- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- applicators

Results for

Applicators - Import export

NOVEXX SOLUTIONS GMBH

Germany

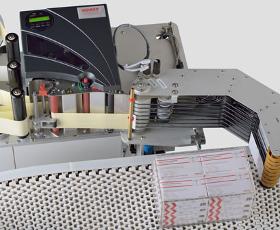

LA-BO - gentile Blow-On Applicator for ALX Print and Apply & ALS Labeling Solutions (ALS 20x, ALS 256, ALS 306, ALX 73x and ALX 92x): • Non-contact labeling of sensitive products • Pivoting applicator allows comfortable material change • Sliding bars enable fast and easy setting of label size • Easy attachment with model-specific mounting plates • Minimal wear means minimal maintenance

Request for a quote

NOVEXX SOLUTIONS GMBH

Germany

LA-TO - economic Touch-On Applicator for ALX Print and Apply & ALS Labeling Solutions (ALS 20x, ALS 256, ALS 306, ALX 92x and ALX 73x): • High output for top, side or bottom applications • Easy change of label pads for different label sizes • Total solution for printing and labeling of items with fixed or variable heights • Industrial design for reliable operation • Available with fixed-, touch down- and blow-on labelpads

Request for a quote

NOVEXX SOLUTIONS GMBH

Germany

LA-SO - flexible Swing-On Applicator for ALX Print and Apply (ALX 92x): • Application of labels on products ranging from individual items to multiple boxes • High output for top, side or leading-edge application to products • Complete solution for printing and labeling in the logistics industry • Durable industrial design for reliable operation • Applies labels to moving products

Request for a quote

NOVEXX SOLUTIONS GMBH

Germany

Corner-edge applicator with wipe on function LA-CE Wipe (for all ALS and ALX with direct application of labels): • Pneumatic applicator folds labels around the back corner of rectangular shaped products • The LA-CE Wipe is mounted directly on the conveyor • Arm is spring driven around the corner

Request for a quote

NOVEXX SOLUTIONS GMBH

Germany

O-ring applicator LA-CE for around the corner application (for ALX 92x): • Easy solution for labeling adjacent two sides of a product with a single label • Suitable for integration in box closing systems • Product runs into applicator which applies a label around the corner on the moving product

Request for a quote

NOVEXX SOLUTIONS GMBH

Germany

Touch-on applicator with blow function LA-TO Blow (for ALX 92x, ALX 73x, ALS 20x, ALS 256, ALS 272, ALS 306): • Suitable for labeling sensitive items with uneven surfaces and/or variable heights • The last part of stroke length is overcome by blowing the label onto the product • Stroke length up to 380 mm • Minimal wear means minimal maintenance

Request for a quote

NOVEXX SOLUTIONS GMBH

Germany

Touch-on applicator with sensor LA-TO Flex (for ALX 92x, ALX 73x, ALS 20x, ALS 256, ALS 272, ALS 306): • Ideal for labeling products with variable heights • Applicator returns as soon as the applicator plate encounters resistance • Easy change of label pads to apply different sized labels • Stroke length up to 380 mm • Available with fixed-, touch down- and blow-on labelpads

Request for a quote

NOVEXX SOLUTIONS GMBH

Germany

Wipe-on applicator LA-WO for small labels (ALX 92x): • Wipe-on applicator for applying labels onto the side of moving products • Typical applications: paper reams, doors, windows, flooring • Ideal for applications with high product speed

Request for a quote

NOVEXX SOLUTIONS GMBH

Germany

Light touch applicator LTSI/LTSA (for 64-xx dispenser, XLP 504 dispenser): • Application of labels on sensitive products without the need of compressed air • Suitable for variable product heights • Applicator extends its ‘telescopic arm’ until sensor encounters resistance • Stroke length up to 400 mm (LTSI only)

Request for a quote

QUELLTECH GMBH

Germany

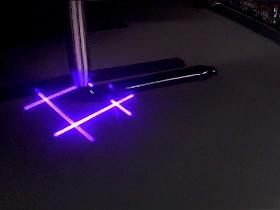

Rotationally symmetrical driving gears in a line producing for automotive industry are mutually connected by electron beam welding. The camera inspection carried out until was not able to assess the quality of the weld seams at the required precision. Non-contact laser measurement system Particular Challenge: As the welding seams show a high reflectivity and are located at a position hard to access, inspection is difficult, all the more so as they dispose of a width of only 500µm. Therefore it is quite a challenge for the laser measurement system. The QuellTech solution: A QuellTech Laser Scanner Q4-5 with extremely small shape factor and high resolution proved to be perfectly suited for this application. In order to suppress reflections from elements in the surroundings, a particular algorithm has been integrated. Furthermore, this laser measurement system features a particularly adapted laser wavelength and an ultrafine laser line.

