- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- press machine

Results for

Press machine - Import export

MARTIN GROUP SRL

Italy

Fusing-Pressing Machines mod. EMS 120 Electronic control of whole equipment electromagnetic closing of plane, it guarantees accuracy of pressure automatic opening of the plane at the end of the planned working cycle "safe hands" safety system

Request for a quote

OGGO TECH MAKINA TEKNOLOJILERI SAN. TIC. LTD. ŞTI.

Turkey

Machine Manufacturing Industry, Pressing Machine, 42CrMo4-QT Material, 500 Kilograms

Request for a quote

YILMAZ MACHINE

Turkey

KP 120 machine is designed and constructed for the hydraulically crimping and correct assembly of aluminum profiles . The machine is semiautomatic and the machining cycle of various units are manual controlled by user who always stays outside of the dangerous area. It is designed through the hydrauliccally crimping system Steel construction of the machine table that is strong and lasting Practically adjustment of the knives according to the shape and height of the profiles Practically adjustment of the cylinder feed and profile stops by means of the milimetricruler The machine is equiped with the pneumatic (for clamps ) and hydraulic (for crimping ) foot pedals for the operation control during the machining cycle Double-acting centering setsquare returns to the home position under the table after crimping Powerfull hydraulic pump with 2 x 5 tons capacity Protection plates made of Polyamide material to prevent being scrathes on the profile surface

Request for a quote

SIMPAC EUROPE GMBH

Germany

Hydraulic presses are suitable for the high-precision forming of various parts, whereby the maximum press capacity is available in every position of the slide. In combination with their flexibility in terms of slide speed and dwell time, they are also particularly suitable for press hardening applications. Overview: ● Press capacity: 1,500 - 25,000 kN ● Part size: small, medium, large ● Application: for the production of drawn parts or as part of a press hardening line Description and benefits: ● Slide movement either pressure and / or travel-dependent ● Specially designed hydraulic system without shift shock during operation ● Motorized oil circulation with cooling or heating unit The models for press hardening are available in 8,000, 12,000 or 16,000 kN and come with a newly developed combination of servomotor and hydraulics that allows higher speeds in the closing and return movement of the slide.

Request for a quote

SIMPAC EUROPE GMBH

Germany

Compact and modular presses for a wide range of medium sized parts. Flexible installation options as a single press in progressive or transfer mode or as fully automated press line. Overview: ● Pressing capacity: 3,000 - 10,000 kN ● Component size: medium ● Slide kinematics: crank ● Applications: stamping, cutting, forming, bending, embossing Features and benefits: ● The compact design requires little floor space and no foundation at presses below 4,000 kN. ● The very solid, low-stress annealed press bodies are FEM-calculated and optimized by so-called “hot-spot analysis” in areas which are subject to higher loads. ● Motor, clutch/brake unit, lubrication system and control are of German origin and guarantee a long service life and maximum dynamics. ● The slide guiding system ensures a high level of tilting rigidity and reduces the cutting impact during the cut through when it comes to the processing of higher-strength materials.

Request for a quote

SIMPAC EUROPE GMBH

Germany

The PTS2 series is designed for prototype production, die set-up and modification work (including drawing, bending and punching tasks). The DSP series is especially suitable for die spotting. The mechanical micro inching system provides an accuracy of 0,05 mm. Overview: ● Press capacity: 300-20,000 kN ● Application: die testing tryout and production start-up

Request for a quote

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 3,000 - 10,000 kN ● Part size: small to medium ● Slide kinematics: servo (freely programmable) ● Application: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes through the use of torque motors that provide high torque even at low speeds ● Maximum production flexibility due to freely programmable slide movement, slide velocity and stroke length ● Significantly higher output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quote

SIMPAC EUROPE GMBH

Germany

C-frame presses are flexible solutions for manual work as well as for automated production processes. The CS is the all-rounder among the C-frame presses, while the ECS is ideal for punching and cutting operations with a higher degree of automation. Overview: ● Press capacity: 350-3,000 kN ● Part size: small ● Slide kincematics: crank ● Application: cutting, stamping, bending, embossing Description and benefits: ● Compact design, no foundation work required, good accessibility for maintenance ● Solid, low-stress annealed press body in monobloc design with minimal frame deflection ● Durable, wear-resistant and very quiet hydraulic clutch ● Casting slide with vibration dampening properties (ECS series) ● 4-fold slide guiding for a high tilting rigidity ● Hydraulic overload protection ● Production time as of 12 weeks

