- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steam turbines

Results for

Steam turbines - Import export

IMM MASCHINENBAU GMBH

Germany

CNC polishing of compressor blades and vanes to optimize flow efficiency while at the same time minimizing differences due to tolerances in blade geometry. This is essential to the balancing of the compressor rotor and the fit of the stator parts. The SPE allows to keep up with the demand of this for the latest F-Class & H-Class Gas Turbine Compressors. The SPE CNC-Machine allows automatic polishing of all rows of the Gas Turbine Compressor, as well as most rows of Steam Turbine Blades within tight tolerances and highest repeatability. A dedicated CAD/CAM software allows for generation of NC part programs. As the SPE is a cartesian type machine tool there is no need for referencing or time consuming in process gauging. The precision and repeatability of the process allows the balancing of the milling process to leave a rougher scallop on the blade and save valuable time and cutter on the milling side. Capable of polishing compressor blades, fan blades and vanes up to 550 mm in length.

Request for a quote

APROVIS

Germany

What you can expect from APROVIS gland steam condensers: - Can be used in regenerative and conventional applications - A complete system including blowers - Materials are adapted to the relevant application - Acceptance currently according to PED 2014/68/EU and the ASME Code; additional certifications to follow

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Sunlight can also be channeled and focused to heat water, which can drive steam turbines in large-scale power plants. This Concentrated Solar Power (CSP) was once dominated by glass mirrors due to their unmatched reflectivity. Recent advances in aluminum reflectivity and brightness, partially due to our processing innovations, however, have made the material an effective substitute. Compared to glass, aluminum solar panels offer significantly lighter weight and better ratio performance versus cost.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

MAINTENANCE PARTNERS

Belgium

Maintenance Partners is the one-stop-shop for steam turbine maintenance. We have all the expertise needed for complete overhauls, repairs, reconditioning, upgrades, revamps and relocations of steam turbines, regardless of type or make. Our rotorshop performs all aspects of rotor, diaphragm & blade carrier repairs, ranging from NDT inspections to high speed balancing. Steam Turbine Maintenance – Service packages The range of service we provide allows you to benefit from the expertise and skills developed by the workshops and field service teams. 24 – hour service Upgrades Full general overhauls Relocations Repairs Service agreements Engineering Partnership agreements Parts supply Condition monitoring Field service Used machinery Re-rates & de-rates Technical consultancy Workshop activities Complete overhauls Rotor repairs Rotor repairs by welding Straightening of bent rotors Re-blading Parts supply by reverse engineering or supplied by OEM

Request for a quote

MAINTENANCE PARTNERS

Belgium

Maintenance Partners is the one-stop-shop for steam turbine maintenance. We have all the expertise needed for complete overhauls, repairs, reconditioning, upgrades, revamps and relocations of steam turbines, regardless of type or make. Our rotorshop performs all aspects of rotor-, diaphragm & blade carrier repairs, ranging from NDT inspections to high speed balancing. We service all types of axial and radial steam turbines (multistage and single stage steam turbines): Impulse turbines Reaction turbines Condensing steam turbines Non – condensing steam turbines Steam Turbine Brands Served: ABB – AEG KANIS – ALLEN – ALSTOHM – ALSTOM – ANSALDO – ASEA STAL – BBC – BLOHM & VOSS – COPPUS DEMAG – DELAVAL – DEAN HILL – DOOSAN SKODA – DRESSER RAND – KOBE – FINCANTIERI – FUJI – GENERAL ELECTRIC (GE) – GHH – NUOVO PIGNONE – KKK – MAN TURBO – PETER BROTHERHOOD – RATEAU – SULZER – STAL-LAVAL TURBIN – TRIVENI – ELLIOTT – SIEMENS – THERMODYN – TUTHILL – WORTHINGTON – … Steam Turbine Maintena

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

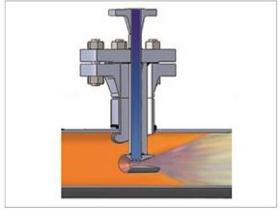

A version of single venturi desuperheater has the same operating conditions. can be mounted easily and quickly in the exisiting pipeline. The unit can be clamped between two flanges. Sizes are between 1 1/2” to 30”

