- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- torque

Results for

Torque - Import export

WIB SA

Switzerland

The resistance generated by the seal (if present), depending on the surface finish of the outside diameter of the inner ring, as well as of the rotational speed. The resistance generated by the cage, depending on the geometrical form and the machining quality of the cages. The resistance generated by the lubricant, depending on the lubricant viscosity and filling quantity as well as the rotational speed. At low speed and with fine instrument oil this resistance is insignificant. It will be higher at low temperatures and at high viscosity of the lubricant. Grease lubricated bearings will show, according to the grease type and filling, a much higher friction torque than oil lubricated bearings.

Request for a quote

NORELEM FRANCE

France

The required torque is set by a set screw and a graduated scale. The set value can be secured using the lateral clamping screw. When the set torque is reached the grip audibly and palpably releases. The loosening torque is higher than the tightening torque so that the torque handle can be released without any problems. The internal thread version has a hole in the set screw so that the torque handle can also be used on threaded rods. Set torque accuracy ± 5%. On request: Other thread lengths.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

The most accurate digital torque tester with Fail Safe Engineering! - Greater accuracy and durability with simplicity and ease of operation - Floating decimal point, 6 digit display is easy to read - Accurate to ± 0.25% (indicated value) from 10% to 100% - Over capacity alert and tracking System 8 error proofs your error-proofing program by letting you know when the unit has been stretched to 120% or more of capacity and may no longer be in calibration. System 8 has an LED that flashes red to alert you to the problem. It doesn’t stop until you reset the unit. The display also tells you the unit has been stretched over capacity. System 8 captures the over capacity data even if the memory was turned off. If memory was turned on and the unit is pulled over 120% capacity and a worker tries to erase the memory to stop the LED from flashing, the display tells the worker to “See Supervisor 120% Over Capacity”. No other torque tester on the market does this.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Preset Clicker Type Torque Wrench Sturtevant Richmont‘s smallest preset torque wrench delivers consistent assembly quality. Designed for assembly operations where access is limited and low torque capacities are required. A tactile impulse and audible click are emitted when the pre-set torque is reached, making it easy for the operator to perform the torque application process properly. The slender design permits use in limited-access applications where larger tools simply will not work. Light weight and smooth vinyl handle provides good ergonomics. More than two dozens of different interchangeable heads are available as standard. Further sizes and/or special tools are available on request. Key Features: - Accuracy ± 6% i.v. (within 20-100% of capacity) - Meets or exceeds ASME B107.300-2010, GGG-W-686E and DIN EN ISO 6789 - Audible click and tactile impulse - Oil-proof and chemicals resisting Vinyl handle - Bi-directional – right / left.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Dial Indicating Torque Screwdriver with mNm scale Tohnichi's MTD series torque screwdriver is suitable for inspection and tightening of very small screws, e.g. small torque motor shafts or the like. Torsion bar mechanism makes accurate measurement possible. With bi-directional scale plate, it can be used for both retightening and loosening torque testing methods. Memory pointer captures peak torque. Applicable for international use including the EU region. Compliant with calibration procedures of ISO 6789 Type I Class D. Key Features: - Bi-directional scale - Peak torque indication via Memory Pointer - Accuracy and calibration compliant to ISO 6789 type I class D - Bit insert #2 Tohnichi Shipping List: - Screwdriver MTD - Calibration Certificate (ISO/JIS) - Operating Manual - Special Bits Cross #0, Slotted 0.15x1, 0.2x1.5, 0.3x2 Options: - Alternatively with english units (ozf·in) available. Metric scale (gf·cm) on request.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Dial Indicating Torque Screwdriver Tohnichi's FTD-S series torque screwdriver is ideal for inspecting tightened screws. With bi-directional scale plate, it can be used for both retightening and loosening torque testing methods. Memory pointer captures peak torque. Model FTD8N-S and FTD16N-S comes with auxiliary tightening tool ("T-Grip") as standard accessory. Applicable for international use including the EU region. Compliant with calibration procedures of ISO 6789 Type I Class D. Key Features: - Bi-directional scale - Peak Torque indication via Memory Pointer - Coloured dial plate - Accuracy and calibration compliant to ISO 6789 type I class D - Tool insert 1/4 inch Shipping List: - Screwdriver FTD-S - Traceable Calibration Certificate (ISO/JIS) - Operating Manual Options: - Models with metric scale (gf·m, kgf·m) on request. Related Products Insert Bits with 1/4“ hex drive acc. DIN 3126 E6.3

