- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- lubricating system

Results for

Lubricating system - Import export

GSW SCHWABE AG

Germany

Good old technology for wellknown processes Roller Lubricators are popular despite minimizer spray solutions. GSW supports you with a preselected range of products and we help with practical advice based on our experience. On top of that, we offer a “highend” solution with our hybrid Lubricators that feature a combination of external spray and roller lubrication.

Request for a quote

GSW SCHWABE AG

Germany

Precise Fogless spray lubrication even with highviscosity lubricants. Powerful pumps and sophisticated accessories make almost any lube application possible.

Request for a quote

HPM TECHNOLOGIE GMBH

Germany

HPM Breeze is the consequent development of the common CL-, MQL and MQCL-procedures. Fluids will be checked during the production process and applied in a certain amount at a certain time and at a predetermined location. The HPM Breeze-procedure is extremely fine with an aerosol that adheres like a dense fog around the working area. HPM Breeze forms a completely closed and highly lubricating film. Where previously many litres of liquid were necessary it is now a small fraction thereof which suffices. The HPM Breeze process is used to lubricate and cool machining processes with extremely small quantities of cooling lubricant. An air-fluid mixture that prevents the development of frictional heat with optimal lubrication is employed for this purpose. The remaining heat is dissipated with the swarf. The LSJ Z35 is offered in 2 versions. 10 bar is standard. For more demanding applications, the LSJ Z35 is available in a version with 16 bar.

Request for a quote

HPM TECHNOLOGIE GMBH

Germany

Our Breeze technology has many enormous advantages over the previous classic lubrication applications. Discover enormous savings potential for mass production when using our LSJ Mini in your process. This system can be used optimally in the event of always consistent tool operations. For the machining process, an average of between 5 and 50 ml of lubricant is used per process hour and tool. These consumption values can also be briefly — depending on the requirements of the individual operation — increased to up to 200 ml per process hour. In addition to this excellent advantage over the previous method, the HPM Breeze method offers further enormous advantages from an economic and ecological point of view. • For optimum use with a cooling channel diameter of 0,9 mm² and up. • Manual adjustment of the pressure parameters • Optimally suited for consistent series processes with one parameter

Request for a quote

ROLLON GMBH

Germany

Versatile transfer system for metal sheet handling, designed as the main element in a series of presses which eventually combine with load/unload systems. The system features high positioning precision with heavy duty cycles and high dynamics, and is also available for very extended lengths. It manages cantilever loads to keep one side of the series free for operations. The system is driven by a belt with Ω transmission. The Z axes can be placed at different distances, according to the loads. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

Versatile multi-axis system designed for feeding machine stations. The Y axis can be realized with a rack and pinion driving system for multiple independent carriages or with a short belt system for connected Z axes. The motion systems can be designed with recirculating ball guides or with bearings depending on loads, dynamics, and different environments. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