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Jet Flow fixed area nozzle desuperheaters are best suited for applications involving minimal load fluctuations. A fixed nozzle desuperheater utilizes high performance fixed geometry nozzles to reduce the steam temperature by directly injecting water inside the superheated steam flow. The water enters the main desuperheater body, passes through the spray nozzles and discharges into the steam line in the form of a fine mist.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Jet Flow Safety Valve represent the most advance technology in value designed for use in intermediate power boiler and organic fluid vaporizer service. Built in conformance to section I of the ASME boiler and pressure vessel code, all capacities am certified by the national board of boiler and pressure vessel inspector at 5% over pressure. Jet Flow Designed Safety Valve with Full Nozzle & hardened disc to minimize maintenance and increase seat life Open bonnet & Close bonnet both design have maximum set pressure 75 bar in Safety Valves. Material of Construction. Set pressure in psig or Kg/cm2 (g). Maximum inlet temperature. Allowable overpressure. ServiceSpecify either the media to be handled or the following physical properties or both. LiquidsSpecific gravity (Water = 1) GasesSpecific gravity (Air=1) VaporsMolecular weight (mixture of vapors. The average molecular weight) Back pressure, if any. Required capacity. Type of Endconnections. Preferred inlet size.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

A Steam Conditioning Valve / Combined PRDS Valve is the combination of pressure reduction and temperature reduction of superheated steam to fit process needs, protect downstream equipment or allow the use of less expensive materials or schedules for downstream piping. This is done with a pressure reducing valve and a spray water addition section either as separate units or a single device. Pressure reduction is carried out with a pressure reducing trim within the valve body, usually multi stage pressure reduction. The pressure is controlled by an upstream or downstream pressure controller, signaling the valve to modulate to maintain the pressure at the required set point.Temperature is controlled by adding water to the steam in such away that it will get fully evaporated in the steam, termed as desuperheatmg. These applications are normally considered to be some of the most severe services of any valves in a modem steam plant.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

High Pressure Control Valve is designed and developed for applications where the high pressure / drop liquid and high pressure / temperature gas/vapour to be handled. Our specially designed Velocity Control Trim, which is a multi turn / multistage velocity control trim, handles these severe/critical applications very effectively – eliminating cavitation & vibration, and reducing the noise to the acceptable levels.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Turbine bypass valves play a very major role in Power Plant applications. Within a short period of twenty four hours, a power plant may be required to operate at minimum load, increase to maximum capacity for major part of the day, immediately lower back to minimum load and then back to maximum capacity. Bypass System permit unit start up and shutdown in a lifesaving manner for critical heavy components in boiler and turbines. Jet Flow Bypass valves are supplied with hydraulic, electric or pneumatic actuators as per the process requirements alongwith complete control systems as an option.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

A Heat Exchanger is a device built for efficient heat transfer from one medium to another, whether the media are separated by a solid wall so that they never mix, or the media are in direct contact.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

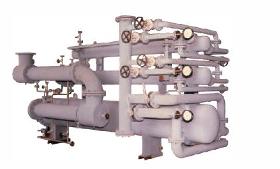

The needs of the power generation industry include year in and year out reliability, optimum performance for maximum efficiency, and absolute on time delivery to meet plant outage schedules. All of the Jet Flow Boiler Feed Water Heaters are designed in accordance with HEI standards, TEMA and ASME codes. Jet Flow uses state of the art computer programs to perform the thermal hydraulic and mechanical design of each Feed Water Heater we fabricate. Jet Flow designs and manufactures both Low Pressure (LP) and High Pressure (HP) feed water heaters which may be installed either vertically or horizontally, depending on the plant design requirements. Each Jet Flow Feed Water Heater will contain from one to three separate heat transfer areas of zones including the Condensing, Desuperheating and Subcooling zones. Our heaters can be provided with multiple zones within the shell side Condensing Zone Included in all heaters,steam is condensed in this zone and non condensable gases are removed.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

When it comes to the performance of a turbine surface condenser in the operational field of a steam turbine cycle, you need utmost reliability and efficiency. Here’s where Jet Flow’s know how is invaluable. We createcustomise package solutions for each particular customer’s needs. Our General Scope of Supply Condenser Circular Condenser having own Flow, Axial flow or side inlet steam entry. Turbine to Condenser steam duct, including necessary expansion joints. Steam Jet Ejector Vacuum System. Flash tank, drain header and Instrument stand pipe. Dump Tube. Condensate Pump system Pumps are in vertical or horizontal arrangement; either API 610, ISO 5199 or standard manufacturer pump design. Control system Including level control valves pressure and temperature indicators, transmitters and controllers. Interconnecting piping with filter, fittings and valves.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Gland seal systems very important to main and auxiliary turbines. Turbine shafts must exit their casings in order to couple up or connect with the unit that the turbines drive (reduction gears, pumps, etc.) The main and auxiliary gland seal systems enable the turbine to be sealed where the shaft exits the casing; in effect keeping "air out and steam in." The purpose of gland seal system is to prevent the leakage of air from the atmosphere into turbine casings and prevent the escape of steam from turbine casings into the atmosphere. The gland sealing system provides low pressure steam to the turbine gland in the final sets of labyrinth packing. This assists the labyrinth packing in sealing the turbine to prevent the entrance of air into the turbine, which would reduce or destroy the vacuum in the associated condenser. Excess pressure (excess gland seal) is removed by the gland seal unloader. Since there are times when steam escapes from the seals, a gland exhaust system is provided.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

