- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- servo controller

Results for

Servo controller - Import export

ÖZKA MACHINE AUTOMATION

Turkey

Photocell Control For Jumbo Film Rupturing Jumbo Edge Motor Control System Edge Folding System Adjustment Oscillation System (Synchronous With Machine Speed) Servo Motor Controlled Rewinding System Omron Brand Servo Motors Omron Brand Plc System Omron Brand 7" Touch Panel

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Multiple sets of servo motors are used to control all the emotion movements of the screw capping head.Use servo control the torque without damaging the caps.

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

width 68 cm age 2006 servo punch machine computer control with monitor touch screen Delivery time: immediatelly from stock Ref: BO240057A Please ask for price. We ship and install worldwide!

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

NP-TS two sides labeling machine is Mostly applicable for square, flat bottles, round containers for medicine, daily chemical, cosmetics, food cultural supplies, Electronic and etc. Advantages: 1. PLC CONTROL, Automatically check the length of labels 2. Equipped with warning device of insufficient labels, broken labels 3. No bottle, no labeling 4. No labels, no labeling 5.Servo motor control, stable labeling

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

it is widely application for the container pasting with two front and back labels, it is one type of self adhesive labeling machine, single and double side labeling is option, using for round container, square and flat container, also carton, boxes ,ect. It is automatic controlled by PLC easy operating. It can change specifications easily. It adopts servo motor, achieved closed loop control low malfunction rate. High efficiency. Double sides labeler we also call it as front and back labeling machine, for it is pasting two labels front and back. Advantages: 1. PLC CONTROL, Automatically check the length of labels 2. Equipped with warning device of insufficient labels, broken labels 3. No bottle, no labeling 4. No labels, no labeling 5.Servo motor control, stable labeling

Request for a quote![UNITEST M1 [Universal Testing Machine]](/filestore/vig280/opt/product/7d/3c/product_63644fce.jpg)

EC PLAZA

South Korea

Universal Testing Machine is a representative test equipment for physical properties. It is capable of measuring load, strength, elongation of products or materials such as rubber, film, plastic, metal, etc. - Frame Load Capacity (Max.) : 5kN - Main Load Cell : 5kN - Load Range : 50 (kgf) ◀(Up to 4-step conversion) - Column Type : Single Column - Load Accurancy : Less than ±0.5% - Crosshead Speed Range : 0.01 ~ 500mm/min - Load Resolution : 1/50,000 - Machine Controller : Touch Type Servo Controller(Position Control Type) - Test Category : Tensile, Tear, Peel, Compression, Bending, Repeat, etc. - Dimensions : 478× 650× 1375(H), 82kg - Main Power : AC 220V 2P, 50/60 - It is single column model that can be tested under 5kN. - UNITEST M1 is widely used for testing materials such as films, rubber, fibers, medical devices, biomaterial, and wires etc. - The main feature of the UNITEST M1 is that it requires a small footprint

Request for a quote

SAMSYS GMBH

Germany

The basis of short bar loader Multi 3000SL was developed in Switzerland. It was specially designed for turning machine types with a large distance between machine cover and spindle end. The bar feeder is supplied as standard with a Z-axis sliding unit to ensure free access to the Spindle Liner. This makes it easy to change the spindle insert tube. The Bar Loading Magazine is manufactured in Germany with first-class materials and components. The MULTI-3000SL guarantees long-term reliability. It impresses with its service and environmentally friendly design. It is also a fully electric and servo-controlled magazine. Due to the easy access to all parts it is extremely user-friendly. It is very simple to understand and therefore easy to operate. Due to the well thought-out design, set-up and changeover is possible within 2-5 minutes. The patented lifting mechanism guarantees an impact-free and fast loading cycle.

Request for a quote

SAMSYS GMBH

Germany

The short bar loading magazine Multi 3000 was developed in Switzerland. Manufactured in Germany with first-class materials and components. The MULTI-3000 guarantees long-term reliability. It impresses with its service and environmentally friendly design. It is also a fully electric and servo-controlled magazine. Easy access to all parts makes it extremely user-friendly. It is very simple to understand and therefore easy to operate. Set-up and changeover is possible within 2-5 minutes due to the well thought-out design. The patented lifting mechanism guarantees an impact-free and fast loading cycle. Further features are the smooth material feed, an optimal control and monitoring of the material feed, as well as the exact positioning of the bar without mechanical stop. Due to its design, the Multi 3000 does not require a shifting device to change the Spindle Liner. A shifting device is optionally available in X- and Z-axis and in different lengths.

