SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Manufacturer/ Producer

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

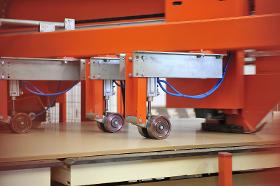

The boards are cut o the endless mat in the saw section. The process becomes a discontinuous one that is characterised by cycle times from this point on. The saw section includes the board edge-trimming and saw units. The board is cut by saws that are positioned at right angles to the endless board and that cut straight proportionally to the feed of the press. It is possible to change the tools without interruption to the production process depending on the number of individual units. longitudinal edge trimming device 2 edge-trimming units – no production possible while tools are being changed 2 edge-trimming units with the option for retrotting additional units 4 edge-trimming units for interruption-free changing of the saw blades Bevelling of the endless board after trimming Multi-diagonalsaw Up to two saw beams each with two units, i.e. four saws maximum Number of saws depending on the feed and desired board length

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

It is possible to reliably remove reject boards without aecting the cycles in the rejects area. Acceptable boards continue to be transported towards the cooling turner. The rejected board stack may optionally be equipped with batch and package forming systems. These are for optimising the cooling turner utilisation and are explained in greater detail in the chapter about the ‘Cooling section’. The rejected board stack is equipped with a variable length adjuster or board lifter for the batch and package forming options. Reject boards are removed by lifting the rst belt conveyor. The rejected board stack may be optionally equipped with a buer for forming the reject stacks or with an additional belt conveyor that transports the rejects to the board breaker.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

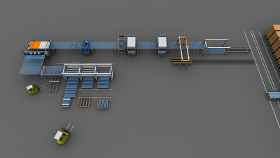

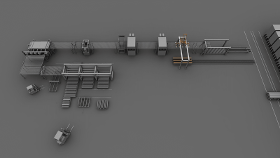

The cooling section's design is optimised while taking account of the product's technological properties (particleboard, MDF, OSB), the range of board dimensions, production capacity and modes of operation. Siempelkamp is a system supplier and is so able to guarantee targeted coordination tailored entirely to the customer's requirements. The number of cooling turners results from the board dimensions and modes of operation Single-board operation moves a single board to the cooling turner and then triggers the turning cycle. The batch operation works with several boards in a row that are moved into the cooling section as one overall length before the turning cycle is triggered. The package operation mode works with several boards on top of each other that are moved as a package into the cooling section before the turning cycle is triggered. Option When the product widths vary greatly, an optional board pusher that slides

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Stacks are created in the high-stack forming section that are then transported to the maturing section to enable the glue to cure. Interim stacks are created on the package-forming table that are built up to high stacks Features High stacks of up to ve metres high Max. weight 60 t Option Protection boards as the top and bottom board

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The large maturing store is for storing and maturing the boards. The fully automated system with aisle vehicle and accompanying satellites is responsible for the stack transport. The aisle vehicle moves the stack in one direction and the satellites assume the task of transporting them into the rack aisles. The size depends on the required storage capacity and on local circumstances. The aisle vehicles are responsible for transfer movements, the satellites pick the stacks up or move them into the individual aisles. Advantages Expandable by modules Options ‘First in - rst out’ strategy ‘First in – last out’ strategy

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Thickness measuring systems THICK-SCAN behind the ContiRoll® optimizes the process and to reduces the costs while, at the same time, assuring the quality standard. If the gauges are located in the sanding line, the tool life of the sanding belts is enhanced and the quality is assured. The time is long past since panel thickness tolerances have been measured during production by handheld devices. Today, however, such measurement is carried out continuously online. In the majority of plants, quality control is not the rst priority for new investment for online thickness measurement. The current trend is to achieve the enormous potential savings in wood raw material, resin and energy consumption. If the upper tolerance level is exceeded, valuable resources are wasted. The Thickness Gauge prevents such losses. It is robust and reliable.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

