- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- lubricating system

Results for

Lubricating system - Import export

DUTCH PERFORMANCE PRODUCTS VOF

Netherlands

Lindemann Diesel Boost cleans and lubricates the entire diesel fuel system. By regularly adding Lindemann Diesel Boost to your tank, you keep the engine and fuel system clean and in good condition

Request for a quote

IGUS® GMBH

Germany

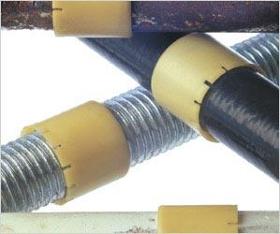

iglidur® PEP, metric d1 [mm]: d2 [mm]: iglidur® PEP, inch d1 [inch]: d2 [inch]: When to use iglidur® PEP plain bearings? When a low-priced plastic plain bearing system is required When freedom is required from shaft material and shaft surface For the protection of expensive and sensitive shafts For extraordinary wear resistance with rare and slow movements. For constantly low coefficients of friction When freedom from corrosion is desired When not to use them? For high surface speeds iglidur® J For high loads iglidur® G iglidur® Q For high temperatures iglidur® V400 iglidur® X iglidur® Z When low-clearance bearings are required iglidur® P iglidur® X Maintenance-free plain bearings usually distinguish themselves by their ability to glide free of lubricants without any further additional layer on the shaft. In these systems it is obvious that shaft materials are as important as the bushings. igus® blazes a new trail with an enclosed and maintenance-free plain bearing concept. iglidur® PEP is an entirely novel lubricant-free plastic plain bearing system with an inner and outer ring. Special feature: The running partner is determined by the inner ring and for the first time, the material and surface finish of the shaft are insignificant. Even thread, rust or scratches do not affect the long-term reliable function. By the specification of the gliding partner and extensive series of tests, the long-term behavior of the bearing system can be precisely forecast. With the PEP polymer plain bearing, the inner ring rotates with the shaft like in ball bearings Relative movements of the shaft to the bearing are dispensed with. This protects the shaft surface from wear and saves costs. Another plus point: Even the most sensitive or unusual materials for the rotating shaft can be used with these new polymer bearings. The PEP polymer bearings are thereby absolutely free from material-dependent corrosion. Wear resistance The wear test results are absolutely convincing with loads up to 5 N/mm². Here the PEP polymer bearings attain values that are virtually comparable with those of the most wear-resistant plastic-steel bearing systems. An exceedingly satisfying result when you consider the costs saved by dispensing with the otherwise essential surface treatment of the shaft. The constantly low friction-coefficient level is also an advantage for the user. As the glide partners are fixed by the defined system, their tribological data too are accurately predictable. The coefficients of friction of the lubricant-free bearing are not determined any more by the shaft materials or surface conditions. If necessary, the coefficients of friction can be further lowered by additional minimum lubrication. Detailed test information with a wide range of lubricants are available and can be had from igus® on request. iglidur® PEP bearings operate independent of the shaft material. iglidur® PEP bearings consists of an inner and outer bearing. X = Load [MPa] Y = Wear [μm/km] A = PEP B = Combination 1 C = Comb. 2 D = Comb. 3 E = Comb. 4 F = Comb. 5 G = Comb. 6 H = Comb. 7 A1 = Wear of the outer bearing B2 = Wear of the inner bearing Fig. 02: Wear tests of various material combinations, p = 0.75 MPa, v = 0.3 m/s X = Load [MPa] Y = Wear [μm/km] A = iglidur® J B = iglidur® PEP Fig. 03: Wear of the iglidur® PEP bearing dependent on the load, v = 0.3 m/s iglidur® PEP, metric d1 [mm]: d2 [mm]: iglidur® PEP, inch d1 [inch]: d2 [inch]: Dimensions according to ISO 3547-1 and special dimensions

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Dosing system DB 10: lubrication made easy The dosing system DB 10 uses a pressure vessel with a capacity of 10 litres. This is equipped with a filler ball valve and plastic funnel, a pressure regulator with bleed screw and a safety pressure relief valve. A float switch is fitted to regulate the fill level. There are two dosing valves on the underside. This dosing system is available in the following versions: DB 10 H – with poppet valve DB 40 – with 40 litre reservoir DB 40 H – with 40 litre reservoir and poppet valve

