- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mixing machines

Results for

Mixing machines - Import export

PLANT OF TECHNOLOGICAL EQUIPMENT, LLC

Ukraine

Dissolver, compact, with one or two shafts, for premises with a low ceiling. It is supplied with an electromechanical lifting of the tool. It is intended for vessels with a volume – from 30 to 500 liters. An electric motor’s power – from 2.2 kW to 11kW, the turnovers – from 100 to 1500 (3000) rpm, 380V. It is carried out in both, Ex and IP design. A milling cutter can be installed on one shaft and a stirrer of the required type can be installed on another shaft.It is possible to produce a dissolver, providing vacuum in the working area.

Request for a quote

PLANT OF TECHNOLOGICAL EQUIPMENT, LLC

Ukraine

The dissolver is hydraulic, single-column, floor-mounted. We can offer such a machine with the power of the main engine (cutter) - from 7.5; up to 75.0 kW., 380 V. for replaceable vessels of 100 to 1500 liters. Electrical equipment can be made in a general industrial or explosion-proof design. The dissolver is equipped with a hydraulic drive for lifting the traverse, on which the shaft with the tool and the lid are mounted. All parts that are in contact with the product are made of food or technical stainless steel (customer's choice). Turnovers are regulated from 50 to 1500 rpm. (possibly from 50 to 3000 rpm) using a frequency converter. For more viscous products, it is possible to manufacture a dissolver with two or three working shafts, one of which will have a milling cutter, and the other will have a low-speed stirrer, for example, an anchor type with cleaning elements, and on the third - a high-speed stirrer.

Request for a quote

BAUSHOP EXPRESS GMBH

Germany

The F-Line - the perfect compulsory mixer for every application, meeting your requirements optimally and economically. Advanced technology, for performance and environmentally friendly operation. The standard gearbox runs at 32U/m, with the Vario gearbox the revolutions can be varied between 9 - 55 U/m. The highlights at a glance: - Powerful and very robust motor/gearbox. - Optimal performance and easy handling - Easy cleaning and maintenance - Fast, effective mixing with large capacity - Optimal mixing functions BARON F-120: - Safety circuit when lid is opened - Position bolt for lid safety during use - Motor protection prevents contamination - Simple and efficient operation - Adjustable mixing blades - Optional rubber blades Attention!!! In order to be able to connect the unit to a normal Schuko socket, the CEE to Schuko adapter must also be ordered under the Optional accessories tab.

Request for a quote

RESODYN EUROPE

United Kingdom

ResonantAcoustic(R) Mixer (RAM) uses sound to generate up to 100 g of mixing and processing energy. Unique technology eliminates blades, impeller and other engineered devices to mix in sealed containers to eliminate cross contamination and simplify clean-up procedures. 10 time faster processing speeds, low heat generation, and 100% material versatility of liquids, powders, gases, and pastes into the millions of cP viscosity. Mix with vacuum, heat; coat, mill, sieve. Capacities range from bench scale to production level. 800 machines in 29 countries across dozens of industries with excellent payback results. Annual Technical InterChange supports theory, practice, and hands-on machine use at all scales. (http://www.resodynmixers.com/ti18date). Event designed for attendees ranging from experts who deliver papers, new users to learn from staff and colleagues, and novices to introduce technology basics. Broad based poster session encourages inclusive participation from all attendees.

Request for a quote

MACHINERY CO. LTD

Canada

Main Features 1) Major sections: barrel, ribbon agitators, feeding parts, discharging part and driven unit 2) Sizes: available from 200L to 10000L. 3) Material: Carbon Steel, Stainless Steel 201,304,316L. 4) Discharge: Flap valve, butterfly valve, slide gate valve, ball valve, manually or pneumatically. 5) Speed:Constant speed rotation,also controls such as variable frequency drives, motor starters and operator stations are available. 6)Temperature: mixer can be equipped with heating or cooling jacket if temperature control is required, 7)Spray :nozzles for liquid introduction. 8)Open cover: pneumatic, manual.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The laboratory model supplements the well-established Lödige mixing granulator range. The laboratory mixing granulator permits the same process steps as the production machines: — Mixing — Moistening — Granulation — Temperature control (using double jacket) The laboratory mixing granulator is delivered operation-ready with a CE conformity declaration. For the sizes, please refer to the machine flyer. A three-bladed impeller rotates at the bottom of the vertical, cylindrical mixing vessel, to create a vortex type of circulation for the material to be mixed. Very short mixing times and excellent mixing quality are achieved, even if the product components are extremely different. The separately driven chopper (only for the 5, 10 and 15 l vessel) is designed for breaking up of agglomerated material, for uniform moistening, wet granulation and streak-free mixing of dyes, as required.