Request for a quote

SAMSYS GMBH

Germany

The small bar feeder Samsys Smart impresses with its high performance in a very small space. The bar feeder is manufactured in Germany with first-class materials and components. The Samsys Smart guarantees long-term reliability. It impresses with its service and environmentally friendly design. It is an electro-pneumatic magazine. This means the feed is servo-controlled and the reloading mechanism is pneumatic. Due to the easy access to all parts it is extremely user-friendly. This makes it very simple to understand and easy to use. Set-up and changeover is possible within 2-5 minutes due to the well thought-out design. Further features are the smooth material feed, an optimal control and monitoring of the material feed, as well as the exact positioning of the bar without mechanical stop. Due to its design, the Samsys Smart requires very little floor space. A shifting unit to gain easy access to the reduction tube is standard in X-direction.

Request for a quote

GSW SCHWABE AG

Germany

When you deal with industrial surface treatment and your expertise is the cleaning, brushing, polishing or coating of strip steel, you most likely do not want to spend any worries about the run of the material. That’s where our Winding Lines keep your worries away – because they take care of a safe run! They work with high tension and special monitoring and deflectors to do this, with the result of a clean wound beginning to end. The machine design thus calls for especially high drive power and precision expansion systems; even something so simple as the machine base is designed special to cope with the forces… To control the precision of one layer to the next, we utilize external edge controls and servo-drive the Reels for adjustment. This way we meet the typical low tolerances in this industry – after all, the coil is the product!

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The servo system + torque module controls the capping head, and the cap tightness is freely set. 2. The whole machine is made of 304 stainless steel material without any dead corner. 3. The cap feeding system is adapt Cap elevator which can storage around 1000caps at a time. 4. For different size of bottle and cap, need adjust no need changeover parts excluding the capping head. 5. Avoid Liquid Shakes Out—Bottles no need to stop for capping 6. Wide Application— fast switching for various caps 7. High success rate cap loading—pick & place capping

Request for a quote

GSW SCHWABE AG

Germany

Motorized rotation Hydraulic wedge type expansion Highend arbor with double bearing Extremely stiff design SHDH Series PullOff Reel with manually adjustable brakes SHDR Series Payoff Reel with threephase motor Pneumatic or hydraulic hold down arms Electromotive or hydraulic traveling feature w optional automatic centering Hydraulic coil car and fullsize back plates Conical keeper rolls w optional motorized travel Larger mandrel heights and segments Vectorcontrolled drive systems for heavy coil weights Servo drive and control systems, etc.

Request for a quote

GSW SCHWABE AG

Germany

Movable keeper arms for coil guidance and centering Most durable hydraulic wedge type expansion, easily operable even under weight Highestquality reel arbor with doubled maintenancefree bearing and minimal deflection Sturdy and warp resistant body in welded construction for highest stability SHH Series PullOff Reel with manually adjustable brake and auxiliary drive to support coil setup SHR Series Payoff Reel with threephase motor and frequency inverter for continuous operation Pneumatic or hydraulic hold down arm Electropneumatic brake system Electromotive or hydraulic traveling feature Hydraulic coil car Concical keeper rolls w optional motorized travel Larger mandrel segments Different mandrel heights Fullsize back plate Vectorcontrolled drive system for heavy coil weights Servo drive and control system Loop control systems...etc. Double End Coil Reels w 180° turning radius Horizontal Coil Reels Recoilers Custom Layouts and Features

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Incremental magnetic measuring heads offer maximum precision over the full range of measurements. As a result of the magnetic operating principle and the robust mechanical construction, they are insensitive to soiling and are therefore ideally suited to use in production facilities. Thanks to the high quality of their measurements, their high protection and long service life, these sensors are used in many technologies (industry, research, development etc.). Typical applications include: —Monitoring both slow and fast movements between machine parts —Measurements of position and positional changes in components and structural foundations, of servo regulators, valve and robot controllers —Measurement of growth, and so on The incremental displacement sensors are based on a magnetic principle: consisting of a magnetic scale and a multi-slot reading head that responds to changes in magnetic flux, they detect linear movements with high precision and resolution.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Incremental magnetic measuring heads offer maximum precision over the full range of measurements. As a result of the magnetic operating principle and the robust mechanical construction, they are insensitive to soiling and are therefore ideally suited to use in production facilities. Thanks to the high quality of their measurements, their high protection and long service life, these sensors are used in many technologies (industry, research, development etc.). Typical applications include: —Monitoring both slow and fast movements between machine parts —Measurements of position and positional changes in components and structural foundations, of servo regulators, valve and robot controllers —Measurement of growth, and so on The incremental displacement sensors are based on a magnetic principle: consisting of a magnetic scale and a multi-slot reading head that responds to changes in magnetic flux, they detect linear movements with high precision and resolution.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Incremental magnetic measuring heads offer maximum precision over the full range of measurements. As a result of the magnetic operating principle and the robust mechanical construction, they are insensitive to soiling and are therefore ideally suited to use in production facilities. Thanks to the high quality of their measurements, their high protection and long service life, these sensors are used in many technologies (industry, research, development etc.). Typical applications include: —Monitoring both slow and fast movements between machine parts —Measurements of position and positional changes in components and structural foundations, of servo regulators, valve and robot controllers —Measurement of growth, and so on The incremental displacement sensors are based on a magnetic principle: consisting of a magnetic scale and a multi-slot reading head that responds to changes in magnetic flux, they detect linear movements with high precision and resolution.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STATEC BINDER GMBH