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Torque Screwdriver with reversible digital display Tohnichi's digital screwdriver STC2-G is ideal for controlled screw tightening or inspections. Manual screw tightening always represents a risk because fasteners are often overloaded and a fracture hazard. This risk is minimized by the torque screwdriver with LED indicator ring and reversible display. The STC2-G is powered by a Li-Ion battery pack that allows a continuous use of up to 30 hours. Available measuring units are cN·m, kgf·cm, Lbf·in, and ozf·in. Up to 1000 readings can be stored in the internal memory. The display of STC2 -G can be reversed, whereby the reading from the respective viewing angle is greatly facilitated. This increases the reliability of results and ease of use. Key Features Accuracy ± 1% Track or Peak mode in both directions 3-colour LED indicator ring shows torque status Memory for up to 1000 readings USB interface for data export 1/4“ hex insert for bits and adaptors acc. to DIN 3126 E6.3

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Preset Torque Screwdriver Sturtevant Richmont PM-Series Preset Torque Screwdrivers are ideal for any application where 1. high repeatability for low torque is needed, 2. excellent durability and versatility is needed. These needs are common in high-precision assembly operations and for maintenance tool kits for electronic and electro-mechanical products. The operator cannot overtorque. A clutch releases automatically when desired torque has been achieved. The anti-backlash design enhances the repeatability. PM torque screwdrivers are incredibly durable. Many owners experience a service life of 15+ years. Key Features: - Bi-directional accuracy of ± 6% i.v. (20-100% of capacity) - Meets or exceeds ASME B107.300-2010 & EN ISO 6789 - Anti-backlash design - Short dwell designed to prevent repetitive motion injuries - 1/4 hex drive (C 6.3) Can be ordered preset from factory with certificate of calibration from SR's ISO/IEC 17025 Accredited Calibration Laboratory.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Micrometer Adjustable, Reliable, Complete - Perfect for the Field! Our kits both have the CAL 36/4 Micrometer Adjustable Torque Screwdriver at their heart, assuring efficient and reliable repair and maintenance operations! Features an Benefits Each includes a CAL 36/4 Micrometer Adjustable Torque Screwdriver. A free NIST-traceable tabulated Certification is included from SR's ISO/IEC 17025 Accredited Calibration Laboratory! Each includes a custom blow-molded plastic case for convenient organization and safe storage and transport. Each includes slotted bits, Phillips bits, and an adapter to permit use with sockets.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Micrometer Adjustable Torque Screwdriver with Dual Scale Sturtevant Richmont's CAL 36/4, with its' dual English/Metric scale, amazing durability, and ease of use has been an industry leader for decades – for good reasons! The CAL line of torque screwdrivers is first choice for many electronic and small-component manufacturers. The SR CAL-Series Adjustable Torque Screwdrivers are ideal for any application where: High repeatability for low torque is needed, Excellent durability and versatility are needed. These needs are common in high-precision operations such as electronics and electro-mechanical repair. To operate, simply dial torque setting and insert bit. The Micrometer scale on the shaft is marked in dual incrementation (lbf·in and N·m on CAL 36/4, kgf·cm on CAL 40). The operator cannot overtorque. A clutch releases automatically when desired torque has been achieved. The anti-backlash design enhances the repeatability. CAL torque screwdrivers are incredibly durable. Many...

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Micrometer Adjustable Torque Screwdriver The ExacTorq® torque screwdriver permits single-digit adjustment. Gone are the days of estimating torque. A simple twist of the end-mounted DigiLock mechanism sets your torque levels in exact, single digit increments. The positive locking detent secures your selection. Its‘ unique tri-lobular grip design for enhanced comfort and handling translates into improved operator technique and lower risk of repetitive motion injury. Enhanced comfort translates into enhanced accuracy. The operator cannot overtorque. A clutch releases automatically when desired torque has been achieved. The anti-backlash design enhances the repeatability. Additionally, the ExacTorq® is comfortable in even the smallest of hands, performing flawlessly when used by women and men on the assembly line. To operate, simply dial torque setting and insert bit.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Adjustable Torque Screwdriver for Small Screws (M1-M2) Tohnichi's BMRD series torque screwdriver provides same features as series RTD, except designed for tightening small screws. Thereby this model is ideal for assembly of watches, precision electronic equipment, computer, etc. Via micrometer scale torque can easily and quickly be adjusted. Index finger holding feature allows the operator to tighten with precise movements. Upon reaching the set torque, it clicks to signal tightening is complete. Integrated rotary clutch mechanism reliably prevents over-torque. Key Features: - Accuracy and calibration compliant to ISO 6789 type II class D - Micrometer adjustable - Clockwise direction - Click signal - Rotary clutch - Calibration certificate (ISO/JIS) incl. Options: - Counterclockwise tightening model available on request. - Optionally available in metric (gf·cm) or in english units (lbf·in bzw. ozf·in).