The Steam Surface condenser is a critical component of both the traditional coal fired power plant and the new generation cogeneration and combined cycle power plants. Main duties of any Surface Condenser are to convert the exhaust steam from its gaseous to its liquid state at certain under atmospheric pressure, and also, to release non condensable presented in the steam cycle, together with vacuum unit. Jet Flow designs and economically sized condenser suitable for smaller turbine ratings under 100 MW. The circular configuration is compact for easy shipping and maintains the level of quality afforded all of our condenser designs. All of Jet Flow’s Surface Condensers are designed and built to the Heat Exchange Institute latest Standards. We also strive to meet all of our client’s project specific requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

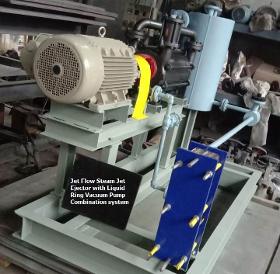

Jet Flow Steam Jet Ejector and Liquid Ring Pump Combination type Hybrid Ejectors Systems are getting popular in major Chemical, Soap, Food, Edible oil sectors. A typical combination of steam jet ejector system followed by inter-condenser and liquid ring vacuum pump. This type of combination system can achieve vacuum as high as 0.05 Torr. It can be configured as single or multistage ejectors, single or two stage liquid ring vacuum pumps and inter-condenser. It is designed to operate at the same capacities and suction pressures as conventional steam jet ejector systems. Jet Flow Hybrid Ejectors provide a solution for high vacuum operations. They are versatile in handling both wet and dry loads, can be supplied with low level skid mounted packages with instrumentation and with closed loop seal water recycle system for vacuum pumps for the total reduction of effluent. Jet Flow combination type vacuum systems major applications in distillation, evacuation, drying, evaporation, cooling etc.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Vacuum is necessary during various steps of edible / vegetable oil and food processing. These steps essentially include hydrogenation, fractionation, bleaching, deodorization and deacidification. Out of all vacuum equipments, Ejector Vacuum System has established the superiority and versatility of their use as compared to mechanical vacuum pumps. The most outstanding advantage of the Steam Jet Ejector is total absence of moving parts which eliminate mechanical breakdown, and assures constant and dependable operation with freedom from repairs. No adjustment or lubrication is required nor are any specially trained operator necessary as their operation is very simple. Over and above, Steam Jet Ejector Vacuum System convey at very high velocity which are many times the speed of sound, they are capable f handling large volume under vacuum thus making them eminently suitable for deodorization application wherein high quality of open / sparging steam has to be handled.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

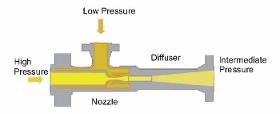

Large industrial plants often vent significant quantities of low pressure steam to the atmosphere, wasting energy, water, and watertreatment chemicals. Recovery of the latent heat content of lowpressure steam reduces the boiler load, resulting in energy and fuel cost savings. Lowpressure steam's potential uses include driving evaporation and distillation processes, producing hot water, space heating, producing a vacuum, or chilling water. If the steam pressure is too low for the intended application, a steam jet thermocompressor can boost the pressure and temperature to the required level. Operating Principles - Thermocompressors and ejectors operate on the same thermodynamic and physical principle energy contained in high pressure steam can be transferred to a lower pressure vapor or gas to produce a mixed discharge stream of intermediate pressure.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

The efficiency of a Steam turbine is mainly determined by the pressure of the steam at its outlet. The Turbine Surface Condenser is therefore maintained under vacuum. To enable this, the Steam Jet Ejector Vacuum System must be capable of removing all non condensable and associated water vapour from the Surface Condenser to produce the minimum steam condensing pressure consistent with physical dimensions and heat transfer and to provide for deaeration of the condensate. The sources of non condensables include air leakage through all system components operating below atmospheric pressure, gases released from feedwater drains and vents admitted to the condenser, gases released for makeup admitted to the condenser, condensate surge tank when utilized in a closed cycle and disassociation of feedwater into oxygen, hydrogen and non condensables.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Based on the process requirement, a Multi Nozzle Ejectors can be designed five or seven nozzles type. Generally, one nozzle in the centre and remaining four or six nozzles are evenly circled around it. Multi Nozzle Ejectors can reduce the steam consumption by 15% to 20% as compared to Single Nozzle Ejectors when designed for the same conditions and it is more efficient to single nozzle ejectors. At times it is also considerably shorter in length when compared with same rated single nozzle ejectors.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Five Stage and Six stage Steam Jet Ejectors with Condenser Five stage and six stage ejectors are designed for absolute pressure in Micron Range. The arrangement of these ejectors is similar to the four stage ejector with additional one or tow non condensing stages. Special Precautions while measuring Low Absolute Pressures : Do not use spring type vacuum Gauges Ensure that the guage tubes are clean and free form contamination Ensure that the guage liquid is clean and free from contamination