Request for a quote

SIMPAC EUROPE GMBH

Germany

The Scotch-Yoke drive of the DTL series has a modified link drive characteristic and reduces the slide speed during the forming phase. Thus the presses are not only suitable for cutting, punching and forming tasks, but also for drawing operations. The extra time that the material receives for plastic flow significantly increases the quality of the produced parts. The reduced impact speed of the slide extends the life of the press and the die. Overview: ● Press capacity: 6,000 - 30,000 kN ● Part size: large ● Slide kinematics: link ● Application: as a single press system either as progdie or transfer mode, as well as a press line Description and benefits: ● The outside located pressure points and a long 8-fold slide guiding system well compensate off-center loads, spare press and die and ensure a constant part quality. ● The automatic centralized lubrication system increases pro-ductivity and availability.

Request for a quote

SIMPAC EUROPE GMBH

Germany

Compact presses for a wide range of medium sized parts. Due to its drive-related slide kinematics, the MCL series is particularly suitable for drawn parts. Overview: ● Pressing capacity: 3,000 - 8,000 kN ● Component size: medium ● Slide kinematics: link ● Applications: stamping, drawing, forming Features and benefits: ● The compact design requires little floor space and no foundation at presses below 4,000 kN. ● The very solid, low-stress annealed press bodies are FEM-calculated and optimized by so-called “hot-spot analysis” in areas which are subject to higher loads. ● Motor, clutch/brake unit, lubrication system and control are of German origin and guarantee a long service life and maximum dynamics. ● The slide guiding system ensures a high level of tilting rigidity and reduces the cutting impact during the cut through when it comes to the processing of higher-strength materials.

Request for a quote

HIDROKAR HYDRAULIC PRESS MACHINES INDUSTRY

Turkey

Our manufacturing style is user-oriented, and we manufacture in different features, heights, widths,tonnages through our customers' desires and options. The machines and the matarials used in manufacturing process are durable , you can utilize for many years.

Request for a quote

HIDROKAR HYDRAULIC PRESS MACHINES INDUSTRY

Turkey

Our manufacturing style is user-oriented, and we manufacture in different features, heights, widths,tonnages our customers' desires and options. The machines and the matarials used in manufacturing process are durable , you can utilize for many years.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Press&snap capping machine is used for snapping press type caps, including three main parts: cap feeding system, cap loading system and cap snapping system. It is characterized by its simple structure and high qualification rate. Can be used alone or inline. Linear design makes it suitable for various caps & bottles with good adaptability, widely used for pressing jar cap, plastic bottle cap, can caps, in industries like food, beverages, cosmetics, chemicals,etc. The machine use the straight line into the bottle, automatically arrange caps, sleeving caps ,caps after sleeve and check will go into the gland system by the clamping belt. Due to the lid-cover flat belt design have a drop of slop, the caps after press will become more and more tightly.The machine has simple structure, convenient adjustment, production speed fast, high pass rate, after cap pressing has good performance, suitable for cap pressing of foodstuff, soy sauce, vinegar, vegetable oil’s bottle shape.

Request for a quote

METAL IN LTD

Bulgaria

The modern equipment with CNC machines, which we possess allow us to work sheet iron with thickness till 18 mm and dimensions 1500x3000 mm. These products are with high quality, precise manufacturing and excellent external look. Thank to different machines and equipment (lazer cutting, stamp press, punching, shears, eccentric and hydraulic presses, machine shafts, bending machine for metal sheets straightening , spot welding, robotic MIG-MAG welding, WIG welding, powder coating. The company produce big variety of products as the more important are: Hydraulic reservoirs Metal boxes for electronics Wardrobes Cabinets for instruments Metal cabinets for coffee machines Front panels for professional speakers Fireplaces, burners and barbecues Gun safes and storage of documents Control panels for machines Doors and lids for machines and vacuum cleaners Equipment for stores Lamps for lighting Steps of excavators

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Our metal work unit is equipped with all the equipment required to carry out the majority of operations related to the production and shaping of metal objects: mortising machine, press, drilling machines, rolling machines, semi-automatic welding stations and TIG/Plasma/Oxycutting workstations. Our vast range of metal work equipment and the adaptability of the workshop’s covered areas are ideal for performing almost every type of shaping.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

In addition to being able to work on site in an emergency to diagnose an unexpected breakdown and repair your installation, we are equipped with: a comprehensive machine fleet (numerically-controlled machining centres, lathes and milling machines, mortising machine, press, drilling machines, rolling machines, semi-automatic welding station, TIG/Plasma/Oxycutting station) meaning that we can manufacture products to measure and supply all your replacement and wear parts in an emergency an assembly workshop (mechanics, hydraulics, pneumatics, electrics, automation), lifting equipment and testing and programming stations, where mechanical and electrical assemblies and sub-assemblies can be produced urgently and with a high degree of flexibility