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Tohnichi's AMRD series torque screwdriver provides same features as series RTD, except designed for tightening small screws. Thereby this model is ideal for assembly of watches, precision electronic equipment, computer, etc. Via micrometer scale torque can easily and quickly be adjusted. Index finger holding feature allows the operator to tighten with precise movements. Upon reaching the set torque, it clicks to signal tightening is complete. Integrated rotary clutch mechanism reliably prevents over-torque. Key Features: - Accuracy and calibration compliant to ISO 6789 type II class D - Micrometer adjustable - Clockwise direction - Click signal - Rotary clutch - Calibration certificate (ISO/JIS) incl. Options: - Counterclockwise tightening model available on request. - Optionally available in metric (gf·cm) or in english units (lbf·in, ozf·in).

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Precise, reliable measurements of both static and dynamic torques in either direction can be made with this range of sensors. This opens a wide range of possible applications to the user. These torque sensors are standard equipment in a wide range of industrial automation, quality control and automotive components industry applications, as well as in laboratories. Typical applications: Screwing technology — Checking and adjusting bolting tools such as torque limiting wrenches, screwdrivers — Testing bolted connections Measuring the drag torque of motors and pumps — Frictional torques of gears, bearings and seals — Testing torsion springs — Adjusting equipment in the automobile industry (sunroof, power windows etc.) Strain gauges are mounted on the torsion shaft of the sensor element, itself made of steel, connected to form a full bridge.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This torque sensor is qualified for static and dynamic measurements on non-rotary applications. Further the measurement of reaction torques on rotating machine parts is possible. Especially the torque sensors with flanges are preferred. They are mounted between motor and stator, e.g. in agitator drives. This enables a maintenancefree torque measurement. For individual measuring tasks the design of our torque sensors can be adapted to the customer’s installation conditions. More application examples: Test structures in the field of precision mechanics Determination of friction torques Acquisition of breakage moments on screw caps The design has been optimized regarding overall length, weight and volume, so that axial forces up to relatively high limit values and bending moments of up to 20 % of the measuring range have only a small effect to the influence of the measuring element.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The 8661 precision torque sensor is the ideal choice for reliable measurement of static and dynamic clockwise and counter-clockwise torques. Thanks to its high measurement quality and low linearity error, the sensor is equally at home in quality control or research & development. Designed for non-contact operation and zero-maintenance, the 8661 is also ideally suited to the production environment, whether on shift-based production lines, test benches or end-of-line test systems. The 8661 torque sensor is the specialist device for constant torque measurements during continuous operation and for test-bench measurements of holding, friction, break-away or tightening torques. An optional built-in incremental encoder disk with up to 2000 increments makes the sensor the perfect alternative where space or budget rule out an additional angle or speed sensor. For mobile use and for instant digital access to measurement data, the 8661 torque sensor is also available with a USB interface.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This high precision torque sensor is designed for both static and dynamic measurements on non-rotating applications. It is particularly suitable for torque measurements on, for instance, extremely small electrical actuating drives and micro-mechanical actuator elements, or for measuring reaction torques e.g. on micro-motors. The high accuracy of measurement also makes this sensor ideal for use as a reference in many fields of industrial manufacture as well as laboratory research and development projects. Not containing any rotating parts, it requires no maintenance if properly used. The strain-gage based sensor’s modular design allows precise configuration for the desired application. With the integrated amplifier option, the sensor directly supplies a voltage signal of 0 ... ±10 V that is proportional to the torque. The sensor can be configured via the micro-USB interface, providing access to, for example, a filter frequency setting, averaging, and a tare function.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ETH MESSTECHNIK GMBH