Request for a quote

MICRON AMERICA

Turkey

Micron M-500 fully automatic, eyelet and washer attaching machine. This machine is built around a newly designed frame that requires less space and is much lighter than previous generations of machines. The M-500 fully automatic machine that feeds both the eyelet and washer punches the hole in the material and attaches the eyelet and washer, all in a single cycle. This machine has been specifically engineered for light to medium duty applications.

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

GRUNDODRILL 4X GRUNDODRILL 11XP GRUNDODRILL 15XP GRUNDODRILL 15XPT GRUNDODRILL 18N GRUNDODRILL 18ACS GRUNDODRILL 28Nplus Mixing units Mixing unit MA07 Mixing unit MA09 Mixing unit MA010 Accessories Used Machines

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XM barrel emptying system with volumetric pump based on the endless piston principle. Your advantages: - for medium to high viscosity products (up to 7,000,000 mPas) - suitable for abrasive, shear-sensitive or lumpy materials loaded with fillers - clean wiping of the inside wall of the barrel due to follower plate with special sealing lip - suitable for cylindrical, ribbed or slightly conical barrels, plastic containers or containers with inliners - no lateral squeezing of the medium, as the follower plate is guided almost without pressure - discharge speed electronically adjustable - easy handling - pulsation-free conveyance/discharge - Residual quantity in the barrel: < 1% - compact design Application: Withdrawal of products directly from the delivery or storage container, e.g.: Tomato paste, honey, fats, icing, mascara and much more. pressure-controlled or level-controlled feeding of the products to filling machines or mixing processes.

Request for a quote

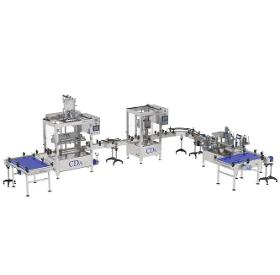

CDA

France

CDA’s Ninon Mix facilitates adhesive labelling on the sides and tops of square, cylindrical, ovalized, and conical products without requiring any material changes. This linear automatic labeller boasts the capability to apply up to 5 labels, with a labelling capacity reaching up to 60 products per minute depending on the packaging. The Ninon Mix stands out for its versatility and streamlined touch screen management, making it seamlessly integrable into a complete packaging line. This automatic labelling machine accommodates all formats and finds applications in various sectors, including: Food processing (sauce, honey, jam, oil, vinegar, mustard, etc.), Cosmetics (cream, perfume, body oil, soap, shampoo, etc.), Paint and varnish (buckets, cans, jars, etc.), Chemistry (dishwashing liquid, detergent, solvent, household products, etc.).

Request for a quote

CDA

France

On this line, filling is provided by the K Net Auto, an automatic machine that can fill up to 1,200 products / hour with an accuracy of +/- 0.5% of the dosed liquid. Depending on your industry and your product range, the K Net Auto will be equipped with a suitable dosing system (peristaltic, flowmeter, volumetric, etc.). Capping is carried out using the VS 400. This automatic capper is versatile and allows the capping of many cylindrical caps (caps with vertical grooves, dropper caps, pre-threaded screw caps, screw caps, hinged lids, etc. etc.). The operator manually places the cap onto the container which will then be detected and then automatically be capped (tightening torque set via the touch screen) by the capping head. Finally, the labeling is carried out by the Ninon Mix machine. This labeler is one of the most versatile in the CDA range. Square, cylindrical, oval, tapered products … Our labeler covers all of these containers with one to several labels.

