- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel conveyor belt

Results for

Steel conveyor belt - Import export

FORBO SIEGLING GMBH

Germany

Conveying heavy-duty products presents huge challenges to the conveyor belts used. With four product series, the Siegling Transtex range offers top performance in the most diverse of applications. Global logistics service providers have been using Siegling Transtex successfully for years when typical conveyor belts for light-materials handling reached their limits. In wind and extreme weather conditions, high temperatures and unusual mechanical stress, steel and rubber conveyor belts were the first choice for a long time. Siegling Transtex is the ideal alternative for many applications – with all the benefits of fabric-based conveyor belts: -easy to make endless -low energy consumption -simple conveyor design -low maintenance and repair costs

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is an experienced fabricator of structural steel fabrications for bulk handling projects. With our modern CNC Machinery Park and experienced engineering team, Novelty Steel produces bespoke steel frames according to the EN 1090-2 European Norms. Some examples of the bulk material structure fabrications are : Steel frame for Conveyor Belts Feeders Transfer Towers Bunkers Hoppers Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Belt Conveyor systems consist of several key components with each playing a crucial role in the conveyor’s operation and efficiency. Novelty Steel supplies; *Belt (Belt Carcass) *Conveyor Idlers ( Rollers) *Pulleys *Drives *Other Components

Request for a quote

BIZERBA SE & CO. KG

Germany

The robust metal detector can be variably used in dry and wet environments. It ensures best test results for packaged or unpackaged piece goods. VARICONcompact safely checks for any contaminants enclosed in the product such as steel, stainless steel and non-ferrous metal, e.g. aluminum. The compact metal detection system works with highest detection sensitivity. Ideally suitable for a save test performance. With its robust stainless steel conveyor belt construction the VARICONcompact inspects piece goods of up to 20 kg. A very short metal-free zone (MZ) ensures interference-resistant, reliable inline metal detection.

Request for a quote

BIZERBA SE & CO. KG

Germany

Quick and reliable detection of all ferrous and non-ferrous metals in packaged and unpackaged piece goods. The compact metal detection system offers you safe performance and highest detection sensitivity. With its robust stainless steel conveyor belt construction the VARICON+ inspects piece goods of up to 50 kg. A very short metal-free zone (MZ) ensures interference-resistant, reliable inline metal detection. To suit the area of installation the system is available with a modular belt (wet area) or a flat belt (dry area). The conveyor belts are available with variable belt widths. The motor controller is fitted either with a conveyor stop in case of metal detection or an application-specific rejection system. For easy and thorough cleaning the VARICON+ series has a hygienic design. Quality which is reflected in BRC, IFS and HACCP certifications. The VARICON+ comes with IP65 protection. Higher IP ratings are optionally available.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is an experienced fabricator of structural steel fabrications for bulk handling and mining projects. With our modern CNC Machinery Park and experienced engineering team, Novelty Steel produces bespoke steel frames according to the EN 1090-2 European Norms. Some examples of the bulk material structure fabrications are : Steel frame for Conveyor Belts Feeders Transfer Towers Chutes Hoppers Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is an experienced fabricator of structural steel fabrications for bulk handling projects. With our modern CNC Machinery Park and experienced engineering team, Novelty Steel produces bespoke steel frames according to the EN 1090-2 European Norms. Some examples of the bulk material structure fabrications are : Steel frame for Conveyor Belts Feeders Transfer Towers Bunkers Hoppers Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

TASK ITALY SRL

Italy

The drying tunnel is used to remove residual water on the external surface of bottles or jars after the filling or pasteurization process. Main construction features include: - Linear stainless steel bottle conveyor belt with adjustable side guides - Structure entirely made of stainless steel, mounted on height-adjustable supports - Upper housing for high-pressure blowing turbines, in stainless steel with sound-absorbing panels - Fully openable plexiglass doors for adjustment of the blowing blades - High-pressure blowing turbines, without the use of electric resistors for low consumption * Specifically designed terminal blades to achieve adequate air force and compression * Adjustable height and inclination of the blowing blades for adaptation to different containers (bottles, jars, cans).