Request for a quote

QUELLTECH GMBH

Germany

Testing requirements for a manufacturer in electronics industries had changed: For an assembly included in a smartphone, the absence of contact between speaker ultra fine wires and adjacent components is essential. Fulfillment of this condition, until now only subjected random sampling by microscopy, from now on has to be verified in a 100% procedure. Due to labor cost, microscopy for this amount of inspection is no more lucrative. Detection of ultra fine wires in electronic device The particular challenge The fine wires made of copper in smartphone speakers dispose of a high reflection and only a small diameter. The QuellTech Solution A high-resolution QuellTech 2D/3D Q4-5 Laser, featuring a particularly adapted laser wavelength and an ultrafine laser line in the corresponding installation, is combined with a linear axis equipped with a convenient encoder output. Due to its special chip analysis, the Quelltech sensor delivers a stable and highly reproducible signal on the fine wires

Request for a quote

QUELLTECH GMBH

Germany

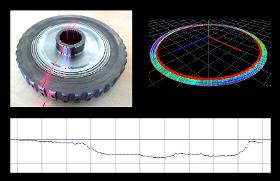

Within the frame of quality assurance, the forged pieces of this client have to be checked in an inline inspection with respect to several parameters: Inner and outer diameters, as well as the absence of surface defects have to be verified. Video of inline forgings inspection for dimensional accuracy and surface defects with QuellTech LaserScaner. Particular Challenges Manual inspection carried out until now turned out to be not reliable enough, particularly after an increase in production. The final rejection rate has seriously affected the productivity of the entire manufacturing process. A solution for a contactless inline inspection was needed. The QuellTech Solution A testing station including an index table has been designed. This configuration acts as a support for two QuellTech Q4-60 laser scanners, used for inspection of the parameters mentioned above.

Request for a quote

QUELLTECH GMBH

Germany

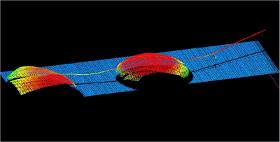

Initial Situation: Inspection of a laser weld seam for pores and geometrical anomalies The production of a client in automotive industry is subjected to extremely stringent quality requirements. This is valid particularly also for the precision of laser weld seam of fine mechanical work. 100% inline supervision is required for the following task: A laser weld beam (width ca. 200µm) has to be verified with respect to the presence of pores and geometrical anomalies. Camera inspection performed until now turned out to be not stable. Therefore the client is forced to implement an improved monitoring process. The challenge The resolution required amounts to 4µm. The high gloss finished material and glossy laser weld seam may give rise to reflections, and the space for installation is restricted. A low form factor for the monitoring equipment is imperative.

Request for a quote

QUELLTECH GMBH

Germany

A client in automotive industry intends to improve the inline glue bead supervision performed when automatically applying glue beads inside body parts. The system to be purchased should be able to monitor position, height and width of the glue bead any time. Until now, the client makes use of a 3D laser system with very complex beam guidance, in order to compensate problems arising from narrow space available. This present configuration however involves difficulties in adjustment, often giving rise to trouble and interruptions. Therefore the client is looking for a safe and less complicate solution. The chellenge in glue bead supervision: While the glue bead is being applied, very complex geometrical patterns are followed; the nozzle for the glue meanwhile does not rotate. Therefore this nozzle must be supervised in the total angle of 360°. This glue bead supervision can only be met by a laser scanner featuring an extremely low form factor.

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

Every year, Germany produces around 10 million tonnes of cardboard and paperboard for the packaging industry. After their use, these items of cardboard packaging and boxes must then be reduced in volume before passing through the recycling process. This volume reduction step is performed by recycling companies and public recycling depots or in cardboard packaging and corrugated board factories. Reasons for volume reduction: For these requirements, ERDWICH has developed a specialised product range – the EKZ and FKZ cardboard shredders – which can be supplied in a range of sizes. The ERDWICH plant items have been designed as a perfect match for downstream transportation systems. The EKZ has two shafts with independent drives: one high-speed shredder shaft and one slow-speed feed-in shaft. The feed-in shaft feeds the packaging to the shredder shaft, which then shreds the cardboard into fragments of the desired size. The machines can also easily handle fruit crates and polystyrene...

