- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- marking technology

Results for

Marking technology - Import export

GRAVOTECH

France

VIN ENGRAVING MACHINE The Vehicle Identification Number (VIN) marking on chassis requires a reliable scribing machine, able to perform deep marking on all materials, from soft, such as aluminum to the hardest steels at a high speed. Our SV530 scribing marking machine has been used for more than 10 years with automotive products, proving fantastic durability and strength. SILENT MARKING SYSTEM Scribing technology performs silent marking on hollow metal parts (tubes and pipes) or formed plates (chassis and body parts) when these objects will naturally resonate during rotary marking. DIRECT PART MARKING Designed to combine depth with high speed and aesthetic results, our scribe marking machine has one of the best-marking speed/depth ratios: mark 17 characters of 7mm high. Powerful and fast, this machine creates deep marking before and after the treatment of parts.

Request for a quote

REA ELEKTRONIK GMBH

Germany

The REA JET One Dot Systems (EDS) are particularly well suited to very fine dot and line markings. The dot size is configured by selecting the nozzle size and by varying the material pressure, and the stepless setting on the controller. Applications — for quality assurance you can mark products with a dot to be recognized as either good or bad (use automatic camera recognition) — colored line marking for pipes, profiles and endlessly manufactured products (e.g. extruded goods) — applying oils, separating agents, soaps or process water — welded seam marking in the manufacturing of metal profiles — applying fragrances to cosmetic samples

Request for a quote

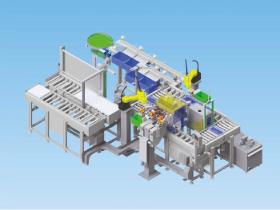

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

This powerful HSF friction feeder is the optimal solution when empty folding boxes have to be marked with variable data offline from the production line. The modular design of the system enables an easy integration of the desired marking technology. The HSF separates the folding boxes from the stack in the infeed magazine. The cartons are guided to the printing station by two parallel running belt conveyors. Print information could be e.g. serialisation data in the form of bar codes or data matrix codes and text. Depending on requirements, thermal inkjet, laser coders or label print- and apply systems can be used (also in combination). The printed data is inspected and verified by an integrated vision system. The b+b Linemanager recognized all 21CFR Part 11 data for each serial number and is able to report this back to the Siteserver system (e.g. b+b Siteserver).

Request for a quote

REA ELEKTRONIK GMBH

Germany

The latest generation of REA JET GK 2.0 high-resolution coding and marking systems using piezo technology is suitable for direct, high-contrast coding and marking on absorbent and porous surfaces, such as wood, cardboard and paper, with a variable print height of up to 100 mm. Applications: — Porous and absorbent surfaces: paper, cardboard boxes, wood, textiles, fleeces, building materials, polystyrene, grinding wheels etc. — Variable print data such as date, time, counter, shift code or database content — Alphanumeric texts, barcodes, data matrix codes, logos, warning notes — Coding and marking of packaging — IPPC coding and marking on pallet blocks — EPAL coding and marking of pallets — CE marking on wood — Marking of paper sacks — All-round coding and marking of fiber drums — Marking of OSB panels with logo — Coding and marking of pallet boxes — Marking of gypsum boards or board stacks with large logos — Serialization and track & trace applications

Request for a quote

SIM AUTOMATION GMBH

Germany

- Entire system solution from a single source - from construction of the laser cell to integration of your chosen KEYENCE laser - self-contained and high-performance solutions for laser labeling small batches of individual parts Versions: - Compact - Rotary - Plus - Classic - Mini - Set up: directly on a desk or mounted onto the movable base frame - Latest three-axis laser marking systems offers a laser labeling system that can be precisely adjusted to the materials and part geometries that shall be labeled Advantages of integrated optical three-axis technology: - focal point to be freely set and is especially impressive - marking laser follows various shapes - easily switch between different heights (± 21 mm = 42 mm) - mark on any shape with outstanding sharpness, including on slanted surfaces, cylinders and cones Size of the labeling field (depending on the type of laser): between 120 x 120 mm and 330 x 330 mm.

Request for a quote

TAMPOPRINT GMBH

Germany

For over 30 years TAMPOPRINT GmbH has been an established partner of the beverage and closure caps manufacturing sector and their suppliers. Today our high know-how distinguishes us and makes it possible to supply you with decorating and marking solutions with our rotary pad printing and laser marking technology. Our pad printing and laser automations meet highest quality requirements for the applications in multi-shift operations with high throughput speeds. As an expert for special solutions our project planning can draw on many years of experience.Our rotary pad printing automations offer highest precision in print image registration on convex, round or flat parts, one- or multi-colored. Additionally we offer with our brand ALFALAS® the laser marking ”Mark on the Fly” – bottle caps marking for competitions and promotion campaigns.

