- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- roller conveyors and driven roller conveyors

Results for

Roller conveyors and driven roller conveyors - Import export

KRAUS BETRIEBSAUSSTATTUNG UND FÖRDERTECHNIK GMBH

Austria

Power-driven conveyor rollers are used with round belts, Multi-W belts, toothed belts or chain drives. Power-driven conveyor rollers can be used for goods with a wide range of load-bearing capacities.

Request for a quote

MOSCA GMBH

Germany

• Top-mounted SoniXs ultrasonic sealing unit • Up to four strap lances for palletized products • Strap guide distance of 440, 625 and 810 mm • 1 or 2 sealing units laterally movable • Siemens PLC control system • Operation via Siemens 9” touch panel • Can be integrated into any production line • Potential-free contacts to upstream and downstream machines • Strapping with medium compression [up to 30,000 N – version KC_] • Strapping with high compression [up to 50,000 N – version KP_] Different Models: [K_R] Basic Model \ Driven roller conveyor [K_K]-Version \ Driven roller conveyor with lift turncross [K_Z]-Version \ Driven roller conveyor with centering device [K_A]-Version \ Driven roller conveyor with lift turncross and centering device [K_T]-Version \ Driven roller conveyor with turntable [K_S]-Version \ Driven roller conveyor with turntable, laterally moveable

Request for a quote

LANGHAMMER GMBH

Germany

Advantages • Complete building block system with modular standard components • Individually planned conveyor units, fine-tuned to task requirements • Large assortment of pallet transport technology: • Pallet Roller Conveyors • Pallet Chain Conveyors • Pallet Buffer Conveyors • Pallet Turntables • Pallet Transfer Units • Pallet Shuttle Cars • Empty Pallet Dispensers • Empty Pallet Testers • Pallet Lifts Just some of the tasks for which Langhammer offers the right solution: stacking or separating empty and full pallets, transporting pallets on different transport levels, a wide range of roller conveyors available up to driven roller conveyors with reversible transport direction and high pulling power, driven roller conveyors for lowest building heights, transfer units and turntables enable flexible pallet transport, connect transport lines and change transport direction of the pallet as required.

Request for a quote

LANGHAMMER GMBH

Germany

Advantages • Quick throughput times, high processing exactness as well as improved working conditions through optimally planned material flow • Compatible components reduce interfaces • Large assortment of standard components: Belt Conveyors: • Curved Belt Conveyors • Small Belt Conveyors • Inclined Belt conveyors Roller Conveyors: • Wheel Conveyors • Light Roller Conveyors • Roller Conveyor Curves • Gravity Roller Conveyors • Driven Roller Conveyors Chain Conveyors: • Chain Conveyors • Traction Lifts Product transportation is an essential element of in-plant logistics. Exact and precise handling is a prerequisite for optimal material flow. Belt conveyors are ideal for transporting light to moderately heavy products. Roller conveyors can be adapted to a variety of space conditions. They are used for transporting light as well as heavy products, are impervious to dust and thus ideal for use in dusty environments.

Request for a quote

FEMIA INDUSTRIE

France

Saws the husked ears of corn into several pieces (1 to 3). Capacity (automatic feeding version) of 110 ears/minute with the ACC feed system of the cutter. Capacity (manual feeding version) of 60 ears/minutes with two operators. Machine primarily comprised of an automatic feed (automatic feeding version only), a roller conveyor and a cutting head with circular saws. For the two versions, an operator manages the orientation of the ears on the conveyor belt Roller conveyor for visual control and feeding the saw. Adjustment of the cutting of the ends of the ears and of the pieces for a desired length.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The BestFlex Roller is excellent for handling oddshaped boxes, bags and lowgrade cartons in low to medium volume applications. Designed to expand, contract and move easily, the BestFlex Roller is a selftracking, gravity roller conveyor that has a per linear foot capacity of 220Kg per linear metre. The allsteel frame construction provides unmatched structural integrity, whether the conveyor is extended, contracted or configured in simple or compound curves. It is the best choice for moving items without a flat, solid surface. SelfTracking Cartons follow the path of the conveyor without using engineered curves. Adjustable Height Telescopic leg sections are used to raise or lower the conveyor height. Square Tubing Legs Heavyduty square tubing legs offer longer service life and stability. 40mm Side Plate Aluminium alloy construction features a ribbed design for added strength. Assembled with bolts and locking nuts. Castors with Brakes 127mm x 38mm Swivel Castors allow easy movement.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Flexible powered conveyors provide maximum productivity in shipping, transportation and packaging applications where usability and adaptability are most needed. With its innovative design, the PowerFlex15 powered roller conveyor requires less storage space when fully retracted and can service multiple docking doors for maximum productivity. By powering the conveyor, any package size can be moved, any distance at variable rates of speed. This powered conveyor has a capacity of 150Kg per linear metre. The PowerFlex15 also features an easy and quick way to change out the drive belts giving you added durability and less maintenance downtime. Continuous Duty Multiple Drive Motors Line speed is adjustable from 0 to 36 metres per minute. Start/stop controls at both ends. Self Tracking Cartons follow the twists and turns of the conveyor path without using engineered curves. Adjustable Height Telescopic legs to raise or lower the conveyor bed height.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

