- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- water extraction - systems and equipment

Results for

Water extraction - systems and equipment - Import export

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

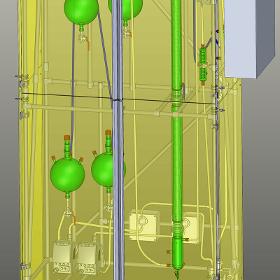

The unit for the liquid/liquid extraction operates in a countercurrent flow and is designed as a pulsed column with sieve trays and packing material alternatively. The working principle of this unit is based on the fact, that the two liquid phases are pressed through the holes of each sieve tray or through the packing respectively, forced by the used pulsation, thus one phase will be dispersed into the other. The large contact surface which will be formed by this specific design, makes the product exchange between the two phases highly efficient. During the return travel of the pulsator, the drops previously dispersed are agglomerating into a homogeneous phase. The light phase will be fed into the system at the lower end of the column, while the heavy phase is entering the tower at the upper end. Due to the gravitation, supported by the said pulsation, both phases are passing the column in countercurrent way and are withdrawn at the opposite ends.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

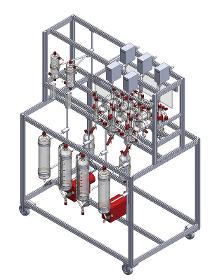

For liquidliquidextraction according to the MixerSettlerprinciple, design acc. to Dr. E. Müller (Lurgi). With screw stirrer for intensive mixing of the phases, especially suited for metallic salt extraction. Pumping capacity and residence times are changed by adjusting the stirrer speed. An additional advantage of the unit is the application for extractions during which reactions of considerable density changes occur. Typical applications for this universal apparatus are metal salt extractions mixtures with low surface tension if the dispersed phase coalesces with difficulty if variation in residence time of the phases occur in the extraction stages if reactions are expected during the extraction process if considerable changes in density are expected as a result of extraction

Request for a quote![Distillation Control System ILUDEST® [DC / MoS]²](/filestore/vig280/opt/product/ea/9a/distillation-control-system-dc-mos2_3ede0556.jpg)

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

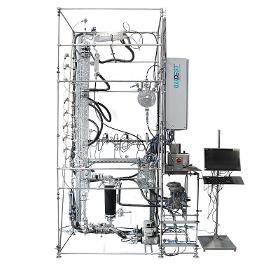

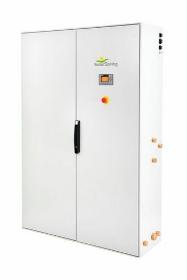

The use of a computeraided system is well suited for the control and regulation of distillation and rectification plants the wide range of measurement and regulating tasks, the need for flexibility, ease of operation and a display of the operating parameters make the use of a computer with the relevant software and peripherals appear the ideal solution.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

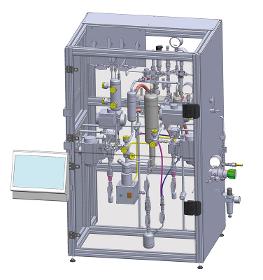

Comprehensive range of microprocessor operated units for various control modes/functions. The indication and modification of all set points and actual values is done via touchscreen LCD. With optional Ethernet interface for the communication with a PC and CANBUS for the connection to other controller types.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

ILUDEST® designs / manufactures a comprehensive range of Teaching Units for the Thermal Process Engineering