IGUS® GMBH

Germany

iglidur® PEP, metric d1 [mm]: d2 [mm]: iglidur® PEP, inch d1 [inch]: d2 [inch]: When to use iglidur® PEP plain bearings? When a low-priced plastic plain bearing system is required When freedom is required from shaft material and shaft surface For the protection of expensive and sensitive shafts For extraordinary wear resistance with rare and slow movements. For constantly low coefficients of friction When freedom from corrosion is desired When not to use them? For high surface speeds iglidur® J For high loads iglidur® G iglidur® Q For high temperatures iglidur® V400 iglidur® X iglidur® Z When low-clearance bearings are required iglidur® P iglidur® X Maintenance-free plain bearings usually distinguish themselves by their ability to glide free of lubricants without any further additional layer on the shaft. In these systems it is obvious that shaft materials are as important as the bushings. igus® blazes a new trail with an enclosed and maintenance-free plain bearing concept. iglidur® PEP is an entirely novel lubricant-free plastic plain bearing system with an inner and outer ring. Special feature: The running partner is determined by the inner ring and for the first time, the material and surface finish of the shaft are insignificant. Even thread, rust or scratches do not affect the long-term reliable function. By the specification of the gliding partner and extensive series of tests, the long-term behavior of the bearing system can be precisely forecast. With the PEP polymer plain bearing, the inner ring rotates with the shaft like in ball bearings Relative movements of the shaft to the bearing are dispensed with. This protects the shaft surface from wear and saves costs. Another plus point: Even the most sensitive or unusual materials for the rotating shaft can be used with these new polymer bearings. The PEP polymer bearings are thereby absolutely free from material-dependent corrosion. Wear resistance The wear test results are absolutely convincing with loads up to 5 N/mm². Here the PEP polymer bearings attain values that are virtually comparable with those of the most wear-resistant plastic-steel bearing systems. An exceedingly satisfying result when you consider the costs saved by dispensing with the otherwise essential surface treatment of the shaft. The constantly low friction-coefficient level is also an advantage for the user. As the glide partners are fixed by the defined system, their tribological data too are accurately predictable. The coefficients of friction of the lubricant-free bearing are not determined any more by the shaft materials or surface conditions. If necessary, the coefficients of friction can be further lowered by additional minimum lubrication. Detailed test information with a wide range of lubricants are available and can be had from igus® on request. iglidur® PEP bearings operate independent of the shaft material. iglidur® PEP bearings consists of an inner and outer bearing. X = Load [MPa] Y = Wear [μm/km] A = PEP B = Combination 1 C = Comb. 2 D = Comb. 3 E = Comb. 4 F = Comb. 5 G = Comb. 6 H = Comb. 7 A1 = Wear of the outer bearing B2 = Wear of the inner bearing Fig. 02: Wear tests of various material combinations, p = 0.75 MPa, v = 0.3 m/s X = Load [MPa] Y = Wear [μm/km] A = iglidur® J B = iglidur® PEP Fig. 03: Wear of the iglidur® PEP bearing dependent on the load, v = 0.3 m/s iglidur® PEP, metric d1 [mm]: d2 [mm]: iglidur® PEP, inch d1 [inch]: d2 [inch]: Dimensions according to ISO 3547-1 and special dimensions

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of friction and rolling bearings, chains, joints or slideways at higher temperatures For conveying systems under radiation heat in painting, stoving and drying systems, travelling grates in firing systems Dry lubrication at temperatures above 200°C Lubrication of elastomers and plastics not resistant to mineral oil Advantages and benefits Highly suitable as a high-temperature lubricant Very effective due to finest, homogeneous MoS₂ distribution in the oil Resistant to water and many chemicals, fuels, lubricants and hydraulic oils For best adhesion, clean the surfaces. Best way is to clean mechanically first and then with OKS 2610/OKS 2611 universal cleaner. With a brush, drip oiler or by immersion or using a suitable automatic lubrication system, apply a sufficient quantity to the locations to be lubricated. If at all possible, avoid excess. Observe the machine manufacturer's instructions. Assess the lubrication frequency

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of chains, hinges, joints, ejector pins, clamping and drying frames or slideways at temperatures up to 250°C or under influence of water, for example conveying systems in painting, stoving, drying and cooling bed installations Advantages and benefits Outstanding oxidation properties Resistant to water and steam Good creep properties Outstanding adhesion and lubrication effect with no tendency to drip No formation of hard residues Extreme wear protection through Moₓ-Active Resistant to ultraviolet radiation Also available as spray version OKS 3541 For optimum effect, clean the surfaces. Best way is to clean mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Stir/shake well before use. Apply OKS 354 with a brush, drip oiler or by immersion or using a suitable automatic lubrication system to locations to be lubricated. Spray OKS 3541 on evenly. Allow excess to drip off and wait for lubricant to penetrate

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Dosing system DB 10: lubrication made easy The dosing system DB 10 uses a pressure vessel with a capacity of 10 litres. This is equipped with a filler ball valve and plastic funnel, a pressure regulator with bleed screw and a safety pressure relief valve. A float switch is fitted to regulate the fill level. There are two dosing valves on the underside. This dosing system is available in the following versions: DB 10 H – with poppet valve DB 40 – with 40 litre reservoir DB 40 H – with 40 litre reservoir and poppet valve

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For highest contact pressure and high circumferential speed, e.g. for rotary kilns, ball mills, rotary barrel mixers, ball mills, rope winches or friction presses also for guiding elements, slide bars, heavy transport chains and closed wire ropes Lubrication of rotating assemblies of convertors, cranes, crushers and dredges with spray or central lubricating systems Lubrication of heavily loaded gear couplings Advantages and benefits Most suitable for reliable supply of open gears, even at high circumferential speed Very efficient through EP additives in association with a specific combination of solid lubricants and adhesive additives Reliable protection of tooth flanks, even at high temperatures and with extended relubrication time Good pressure resistance of the lubricating film, excellent wear protection The film is not embrittling and aging. Without bitumen, solvent, does not contain heavy metals

