- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical brakes

Results for

Mechanical brakes - Import export

AMSBECK MASCHINENTECHNIK GMBH

Germany

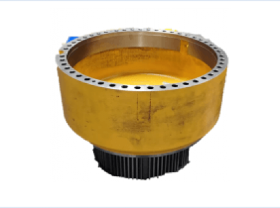

Product characteristics of the centrifugal brakes The centrifugal brake generally works like a centrifugal clutch, but with the housing secured against twisting. A centrifugal brake generally does not brake to standstill but only keeps the revolutions constant. Typical applications for centrifugal brakes are roping-down devices, cranes, lifts, safety gates, and also speed limiters. Areas of use for centrifugal brakes Centrifugal brakes are often used as backup brake systems for electronic brakes. They have the advantage of braking reliably and securely, independently of any other power supply. We supply the centrifugal brake without a housing if the customer already has a brake housing, too.

Request for a quote

JR AUTOMATION FSA TECHNOLOGIES

Romania

- 4 transfer lines for free-entry pallets (A, LM1, LM2 and MT) - 40 pallets - 1 robotised cell - 1 automatic washing machine - standard FSA cells (automatic, semi-automatic or manual) - gravity-fed conveyors Hourly production efficiency: 40.6 parts /hour Instantaneous cycle time: 79.8 sec Supervision MELODIE Realisation : 2009 - Site : BWTS - F-Eyrein

Request for a quote

SPIROL

Germany

The mechanical back-up design uses SPIROL® Disc Springs. Under normal circumstances, the hydraulic system holds a constant pressure on Disc Springs stacked in series. If pressure fails to be maintained, the stack of Disc Springs decompresses to actuate the braking mechanism. A compression spring or wave spring is not capable of providing the force required (in the space available) to actuate the brakes. The reliability of this safety system is dependent on the consistent performance of Disc Springs. In this critical application, the Disc Spring’s performance and level of predictability improves product quality and ensures overall safety. SPIROL® Disc Springs have a high capacity to consistently store releasable mechanical energy. Visit www.SPRIOL.com to learn more!

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

A drive motor can also act as a generator. If the drive system is built so as to allow reverse power to flow then this power can be fed into a resistor, thus taking energy out of the system and causing whatever is driving the motor to slow down. Following to this the braking resistor converts the stop energy into heat. Electrical drive systems are being used more and more on ships, oil rigs, crane barges and offshore vessels of all types. An important benefit from using an electric drive is that reliable systems of regenerative and dynamic braking resistors are available to complement or replace traditional mechanical braking systems. The advantages of electric braking include control, reliability, mechanical simplicity, weight saving and in some cases the opportunity to make use of the regenerated braking energy. The Braking Resistor Units from Klöpper Therm are designed according to specific applications.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of rolling and friction bearings, as well as other machine elements at medium rotating speeds or sliding speeds in a broad temperature range For example, electric motors, drives, control systems and telecommunication and navigation systems under arctic conditions, Bowden cables and brake mechanisms in aircraft, sliding parts in shock-freezing systems etc. Lubricating grease for plastic/plastic and plastic/metal pairs and elastomers For plastic sliding coatings in bridge supports and as a parting agent in plastics processing Advantages and benefits Highly effective due to optimum formula Broad temperature range with a wide range of possible uses Excellently suited for lubricating plastics and elastomers Lubricating grease resistant to ageing, especially at low temperatures

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Calibrate and adjust mechanical yarn brakes for the textile industry The test specimen is inserted in the UUT, which is mounted on a pneumatic slide. By pressing a button, the candidate moves to the running belt drive. The sample is then tested in different locking positions, the switching of the individual Paramtersätze is realized via a rotary switch. In each latching position, IO / NIO statement about the GMV2 light mounted on the column is displayed visually. After passing the examination, the tray will open again and the next candidate can be inserted. A speed controller as well as an ON / OFF switch for the drive are also integrated in the switch box under the GMV2. The entire inspection unit is mobile and complained to a height-adjustable lifting unit. The GMV2 and connect the switch are also mounted height adjustable in the profiles.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