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Numerically-controlled hydraulic press brake, numerically-controlled hydraulic shearing machine, numerically-controlled machining centres, numerically-controlled lathes and milling machines, mortising machines, presses, drilling machines, rolling machines, semi-automatic welding station, TIG/Plasma/Oxycutting workstation, paint booth, assembly workshop (mechanics, hydraulics, pneumatics, electrics, automation), lifting equipment, testing and programming workstations, etc. With our diverse range of facilities and modular covered areas, we can manufacture practically any type of installation or equipment, with unlimited space and technological expertise. Our multidisciplinary team of highly qualified specialists, combining long-standing experience with the technical skills of youth, guarantees the optimal operation of our equipment and the quality of the facilities delivered to you.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STANDART ALUMINIUM

Turkey

Our dynamic mechanical processing team with deep measurement precision and surface quality, precision single head, double head angled cutting saws, undercut saws, punch machines, solar frame machines, eccentric presses, hole drilling drills, tapping machines, CNC benches, perfect quality and offers superior service

Request for a quote

TEKNIK CIZGI KESIM BUKUM METAL SAN VE TIC LTD STI

Turkey

Metal sheets of various types and thicknesses are produced quickly and at low cost by making millimetric calculations on computer-controlled machines. Thanks to the pressure force that can be applied from 35 tons to 640 tons with press brake bending machines, materials up to 6000 mm in length and up to 20 mm in thickness can be processed.

Request for a quote

BORNEMANN GMBH

Germany

Machine stamping presses with peg or threaded hole for mounting onto a press. For standard stamping presses we also offer font sizes of 1 to 10 mm with 11 labelling fields on the wheel circumference here. By removing the pin stop, the wheels can be easily rotated, which allows setting the desired combination.

Request for a quote

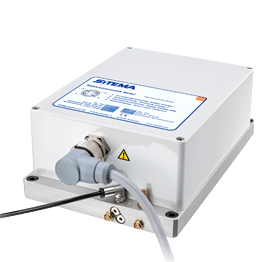

SITEMA GMBH & CO KG

Germany

Mechanical Valve Actuator MVA Rod leaving clamping head Auto Bleeder Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electropneumatic module EPM The Electropneumatic Module EPM acts as interface between (electrical) power supply / control and a pneumatic SITEMA clamping head. All pneumatic SITEMA clamping heads with an operating pressure of up to 4 bar and an operating volume of up to 220 cm³ can be pneumatically controlled by the EPM. It is also possible to operate several clamping heads in parallel with one EPM. The EPM is controlled by a 24V supply and switching voltage. The outlet pressure which is required to open or keep open a pneumatic clamping head is controlled by a control signal. If the voltage fails or the input signal is switched off, the pressure is...

Request for a quote

SITEMA GMBH & CO KG

Germany

KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electric Locking Unit The electric Locking Unit KFE is used as a stepless locking device on round rods and holds axial forces in both load directions without axial play. It is used where hydraulic or pneumatic solutions are not possible. The holding force is created by the proven spring-operated clamping system as it is used in SITEMA’s hydraulically or pneumatically operated Locking Units. At a drop of the control voltage or in case of failure of the electric supply, the Locking Unit KFE clamps automatically. Therefore, it is also suitable for use in safety relevant applications. To operate the Locking Unit KFE, a supply voltage of 24 V and a control signal for the input command “clamp/release” are sufficient. The Locking Unit is self-monitoring and provides output signals...

Request for a quote

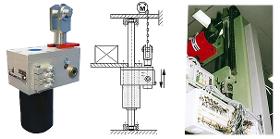

SITEMA GMBH & CO KG

Germany

KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Mechanical Safety Catcher The Mechanical Safety Catcher KRM is operated purely mechanically and requires neither a hydraulic nor a pneumatic system for control. The clamping head is kept open mechanically and acts upon rupture of the suspension (rope, belt, chain, etc.). The energy of the falling mass is then used to generate the clamping force. In applications where lifted loads can be dangerous in case of rupture of the suspension device, Safety Catchers KRM are used to protect people and assure accident prevention. Safety Catchers KRM secure the load at any point of the stroke in a mechanically safe and absolutely reliable way. Due to the principle of self-reinforcing clamping, a very high level of safety is reached. Application example Packing...