With its innovative design, the PowerFlex19 powered roller conveyor requires less storage space when fully retracted and can service multiple docking doors for maximum productivity. By powering the conveyor, any package size can be moved, any distance at variable rates of speed. It is an allpower conveyor that has a capacity of 150Kg per linear metre. The PowerFlex19 features an easy and quick way to change out the drive belts giving you added durability and less maintenance downtime. Flexible power conveyors provide maximum productivity in shipping, transportation and packaging applications where usability and adaptability are needed. Continuous Duty Multiple Drive Motors Line speed is adjustable from 0 to 36 metres per minute. Start/stop controls at both ends. Self Tracking Cartons follow the twists and turns of the conveyor path without using engineered curves. Adjustable Height Telescopic legs to raise or lower the conveyor bed height. Square Tubing Legs

Request for a quote

FERPLAST SNC

Italy

Idler roller conveyors made of a sturdy structure in painted steel, supports with adjustable and height-adjustable feet, galvanized steel rollers with rotation on shielded ball bearings. In this position a convenient and economic box holder has been installed and allows the operator to lock and fill the box in comfort. Once the filling is complete, the operator can detach the box by simply pushing it forward.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The implementation of impact absorber stations provides effective protection against damage to the conveyor belt in the loading area. The belt is often pierced by sharp, large and bulky goods. Specially manufactured stations supporting impact bars absorb the impact speed. Repair and maintenance costs are thus reduced. In addition, the life expectancy of the conveyor belt and conveyor system is extended as well as the operating conditions significantly improved. Further advantages no jammed rollers causing belt misalignment absorb the drop energy, support the conveyor belt instead of the conveyor rollers in the transport area of the conveyor system and make a reliable running of the belt possible whilst ensuring the least possible friction. infinitely variable alignment to the angle of inclination by means of spindle displacement possible better material sealing due to adjustment of the material guide to within a millimetre

Request for a quote

NOVELTY STEEL

Turkey

While various idlers have been developed to perform adequately in different installations, determining the most appropriate one remains a challenging task. The primary function of an idler roll is to provide load support with minimal resistance to movement, particularly addressing radial loading from the belt and materials across specific idler spacing. This role encompasses absorbing impact at the loading point and managing belt tension in curved sections, which can be challenging to quantify. Modern conveyor design methods have enhanced our comprehension and control, providing clearer insights into idler implications. Assemblies of idler rolls are strategically designed to influence the belt profile, often forming a trough or tube. It’s essential to acknowledge that the trough’s shape, consistency, and flexibility significantly impact idler roll behaviour.

Request for a quote

FERPLAST SNC

Italy

FREE ROLLER CONVEYORS DIAMETER MM. 60 AND PITCH MM. 80 FOR PALLETS The free roller conveyors P80 are characterized by a rollers diameter of mm. 60 mm and pitch mm. 80 and are the ideal solution when handling pallets, containers with reduced base and standard pallets with cross feed. They consist of a robust structure coated steel profile, with fixable supports and adjustable feet. The rollers are of high quality made of galvanized steel. Rotation on shielded ball bearings with permanent lubrication. The roller conveyors are built according to the scale, size and characteristics of packages to be handled.

Request for a quote

FERPLAST SNC

Italy

IDLE ROLLER CONVEYORS EXTENSIBLE WITH METAL ROLLERS Roller conveyors extensible with metal rollers for handling boxes, cassettes and packages with a flat base. They are normally positioned at the outlet of packaging machines and taping machines for the accumulation of packages and allow to realize different forms of route with curves up to 180 ° (depends on the length of the roller conveyor). The roller conveyors are equipped with supports with wheels with brakes and they are easily extendable and resealable, they can thus be moved and stretched, taking up very little space when not used. The movement of the boxes occurs by gravity and the box stopper terminal (included) avoid the fall. The roller conveyors with width mm. 800 are equipped with central pantograph to make the structure more robust. Standard supports are adjustable in height from mm. 650 to mm. 900 but on request you can have supports with height mm. 450-650 (same cost) or mm. 950-1250 with increase.

