- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- forming- rubber - machinery

Results for

Forming- rubber - machinery - Import export

QUELLTECH GMBH

Germany

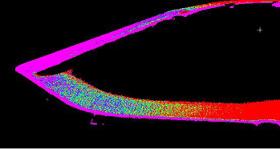

Particular Challenges: The seal surfaces in this case are made of very glossy metal, with the drawback of emitted reflections. This effect during an optical measurement must be eliminated. Furthermore, it is absolutely necessary to guide the laser scanner on a linear path over the surface, since fluctuations of distance may falsify the measurement result. QuellTech Solution: The Quelltech model Q5 disposes of an adequate resolution in X and Z direction and proves to be able to verify the planarity tolerances and to measure the size of defects. Meanwhile a precise rotary axle, used as guiding element, moves the scanner over the surface to be evaluated. Interfering artefacts caused by the glossy finish are suppressed by particular algorithms integrated within the software. As an encoder value is permanently supplied by the rotary axle, the position of each scanner profile within the point cloud can accurately be determined.

Request for a quote

JUNTA POLYMERS

Belgium

Junta Polymers offers you a wide range of rubber molded parts. Our specialized machines for compression or injection can produce every possible shape in VMQ (silicone), EPDM, NBR, CR, FKM or SBR rubber molded parts.

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

Silicone Processing Systems with Silicone Vacuum Treatment

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

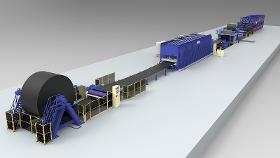

Siempelkamp’s steel-cord conveyor belt presses distinguish by an innovative steel-cord tensioning concept: the controlled steel-cord tension distribution system increases production safety and improves product quality. The electromotive tensioning system, which is individually controlled and installed directly in the creel with integrated measuring and control functions, allows a 100%-control over the actual steel-cord tension distribution. The exact quality reporting enables our customers to optimize the production, hence the product’s quality. The new concept replaces the xed-nger comb used in previous systems with a roller comb. The friction between comb and steel cables is thus eliminated. Consequently, the abrasive wear on the galvanized steel cables is reduced. Unlike the traditional concept, the new roller comb prevents any variations in tension distribution. Services Direct tensioning control in the creel Individually controlled steel-cord tension distribution

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

For the production of conveyor belts with steel-cord or fabric layers, Siempelkamp oers a multi-cylinder down-stroke press including 2-track production. Conveyor belts having a width of up to 3,200 mm and a thickness of up to 50 mm can be manufactured at a pressure of 400 N/m2. To this end, Siempelkamp's multi-cylinder presses provide a pressure distribution previously unattainable with hydraulic-mechanical press systems. In addition, the thickness tolerances of the conveyor belts could be reduced here compared to traditional press concepts. Services Conveyor belt thickness starting at 5 mm Optimal pressure distribution due to our multi-cylinder concept Material reduction by eliminating the hot platen insulation Stable press gap parallelism High safety standards Advantages Improved process safety Low material and production costs due to reduced thickness tolerances Minimal foundation requirements Ease of maintenance and long service life

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

One of Siempelkamp’s core competences is the design and manufacture of presses for the rubber industry. With our expertise in this eld we are the world’s number one in steel-cord and conveyor-belt presses with many of the conveyor belts used around the world being manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straightrunning stability. Siempelkamp's excellent manufacturing and high-quality plants are eld proven. Services Single-source supplier Uniform pre-tensioning of the individual steel cables Best pressure distribution in our vulcanising presses Cable clamping and tensioning device with a heavy clamp Compactor lorry with pre-press Pull-roll stand Reeling elements Advantages Excellent thickness tolerances due to multi-cylinder press without requiring press bolsters Safe vulcanizing process for various belt widths by controllable pressure distribution Transparent and controllable production process

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Design and production of press-systems for the rubber industry is one major core competences of Siempelkamp More than 100 years of experience in rubber press lines More than 100 years ago, we put in operation the first conveyor belt press on the market. Only 20 years later, the first large vulcanizing press with a closed frame construction went successfully in operation. Even today, our presses and systems for the rubber industry have unqiue advantages: Durability, speed, high availability and efficiency, which are the most important arguments for our customers to choose a Siempelkamp plant. Proven technology that is trusted in the rubber industry With our broad expertise in the fields of rubber processing industry, we are the world market leader for steel cord and conveyor belt presses. A large part of the conveyor belts used around the world are manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straight-running stability.