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Four Stage Ejector with Condenser Four Stage Ejector is having construction and working similar to Single Stage, Two Stage & Three Stage Ejector. When ejector is to be installed at low ambient temperature area, primary booster should be steam jacketed to prevent building up of ice on the diffuser internal bore. Sometimes both primary and secondary boosters are completely jacked to avoid deposition of product inside the ejector. The Four Stage Ejector consists of following components Primary Booster Ejector Secondary Booster Ejector Booster Condenser Vacuum Ejector Inter Condenser Low Vacuum Ejector

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Three Stage Ejector is similar in construction as of Single Stage Ejector, but having intermediate condensers. Three Stage Ejector comprises of Booster Ejector, Booster condenser and a Two Stage Ejector. And Two Stage Ejector consists of a high vacuum ejector, a inter condenser and a low vacuum ejector. This system will give higher vacuum and can handles larger quantity of condensable vapors. Gas or Gas vapor mixture is discharged from the first stage into the condenser where the operating steam is condensed and gases are cooled. The cooled gases are then entrained by the second stage and discharged into the second inter condenser. Here, the steam used in the second stage is condensed. The gases are finally entrained by the third stage and discharged to atmosphere.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

SingleStage Steam Jet Ejectors are based on the ejectorventuri principle. In operation, steam issuing through an expanding nozzle has its pressure energy converted to velocity energy. A vacuum is created and the high velocity of steam entrains air or gas and the mixture of gas and steam enters the converging end of the venturi, passes through the diffuser where its velocity energy is converted into pressure sufficient to discharge against a predetermined back pressure. Single stage steam jet ejectors are used to create vacuum covering 40 mm Hg. Absolute. Two Stage Ejector with Condenser The system is the assembly of two units whose construction is similar to single stage with inter condenser (direct contact type or surface type). Steam of the first stage is expanded through nozzle entrains the air or other gases and discharges them to diffusers at a higher pressure in the condenser.

Request for a quote

SCHARFF TECHNIEK

Netherlands

Clean Steam, clean steam, culinary steam or pure steam, maybe one of these terms sounds familiar to you. Never heard of it, and do you work in the food pharmaceutical or chemical industry? Then it is especially important to read the following information. On this page we briefly explain the difference between different types of steam. That can make all the difference for a safe end product. Steam is an extremely widely used product in many different industries. For example, most of our customers in the food industry use steam in the production process where it comes into direct contact with their food product. For example, soups and sauces are heated by the direct injection of steam. In this case, the quality of steam becomes important. There are different types

Request for a quote

SCHARFF TECHNIEK

Netherlands

The automatically functioning thermal oil boilers are designed for thermal oil with a temperature of up to 400 °C. The thermal oil boiler contains a double rear wall that cools the thermal oil and is part of the VO. This makes a high boiler efficiency of 93% achievable and you will notice this in the gas consumption. Due to the lack of a bricked rear wall, periodic checks of the rear wall are not necessary. As a result, you save on maintenance. Electric thermal oil boilers are also part of our program. All thermal oil boilers can be equipped with all common gas or oil burners both ex works and on site. the burner The installation is supplied as high/low or modulating , depending on the capacity of the Inplan thermal oil boilers .s

Request for a quote

SCHARFF TECHNIEK

Netherlands

The right choice for your application(s). We not only distinguish ourselves by high-quality products, but we are involved. We are on site during all phases of delivery and installation to ensure that everything runs smoothly and according to your wishes. CERTUSS steam generators are of high quality and generate boiler efficiencies of up to 98%. They have been developed from innovative standards, according to PED guidelines, i.e. the latest applicable regulations. And as required, the steam boilers are TUV-approved and provided with a CE certificate, which means that our product complies with the applicable

Request for a quoteResults for

Steam turbines - Import exportNumber of results

66 ProductsCountries

Company type

Category

- Steam turbines (36)

- Lubricants, industrial (3)

- Offshore services (3)

- Compressors (2)

- Electricity generators (2)

- Gas turbines (2)

- Aluminium sheets and bands (1)

- Boilers, industrial (1)

- Casting, steel (1)

- Condensers (1)

- Expansion joints - ferrous metal (1)

- Heat recovery systems (1)

- Polishing - machine tools (1)

- Polishing equipment and materials (1)

- Seamless pipes and tubes - ferrous metal (1)

- Silicones (1)

- Steam polishers (1)

- Technical textiles for industrial applications (1)

- Turbine-driven power stations, installations and equipment (1)

- Turbines (1)