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

ILUDEST® designs / manufactures a comprehensive range of Teaching Units for the Thermal Process Engineering, e.g. Continuous distillation Thin film evaporation Short path evaporation Pulsed counter current extraction Absorption/desorption Residence time determination (reactor/cascade) etc. Other types and/or customized versions are available upon request.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Because of the thermal sensitiveness of products, this separation method is applicable. The sample to be distilled is exposed only for a very short time to the heating substances because the film, created by the wiper, can evaporate very quickly. The residence time of medium on the heating surface is a matter of seconds, thus essentially less than in a reboiler flask, circulating evaporator etc. The evaporated product (operation pressures down to 103 mbar and temperatures up to about 300°C) has to pass a “short path” to the condenser only, which is located in the middle of the evaporator. Evaporators in borosilicate glass 3.3 are available with heat exchange areas 0.02…0.8 m². Evaporators in stainless steel can be heated by a heating jacket to higher temperatures with more heat transfer area for higher throughputs.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Because of the thermal sensitiveness of products, this separation method is applicable. The medium which is to be distilled is exposed only for a very short time to the heating substances because the film, which is created by the wiper, can evaporate very quickly. The residence time of medium on the heating surface is a matter of seconds, thus essentially less than in a reboiler flask, circulating evaporator etc. Evaporators in borosilicate glass 3.3 are available with heat exchange areas 0.02…0.8 m². Alternative design versions in stainless steel for higher throughputs are available upon request. Please equire.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The instrument has a capacity of 6 litres of solvent mixture with a throughput of up to 1 l / hr (e.g. when recovering Xylene). A microcomputer controller holds up to 100 programs as well as monitoring the distillation process for normal and safe operation. Variable reflux ratios and equilibrium times are possible so that the operator has maximum flexibility to design a program for optimal efficiency. Other capacities are available upon request.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Especially the theoretically additional evaluation of the temperature and pressure dependence of phase equilibrium is insufficient very often in daily practice, thus the experimental determination of VLEdata is increasingly requested in the overpressure range, too. ILUDEST®/ iFischer® modified the VLEequipment, since decades sold under the worldknown FISCHER® brand, suitable for the overpressure range up to 50 bar. The VLEequipment is designed for a charge of 50 ml (dynamic mode) and can be operated under vacuum (1...1,013 mbar), atmcondition and overpressure (1...50 bar) as well as temperature up to 250°C. An extended operating range up to 100 bar is possible.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Scientists and chemical engineers still measure phase equilibria despite the significant improvement in theoretical evaluations. Therefore, our phase equilibrium apparatus is part of the standard equipment in chemical engineering laboratories. The vapourliquid equilibrium of binary and multicomponent mixtures constitute an essential basis for the determination of the theoretical plates necessary for the evaluation of separation processes. Although VLEdata are known from literature, there is still an increasing tendency towards redetermining equilibrium data by experiments, because the thermodynamic parameters like pressure, temperature and concentrations are different or inadequate. For designing e.g. extractive distillation processes the evaluation of vapourliquidliquid phase equilibria (VLLEdata) are required. The practical measurement and determination of these data proves difficult with the standardised VLEunits because of the phase formation of the liquids.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Automatic SemiMicroDistillationUnit with the FISCHER® SPALTROHR® Column Compact and especially versatile, the fully automated FISCHER® LABODEST® HMS 500 AC is a unit with highest separation efficiency A modular system, which can be designed according to specific requirements including an equipment for recording the distillation curve or for printingout the distillation record by means of a printer or for connection for electronic data processing. Technical Data Charge Quantity 10...500 ml Operation Temperature up to 200°C, with optional extension up to 350°C Operation Pressure Atmospheric or Vacuum 10 0...0.1 mbar Pressure Drop < 0.1 mbar Separation Efficiency up to 90 theoretical plates Mains Supply 230 V, 50 Hz Dimensions (w x d x h) 1.25 x 0.60 x 1.70 m Weight approx. 100 kg

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The iFischer® DIST D5236 CC / FISCHER® AUTODEST® 860 AC can be converted to the “HV” version by adding an extended Potstillcolumn to the standard ASTMsystem (Potstill). The respective distillation process is performed in the range of 0.005...0.1 mm Hg. The iFischer® DIST D5236 HV 6 ltr / FISCHER® AUTODEST® 860 HV 6 ltr is a fully computer controlled unit of turnkey design, and ready for use after installation and commissioning. The system is fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The automatic fraction collector with 12 receivers includes a builtin internal balance, which is used for the simultaneous determination of the fraction weight and for the direct distillation rate control. The vacuum equipment and the control system are designed for highest accuracy, repeatability and reproducibility of data. The system is also available with a capacity of up to 50 ltr.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The iFischer® DIST D5236 CC / FISCHER® AUTODEST® 860 AC is a fully computer controlled unit of turn key design, and ready for use after installation and commissioning. The system is fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The automatic fraction collector with 12 receivers includes a builtin internal balance, which is used for the simultaneous determination of the fraction weight and for the direct distillation rate control. The vacuum equipment and the control system are designed for highest accuracy, repeatability and reproducibility of data. Also available are the iFischer® DIST D5236 CC 50 ltr, 100 ltr, 150 ltr and 250 ltr fully automated computerised distillation systems acc. to ASTM D5236 equipped with a set of comprehensive safety features in correlation with the applicable EU Machine Directives and refinery standards. Numerous optional items available.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Fully Automated/Computerized Distillation System for fractionating of crude oil samples, atmospheric residues resp. vacuum distillations of lubricating oil samples up to very low operation pressure (high vacuum HV Operation pressures down to 0.005 mmHg, allowing fraction temperatures up to 600 °C AET). The unit is equipped with an automatic fraction collector (FC) and combined automatic fraction discharge into final receivers, which are closed automatically. The fraction volumes and weights are determined by builtin volume follower system and internal balance (included software "FCExtension" allows to operate very narrow fractions by using max. 40 receivers).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The system is a fully computer controlled unit of turn key design, and ready for use after installation and commissioning. It is fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The automatic fraction collector with 20 receivers includes a builtin internal balance for the determination of the fraction weight, while the separate volume follower system is used for discharging the fractions into the final receivers and the determination of the fraction volume as well as for the direct distillation rate control. The vacuum equipment and the control system are designed for highest accuracy, repeatability and reproducibility of data. Numerous optional items available.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The iFischer® DIST D1160 CC / FISCHER® AUTODEST® 850 AC is a fully computer controlled unit of turn key design, and ready for use after installation and commissioning. The unit extends the current test method and does not limit your vacuum distillation testing options. You are able to define your own tailored program also beyond the current standard. The system is fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The design also grants an easy maintenance by the operator. The analysis protocol is printed out simultaneously to the distillation and the distillation curves in actual boiling temperatures (ACT) and atmospheric equivalent temperatures (AET) as well as essential distillation parameters are shown on the monitor. The final data and the distillation curves are printed and stored on harddisk.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The iFischer® DIST D2892/5236 CC or FISCHER® AUTODEST® 800/860 AC is a fully computer controlled unit of turnkey design, and ready for use after installation and commissioning. Fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The automatic fraction collector (in the system section TBP with 20 receivers) includes a builtin internal balance for the determination of the fraction weight, while the separate volume follower system is used for discharging the fractions into the final receivers and the determination of the fraction volume as well as for the direct distillation rate control. The automatic fraction collector (in the system section Potstill with 12 receivers) includes a builtin internal balance, which is used for the simultaneous determination of the fraction weight and for the direct distillation rate control.