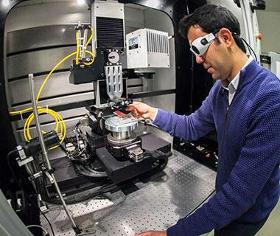

The continuous non-contact Area-Weight Scale CONTI-SCALE X MULTIENERGY determines the panel weight and its distribution during production by measuring the area-weight and by taking the known panel dimensions into account. CONTI-SCALE X MULTIENERGY uses X-ray technology. Two X-ray tubes are located on a horizontal frame above the panel. The low energy X-ray beams are focused across the production width, but scan the full width of the panel. Metal plates on each side of the system prevent someone reaching inside the radiation area. There is no risk to human body parts which might stay beside/outside the system. The X-ray energy will be absorbed. Several detectors are lined up along the lower beam under the panel to measure (per track) the absorbed X-ray energy. This is how the area-weight is measured.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp Bond Analyzer BLOW-SCAN is a detection systems which automatically detect blows and unbonded areas during the production of wood panels. It utilizes ultrasound and therefore is suitable for harsh production environment. Self-Calibration takes place in each panel gap. This compensates inuences raised from waste deposits and temperature variations. The models CONTI-SOUND and BLOW-SCAN are preferably installed in particleboard, MDF and OSB production lines. Changes of the panel properties are shown so the measurement can be used as an early warning System Features and Function Board thickness < 60 mm Density > 550 kg/m3 Detectable blow size > 28 mm Online calibration Automatic adjustment of sensor sensitivity Automatic recognition and compensation of dust load on sensors Automatic compensation of temperature drift Real-time data analysis Remote service

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The sanding / saw line manufactures the end product to be sold / the basis for subsequent processes – e.g. lamination – from the master board. Very smooth surfaces and dened dimensions may be realised with great accuracy. The sanding line may be installed separately or combined with the saw line as a closed concept. The sanding machine, saws and other process components are designed and combined on the basis of customer requirements. Our goal: to achieve the best product in all forms through the optimum use of resources! Advantages High capacity Safe and gentle material transport, short conveying distances due to direct connection to machines High exibility Rapid access times Optimum coordination of the machines used with the products, the required capacity and interactions

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The stack of boards needs to be separated again for the subsequent processes. Siempelkamp provides process-reliable, dependable solutions for all products and board properties here. Features and functions Stack feeding using forklift trucks, aisle vehicles or conveyors Board separation and feeding from the stack by the highly dynamic Siempelkamp feeding system. Advantages Absolutely process-reliable for all products (e.g. MDF, particleboard, OSB), board thicknesses and lengths irrespective of the width Variants, options Buer for interruption-free feeding during stack changes Protection board handling.

Request for a quoteManufacturer/ Producer

Siempelkampstr. 75

47803 Krefeld - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in mechanical shaft.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

Engines for combined heat and power plants are operated with different fuels, including hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels. In an exhaust gas heat exchanger, the hot exhaust gas from the CHP engines or CHP gas turbines is cooled, in the process heating water, a water-glycol mixture or thermal oil. This thermal energy can be used in a local or district heating system or for other industrial purposes.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

Silencers/Mufflers; diesel and gas engine exhaust noise is designed based on required target noise levels and current pressure drop. In addition to the standard silencers for stationary engines, special silencers are designed and manufactured according to customer specifications. In addition to reducing exhaust noise, extremely compact designs are made with the available space in mind.

Request for a quote

STEEC

France

Wire spark erosion, laser micro-cutting, micro-milling and micro-drilling STEEC is also involved, both as a subcontractor to numerous SMEs and agencies in the metallurgy and mechanical engineering sectors which very often engage in subcontracting activities themselves. STEEC enables these players to respond to invitations to tender that involve meeting precision micro-machining requirements for which they are not equipped. The wide variety of precision micro-machining operations which STEEC offers is highly beneficial to these SMEs and agencies, which are able to offer a comprehensive service in micro spark erosion, laser micro-cutting, micro-drilling and milling.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free