Austria

The high-performance bagging carousel CIRCUPAC has been specially developed for the packaging of flour and powdery products in pillow bags and gusset bags with a filling weight of 10 kg to 50 kg. The CIRCUPAC is ideal for filling prefabricated open mouth bags made of woven PP, PE or paper. The special feature of the packaging machine is the continuously rotating carousel: All components are precisely matched to each other, so that the entire process is carried out without a start-stop system. A maximum output of up to 1200 bags per hour can be achieved. All movements are controlled by an intelligent master servo motor controller and are precisely coordinated with each other. An extended filling time by six filling stations as well as the constant compression of the product by special vibration plates result in a well-filled bag.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

EC Calibration Bench for Torque Wrenches The EC Calibration Device for torque wrenches is characterized by high torque accuracy, an exemplary sensitive and freely programmable control of the servo drive as well as a simple and uncomplicated software parameterization. The system is just as suitable for the hard daily work for the examination of a large number of torque wrenches as for fastidious torque analyses in the QA laboratory. The calibration device provides the necessary metrological characteristics and driving procedures to accomplish tests according to EN ISO 6789 or other test methods. The operator is allowed to program his test procedures freely and conduct tests or calibrations automatically. The different measuring sensors were accommodated in a LED storage, which is equipped with approximation sensors, so that the operator uses always clearly the measuring sensor suitable for the test specimen. The software integration of the LED storage prevents possible operator...

Request for a quote

PRESSTA EISELE GMBH

Germany

High-Performance automatic circular saw for aluminium and non-ferrous heavy metal Fully automatic operation Use of TCT or solid carbide blades ø 250 mm Motor 7,5KW, 400 V, 50 Hz, infinitely adjustable Blade feeder hydropneumatic Material feeder with ball screw spindle and servo motor 2-axis NC control Simatic S7-300 with 7“ touch screen Cutting range: height up to 60 mm, width up to 140 mm Manual safety cover 2x Ø 100 mm swarf extraction connector Blade feeder pneumatic hydraulic controled vertical top to down Manual blade feed adjustment to optimize the feed length Pneumatic clamps horizontal left and right of the blade Diagnosis of errors, trouble shooting Pneumatic clamps vertical left of the blade Mist spray blade lubrication (filling level controlled) 1 l tank Parts slide (Option: conveying belt) Material feeder from 2 – 650 mm with ball screw spindle and servo motor Multiple material feed possible up to 3250 mm cutting length Vertical and horizontal clamps Reducer of...

Request for a quote

KUZEY GLOBAL

Turkey

4-column, servo-controlled station groups Needle bearing toggle system Cooling water flow control system Max stroke upper/lower 150 mm Lubrication system for each bearing Easy mould damping (with Locking System) Support piston upper and lower group Upper group spacing system (Positioning block parallelism) Ability to work with frame or press in upper and lower press Servo controlled seal system Compression force 70 tons

Request for a quote

KUZEY GLOBAL

Turkey

4-column, servo-controlled station groups Needle bearing toggle system Cooling water flow control system Max stroke upper/lower 150 mm Lubrication system for each bearing Easy mould damping (with Locking System) Support piston upper and lower group Upper group spacing system (Positioning block parallelism) Ability to work with frame or press in upper and lower press Servo controlled seal system Compression force 60 tons

Request for a quote

MH MULTIPACK SDN BHD

Malaysia

Full Servo Driven for highest flexibility, highest repeatability and operator friendly conversion. Precision Auger Filling System with wide filling range without change part. Bottle lifted during filling for clean filling. Swingable Filling module for easy dismantle when cleaning. Contact parts are FDA Approved material and autoclavable. Patented Elevator cap sorter without vibration noise, less than 70dB. Cap closing torque are servo control for highest consistency. Auto rejection without machine stop. Optional 100% IPC Tare-in, Tare-out weight check. Optional N2 flushing. Optional FDA 21 CFR Part 11. Optional Realtime Equipment OEE monitoring anytime, anywhere. Machine Specification

