 6-Easy to install Applications: 1-Hydropower Intake 2-Lake Application 3-River Application 4-Water Cleaning

Request for a quote

FINDEVA AG

Switzerland

Properties Rated frequency 6,500 – 23,000 rpm Centrifugal force 600 – 6,060 N Continuously variable Can be used up to 100°C Resistant to extreme environmental conditions Field of application Emptying of bunkers Screen filters Vibrating tables Preventing adhesions in pipelines and silos Transporting of fine powders Moving of bulk material

Request for a quote

FINDEVA AG

Switzerland

Properties High torque Rated frequency 10,000 – 36,000 rpm Centrifugal force 1,070 – 12,500 N Continuously variable Can be used up to 150°C Resistant to extreme environmental conditions Field of application Emptying of hoppers and chutes Screen filters Conveying of particulates Preventing adhesions in pipelines and silos Transporting of fine powders Compacting of plastic and concrete in throughs

Request for a quote

FINDEVA AG

Switzerland

Properties Powerful Rated frequency 7,300 – 35,000 rpm Centrifugal force 130 – 4,050 N Continuously variable Can be used up to 100°C HT-Version up to 150°C on request Field of application Emptying of bunkers Screen filters Vibrating tables Preventing adhesions in piplines and silos Moving of goods

Request for a quote

FINDEVA AG

Switzerland

Properties Lubrication-free Low noise level Strong vibration by means of high speed and eccentric working torques Rated frequency 14,000 – 37,000 rpm Centrifugal force 750 – 5,700 N Continuously variable Can be used up to 150°C Resistant to extreme environmental conditions Field of application For foodstuffs and pharmaceuticals, complies with FDA specification Emptying of bunkers Screen filters Vibrating tables Preventing adhesion in pipelines and silos Transporting of fine powders Moving of bulk materials

Request for a quote

FINDEVA AG

Switzerland

Properties Lubrication-free Low noise level Strong vibration by means of high speed and eccentric working torques Rated frequency 6,000 – 46,000 rpm Centrifugal force 130 – 12,000 N Continuously variable Can be used up to 150°C Resistant to extreme environmental conditions Field of application Emptying of bunkers Screen filters Vibrating tables Preventing adhesion in pipelines and silos Transporting of fine powders Moving of bulk materials

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase containment of dialysis system media Designed for depth filtration efficiency, fluid flow, back pressure and excellent chemical and physical resistance, POREX ® retention filters provide specified containment of dialysis system media, such as those that utilize concentrated liquid sodium bicarbonate. Trusted by manufacturers around the world, our customized retention filters: Provide specific containment–Customized filters provide containment of dialysis system media, including those systems that use concentrated liquid sodium bicarbonate. Increase filtration efficiency– Designed for depth filtration, fluid flow, back pressure and excellent chemical and physical resistance of dialysis media. The depth filter provides a more complete and secure filtration vs. typical screen filters. Can be customized –Tailored to accommodate specific device design requirements of dialysis media.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase containment of dialysis system media Designed for depth filtration efficiency, fluid flow, back pressure and excellent chemical and physical resistance, POREX ® retention filters provide specified containment of dialysis system media, such as those that utilize concentrated liquid sodium bicarbonate. Trusted by manufacturers around the world, our customized retention filters: Provide specific containment–Customized filters provide containment of dialysis system media, including those systems that use concentrated liquid sodium bicarbonate. Increase filtration efficiency– Designed for depth filtration, fluid flow, back pressure and excellent chemical and physical resistance of dialysis media. The depth filter provides a more complete and secure filtration vs. typical screen filters. Can be customized –Tailored to accommodate specific device design requirements of dialysis media.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase containment of dialysis system media Designed for depth filtration efficiency, fluid flow, back pressure and excellent chemical and physical resistance, POREX ® retention filters provide specified containment of dialysis system media, such as those that utilize concentrated liquid sodium bicarbonate. Trusted by manufacturers around the world, our customized retention filters: Provide specific containment–Customized filters provide containment of dialysis system media, including those systems that use concentrated liquid sodium bicarbonate. Increase filtration efficiency– Designed for depth filtration, fluid flow, back pressure and excellent chemical and physical resistance of dialysis media. The depth filter provides a more complete and secure filtration vs. typical screen filters. Can be customized –Tailored to accommodate specific device design requirements of dialysis media.

Request for a quote

HEBMÜLLER GMBH

Germany

It is also possible to assemble seals and/or other components such as valves, flaps and springs onto our filter screens to form small assemblies. When joining plastic parts, clip connections are mostly used.

Request for a quoteResults for

Screen filters - Import exportNumber of results

46 ProductsCountries

Company type

Category

- Screen filters (19)

- Filtering equipment and supplies (15)

- Water treatment, industrial - systems and equipment (8)

- Filters, liquid (3)

- Nozzles - ferrous metal (2)

- Cleaning machines, industrial (1)

- Electrical & Electronic Components (1)

- Foods, precooked and gourmet (1)

- Natural polymers (1)

- Water extraction - systems and equipment (1)

- Wires and cables, steel (1)