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Squeeze-on lubricators Maximum efficiency and the highest levels of flexibility Particularly rugged & and long-lasting The ROTOL squeeze-on roller system is a lubricator developed exclusively in house by Eckardt. This is an exceptionally rugged, long- lasting lubricating machine designed to apply lubricant in precisely defined film thicknesses over an entire surface. Thanks to the ROTOL calender rollers our squeeze-on lubricators achieve very high pressures. Thinnest, homogeneous film thicknesses possible. Features & benefits • Far longer service life in comparison with conventional felt rollers • Works with all pumpable lubricants • Achieves thinnest, homogeneous film thicknesses • Very high viscosities possible • Rugged ROTOL calender roller made of non woven material • Practically impervious to mechanical damage • Lubrication media is retained on the surface of the roller; no premature wear resulting from being drawn in How it works Fleece rollers remove cleaning liquid, fo

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Dosing systems The right amount every time Compact & efficient Our supply and dosing systems are designed to harmonize perfectly with all Eckardt lubricators. These range from small integrated dosing devices through to standalone oil supply solutions with filter units and tank heaters. Features & benefits • Individual dosing and storing solutions • Integrated tank heater and filter units optional • Suitable for oils of all manufacturers and viscosities • Available in all sizes and performance data Design versions and details Dosing system VB 10: the sound entry-level solution The VB 10 dosing system operates without any pressure. It hangs above the roller lubricator; the oil is supplied to the machine purely through the force of gravity. The capacity of the VB 10 storage container is 10 litres. Dosing system DB 10: lubrication made easy The dosing system DB 10 uses a pressure vessel with a capacity of 10 litres. This is equipped with a filler ball valve and plastic funnel, a p

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROSAW LIMITED

United Kingdom

Automatic upstroking circular saw with NC Programmable Controls. Yilmaz SK450 Standard Details Designed for high-volume straight cutting of non-ferrous profiles 4 – 6 second cycle time* High precision servo motors accurate to ±0.05mm* 450mm TCT blade with 4 kW motor Servo-controlled infeed speed and saw blade stroke adjustment Horizontal and vertical pneumatic clamping of the workpiece for precise cutting Automatic retraction of stock material at end of cut to protect the surface from scratches Single or multi-bar** (bundle) cutting Computer-controlled blade lubrication system System shuts down automatically after cutting the required quantity Interlocked safety guards Windows-based industrial PC with 7’’ LCD colour touch screen HMI & USB cutting job input Internet connection possible for technical support Automatic feeder stroke from 5 – 600mm. Maximum cutting length 9990mm Automatic end of bar sensor *Depending on material **Extra-cost option

Request for a quote

GLOBAL INDUSTRIAL SEWING MACHINES

Netherlands

WF 9245-35 – Single needle, flatbed, walking foot machine with 35 cm working space. This is a high quality machine suitable to sew on leather, furniture and upholstery. This machine is equipped with a large hook, safety clutch and semi-automatic lubrication system.

Request for a quote

ECO-ALIANCE LLC

Russia

Chain oil is a product of mineral origin containing special additives that improve the lubrication and cooling of saw chains, drive sprockets, tires and extend their use. The oil is suitable for different types of saws all year round in the temperature range from +40°C to -35°C. Chain oils can be used for different types of saws all year round, since the operating temperature range is from plus 40°C to minus 35°C. Also, chain oil protects the metal parts of the saw from the occurrence of corrosion processes, as it creates a film on their surface. Chain oil is used today for many technical devices, but mostly it is all modern gasoline and electric saws. These tools are usually equipped with an automatic lubrication system.

Request for a quote

GLOBAL INDUSTRIAL SEWING MACHINES

Netherlands

WF 9245 – Single needle, fl atbed, walking foot machine. This is a high quality machine suitable to sew on leather, furniture and upholstery. This machine is equipped with a large hook, safety clutch and semi-automatic lubrication system. WF 9245 B – Same as WF 9245, but equipped for binding work (binder not included). Products WF 9245, WF 9245 B Table Top No Table Top, Table grey C WF 9245 (120x55x4 cm), Table Top D 105x55x4 cm Stands No Stand, Stand C (China), Stand K (912 mm), Stand K short (667 mm), Stand Z Motor Set External synchroniser SY0129 (600-29), G 60 Servomotor (optional: external synchroniser G series), i60-4-GL-220, MT0175 – 750 Watt mini motor, No Motor Set, NS clutchmotor 1400 RPM 220 V, NS clutchmotor 1400 RPM 380 V Option External synchroniser for G-series, No option, Thermical switch 220 V, Thermical switch 380 V Option for i60-4-GL-220 pneumatic presser foot lifter WF 1335, 9245, ZZ 1266, Pneumatic backtack WF 1335, 9245, Set PFL + BT WF 1335, 9245,...

Request for a quoteResults for

Lubricating system - Import exportNumber of results

10 ProductsCompany type