Germany

1800 Nm max. on 1 3/8“ shaft according to ISO 500-3:2014 Type 1 On request also available: 1800 Nm max. on 1 3/8“ shaft according to ISO 500-3:2014 Type 2 2500 Nm max. on 1 3/4“ shafts according to ISO 500-3:2014 Type 3 contactless signal transmission built-in measuring amplifier rotation angle measurement (optional) extended EMC strength adjustable output level of rpm and angle signal (5V-24V) Frequency output 10kHz ±5kHz large input voltage range (10-28,8V) strain gauge technology robust design for use in field applications IP67 easy installation accurate results (0.2% accuracy) The torque sensor DRVZ provides a precise measurement of torque and angle of rotation when testing systems that are driven by PTO shafts, such as a tractor gearbox.

Request for a quote

ETH MESSTECHNIK GMBH

Germany

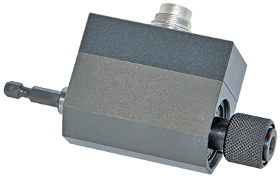

Particularly suitable for small screwing tools 4 torque range from ± 0 - 0,5 Nm to ± 0 - 5 Nm digital output Square drive or hexagon drive No service needed because of contactless data acquisition High accuracy due to frequency modulation and strain gage technology reduced power consumption High noise immunity due to digital signal very compact design Automotive industry Test benches Assembly applications Pulsed tools

Request for a quote

ETH MESSTECHNIK GMBH

Germany

No service needed because of contactless data acquisition High accuracy due to frequency modulation and strain gage technology Single power supply High noise immunity due to amplified active signal integrated sensor-detection chip for use with GMV2 analyzer automotive industry test benches assembly applications pulsed tools hexagonal drive 7 Measurement range from ± 0 - 1 Nm up to ± 0 - 20 Nm optionally with angle measurement

Request for a quote

ETH MESSTECHNIK GMBH

Germany

The transducer is suited for the most varied measurement duties on threaded fasteners, to check and adjust assembly tools, like screwdrivers and spanners, and to sense loosening torques, etc. It can also be deployed in blocked mode to test torque wrenches. The device is powered wirelessly and the electrical output is wireless, as well. Hence, there is practically no wear on the device. This sensor is suited for cyclical as well as continuous testing of tools. As the sensor is designed to be torsionally rigid any errors due to it are minimized. No service needed because of contactless data aquisition High interference immunity due to amplified active signal High accuracy due to frequency modulation and strain gage technology Power supply Optional angle detection torque ranges from 1 Nm up to 10.000 Nm torque with square drive with or without angle (w) function Variant bracket for quick assembly

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Series DRDL torque transducers are suitable for lab and industrial applications because of their small size and multiple mounting options. As supply voltage and output signal are transmitted without contact, the device can operate continuously with low wear and no maintenance. These transducers are also available with optional speed and angular measurement for a host of applications. The integrated signal amplifier is powered with 12 V DC and outputs an electrically isolated analog signal of 0 to ± 10 V per torque range. Simultaneous measurement of peak torque and operating torque Torquesensor with speed or angle measurement High accuracy with 100% overload protection 16 measurement range from ± 0 - 0,5 Nm up to ± 0 - 5000 Nm 2 torque ranges (1/10 - 1/2 of the 1st measuring range) Integral signal amplifier Low moment of inertia Single supply voltage Wide range of applications Multipurpose use Contactless output signals Compact Speed measurement (option) Angular measurement (option)

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Simultaneous speed / torque display universally applicable sufficient for many measuring tasks 11 torque range from ± 0 - 0,5 Nm to ± 0 - 1000 Nm Very short Broad input voltage range Current output and voltage output Measurement accuracy: ≤ 0,5% of full scale Torque ranges from 0,5 to 1000 Nm Contactless transfer of measurement signal Proven strain gage technology Integrated signal amplifier Single power supply Multipurpose use Simultaneous speed/torque indication 4-segment display with sign Peak mode (clockwise only) Indication area on LCD display 30 x 11 mm Speed indication updated 1x sample/second Torque updated 1,000 samples/second

Request for a quote

ETH MESSTECHNIK GMBH

Germany

11 torque range from ± 0 - 0,5 Nm to ± 0 - 1000 Nm Low cost. Very short. Broad input voltage range. Current output and voltage output. Optional speed measurement. Measurement accuracy: ≤ 0,5% of full scale. Torque ranges from 0,5 to 1000 Nm. Multipurpose use. Contactless transfer of measurement signal. Integrated signal amplifier. Proven strain gage technology. Single power supply.