Request for a quote

CDA

France

The K-Line S stands out as an enclosed linear filling machine, appreciated not only for its user-friendly nature and self-cleaning capabilities but also for its remarkable versatility. Tailored to the specific characteristics of your products, we employ the appropriate dosing system—be it volumetric, flowmetric, centrifugal dosing, among others. Remarkably, the K-Line S achieves a filling capacity of up to 3,000 liters per hour while maintaining a high level of accuracy at +/- 0.5%. Complementing this, the VS1000 capper, seamlessly integrated with a linear conveyor (or curved to suit your workshop layout), is also fully enclosed. This capping powerhouse accommodates an extensive range of caps, leveraging an electric screwdriver-operated capping system ideal for various cap types, including gun caps, spray caps, dropper caps, and more. To complete the packaging line, the Ninon Mix labelling machine takes center stage.

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

It’s a fully automatic counting and packing machine for Furniture kits and hardware spare parts like screws, bolts, nuts, washers, springs, and plugs. High precision and fast, save the labor cost you. Widely used in fasteners, hardware, furniture, and bathroom field. You only need to put the spare parts into the hopper and roll film on the packing machine, set in the quantity that you need to in the bag and open the machine. The machine will automatically count the spare parts and make the film to be a bag, filling the spare parts into the bag, sealing, and cutting. The lot number or other printing information is an optional device. Feature 1. According to screw/special parts sample tailored to the vibration plates with a precise count control device, to ensure that every bag is accurate and correct. 2. Adopts pneumatic structure, the whole machine is more secure, stable, and reliable. 3. Advanced PLC control system and various automatic alarm protection functions, convenient for daily

GEDA GMBH

Germany

The GEDA 300 ZP P, GEDA 500 ZP P and the 1500 ZP P have turned out to be efficient height access technology tools throughout the years. They have been transporting people and materials on asphalt producing plants, gravel plants, silos, etc. These transport platforms facilitate and accelerate regular inspections, service and maintenance. Often the producers of mixing machines use these hoist as a useful option for the ordinary stairs tower. They can also be additionally installed to already existing silos and plants without great effort and without any problems. This is possible thanks to low anchoring forces as well as to the fact that occurring vertical loads can be lead down to the basement via the mast. These transport platforms are a good-value for money alternative as you do not need a pit, a machine house and supporting constructions.

Request for a quote

GEDA GMBH

Germany

The GEDA 300 ZP P, GEDA 500 ZP P and the 1500 ZP P have turned out to be efficient height access technology tools throughout the years. They have been transporting people and materials on asphalt producing plants, gravel plants, silos, etc. These transport platforms facilitate and accelerate regular inspections, service and maintenance. Often the producers of mixing machines use these hoist as a useful option for the ordinary stairs tower. They can also be additionally installed to already existing silos and plants without great effort and without any problems. This is possible thanks to low anchoring forces as well as to the fact that occurring vertical loads can be lead down to the basement via the mast. These transport platforms are a good-value for money alternative as you do not need a pit, a machine house and supporting constructions.

Request for a quote

GEDA GMBH

Germany

The GEDA 300 ZP P, GEDA 500 ZP P and the 1500 ZP P have turned out to be efficient height access technology tools throughout the years. They have been transporting people and materials on asphalt producing plants, gravel plants, silos, etc. These transport platforms facilitate and accelerate regular inspections, service and maintenance. Often the producers of mixing machines use these hoist as a useful option for the ordinary stairs tower. They can also be additionally installed to already existing silos and plants without great effort and without any problems. This is possible thanks to low anchoring forces as well as to the fact that occurring vertical loads can be lead down to the basement via the mast. These transport platforms are a good-value for money alternative as you do not need a pit, a machine house and supporting constructions.

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The machine vacuum firstly,mix gases and fill gas mixture then sealing Thus, it provides high vacuum degree Ratio of gas mixture can be set accordingly to different food. After packed with modified gas it will prolong shelf lifemeanwhile maintain the origin taste,fresh colorand good nutrition. Application: All kinds of meat,fresh meat, aged meat, sausages, Seafood and fish,Dried fruits,Vegetables (processed by blanching, drying, or pickling),Ready to eat meals,Cheese (Not all cheese can be vacuum packed) Pasta, noodles totally dried cereals, corn kernels, peanuts, etc.

Do you sell or make similar products?