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

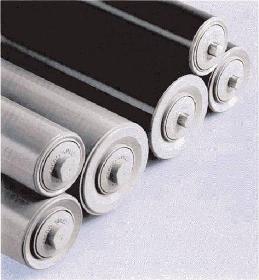

Steel clamped or monobloc rollers mounted on pre-lubricated and protected radial ball bearings.The externally threaded shaft protrudes from only one end of the tube.In belt conveyors, they are vertically mounted in pairs at the edges of the rubber matting, with the function of restricting any lateral slipping. They are installed on self-centring stations with the same function.The technical characteristics of Series 6 rollers are those of the relative base rollers.Other finishes, see page 30.

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

Due to the characteristics of the materials of which they are made, these rollers are used in conveyors operating in highly corrosive environmental conditions.With a state-of-the-art manufacture, they possess the requisites of the specifications for steel rollers on page 4. Operating temperature: 10 ÷ +50 [°C].

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

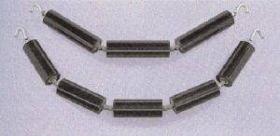

They consist of two steel clamped or monobloc rollers mounted on a single “V”-folded shaft. They have the upper bearing mounting heads with hermetic closure and the lower ones, with protruding shaft, with labyrinth dust protection. The shaft is locked in the housing of the central bracket.The latter, with a base plate fitted with mounting holes, is made of cold-formed steel sheet.They are used in concave belt conveyors that operate, even in bad environmental conditions, at medium-high speed, with medium loads and sizes.

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

Garland roller sets are used in belt conveyors that have to handle blunt, bulky, heavy materials. The increased containment capacity of the roller basin facilitates higher speed of transport than those of traditional stations. For upper stations in current use installations, garland sets with 3 and 5 steel or rubberised impact rollers are mounted; for lower stations, garland sets with 2 steel rollers or with scraping rubber rings are mounted. The flexibility of garland sets enables their adaptation to the material to be transported, facilitates transportation, reduces impacts on the rollers, and limits any lateral slipping of the rubber matting. The diagrams and Table 90 show the shapes of mountings of garland sets envisaged in TECNORULLI’s production programme. Other shapes may be considered on request.

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

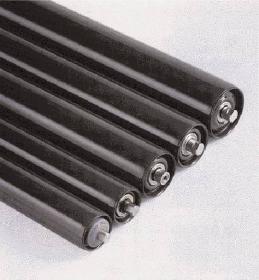

Steel rollers with jacket consisting of tube and bearing mounting head rigidly coupled by welding. They are mounted on pre-lubricated angular or radial ball bearings and protected with double labyrinth, triple labyrinth dust seals with additional watertight protection. Monobloc steel rollers are used in belt conveyors with medium, heavy or very heavy loads. The diagrams and tables on page 42 show the dimensional characteristics and maximum loads.Operating temperature:-10 ÷ +90 [°C].

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

Steel rollers with jacket consisting of tube and bearing mounting head rigidly coupled by pressure. They are mounted on pre-lubricated angular or radial ball bearings protected with double-labyrinth dust seals. Clamped steel rollers are used in belt conveyors with limited or medium-heavy loads. The diagrams and tables on page 34 show the dimensional characteristics and maximum loads. Operating temperature:-10 ÷ +90 [°C].

Request for a quote

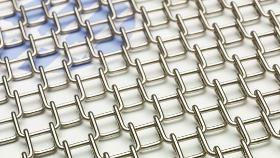

WIRE BELT COMPANY OSTERLOH GMBH

Germany

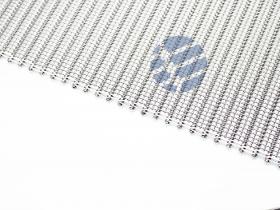

Versa-Link™ stainless steel conveyor belt makes installing your conveyor belt quick and easy! Versa-Link’s Advanced Link Rods join the conveyor belt together in as little as 30 seconds with no tools required. Forged Edge Technology creates an edge that is flush with the side of belt, eliminating any catch points that can damage your belt during operation. With up to 81% open area, Versa-Link™ provides maximum air/liquid flow through capabilities that is great for frying, cooking, coating, and cooling applications. Versa-Link™ is USDA Accepted, with a clean-in-place design that saves time during sanitation.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Compact-Grid™ stainless steel conveyor belt is engineered to offer superior support for small products. The unique grid pattern provides 70% open area which makes it easy-to-clean and offers exceptional air and liquid flow-through properties for heating, cooling and coating operations. Compact-Grid’s no-slip positive drive provides the highest standard in belt tracking, which means the belt will run straight and true even under heavy loads. Joining Compact-Grid is fast and simple, making belt installation easy.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Eye-Flex® steel conveyor belts are engineered for applications that require an extremely rugged, long lasting belt. Eye-Flex’s greater strength, carrying capacity, and open flat surface profile is the answer to all your heavy-duty conveying needs, whether you have a new or a replacement application. Eye-Flex® has almost limitless options and its configurations are custom designed to meet your requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WIRE BELT COMPANY LTD