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of fast-running drive chains of all designs for open or semi-open operation without a permanent re-lubricating device, such as motorcycle and bicycle chains Lubrication of hoisting chains such as multirow roller chains or stacker truck chains, as well as single or multiple flat-link articulated chains Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Extreme adhesive strength Extreme wear protection through Moₓ-Active additive Very high resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral Also available as spray version OKS 341 For best adhesion, clean the surfaces mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Apply OKS 340 with a brush, drip oiler, by immersion or using a suitable automatic lubrication system. Spray on evenly OKS 341 spray. Allow excess to drip off and wait for lubricant to penetrate before resuming operation.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of valve seals, collars, O-rings, drives, piston rods and guides Lubrication of slides, slat-band and roller chains Lubrication of cutting knives as well as of needles and lifters of knitting machines Dismantling of rusted-in parts and removal of oil and greasy soiling Advantages and benefits NSF H1 registered Highly effective due to good creep properties Broad range of uses Displaces water OKS 370 is suitable for use with the OKS Airspray system Also available as spray version OKS 371 Clean the surfaces for optimal effect. Apply OKS 370 with a brush, drip oiler or by immersion or using a suitable automatic lubrication system locations to be lubricated. Spray on evenly OKS 371 spray. Avoid excesses. In as far as available, observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on the basis of the service conditions. Caution: Only mix with suitable lubricants.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For closed gear units and geared motors, plain and friction bearings even at higher rotating speeds, e.g. on filling and packaging machines For joints, propeller shafts and chains when grease lubrication is specified Advantages and benefits Toxicologically harmless as defined in German LFGB Formula in accordance the FDA guideline 21 CFR 178.3570 NSF H1 registered Long operating times due to good resistance to oxidation and ageing Reduced wear due to highly adhesive, load-bearing lubricating film Excellent corrosion protection Low dynamic viscosity enables use with minimal bearing play and gear unit spaces Good pumpability with central lubricating systems Very high resistance to hot and cold water, watery-alkaline and acidic disinfectants and cleaning agents

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/84/ee/dynaGear-Eco_0992140d.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems With planetary gear output flange 3 sizes from T2B= 53 Nm to 210 Nm Feed forces up to 8 kN 2 precision classes Input speeds up to n1max = 5000 min-1 Feed speeds up to 6 m/s Gear ratios from 5:1 to 15:1 Spur gear modules from m2 bis m4

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/af/c8/dynaGear-Ritzel_67543e7d.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems 8 sizes from T2B= 53 Nm to 2160 Nm Feed forces up to approximately 35 kN 3 precision classes Input speeds up to n1max = 8000 min-1 Feed speeds up to 10 m/s Gear ratios from 3:1 to 100:1 Spur gear modules from m2 to m6

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of highly stressed chains, joints or slideways at higher temperatures For conveying systems running beneath radiated heat, in baking and drying lines in the foodstuffs industry Dry lubrication at operating temperatures above 200°C The synthetic oil content evaporates odorlessly without leaving residues, while the solid lubricant content are left behind to carry out dry lubrication Advantages and benefits Highly suitable as a high-temperature lubricant Highly effective due to homogeneous distribution of the finest graphite throughout the oil Versatile application as a liquid lubricant under high temperature conditions Resistant to water, chemicals, fuels, lubricants, and hydraulic oils NSF H1 registered For best results, clean the surfaces. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. With a brush, drip oiler or by immersion or using a suitable automatic lubrication system, apply a sufficient quantity

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of friction and rolling bearings at low operating temperatures Grease lubrication of friction and rolling bearings at high speeds Grease lubrication of bearings with low coasting moments or low bearing play Advantages and benefits NSF H1 registered Low-viscosity, fully synthetic base oil ensures the functionality of the lubricating film up to -70°C Very good conveying capability in central lubricating systems also at low temperatures Clean the surfaces for optimal effect. Before filling for first time, remove anti-corrosion agent. Fill the bearing such that all functional surfaces are certain of being greased. Fill normal bearings up to about 1/3 of the free space inside the bearing