Request for a quote

ROTAKEM

Turkey

Technicial Specifications 1. Origin: Germany 2.Manufacturer: WERNER & PFLEIDERER 3. Production year: 1993 4. Year of renewal: 2020 5.Model No: 200 AES 6. Serial No: 231256 7.200 lt net usage volume 8.Hydraulic cover 9. Motor powers: 75 kW; 56 kW 10.Rotor speed: 0-50 rev / min 11.Extruder speed: 0-40rpm 12. Screw diameter: 180 mm 13.PLC & touch screen Siemens control system 14. Stainless steel bowl and rotor

Request for a quote

ROTAKEM

Turkey

Technicial Specifications: 1. Origin: Germany 2. Manufacturer: Troester 3.Type: r-type inverted array 4. Cylinder dimensions: Ø600 x 1500 mm 5. Roller speed: 3-30 mt / min 6. Cooling: Environmental corrugated watery closed loop system 7.Cooling Unit: With two hoods 8. Bearings: Bronze 9.Transmission: Each mill has independent drive, independent shaft 10. Motor Powers: 65 kW, 1500 rpm 90 kW, 1500 rpm 65 kW, 1500 rpm 11.Open / close: Automatic 12. Siemens PLC & touch screen control system *** All pictures are before revision

Request for a quote

ROTAKEM

Turkey

Technicial Specifications 1. Origin: Italy 2. Year of production: 1996 3.Refurbishment year: 2020 4. Motor power: 220 kW 5.Rotor structure: tangensial with 4 blades 6.Rotor speed: 44/36 rev / min 7.Dump system: sliding cover 8.Heat exchanger gearbox 9.Ram - pneumatic 10. Temperature control 11. Drinking cooling system 12. Original chassis 13. New electrical panel (PLC Control) 14. PLC control

Request for a quote

ROTAKEM

Turkey

Technicial Specifications 1. Origin: Italy 2. Revision year: 2020 3.Machine cylinder quantity: 4 Pieces 4. Cylinder dimensions: 335x1000 mm 5. Bearings: Bronze 6.Cylinder on / off: Manual 7. Motor power: 45 kW 8.Cooling system: Watering, cooling from the core 9. Engine-gearbox transmission type: Direct coupled 10. Transmission between shaft transmission type: Flywheel gear 11. Arrangement of mills: L-type 12. Friction ratio: 1: 1: 1 13. Optional: - motor driver - Rubber feeding unit - Cloth feeding unit - Hooded cooler - Winder unit - Packaged nylon coating unit

Request for a quote

ROTAKEM

Turkey

Technical specifications : 1. Origin: Russia 2. Renovation year: 2020 3. roll diameter: 660 mm 4. Roller length: 1500 mm 5. Front roll liner speed: 15 rpm 6. speed ratio of rolls: 1: 1,15 7. Roller opening range: 1-30 mm 8. Motor power: 160 kW 9. Engine-transmission transmission type: belt / pulley system 10. Transmission type between gearbox shaft: Direct coupling 11. Bearings: Ball Bearing 12. Lubrication: Automatic 13. Cooling system: Central cooled with water head 14. Visor: Fixed 15. Safety: - 4 emergency stop buttons - 2 emergency stop bars - 2 emergency stop pedals - Return - Engine brake 16. New chassis 17. Shafts ground 18. New electrical and control panel 19. Optional: - Stock blender - Automatic on / off - Motor drive

Request for a quote

ROTAKEM

Turkey

Technicial Specifications 1. Year of construction: 2006 2. Revision Year: 2020 3.Cylinder diameter: 660 mm 4. Roller length: 2135 mm 5. Front roller speed: 13 rev / min 6.Friction ratio: 1 - 1.22 7.Cylinder opening range: 1-15 mm 8.Motor power: 280 kW 9. Reducer: Jahnel 450 kW 10. Engine-gearbox transmission type: Direct coupled 11. Transmission type between gearbox and mills: Direct coupled 12. Bearings: Bronze 13. Lubrication: Automatic 14. Cooling system: Central cooled with rotary joint 15. Visor: Fixed 16. Security: - 4 emergency stop buttons - 2 emergency stop bars - 2 emergency stop pedals - Return - Engine brake 17. New chassis 18. Mills grinded 19. New electrical and control panel 20. Optional: - Stock blender - Auto turn on / off - motor driver *** All pictures are before revision

Request for a quote

ROTAKEM

Turkey

Technicial Specifications : 1. Manufacturer: Farrel 2. Renovation year: 2020 3.Cylinder diameter: 660 mm 4. Roller length: 2135 mm 5. Front roller speed: 12 rpm 6.Friction ratio: 1: 1,2 7.Cylinder opening range: 1-15 mm 8.Motor: 250 kW DC 9. Engine-gearbox transmission type: Direct coupled 10. Transmission type between gearbox and mills: Direct coupled 11. Bearings: Bronze 12. Lubrication: Automatic 13. Cooling system: Central cooling with rotary joint 14. Visor: Fixed 15. Security: - 4 emergency stop buttons - 2 emergency stop bars - 2 emergency stop pedals - Return Engine brake 16. New chassis 17. Mills are grinded 18. New electrical and control panel 19. Optional: - Stock blender - Auto turn on / off - Motorcycle driver *** All pictures are before revision