Request for a quote

LASER ISSE LASER TECHNOLOGIES

Turkey

Advantages of Laser Marking System Works with a range of shapes & sizes, Easy to Integrate, Non-Contact, Fast Process, High quality precise marking, Easily adaptable between processes, Permanent marking, Low operational costs, Additional treatment not required, Safe and environment friendly process. We have manufactured and sold 1000+ pulsed laser marking systems worldwide 15+ years of laser application experience We have produced laser engraving and micro cutting systems which are generated by Fiber, CO2, Nd:YAG, UV, Blue and Green Lasers. We have installed systems for global brands We provide project-based automation solutions We are one of the first companies to use laser marking technology in cleaning Available Features; Robotic Integration, Rotary Indexing Table Mark on The Fly 2D & 3D Engraving Feature Auto – Feeder Solutions Precision With Granite Table Integration Existing Production Line Automation Support With 16 I/O Connection

Request for a quote

STRIP'S D.O.O.

Slovenia

We are very flexible with our PCBA process and are able to provide you with customized solutions for your system, including supporting any special requirements when needed, such as stress-free de-panelling. Our PCBA contains all the necessary technologies such as surface mount technology (SMT), laser marking, through hole technology (THT), cleaning, coating, programming, rework and repair, to provide you custom made solution for your system.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

This machine technology developed for coating round steel tubes with a temporary corrosion protection convinces with its high performance. The surface quality of the solvent free coating with 100 % UV lacquer, the fast curing time of ≤ 1 second as well as an overspray recovery rate of more than 95 % are impressive features which, by their very nature, offer high economic efficiency. Additional modules individually perform either the cleaning work, dust removal or marking of tubes. This machine technology ensures perfect transport of the tubes without damage to the lacquer coat, while flexibly taking tube properties into account, such as sleeves or caps, diameters from 20-200 or from 200 to 500 mm, required throughfeed speeds of 30 - 100 m/min as well as surface temperatures from +1°C to +40°C. Whether operated as an individual machine or integrated in an adjustment line, the output parameters are characterised by minimum space requirement and low operating and maintenance costs. An alkaline cleaning station that adjusts to the individual degree of soiling of the tube surface to ensure optimum results can be optionally installed together with a drying unit upstream of the pipe coating line. Venjakob offers individual system solutions for coating tube sleeves. This includes the application of a base coat and coloured rings, as well as marking. Customised solutions for tube marking are available as an option.

Request for a quote

SEIT ELETTRONICA SRL

Italy

Platinum TT is the evolution of the modern induction brazing, this platform can be set up with 4 different stations to: flux, apply brazing paste, cool the parts, mark with galvo laser technology. This system will for sure adapt to all your process and needs. You can use all models of the Platinum series ranging from 2,5KW HF to 25KW MF. The intuitive control system perfectly fit with Seit Elettronica software philosophy: “We provide innovative industrial products with a simple and modern user interface.” These characteristics are pairing and expanding all the new functionalities of “Platinum App” to collect, compare, store and control all the keys datas from Your production cycle time and more.

Request for a quote

SEIT ELETTRONICA SRL

Italy

Platinum HUB is a scalable platform you can customize according to your brazing process. You can set up the layout adding multiple stations to: flux, apply brazing paste or pre-formed brazing alloy, wash, dry and cool the parts you are processing, mark with galvo laser technology, and automatic loading and unloading the line using co-bot or industrial robots. This system will for sure adapt to your process and needs and will give you the chance to expand it and add new functions when you really need it. You can use all models of the Platinum series ranging from 2,5KW HF to 25KW MF. The intuitive control system perfectly fits with Seit Elettronica software philosophy: “We provide innovative industrial products with a simple and modern user interface.” These characteristics are pairing and expanding all the new functionalities of “Platinum App” to collect, compare, store and control all the key data from your production as cycle time, temperature and more.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES numbering heads were used to mark consecutive numbering, serial or model-number on almost all materials like steel, cast iron, aluminum, plastic etc. The application area ranges from the single production up to the integration in automatic production or transfer lines. The numbering heads can be combined with each other and extended with type holders and steel types. Besides numbers, letters or special engravings are also available. All BORRIES products are assembled with the highest precision and quality standard. It guarantees a long life time and a high stability.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES built-in impact units are suitable amongst others for marking applications on transfer lines, rotary tables or testing stations. Because of the big usable stroke workpieces with different heights can be marked without any adjusting.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES roll marking machines can be used to mark massive or hollow round parts. With special tools flat workpieces can also be marked. Options • Special constructions and assemblies, e.g. for brake disks or gas bottles with an automatic part handling • Customer- and workpiece-specific roll marking devices and pin fixture devices