Request for a quote

MAGTROL

Switzerland

The TSC Series is the Torque and Speed Conditioner used to connect Magtrol Eddy-Current (WB) or Powder (PB) Dynamometers to the DSP7000 Dynamometer Controller. Powered by the dynamometer controller, and based on a precision instrumentation amplifier, the unit amplifies and filters the torque signal. It also provides power and connections for the speed pickup sensor which is located in the dynamometer.

Request for a quote

MAGTROL

Switzerland

Magtrol offers three types of torque transducers for dynamic torque and speed measurement. All three transducer models employ our unique non-contact differential transformer torque measuring technology. This measuring technology offers many benefits most notably that no electronic components rotate during operation. Each model has an integrated conditioning electronic module providing a 0 to ±10 VDC torque output and an open collector speed output. Magtrol’s Torque Transducers are very reliable, providing high overload protection, excellent long-term stability and high noise immunity.

Request for a quote

MAGTROL

Switzerland

Magtrol’s Model 3411 Torque Display is designed for use with all Magtrol TS, TM, TMHS, TMB and TF Torque Transducers. This easy-to-use device powers the transducer and utilizes high speed processing to display torque, speed and mechanical power. It includes a tare function to help offset any slight residuals caused by couplings or suspended loads. The 3411 may also be used with any torque sensors requiring 24 V DC power (500 mA max.) with ± 5 V DC torque output (± 10 V DC max.) and open collector, TTL or CMOS output for the speed signal.

Request for a quote

MAGTROL

Switzerland

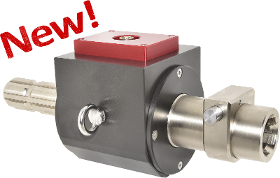

With its compact, bearingless, maintenance-free design, the new TF Torque Flange Sensor from Magtrol brings many appealing advantages to torque measurement applications. The TF’s high torsional rigidity supports direct mounting on the machine shaft or flange, avoiding the use of couplings on one side. This allows easy integration into a test system, shortens the overall length of the test bench and reduces costs. Based on strain-gauge technology, the TF Sensor’s precise telemetry system enables highly accurate signal transmission. A signal amplifier mounted in the measuring flange amplifies the measuring signal, modulates it to high frequency and transmits it inductively (via the HF transmitter) to the receiver. In the receiver, the digitized torque signal is transformed into an analog output signal of ±10 VDC. Rotational speed can be measured and converted to a TTL output signal with the optional speed pickup. more info www.magtrol.com

Request for a quote

MAGTROL

Switzerland

Magtrol’s TS In-LineTorque Sensors provide extremely accurate torque and speed measurement. Each model has an integrated conditioning electronic module providing 0VDC to ±5VDC (±10VDC) torque output through an 8-pole connector, as well as a USB interface which can be directly connected to a computer. The sensor is delivered with software allowing easy connection and data acquisition. A speed encoder provides a minimum of 360PPR (Pulse Per Revolution) in Tach A, Tach B and Index reference Z (1PPR). Magtrol Torque Sensors are very reliable, providing high overload protection, excellent long-term stability and high noise immunity. TSSeries sensor models are strain gauge-based measuring systems with imbedded telemetry signal transmission. Three LED lights allow a visual check of the sensor status by color code. The sensor is powered by 24VDC (12-32VDC) through its connector. TARE & B.I.T.E. (Built-In Test Equipment) can be activated by either software or input from the 8-pole connector.

Request for a quoteResults for

Torque - Import exportNumber of results

238 ProductsCountries

Company type

Category

- Hand tools, non-power (46)

- Measurement and control instruments (23)

- Sensors (19)

- Testing equipment (18)

- Automation - systems and equipment (10)

- Measurement and regulation equipment and instruments - pressure (10)

- Electric motors and parts (5)

- Robotics (4)

- Brakes, servo-brakes and accessories (3)

- Clutches (3)

- Construction machinery (3)

- Electric vehicles (3)

- Fastening devices (3)

- Hinges (3)

- Import-export - oil (3)

- Measurement - Equipment & Instruments (3)

- Newspapers and magazines (3)

- Nuts and bolts (3)

- Electric tools (2)

- Home Furniture (2)