Request for a quote

KUZEY GLOBAL

Turkey

CMK 95/65-S4 Station Thermoforming Machine is eligible to form round and rectangular shape lids, plates and trays, single or mu iti compartment containers, hinged lid containers, leaking-proof containers, egg viyole, flower pots and seeding trays. Machine has the bigger forming area than 85 series station machine, and it is better if high is targeted. Machine adopts the latest thermoforming technology itself and intelligent control. This model combines maximum speed and bulk production, high quality and efficiency, and low consumption in energy. lts mould is equipped to perform well with polymer plastics as well as biodegradable plastics. OTHER TECHNICAL SPECIFICATION AII units are fully automatic Movable touch control panel Screen size 15″ and colour Electricity panel assembled to the machine and cooling by AC Ethernet portal Possible to store different mould settings Convenient and fast mould change and pneumatic fixing Pneumatic control systems with servo motors

Request for a quote

KUZEY GLOBAL

Turkey

CMK 95/65-S3 Station Thermoforming Machine is eligible to form round and rectangular shape lids, plates and trays, single or mu iti compartment containers, hinged lid containers, leaking-proof containers, egg viyole, ete. Machine has the bigger forming area than 85 series station machine, and it is better if high capacity is targeted. Machine adopts the latest thermoforming technology itself and intelligent control. This model combines maximum speed and bulk production, high quality and efficiency, and low consumption in energy. lts mould is equipped to perform well with polymer plastics as well as biodegradable plastics. OTHER TECHNICAL SPECIFICATION AII units are fully automatic Movable touch control panel Screen size 15″ and colour Electricity panel assembled to the machine and cooling by AC Ethernet portal Possible to store different mould settings Convenient and fast mould change and pneumatic fixing Pneumatic control systems with servo motors

Request for a quote

KUZEY GLOBAL

Turkey

CMK 85/55-S4 Station Thermoforming Machine is eligible to form round and rectangular shape lids, plates and trays, single or multi compartment containers, hinged lid containers, leaking-proof containers, hole-punch containers, egg viyole, flower pots and seeding trays. Machine adopts the latest thermoforming technology itself and intelligent control. This model combines maximum speed and bulk production, high quality and efficiency, and low consumption in energy. lts mould is equipped to perform well with polymer plastics as well as biodegradable plastics. OTHER TECHNICAL SPECIFICATION AII units are fully automatic Movable touch control panel Screen size 15″ and colour Electricity panel assembled to the machine and cooling by AC Ethernet portal Possible to store different mould settings Convenient and fast mould change and pneumatic fixing Pneumatic control systems with servo motors Automatic lubrication of moveable parts which is activated as perthe specified time space

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

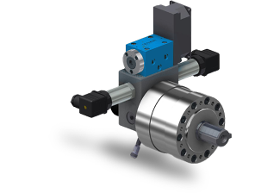

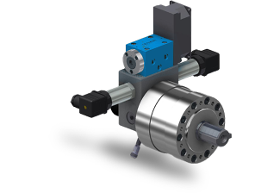

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quote

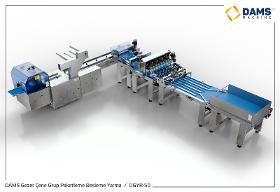

DAMS MACHINE

Turkey

Sandwich and hamburgers coming from the cooling tower or in bulk are placed manually between the product sorting slides with the help of two personnel. When the products are divided into groups, the numbers are checked with the sensors, and if there are missing rows, they wait until the order is completed The queues are divided into groups by the help of two flaps, and the number of packages depends on desired grouping (sandwich 4, 5, 6, Hamburger 4, 6, 8). Here, the products are placed between the product pushers of the packaging machine with the help of a push rod. Product pushers take products to the enveloping unit and allow them to be packaged. Our packaging machine is servo controlled.

Request for a quoteResults for

Servo controller - Import exportNumber of results

115 ProductsCountries

Company type

Category

- Packing and packaging - machinery and equipment (10)

- Food industry packaging machinery (9)

- Electric motors and parts (8)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (8)

- Sensors (4)

- Bottling and filling - machinery and equipment (3)

- Food packaging (3)

- Metal straightening machines (3)

- Metals - Machines & Equipment (3)

- Voltage stabilisers (3)

- Cutters (2)

- Drilling - machine tools (2)

- Driveshafts and micro-motors - electric (2)

- Laser - cutting and welding machines (2)

- Metallurgy - machinery and installations (2)

- Paper and cardboard manufacturing - machinery and equipment (2)

- Testing equipment (2)

- Welding, electric - equipment and supplies (2)

- Agglomeration and emulsification machines for the food processing industry (1)

- Automation - systems and equipment (1)