Sign up to europages and have your products listed

TEKNOVA PRINTING AND CHEMICAL INDUSTRY TRADE

Turkey

This water based printing ink is developed for surfaces with low absorbency like PE, OPP, such as plastic bags, films, diapers, big bag which requiring high print quality. Suitable for flexographic printing. PROPERTIES Thanks to its high adhesion and fast drying, it has superior performance even on non-absorbent surfaces. It is designed to provide high coverage on non-absorbent surfaces. Provides high color strength in printing. It has high brightness. APPLICATION Used as water based ink on flexographic printing machine. Mix well before use. Printing viscosity is 18-22 s (Din cup N°4). The product should be diluted with water. Packaging is 20KG tinplate bucket. * The information on this technical data sheet is based on our general experience.

Request for a quote

TEKNOVA PRINTING AND CHEMICAL INDUSTRY TRADE

Turkey

This water based printing ink is developed for high absorbency surfaces like napkins, diapers which are exposed to liquids such as water and oil. Suitable for flexographic printing. PROPERTIES It has high rub resistance and water resistance. It is designed to provide high coverage on absorbent surfaces. Provides high color strength in printing. It dries to allow high speed printing applications. APPLICATION Used as water based ink on flexographic printing machine. Mix well before use. Printing viscosity is 18-22 s (Din cup N°4). The product should be diluted with water. Packaging is 20KG tinplate bucket. * The information on this technical data sheet is based on our general experience.

Request for a quote

TEKNOVA PRINTING AND CHEMICAL INDUSTRY TRADE

Turkey

This water based printing ink is developed for coated and glossy surfaces like pizza box, label printing, paper bag printing which requiring high print quality. Suitable for flexographic printing. PROPERTIES It has superior performance in high quality printing with its high brightness and coverage. It is designed to provide high coverage on absorbent surfaces. Provides high color strength in printing. It dries to allow high speed printing applications. APPLICATION Used as water based ink on flexographic printing machine. Mix well before use. Printing viscosity is 18-22 s (Din cup N°4). The product should be diluted with water. Packaging is 20KG tinplate bucket. * The information on this technical data sheet is based on our general experience.

Request for a quote

TEKNOVA PRINTING AND CHEMICAL INDUSTRY TRADE

Turkey

It is used as water based ink in flexographic printing machines. This product is used in printing materials such as corrugated board, kraft lineer, test lineer, kraft bag, bag. PROPERTIES Designed to cover absorbent printing materials. Provides high color density in printing. Flawlessly, dries on high speed printing applications. Provides average water resistance and rub resistance. APPLICATION Used as water based ink on flexographic printing machine. Mix well before use. Printing viscosity is 18-22 s (Din cup N°4). The product should be diluted with water. Packaging is 20KG tinplate bucket. * The information on this technical data sheet is based on our general experience. The tests are carried out under controlled laboratory conditions. The information may change as conditions change. The performance of the product and the suitability of the print made depends

Request for a quote

FRIMO GROUP GMBH

Germany

The right mix is what counts. FRIMO offers tailor-made mix and metering machines including various standardized modules for PU product manufacturing.

Request for a quote

KMS-PT, S.R.O.

Slovakia

Pair of socks for the washing machine - Mix colors and separate colors sets

Request for a quote

ESTECHTIC EPS-EPP PROCESSING SOLUTIONS

Turkey

We can supply various types of EPS-XPS foam decoration machines - 2D/3D CNC cutting machines, thermopress or hot press machines, CNC routers, mortar mixing and coating machines and panel printers. For more information about our products and services, please visit www.estechtic.net. You can send your inquiries to fr@estechtic.net.

Request for a quote

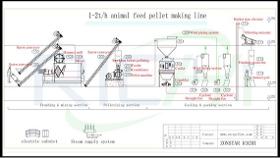

HENAN RICHI MACHINERY

United States

The feed pellet manufacturing line can process feed pellets for various animals, such as chickens, cattle, fish, pigs, rabbits and shrimps. Due to the pelleted feeds are nutritious, easy to digest and absorb, easy to store and transport, more and more farmers tend to make feed pellets for their animals. The main equipment in this manufacturing line are: animal feed pellet maker, feed crushing machine, feed mixing machine, feed cooling machine, feed packaging machine, etc. With 27 years of experience in in feed machinery manufacturing and development, RICHI Machinery can not only provides animal feed pellet production lines of various scale, but also can customized animal feed production business plan according every customers’ requirements. If you have any need in making feed pellets, welcome to contact RICHI, we will reply to you within one business day.