Request for a quote

CIMAT

Poland

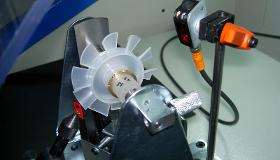

Balancers for Water Meters is one of CIMAT compact balancing machines. The greatest advantage of compact balancing machines is the possibility of easy placement—embedded vibration insulators do not require foundations. As such, our compact machines occupy a small area in comparison to conventional balancing machines on a bed. This is made possible by a guard coupled with the balancing machine body—these guards do not occupy additional square meters of area. In spite of their small dimensions, these compact balancing machines have a robust body with silica sand filling to dampen vibration. As a result, our machines are capable of very accurate measurements and they are less sensitive to outside disturbances. Main features Using an appropriate machine design and a suitable safety guarding machines, Permanent calibration and rotor specific calibration, Pedestals with integrated pins and Vblocks, Latest measuring and control unit ROTORTEST,

Request for a quote

COLLOIDE ENGINEERING SYSTEMS

United Kingdom

Clarifiers are settling tanks built for continuous removal of solids. Clarifiers are generally used to remove solid particulates or suspended solids from liquid for clarification and (or) thickening. We use lamella settlers within our clarifiers, which greatly increases the clarifier capacity and enables a much greater flow to be treated in the same footprint as conventional clarification. Our design also ensures maximum efficiency in terms of upward flow velocities. The lamella settlers can be used in new builds and are also an excellent option for upgrading and increasing the flow through an existing plant. Our clarifiers can be designed in a wide range of sizes and configurations to suit the individual needs of each of our clients. The clarifier can be used as a standalone system, taking the full plant flow, with or without additional equipment such as sand filters, screens, etc.

Request for a quote

COLLOIDE ENGINEERING SYSTEMS

United Kingdom

These packages are tailored to suit our clients’ requirements while adhering to European Standards, Ciria and HSE guidance. We engineer solutions to integrate into existing or new sites and can also provide packaged, standalone systems which are largely independent of the main plant. We provide solutions for chemicals such as sodium hydroxide, sulphuric acid, hydrochloric acid, ferric sulphate, aluminium sulphate, ferric chloride, antifoam, ortho-phosphoric acid, etc. Storage capacity, duty/standby configurations, materials of construction, etc. are tailored to the application, to provide adequate storage and ensure that the system can be operated and maintained safely. The chemical storage and dosing systems are fully fitted with instrumentation such as level controls, leak detection, flowmeters, etc. and are generally PLC controlled with an operator interface panel or PC used to allow the operator to view the plant operation and change parameters.