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/6d/7d/ks30kh_815e350b.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems 8 sizes from T2B = 225 Nm to 11250 Nm Feed forces up to approximately 200 kN 3 precision classes Input speeds up to n1max = 8000 min-1 Feed speeds up to 4 m/s Gear transmission ratios from 15:1 to 75:1 Spur gear modules from m2 to m8

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/4c/de/de-dg-system_7cee2ba1.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems 4 sizes from T2B= 53 Nm to390 Nm Feed forces up to 11 kN 2 precision classes Input speeds up to n1max = 6000 min-1 Feed speeds up 6 m/s Gear ratios from 5:1 to 15:1 Spur gear modules from to m2 bis m4

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of parts subject to high levels of stress such as plain, roller and rod-end bearings, spindles and guideways Advantages and benefits Highly suitable for high-stressed lubrication points Highly effective caused by optimal combination of components Saving of maintenance and lubrication costs by reducing downtimes and corrective maintenance Reduction of down times due to wearFor highest effectiveness, carefully clean the lubrication point, for example with OKS 2610 or OKS 2611 universal cleaner. Before filling for first time, remove anticorrosion agent. Fill bearing such that all functional surfaces are certain of being greased. Fill normal bearings up to about 1/3 of the free space inside the bearing. Low-speed bearings (DN value below 50 000) and their housings should be filled completely. The bearing and machine manufacturer´s instructions should be observed. Subsequent lubrication at the lubrication nipples by grease gun or by automatic lubrication system.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of valve seals, collars, O-rings, drives, piston rods and guides Lubrication of slides, slat-band and roller chains Lubrication of cutting knives as well as of needles and lifters of knitting machines Dismantling of rusted-in parts and removal of oil and greasy soiling Advantages and benefits NSF H1 registered Highly effective due to good creep properties Broad range of uses Displaces water Duolabel Clean the surfaces for optimal effect. Apply OKS 370 with a brush, drip oiler or by immersion or using a suitable automatic lubrication system locations to be lubricated. Spray on evenly OKS 371 spray. Avoid excesses. In as far as available, observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on the basis of the service conditions. Caution: Only mix with suitable lubricants.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of chains, hinges, joints, clamping and drying frames, and slideways at higher temperatures For conveying systems in painting, stoving, drying and cooling bed installations Advantages and benefits Non-contaminating liquid lubricant for higher temperatures Highly effective due to optimum wear protection, outstanding oxidation behaviour and good creep properties Absolutely resistant to water and steam, inert with respect to acidic media Outstanding adhesion and lubrication effect with no tendency to drip and no formation of hard residues For best results clean the cold surface, first mechanically and then with OKS 2610/OKS 2611 Universal Cleaner. Apply sufficient amount onto the lubrication areas with brush, dip oiler, dipping or suitable automatic lubrication systems. Let excess drip off and let product affect before the beginning of operation. Instructions of the machine manufacturer have to be considered. Relubrication period and amount should be stated

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of chains, hinges, joints, clamping and drying frames or slideways at higher temperatures Suitable for conveying systems in painting, stoving, drying and cooling bed installations Advantages and benefits Highly effective due to optimum wear protection and outstanding oxidation properties Resistant to water and steam Good creep properties Very good adhesion and lubrication effect with no tendency to drip Also available as spray version OKS 3521 For optimum effect, clean the surfaces. Best way is to clean mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Apply OKS 352 with a brush, drip oiler or by immersion or using a suitable automatic lubrication system to locations to be lubricated. Spray OKS 3521 on evenly. Allow excess to drip off and wait for lubricant to penetrate before resuming operation. Observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on basis of service conditions

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of chains, fringe bearings, hinges, joints, clamping and drying frames or slideways at higher temperatures and loads For conveying systems under radiation heat in painting, stoving and drying systems Advantages and benefits Highly effective due to finest, homogeneous MoS₂ distribution in the oil Emergency running properties through MoS₂ at dry running Outstanding adhesion and lubrication effect with no tendency to drip or dry out Silicone-free For best adhesion, clean the surfaces. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. With a brush, drip oiler or by immersion or using a suitable automatic lubrication system, apply a sufficient quantity to the locations to be lubricated. Allow excess to drip off. Allow OKS 350 to soak in before operating. Observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on basis of service conditions

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of fast-running drive chains of all designs for open or semi-open operation without a permanent re-lubricating device, such as motorcycle and bicycle chains Lubrication of hoisting chains such as multirow roller chains or stacker truck chains, as well as single or multiple flat-link articulated chains Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Extreme adhesive strength Extreme wear protection through Moₓ-Active additive Very high resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral For best adhesion, clean the surfaces mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Apply OKS 340 with a brush, drip oiler, by immersion or using a suitable automatic lubrication system. Spray on evenly OKS 341 spray. Allow excess to drip off and wait for lubricant to penetrate before resuming operation.