Request for a quote

ROTAKEM

Turkey

Technicial Specifications: 1. Revision year: 2020 2.Cylinder diameter: 660 mm 3.Cylinder length: 2130 mm 4. Roller opening range: 1-15 mm 5. Motor power: 200 kW 6. Engine-gearbox transmission type: Direct coupled 7.Transmission between gearbox and mills: Flywheel gear 8. Bearings: Bronze 9. Lubrication: Automatic 10. Cooling system: Closed circuit water cooling system with rotary joint 11. Visor: Fixed 12. Brake system: - 4 emergency stop buttons - 2 emergency stop bars - 2 emergency stop pedals - Return - Engine brake - Automatic on / off 13. New chassis 14. Mills grinded 15. New electrical and control panel 16. Optional: - Stock blender - Motor driver *** All pictures are before revision

Request for a quote

WILHELM-PLASTIC GMBH & CO KG

Germany

In the production of rubber grommets and rubber seals, we use tools with special coatings and tooling concepts that prevent the adhesion of rubber parts (including TPE, EPDM). With this protocol, we guarantee safe mass production.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

In the cryogenic blasting process, an enrichment of rubber and plastic waste powder takes place due to fine abrasion during the treatment procedure. Thus the performance and processing time of the blasting-media will deteriorate and decrease its jet-energy. In our cryognic deflashing machines, the blasting-media is primary screened by the treatment drum perforation, however, after a long operating time the amount of rubber and plastic waste powder increases. In order to guarantee a constant, statistically secure and economic processing, this powder has to be removed periodically from the blasting-media. Our automatically working blasting-media recovery machine consists of a suction & drying system and a vibrating-screen unit. The used blasting-media has to be aspirated manually from the deflashing machine. The drying of the polluted wet and cold media takes place in the suction tank and the cleaning by screening with final separation into waste powder, waste media & re-usable media,

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This machine provides high efficiency cleaning of medical and technical elastomers and is construed for big sized batch demands at high throughput. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option. For industry 4.0 demands, the W90 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control of the machine via OPC-UA server can be installed additionally. By special request, siliconisation of rubber parts or coating with other glide agents is additionally possible. The W90 offers maximum economic efficiency on treatment of big batch volumes at high throughput!

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This machine offers high efficiency cleaning of medial & technical elastomers and is construed for mid sized bach demands. The W40 is, like any of our machines, designed for high performance with economic efficiency. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option. For industry 4.0 demands, the W40 is best prepared. On option, the control of the machine via OPC-UA server can be installed additionally. By special request, siliconisation of rubber parts or coating with other glide agents is additionally possible. The W40 is the optimal solution for mid-sized batch demands at high througput!

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This small-sized machine can be integrated into the production line easily. This safes temporary storage or extra transports and finally corresponding time loss and costs. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option. By special request, siliconisation or coating with other glide agents is also possible. The W30 uses exchangeable bastekts for the (un)loading. These baskets are also compatible to our cryogenic deflashing machine E30W, and furthermore, optimally suited for a linear in-line processing → production → deflashing → washing → postcure tempering, The W30 is best pepared for industrie 4.0 demands. (on option with OPC UA server) With this small-sized machine, your treatment capacity is at best cost-performance ratio!

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This high performance computer-controlled machine provides maximum economic efficiency at treatment of big batch volumes at high throughput! The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. At any time, this machine is ready for upgrade to automated application, from the automatic loading & deloading of the machine up to a complete full automated feeding & forwarding system. For industry 4.0 demands, the E90 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control via OPC-UA server is possible, too. Furthermore, this machine is able to perform cryogenic deburring without need of blasting media (drum-only deflashing), suitable for special applications only.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This high performance computer-controlled machine is the optimal solution for mid-sized batch demands at fast throughput times! The E 40 is, like any of our machines, designed for high performance at low consumption of nitrogen, blasting media and electric energy. The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. For industry 4.0 demands, the E40 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control OPC-UA server is possible, too. Furthermore, this machine is able to perform cryogenic deburring without need of blasting media (drum only deflashing), suitable for special applications only. mid-sized batches > fast throughput times > E40

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This small sized computer controlled deflashing machine can be integrated into the production line easily. This saves temporary storage or extra transports and finally corresponding time loss and costs. The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. Alternatively the E30 is available with quick-exchange basket system. This basket is compatible to our high-pressure washing machine W30 and furthermore optimally suited for a linear in-line-processing →production →deflashing →washing →termpering, as this charge-baskets may be used compatible for each machine. For industry 4.0 demands, the E30 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control via OPC-UA server is possible.

Request for a quote

OZPAR KALIP VE KAUCUK SANAYI TIC.LTD STI

Turkey

NR-NBR Strenght 65-85 Shore A Strenght Tolerance +- 5 Shore A Coating CR+3 White Zinc Chrome Coating Orange Coloured.Reduced the vibration and noise *No need ground connection prevent the moving of the machine *Easy installation and displacement *Reduced to rubber based lube oil, diesel, hard oil and some kind of acid APPLICATIONS Working tables, Injection Machines, Packing, Printing Press, Marble and Woodworking Equipments. *2 different type colour options *stainless steel option is available

Request for a quoteResults for

Forming- rubber - machinery - Import exportNumber of results

25 ProductsCountries

Company type