Request for a quote

FERPLAST SNC

Italy

EXTENDABLE MOTORIZED ROLLER CONVEYORS SERIES REM The motorized extensible roller conveyors are designed for moving boxes and packages with flat surfaces. They are normally positioned in automatic lines and used for the accumulation of the boxes. They are equipped with legs with wheels and are easily extendable and closable. They can then be moved and stretched, taking up very little space when not in use. Series of roller conveyors with pantograph painted steel structure equipped with wheels with brakes, galvanized steel rollers diameter mm. 50, variable wheelbase based on the extension of the roller conveyor, Supports adjustable galvanized steel with height mm. 650/850, gear motors with start / stop switch (for each module). Motorized extensible roller conveyors are available in different models with width mm. 500-650-800 maximum length ranging from mm. 1400 to mm. 6900.

Request for a quote

FERPLAST SNC

Italy

Roller conveyors extensible with metal rollers for handling boxes, cassettes and packages with a flat base. They are normally positioned at the outlet of packaging machines and taping machines for the accumulation of packages and allow to realize different forms of route with curves up to 180 ° (depends on the length of the roller conveyor). The roller conveyors are equipped with supports with wheels with brakes and they are easily extendable and resealable, they can thus be moved and stretched, taking up very little space when not used. The movement of the boxes occurs by gravity and the box stopper terminal (included) avoid the fall. The roller conveyors with width mm. 800 are equipped with central pantograph to make the structure more robust. Standard supports are adjustable in height from mm. 650 to mm. 900 but on request you can have supports with height mm. 450-650 (same cost) or mm. 950-1250 with increase.

Request for a quote

FERPLAST SNC

Italy

MODEL RG - FREE ROLLER-COATED DIAMETER 32 MM - PITCH 40 MM FOR SMALL AND FRAGILE PACKAGES Free rollers conveyors that consist of sturdy painted steel 2 mm thick, 50x25 mm tubular support, legs fixable on floor and adjustable in height, 32 mm diameter steel rollers coated with rubber, rotating on ball bearings (8mm axle). The versions with a width of 1000 mm consist of a 2-roller axis with central support. This solution allows to have a greater flow rate that reaches up to 90 Kg/m.

Request for a quote

FERPLAST SNC

Italy

Extendable roller conveyors with plastic wheels and galvanized steel pantograph structure for handling boxes, cassettes and packages with a flat base. They are normally positioned at the outlet of packaging machines and taping machines for the accumulation of packages and allow to realize different forms of route with curves up to 180 ° (depends on the length of the roller conveyor). The roller conveyors are equipped with supports with wheels with brakes and they are easily extendable and resealable, they can thus be moved and stretched, taking up very little space when not used. The movement of the boxes occurs by gravity and the box stopper terminal (included) avoid the fall. The roller conveyors with width mm. 800 are equipped with central pantograph to make the structure more robust. Standard supports are adjustable in height from mm. 650 to mm. 900 but on request you can have supports with height mm. 450-650 (same cost) or mm. 950-1250 with increase.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FERPLAST SNC

Italy

STANDARD MODELS WITH FREE ROLLER DIAM. MM 50 - PITCH MM. 75 FOR MEDIUM AND LARGE PACKAGES Roller conveyors consist of a sturdy structure profiled in painted steel, with supports legs fixable to the floor and adjustable in height, rollers in galvanized steel with rotation on shielded ball bearings. The roller conveyors are built according to the capacity and size of the boxes to be handled.

Request for a quote

FERPLAST SNC

Italy

STANDARD MODELS WITH FREE ROLLER DIAM. MM 32 - PITCH MM. 40 FOR SMALL PACKAGES Roller conveyors consist of a sturdy structure profiled in painted steel, with supports legs fixable to the floor and adjustable in height, rollers in galvanized steel with rotation on shielded ball bearings. The roller conveyors are built according to the capacity and size of the boxes to be handled.

Request for a quote

FERPLAST SNC

Italy

It can be realized in economic manner and with reduced overall dimensions with roller conveyors curves up to 180 °. This type of roller conveyors are an economical solution to the problem of handling boxes and packs along 90 ° or 180 ° paths, avoiding the use of more expensive pneumatic diverters. The idle 90 ° curves can be combined to obtain 180 ° curves, and allow you to create packaging lines even in confined spaces, thanks to their small footprint. They have widths of 500-650-800 mm and can be equipped with metal wheels with a diameter of 48 mm, or metal rollers with a diameter of 32 or 48. The metal wheels, thanks to their particular smoothness, allow the advancement of the boxes also with a minimum inclination.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

DAMBACH roller conveyors consist of a stable frame with rollers bolted in place. The rollers are driven by an easily serviced tangential chain drive with tensioning unit housed in a drive enclosure. The entire drivetrain is enclosed for safety and to prevent tampering. Flanged wheels rotate with the rollers to help transport goods carefully. The frame is height-adjustable. DAMBACH chain conveyors consist of self-supporting chain strands mounted on a rigid frame. The number of strands can be varied to suit the application. Duplex chains with straight side plates guarantee careful transport of your goods on an optimised support surface. Chains are supported on low-friction slide rails and can be individually tensioned. All chain strands are driven via a common driveshaft fully enclosed for safety. The mounting frames bolted to the main frames are height-adjustable. High throughput rates Travelling speed up to 0.5 m/s and acceleration up to 0.8 m/s² Max. 1500 kg per storage position