Request for a quote

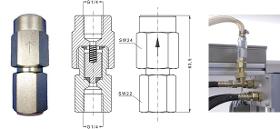

SITEMA GMBH & CO KG

Germany

Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Auto Bleeder The SITEMA Auto Bleeder has been specially designed for the use with a SITEMA clamping head. It makes sure that the hydraulic system is constantly bled. Air bubbles in the hydraulic fluid might combust spontaneously under certain conditions (so-called Diesel effect). As a consequence, seals and sealing surfaces can be damaged, causing leakages. Clamping heads are especially susceptible for this phenomenon, as they have only a very small hydraulic volume and are not flushed through at each activation. Air can therefore easily accumulate in the clamping head. This is the reason why the usual initial bleeding at commissioning is often not enough, especially when the line leading to the clamping head points upwards...

Request for a quote

SITEMA GMBH & CO KG

Germany

Rod leaving clamping head Auto Bleeder Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Mechanical Valve Actuator MVA Secure the rupture of a chain with the full comfort of a pneumatic SITEMA clamping head When a load has to be secured against rupture of a suspension device (e.g. a chain), many customers use our Mechanical Safety Catcher KRM. This unit has the advantage to hold the load immediately upon rupture of the suspension device. Additional sensors to detect rupture of a chain are not necessary. On the other hand, it is not possible to activate the KRM in a user-defined position without rupture of the suspension device, e.g. for maintenance purposes. Here, the Mechanical Valve Actuator MVA comes to your rescue. It is simply put between the suspension device and the...

Request for a quote

BORNEMANN GMBH

Germany

Manual stamping presses for steel, tool and machine engineering for simply labelling of multi-digit texts. For standard stamping presses we offer font sizes of 1 to 10 mm with 11 labelling fields on the wheel circumference. By removing the pin stop, the wheels can be easily rotated, which allows setting the desired combination. The striking cap can also be replaced.

Request for a quote

MICRON AMERICA

Turkey

All dies, sold separately. Its dependability and affordable pricing makes this machine a perfect entry level hand press machine which is ideal for people who don’t use a large variety of fastener products. This machine is a low cost machine perfect for the semi professionals that install snaps, rivets, jean button and self piercing grommets up to size #3.

Request for a quote

MICRON AMERICA

Turkey

All dies, sold separately. This machine can accommodate every die we manufacture Simple straightforward design allows even a novice to professionally set grommets, rivets and snaps. Portable design allows you to take it to a job site. The Micron M 3 is our favorite manual fastener press. The versatility of this amazing fasteners press is simply unmatched as far as manual fastener presses are concerned. 1. Versatile The Micron M 3 is specifically designed to attach curtain grommets size #12 # 15 and #18. The M 3 does a great job of installing curtain grommets. This is rare for a manual grommet press the size of the M 3. If you are looking for a portable manual grommet press to attach curtain grommets, this is it. This resourceful Grommet Press does a lot more than install curtain grommets. Because of its ability to accommodate interchangeable dies, the M 3 is one of the most versatile fastener attaching machines available today.

Request for a quote

MICRON AMERICA

Turkey

The Micron Tep 3 machine is the machine that bridges the gap between the hobbyists and professionals. The free standing or bench mounted feature of this machine makes it top of the line choice as its deep frame feature allows a comfortable work space and can easily be transported to the job site. The machine is made out of heavy duty cast iron and will last you for years to come. This machine will accommodate all fastener installations up to size #5 grommets. The Micron TEP 3 is the grommet press that bridges the gap between hobbyists and professionals. The Professionals like this machine because it is a fully capable well built machine that is light weight so it is easy to carry from station to station in the shop and to outside jobs. The hobbyists love this grommet press because they can get professional results at very affordable price.

Request for a quoteResults for

Press machine - Import exportNumber of results

134 ProductsCountries

Company type

Category

- Metal industrial presses (13)

- Roofing contractors (5)

- Cutting - machine tools (4)

- Motor mechanics - hand tools, non power (4)

- Presses, hydraulic (4)

- Steels and metals - forming and cutting (4)

- Aluminium and aluminium alloys (3)

- Bending - steels and metals (3)

- Bending machine tools (3)

- Chemical industry - machinery and equipment (3)

- Handling trolleys (3)

- Laser - cutting and welding machines (3)

- Lubricants, industrial (3)

- Machine tools, cutting - parts and accessories (3)

- Resins (3)

- Vertical storage cabinets (3)

- Automation - systems and equipment (2)

- Industrial cutting machine tools (2)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (2)

- Mechanical surface treatment - machinery (2)