Request for a quote

ALCHEMIST TECHNOLOGIES

Turkey

•The machine works with an electric motor. • Feed mixer is produced in order to ensure a homogeneous mixture of different feeds and to distribute this mixture equally to animals. Thanks to this machine, feed utilization coefficients of animals are maximized. • Feed feed prepared with feed mixer is easier to digest. • A significant increase in the meat and milk yield of animals is achieved. • Feed (ration) prepared with feed mixer is more homogenous than the feeds which are fed by hand, this homogeneity allows the animals to eat more feed. • Meat consuming feed mix machine will consume feed at the same rate and with the same homogeneity. • Feed mixer fills fiber feed by chopper blades. It provides homogeneity by mixing the fiber feeds which are shredded with the other feed materials. In this way; fiber feeds are prevented from being digested without digestion.

Request for a quote

ALCHEMIST TECHNOLOGIES

Turkey

It is connected to the tractor by the towing system. • Takes the movement from the tractor tail shaft. • Hydraulic systems in the feed mixer machine provide a comfortable use by the ergonomic control arms extending up to the user. • Feed mixer is produced in order to ensure a homogeneous mixture of different feeds and to distribute this mixture equally to animals. Thanks to this machine, feed utilization coefficients of animals are maximized. • Feed feed prepared with feed mixer is easier to digest. • A significant increase in the meat and milk yield of animals is achieved. • Feed (ration) prepared with feed mixer is more homogenous than the feeds which are fed by hand, this homogeneity allows the animals to eat more feed. • Meat consuming feed mix machine will consume feed at the same rate and with the same homogeneity.

Request for a quote

TOSCANO AGRICULTURAL MACHINERY

Turkey

ROTARY TILLER is a tillage machine which mixes the soil with the help of horizontally rotating hoes. It is used for preparing the seed beds. The machine is commonly used on small fields, gardens and vineyards. It is a tillage machine that crumbles the soil so the seeds will find an easy way to grow. The machine mixes the plant wastes into soil homogeneously. Plant wastes, which are mixed with soil, make the soil more organic and fertile. A skid hydraulic system provides the user to shift the machine from the tractor’s control unit when the machine encounters a tree or a hard material. -Universal 3point CAT II Linkage -1 3/8’’ Z6 Spline PTO Protective Shaft -540 Gearbox provides 170rpm Rotor Speed -7 mm thick; C type high quality blades. -Transmission set with robust gears -2 slides -Adjustable & Flexible back cover -Hydraulic offset -36/42/48 blades; 6 blades per flange; 3 blades on side flanges.

Request for a quote

TOSCANO AGRICULTURAL MACHINERY

Turkey

ROTARY TILLER is a tillage machine which mixes the soil with the help of horizontally rotating hoes. It is used for preparing the seed beds. The machine is commonly used on small fields, gardens and vineyards. It is a tillage machine that crumbles the soil so the seeds will find an easy way to grow. The machine mixes the plant wastes into soil homogeneously. Plant wastes, which are mixed with soil, make the soil more organic and fertile. A skid hydraulic system with a sensor automatically shifts the machine when the machine encounters a tree or a hard material. -Universal 3point CAT II Linkage -1 3/8’’ Z6 Spline PTO Protective Shaft -540 Gearbox provides 170rpm Rotor Speed -7 mm thick; C type high quality blades. -Transmission set with robust gears -2 slides -Adjustable & Flexible back cover -Hydraulic offset -Automatic skid sensor device -36/42/48 blades; 6 blades per flange; 3 blades on side flanges.

Request for a quoteResults for

Mixing machines - Import exportNumber of results

54 ProductsCountries

Category

- Agricultural machines and accessories (8)

- Mixers (4)

- Hoists and elevators, construction (3)

- Labelling machines (3)

- Mixing machines for textile fibre (3)

- Varnishes (3)

- Axles, vehicle (2)

- Brick-making - machinery and equipment (2)

- Chemical industry - machinery and equipment (2)

- Packing and packaging - machinery and equipment (2)

- Paint mixers and grinding machines (2)

- Bakery - machinery and equipment (1)

- Bending machine tools (1)

- Bottling and filling - machinery and equipment (1)

- Concrete constructions (1)

- Concrete mixers (1)

- Concrete, ready-mixed (1)

- Construction - Machines & Equipment (1)

- Construction machinery (1)

- Dosing - machines and equipment (1)