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

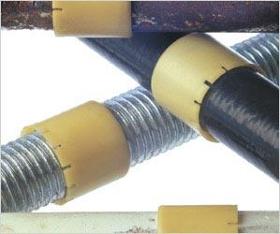

Squeeze-on lubricators Maximum efficiency and the highest levels of flexibility Particularly rugged & and long-lasting The ROTOL squeeze-on roller system is a lubricator developed exclusively in house by Eckardt. This is an exceptionally rugged, long- lasting lubricating machine designed to apply lubricant in precisely defined film thicknesses over an entire surface. Thanks to the ROTOL calender rollers our squeeze-on lubricators achieve very high pressures. Thinnest, homogeneous film thicknesses possible. Features & benefits • Far longer service life in comparison with conventional felt rollers • Works with all pumpable lubricants • Achieves thinnest, homogeneous film thicknesses • Very high viscosities possible • Rugged ROTOL calender roller made of non woven material • Practically impervious to mechanical damage • Lubrication media is retained on the surface of the roller; no premature wear resulting from being drawn in How it works Fleece rollers remove cleaning liquid, fo

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Dosing systems The right amount every time Compact & efficient Our supply and dosing systems are designed to harmonize perfectly with all Eckardt lubricators. These range from small integrated dosing devices through to standalone oil supply solutions with filter units and tank heaters. Features & benefits • Individual dosing and storing solutions • Integrated tank heater and filter units optional • Suitable for oils of all manufacturers and viscosities • Available in all sizes and performance data Design versions and details Dosing system VB 10: the sound entry-level solution The VB 10 dosing system operates without any pressure. It hangs above the roller lubricator; the oil is supplied to the machine purely through the force of gravity. The capacity of the VB 10 storage container is 10 litres. Dosing system DB 10: lubrication made easy The dosing system DB 10 uses a pressure vessel with a capacity of 10 litres. This is equipped with a filler ball valve and plastic funnel, a p

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of rolling and friction bearings, as well as other machine elements at medium rotating speeds or sliding speeds in a broad temperature range For example, electric motors, drives, control systems and telecommunication and navigation systems under arctic conditions, Bowden cables and brake mechanisms in aircraft, sliding parts in shock-freezing systems etc. Lubricating grease for plastic/plastic and plastic/metal pairs and elastomers For plastic sliding coatings in bridge supports and as a parting agent in plastics processing Advantages and benefits Highly effective due to optimum formula Broad temperature range with a wide range of possible uses Excellently suited for lubricating plastics and elastomers Lubricating grease resistant to ageing, especially at low temperatures

Request for a quoteResults for

Lubricating system - Import exportNumber of results

99 ProductsCountries

- Germany (99)

- Bonn, Düsseldorf and North Rhine and Westphalia (23)

- Frankfurt am Main and Hesse (10)

- Hannover and Lower Saxony (7)

- Leipzig and Saxony (1)

- Mainz and Rheinland-Pfalz (4)

- Munich, Nuremberg and Bavaria (16)

- Schwerin and Mecklenburg-Vorpommern (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (26)

- Weimar and Thuringia (11)

Category

- Lubricants, industrial (20)

- Silicones (15)

- Lubrication equipment and machinery (10)

- Gas and oil - exploitation (8)

- Conveyor belts (6)

- Oiling - machines and systems (4)

- Metal industrial presses (3)

- Packing and packaging - machinery and equipment (2)

- Internal transport systems (2)

- Machine tools, metal shaping - parts and accessories (2)

- Metals - Machines & Equipment (2)

- Bearings, ball (1)

- Concrete mixers (1)

- Engines & Parts (1)

- Fuels, diesel (1)

- Hydraulics systems (1)

- Machine tools, metal machining - parts and accessories (1)

- Measurement and regulation equipment and instruments - pressure (1)

- Mechanical engineering - custom work (1)

- Paper and cardboard manufacturing - machinery and equipment (1)