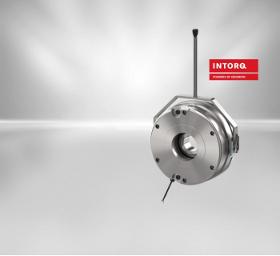

The BFK455 double-brake from INTORQ is a dual spring-applied brake with four friction surfaces and two electrically and mechanically separated brake circuits. The brake circuits can be individually controlled. Separate connecting lines can be used to control the brake circuits individually. The switching state of the two spring-applied brakes is monitored by two individual microswitches. The dual spring-applied brake is designed for one brake alone to provide the necessary braking torque. The second brake is used for redundancy, thus complying with the legal requirements for elevator standards. The BFK455 dual spring-applied brake from INTORQ is a redundant brake system with effective and stable noise reduction. It is ideally suited to elevator and platform applications.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

When operating in crane and port facilities, a braking system must primarily be reliably protected and, secondly, must operate very powerfully. The INTORQ BFK 471 product series combines these two features perfectly. These specially sealed brakes have a newly designed hand-release mechanism which, like the brakes themselves, is IP66 compliant. This series also features high braking torque and requires only a compact installation space.

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel vertical lifeline system is designed for permanently-installed, standard ladders made of steel or aluminium (welded-on or crimped rungs) and is simply clamped onto the rungs of your ladder. We also offer an optional model with a longer protrusion (130 cm) which allows the user to climb on and off safely. EN 353-1:2018 (incl. in former times CNB/P/11.073) Suitable for simultaneous usage by 2 individuals (1 person per glider Fixed guide with stainless steel cable (8 mm) A range of top section protrusions available - up to 130 cm Specially-designed vertical ladder glider with a blocking mechanism to apply the brakes in the case of a fall For rungs measuring max. 3.5 cm x 3.5 cm; other sizes available upon request

Request for a quote

OTOBILYA AUTOMOTIVE

Turkey

Kaffer 500 ml. Brake and Parts Cleaner.The Product is qualifeid and has competitive prices compared to similar products.

HAKERMAN CORP.

Turkey

- Complete 304 quality sandblasted stainless steel main case - Reinforced seat and backrest - Carrying capacity up to 200 kg - Sturdy, durable self-folding footplate - Standard IV pole, double direction urine bag hanger - Standard manual seat belt - Standard internal advertising space on the back - Easy to use and powerful brake mechanism Hakerman Sypha Stockable Transfer Wheelchair is not only for hospitals and policlinics but for all public places like airports, parks, malls and etc.

Request for a quote

GAFUROV SERVIS EOOD

Bulgaria

The metal waste container with round lid is made of 1.5 mm. sheet metal (steel sheet with additional galvanizing). Hot-dip galvanized according to EN ISO 1461: 2009. The ribbed body on several levels gives strength to the metal container. Highly resistant to extreme weather conditions - low and high temperature! Cover all European norms and standards for metal garbage container with round lid: EN ISO 840 - 3, EN ISO 840 - 5, EN ISO 840 - 6! They are serviced by all specialized vehicles with standard EN 1501-01 or equivalent, unloading with side pipes. The presence of a sealing mechanism at the bottom allows the removal of the collected liquids in it. The construction ensures tight closure and reduction of emissions from unpleasant odors in urban environments. For easier handling, each container has two handles on each side. It is actuated by four wheels, two of them with a brake mechanism. It is possible to install a pedal for foot opening of the lid!

Request for a quote

KURTBAY PLASTIK VE KALIP SAN.TIC.LTD.STI.

Turkey

Provides effective cleaning of dust and oil accumulated on brake systems. Provides healthier braking and lengthens the life cycle of braking mechanism.

Request for a quote

ENGIFIELD - MECHANICAL POWER TRANSMISSION

Spain

Engifield provide mechanical electromechanical clutches and brakes for the industrial sector and for motion control

Request for a quoteResults for

Mechanical brakes - Import exportNumber of results

16 ProductsCountries

Category

- Brakes, servo-brakes and accessories (3)

- Mechanical brakes (3)

- Disc springs (1)

- Dustbins, waste bins (1)

- Electrical & Electronic Components (1)

- Lubricants for cars (1)

- Measurement and control instruments (1)

- Mechanical engineering - custom work (1)

- Metal straightening machines (1)

- Rehabilitation apparatus and equipment (1)

- Screw cutting - steels and metals (1)

- Silicones (1)

- Storage and collection of waste - equipment (1)

- Vehicle brakes (1)