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES stamping machines can be used in a workshop for single, small batch and batch production. They are adaptable for almost every deformable material. Because of the big usable stroke workpieces with different heights can be marked without any adjusting. The easy handling, the well-engineered construction and the large range of marking stamps offer a lot of different application areas and make the BORRIES stamping machines to an indispensable tool.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES hand stamping tools are especially used for control stamping, numbering or as a center punch. They are usable as hand held tools or integrated units. These units are easy to use for flexible applications and the stamping inserts are quickly and easy changeable. These features make it to an indispensable tool for craft and industry.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES pneumo-hydraulic marking machines are suitable for applications that need big marking forces. They are available either as complete units with column or C-clamp rack or as built-in units for transfer lines and round cycle facility.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BORRIES MARKIER-SYSTEME GMBH

Germany

The workshop unit 322 is a name plate marking unit and is used for very deep markings to mark individual components, prototypes and limited-lot productions. Stable, long life and low-maintenance machine design. Designed for continuous production. Available marking technologies: scribe, stylus, dot marking or DataMatrix marking.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The built-in unit 313 can be integrated in production lines. It is suitable for plain text markings in stylus marking or DataMatrix coding in steel or aluminium. Scribe marking is also possible. Standard delivery is with LDM Macro software. Standard settings are printer or layout mode. As an option the VisuWin SE as well as VisuWin PRO PC software are available. Diversity in marking technologies: stylus, scribe and dot marking, DataMatrix coding (ECC 200).

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The built-in marking unit 312V can be integrated in production lines. It is suitable for plain text markings in stylus marking or DataMatrix coding in steel or aluminium. Scribe marking is also possible. Standard delivery is with LDM Macro software. Here, standard settings are printer or layout mode. As an option VisuWin SE as well as VisuWin PRO PC software are available. Diversity in marking technologies: scribe, Stylus or dot marking, DataMatrix coding (ECC 200).

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The built-in marking unit 314 can be integrated in production lines as well as in stand-alone cells. The marking unit can also be mounted on other holding devices provided by the customer for example in production systems. The connection to a superordinate control (for example SPS) for data transfer or to control the marking process including emergency stop functions is possible. Standard delivery is with LDM Macro Software. Optionally VisuWin SE and VisuWin PRO PC software are available. Available marking technologies: scribe, stylus or dot marking, DataMatrix coding (ECC 200). Options • Pneumatic or electric adjustment unit (only in conjunction with EG2-Box) • Surface detection (only in conjunction with electric adjustment unit)

Request for a quote

THAGORA

Romania

The leather inspection process is very important in achieving efficient leather consumption while maintaining the high quality of the products. Thagora has developed Thagora Leather Scanning Machine LS 3000 AR, a new standard for precision, speed and ergonomics. Key advantages of Thagora Leather Scanning Machine -High precision for quality zones marking using Infrared technology -Ergonomics and automation of the leather inspection process based on augmented reality -Designed for mass production, with a second conveyor for automatic hides unloading -The LED inspection lights with the glare-free lenticular lens are adjustable in terms of intensity and color, ensuring the best condition for the hides inspection regardless of their color and structure -Integrated software module for quick automatic ranking of hides -Integrated stretching system that allows the identification of the fine cuts on the hides Find more details at: www.thagora.com

Request for a quoteResults for

Marking technology - Import exportNumber of results

23 ProductsCompany type

Category

- Stamping - machine tools (6)

- Embossing machine tools (5)

- Marking machines (3)

- Induction heating systems (2)

- Automation - systems and equipment (1)

- Brazing - equipment and supplies (1)

- Chemicals and pharmaceuticals - packaging machinery (1)

- Electric and electronic components - machines for manufacturing (1)

- Leather and skins for furniture (1)

- Marking and labelling machinery (1)

- Metal engraving - machine tools (1)

- Outsourcing - product development (1)

- Pad printing (1)

- Welding, soldering and brazing - equipment and supplies (1)