United Kingdom

Eye-Flex® steel conveyor belts are engineered for applications that require an extremely rugged, long lasting belt. Eye-Flex’s greater strength, carrying capacity, and open flat surface profile is the answer to all your heavy-duty conveying needs, whether you have a new or a replacement application. Eye-Flex® has almost limitless options and its configurations are custom designed to meet your requirements.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

Compact-Grid® stainless steel conveyor belt is engineered to offer superior support for small products. The unique grid pattern provides 70% open area which makes it easy-to-clean and offers exceptional air and liquid flow-through properties for heating, cooling and coating operations. Compact-Grid’s no-slip positive drive provides the highest standard in belt tracking, which means the belt will run straight and true even under heavy loads. Joining Compact-Grid® is fast and simple, making belt installation easy.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer stainless steel hygienic system has stood the test of time for transporting general cargo across long distances. The open construction prevents dirt deposits. Common hinged belt chains and drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. Technical data —Conveyor body material: stainless steel —Conveyor body width: 106 mm, 131 mm, 206 mm —Chain width: 82.5 mm, 114.3 mm, 190.5 mm —Conveyor speed: up to 80 m/min Optional equipment —Moving deflecting pulleys in the curves to reduce wear on chains and slide rails —Product guides, fixed or adjustable, design depending on product —Supports to stabilize the conveyor systems at the desired conveying height —Other accessories, such as sensors, stoppers, etc.

Request for a quote

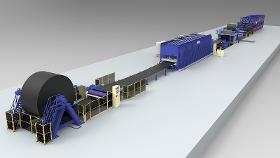

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp’s steel-cord conveyor belt presses distinguish by an innovative steel-cord tensioning concept: the controlled steel-cord tension distribution system increases production safety and improves product quality. The electromotive tensioning system, which is individually controlled and installed directly in the creel with integrated measuring and control functions, allows a 100%-control over the actual steel-cord tension distribution. The exact quality reporting enables our customers to optimize the production, hence the product’s quality. The new concept replaces the xed-nger comb used in previous systems with a roller comb. The friction between comb and steel cables is thus eliminated. Consequently, the abrasive wear on the galvanized steel cables is reduced. Unlike the traditional concept, the new roller comb prevents any variations in tension distribution. Services Direct tensioning control in the creel Individually controlled steel-cord tension distribution

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

For the production of conveyor belts with steel-cord or fabric layers, Siempelkamp oers a multi-cylinder down-stroke press including 2-track production. Conveyor belts having a width of up to 3,200 mm and a thickness of up to 50 mm can be manufactured at a pressure of 400 N/m2. To this end, Siempelkamp's multi-cylinder presses provide a pressure distribution previously unattainable with hydraulic-mechanical press systems. In addition, the thickness tolerances of the conveyor belts could be reduced here compared to traditional press concepts. Services Conveyor belt thickness starting at 5 mm Optimal pressure distribution due to our multi-cylinder concept Material reduction by eliminating the hot platen insulation Stable press gap parallelism High safety standards Advantages Improved process safety Low material and production costs due to reduced thickness tolerances Minimal foundation requirements Ease of maintenance and long service life

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

One of Siempelkamp’s core competences is the design and manufacture of presses for the rubber industry. With our expertise in this eld we are the world’s number one in steel-cord and conveyor-belt presses with many of the conveyor belts used around the world being manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straightrunning stability. Siempelkamp's excellent manufacturing and high-quality plants are eld proven. Services Single-source supplier Uniform pre-tensioning of the individual steel cables Best pressure distribution in our vulcanising presses Cable clamping and tensioning device with a heavy clamp Compactor lorry with pre-press Pull-roll stand Reeling elements Advantages Excellent thickness tolerances due to multi-cylinder press without requiring press bolsters Safe vulcanizing process for various belt widths by controllable pressure distribution Transparent and controllable production process