Request for a quote

TIKIR MACHINE INDUSTRY

Turkey

Roller conveyor disc transfer line is used for the transfer of yarn bobbins. It has been specially designed. It is a turnkey project with barcode readers, bagging machine, robot centering and separator systems and diameter measuring mechanisms. It was designed by our talented engineers in Tıkır Makina design offices, manufactured in our 3000 square meter indoor facility, and assembled on site by our trained personnel. Tıkır Makina has been producing vertical and horizontal transfer systems for the industry since its establishment. It has the ability to produce conveyors, elevators, autonomous driverless forklifts and special design projects according to your needs. We have worked with world giant automotive brands such as Ford, Toyota and Fiat. It has cooperated with world-renowned textile companies and has been a solution partner in the transfer systems of dozens of companies in Turkey, including textile, food and heavy industry. We are ready to listen to you.

Request for a quote

BEHA INNOVATION GMBH

Germany

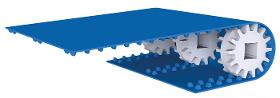

The positive driven AT5 conveyor belts from BEHAbelt enable slipfree traction, even with the smallest pulley diameters of only Ø 18 mm. This means that even conveyor sections with the smallest transfers can now be utilized with a slipfree belt solution. In combination with a maximum belt width of up to 700 mm, the new product series from BEHAbelt represents a new product solution which once again shifts the previous limits of the possible applications of positivedriven belt solutions on the market. This makes the positive driven conveyors perfect for applications that require precise timing, positioning and reversing. The low preload minimises the bearing load and thus reduces the energy requirement as well as the maintenance effort.

Request for a quote

MAFDEL

France

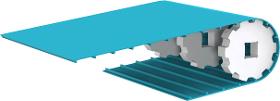

Positively driven conveyor belts POSITIVEBELT offer an exceptional guidance thanks to the dual rows of teeth. The perfectly smooth upper face facilitates the cleaning and helps maintaining a high hygiene level. Compliant with the strictest standards, the POSITIVEBELT is also resistant to abrasion and cut. The POSITIVEBELT can be equipped with accessories (cleats, sidewalls, scrapers...) to meet the conveyance constraints.

Request for a quote

MAFDEL

France

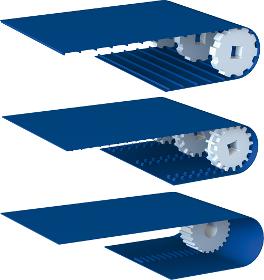

The range DEL/DRIVE conveyor belt is the ideal alternative to conventional modular belts: it can replace a modular belt without any modifications. To meet all needs, DEL/DRIVE range is composed by several versions: - DEL/DRIVE 50: Made in polyurethane, it is both flexible and resistant and has high tensile strength. - DEL/DRIVE 25: The pitch of 25mm allows using smaller diameter of sprockets. The space required is thus reduced, and the transfer of the transported products is facilitated. - DEL/DRIVE 50H: Made in polyester elastomer, it is recommended for the transport of medium to heavy-weight - DEL/DRIVE 50AM: It benefits of an antimicrobial treatment which improves the hygiene level. - DEL/DRIVE 50AMEM: It also benefits of an antimicrobial treatment and has an embossed upper face that reduced the adherence of transported products. - DEL/DRIVE 50EMLT: It works in very low ambient temperatures and its embossed upper face facilitates the conveyance of frozen poducts.

Request for a quote

MAFDEL

France

Positive drive conveyor belts associate advantages of modular belts and monomaterial conveyor belts without their disadvantages. The hygiene level is thus optimized, and the risks of slippage are eliminated. MAFDEL proposes 3 positively driven conveyor belts: - DEL/DRIVE: The alternative ideal to conventional modular belts - POSITIVEBELT: The self-tracking positive belt - DEL/SYNC: Fully synchronous drive The positive drive conveyor belts can be equipped with accessories (cleats, sidewalls…) and are adapted to many conveyor configurations: inclined, swan-necked, bidirectional, troughed conveyor… The whole range is compliant with the strictest hygiene standard, and contribute to meet the needs of HACCP requirements.

Request for a quoteResults for

Roller conveyors and driven roller conveyors - Import exportNumber of results

32 ProductsCompany type

Category

- Conveyor systems (19)

- Conveyor belts (11)

- Packing and packaging - machinery and equipment (2)

- Palletising machinery (2)

- Turning - steels and metals (2)

- Conveyors, overhead and floor (1)

- Flour milling - machinery and equipment (1)

- Storage equipment and systems (1)

- Wheels, castors and rollers - metal (1)