Request for a quote

COLLOIDE ENGINEERING SYSTEMS

United Kingdom

Colloide‘s Dynamic Sand Filter offers an excellent treatment system for the removal of solids and other contaminants from a water/wastewater stream. This filter is always on line, continually filtering the incoming water while continually backwashing a small portion of the sand bed. The Dynamic Sand Filter process: The feed water is fed into the filter at the base of the active sand bed through the distribution ring. It then flows upward through the downward moving sand bed where the solids are filtered out. The clean filtrate exits the filter through the overflow weir. The continuous reject flow of washing water is discharged through a separate outlet. The dirty sand is continuously removed from the active sand bed thanks to the action of the air-lift pump. This pump draws the contaminated sand from the bottom of the filter body. A mixture of sand, dirty particles and water is transported upward through the air-lift pipe into the washing chamber at the top of the filter.

Request for a quote

COLLOIDE ENGINEERING SYSTEMS

United Kingdom

Colloide provides circular and rectangular scraping systems (plastic and steel) for settlement and flotation tanks. These tanks are generally rectangular or circular, designed to separate solids from the liquid by either settlement or flotation. Circular Tanks We offer two alternatives for circular tanks: -A rotating bridge structure powered by a peripheral drive unit. The bridge supports a frame below it onto which is fixed sludge scraping blades at floor level and a scum blade at top water level. -A fixed bridge mounted on the walls of the tank. A central drive unit rotates the scraping mechanism around the tank, the sludge scraping blades diverting the sludge to a hopper. Rectangular Tanks A chain and flight principle is used for rectangular tanks, consisting of two main chains which move the scraping booms up and down the tanks. When scraping at top water level, the booms push the floated material to one end of the tank, where it is collected by a rotating sludge pipe.

Request for a quote

OKAY ENERGY EQUIPMENT CO., LTD.

China

the water systems's water output 10L/h,20L/h,40L/h,60L/h are available. Features: 1.two way online water quality sensor,RO water, deionized water, or ultrapure water respectively. 2.Cartridges replacing alarm function, based on time and water quality, show cartridges´ used and residual life. 3.Multiple alarm function: no feed water, full water, water quality´s standard exceeding, and cartridge life ending. 4.top polishing resin, ensure ultrapure water´s quality up to 18.2 MΩ.cm, with the lowest TOC level. 5.integrated design of the whole machine, small occupancy, simple appearance, easy to use and safe. Lab Type 1 ultrapure water can be widely used for Flow cytometry, pyrogen sensitive applications, cell and tissue culture, and sentitive analytical work such as HPLC,ICP-MS,GC-MS. TheType 3 RO pure water is for filling water baths and incubators,feeding glassware washing machines and autoclaves.

Request for a quote

SOLARSPRING GMBH MEMBRANE SOLUTIONS

Germany

"Clean water with clean electricity Billions of people still have no access to clean drinking water or lack adequate sanitation. Residents of rural areas are particularly affected. If drinkable water is needed far away from any infrastructure, SolarPurification can help. The system can produce up to 200,000 litres of clean drinking water per day even from heavily polluted surface and ground water. Clean drinking water without chemicals Several treatment stages make it possible that the drinking water is not only clean but also safe. The SolarPurification filters 99.999 % of all bacteria and viruses from the existing water - and this completely without the use of chemicals. This is made possible by a combination of ultrafiltration, activated carbon filtration and UV disinfection. High-quality components, automatic operation with PLC and online monitoring characterize this compact water treatment system. Low maintenance and solar powered

Request for a quote

SOLARSPRING GMBH MEMBRANE SOLUTIONS

Germany

"The MBS-Outdoor from SolarSpring is a compact and innovative water treatment plant.The system guarantees a reliable and safe water supply from contaminated and microbiologically contaminated water sources without the use of Chemicals. Tecnical data: Nominal flow rate: 50-200l/h Energy consumption: 40W Weight: 22kg"

Request for a quote

INTEGRATEAIR FILTRATION

United Kingdom

Introducing integratedAIR Filtration’s BlueClean® VCP range of self-cleaning pulse jet cartridge filter units. A versatile range of high efficiency filter units incorporating conical filter elements providing highly effective filter cleaning even when dust loadings are high. Our VCP Square unit can be supplied as an insertable, flanged open base or complete free standing filter unit with each design being able to be supplied with or without inlet mounted fan sets. The VCP Square, a range of high quality pulse jet filter units designed for use within processing and dust control applications and part of the Industrial Air Filtration range, dust control filter units built without compromise.

Request for a quoteResults for

Water extraction - systems and equipment - Import exportNumber of results

34 ProductsCountries

Company type

Category

![Distillation Control Unit ILUDEST® [DC / MIC]³](/filestore/vig280/opt/product/44/e3/dist-control-unit-iludest-dc-mic_1_e7dfd410.jpg)