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Design and production of press-systems for the rubber industry is one major core competences of Siempelkamp More than 100 years of experience in rubber press lines More than 100 years ago, we put in operation the first conveyor belt press on the market. Only 20 years later, the first large vulcanizing press with a closed frame construction went successfully in operation. Even today, our presses and systems for the rubber industry have unqiue advantages: Durability, speed, high availability and efficiency, which are the most important arguments for our customers to choose a Siempelkamp plant. Proven technology that is trusted in the rubber industry With our broad expertise in the fields of rubber processing industry, we are the world market leader for steel cord and conveyor belt presses. A large part of the conveyor belts used around the world are manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straight-running stability.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The use of wide belt, grid, steel band or narrow belt conveyors is adapted to the type of workpieces as well as to the customer-specific conditions. They can be flexibly planned either as an individual solution or incorporated in a Venjakob machine line. A wide spectrum of belt types is available, matched to the individual fields of application. This even includes applications up to a maximum temperature of 450°C. VEN TRANS system techniques enable tailor-made workpiece conveying and handling concepts. We create Our solutions take into account

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

Structure of germanBelt® steel cord conveyor belts Steel cord reinforcement: The standard steel cords have been hot-dip galvanised and have diameters from 2.6 to 12.8 mm. They are manufactured in 7x7 or 7x19 designs (other designs are possible). Their design allows good rubber saturation and distribution. Skim layers: A special chemical process provides excellent rubber/metal adhesion in the steel cord conveyor belt. The design of the steel cords leads to outstanding adhesion that surpasses any standards. Good rubber saturation and high adhesion on each cord provide germanBelt® steel cord conveyor belts with extraordinarily high longevity. Covers: The covers’ abrasion resistance, tensile strength and elongation value depend on the quality of the chosen combination of covers of the steel cord conveyor belt. Lateral reinforcements: The steel cord conveyor belts’ reinforcements consist of lateral steel cords with very high elasticity, or of textile fabric. The lateral reinforcements are worked into the carcass or the cover.

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanBond® REPAIR Applications: One component repair compound for the filling of damaged areas of rubber conveyor belts such as fabric conveyor belts or steel cord conveyor belts, rubber linings, drums/conveyor belt pulleys and cylinders. Specifications: Colour: black Final hardening after: approx. 24 h (at 20°C) Application quantity: approx. 1 kg/m² for 1 mm thickness Oil resistance: oil resistant according to DIN 53521 Shrinkage: 15 - 20 % Hardness Shore A: approx. 65 ° (after complete curing) Packing units: 1.0 kg Downloads: Safety Data Sheet germanBond® REPAIR - English [PDF] Application Instructions germanBond® REPAIR - English [PDF]

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanBond® HS CFC-free Applications: For hot vulcanising rubber steel cord conveyor belts and fabric conveyor belts. Specifications: Colour: black Density: 0.75 g/ml Application: Brush Application quantity: approx. 150 - 200 g/m² per coat Storage requirements: dry, cool, in tightly closed buckets Shelf life: minimum of 6 months Packing units: 0.6 kg - 4.0 kg - 20.0 kg Downloads: Safety Data Sheet germanBond® HS - English [PDF] Application Instructions germanBond® HS - English [PDF]

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

Heating solution germanBond® HS CFC-free Universally usable solution for hot vulcanization of splices at steel cord and fabric conveyor belts made of rubber. Our germanBond® HS heating solution contains a special elastomer compound whose adhesive system significantly improves the stickiness of the connecting parts and thus contributes to an optimal splicing strength. Applications: such as in the vulcanization of conveyor belt splices and conveyor belt repairs. ... more

Request for a quoteResults for

Steel conveyor belt - Import exportNumber of results

159 ProductsCountries

Category

- Conveyor belts (142)

- Grids, gratings and wire mesh (8)

- Bearings - ball, needle and roller (6)

- Conveyor systems (4)

- Forming, rubber - machinery (4)

- Cutting - steels and metals (2)

- Metal detectors (2)

- Turning - steels and metals (2)

- Biscuits (1)

- Bridges, metal (1)

- Industrial robots (1)

- Mining and quarrying - machinery and equipment (1)

- Welding, electric - equipment and supplies (1)