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

GIVING SHORT SHRIFT TO THE LONGEST SPIRAL SWARF! GENERATING NEW VALUE FROM OLD ELECTRONICS! CUTS THE BIGGEST CARDBOARD WASTE DOWN TO SIZE! AT 99% PURITY, WE GIVE EVEN PENTANE AND CFCs THE COLD SHOULDER! CONFIDENTIAL DATA, 100% DESTROYED - AND THAT’S NO SECRET! IT MIGHT BE SPECIAL WASTE, BUT IT MIGHT BE SPECIAL WASTE, BUT WE SHRED IT LIKE IT THE REST! A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z A Air filters Aluminium parts Aluminium swarf Ammunition B Bales, compacted Bank cards Banknotes Bathroom fittings Batteries Beverage cans Beverage crates Biscuit waste Blister strips, blister punching scrap Bone Bottles Brass swarf Briquettes C Canteen waste Car batteries Car bumpers Car interior parts Car number plates Carbon fibre composites Cardboard packaging Cardboard punching scrap Carpet edge trimmings Cassettes Catering waste CDs Cellulose covers + sheets Ceramic catalytic converters Chewing tobacco Cigarettes Coated...

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

Analytical shredding systems for QA work are a fundamental preliminary component in the production of substitute fuels. With primary fuels and finite resources subject to continuous price increases, the significance of substitute fuels continues to rise unabated. For plant operators, this offers first-class potential and attractive prospects for the future. Businesses that buy in their substitute fuel from external suppliers are faced with two key analytical requirements before putting it to use: pollutant analysis and calorific analysis. To ensure the proper handling of these analyses, a sophisticated sampling system is required. System criteria: To satisfy these requirements while ensuring optimum process reliability, you need a partner who possesses long-standing expertise and manufacturing proficiency.ERDWICH is that partner. Combining over 30 years of experience and the deployment of our proven single-shaft shredder, we have developed an automated, integrated system that...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

In metal-working shops utilising swarf-producing manufacturing techniques, the generated swarf is often an underestimated cost factor: This means your expensive machine tool cannot attain its full productive potential. The key challenge here is therefore: PROCESS RELIABILITY But there is another way. In fact, there are several proven solutions – centralised and decentralised – to this problem. ERDWICH machines and plant for swarf shredding and processing offer the highest levels of economic viability, safety and efficiency. With the decentralised solution, the ERDWICH swarf breaker is set up directly next to the lathe or machining centre. The swarf is removed and transported away to a central processing point either manually using a swarf cart or by means of pneumatic extraction, pumping or some other conveyor system. With the centralised solution, the swarf is collected in swarf carts at each machining centre and then transported to the ERDWICH master processing plant. This...

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

One of the greatest challenges facing our society is the reclamation of valuable raw materials from electrical and electronic scrap. A global scrap volume exceeding 40 million tonnes a year – a figure forecast to double by 2025 – presents both a challenge and an opportunity. Since even in Germany only some 40% of scrap is currently fed into a waste management process, we may assume that the global rate of waste management is still substantially lower. With additional support from WEEE Directive legislation, this represents enormous growth potential for recycling companies in all consumer-oriented markets. For many years now, ERDWICH has specialised in the reclamation of valuable primary materials from electronic waste with its shredding machinery and turnkey plant solutions. As a result, economical and mature solutions are available for meeting any of these challenges. ERDWICH pre-processing: Whether you’re handling electrical/electronic waste, small/large household appliances,...

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

According to initial estimates, in Germany about three million LCD monitors will be recycled in the year 2016. However, they often still have backlighting containing mercury and therefore have to be classified as “hazardous waste” in accordance with the German General Administrative Regulation (AVV) and registered in compliance with the German Electrical and Electronic Equipment Act (Elektro G) under category 3. Whereby special conditions must ensure that no risk arises from the mercury for the environment or for humans. However, because of a lack of suitable automated procedures for the recycling of LCD monitors, it was to date only possible to dissemble the appliances laboriously by hand, with the ensuing health dangers for the workers. For this, ERDWICH now offers two alternatives which are both safe and time-saving for recycling LCD monitors. Mercury and valuable resources can be removed and recycled in an environmentally sound way in the future: 1. Monitor sawing plant for...

Request for a quote

APROVIS

Germany

* High-temperature heat exchangers * Gland steam condensers

Request for a quote

PAUL BOETTGER GMBH & CO. KG

Germany

Cotton Applicator 200 mm Wood, Big Head

Request for a quote

PAUL BOETTGER GMBH & CO. KG

Germany

Cotton Applicator 150 mm PP, Big Head, sterile 2 pcs

Request for a quote

PAUL BOETTGER GMBH & CO. KG

Germany

Cotton Applicator 150 mm PP, Big Head

Request for a quote

PAUL BOETTGER GMBH & CO. KG

Germany

Cotton Applicator 200 mm Wood, Small Head

Request for a quote

PAUL BOETTGER GMBH & CO. KG

Germany

Cotton Applicator 150 mm Wood, Small Head, sterile 2 pcs

Request for a quote

PAUL BOETTGER GMBH & CO. KG

Germany

Cotton Applicator 150 mm Wood, Small Head, sterile individually

Request for a quote

PAUL BOETTGER GMBH & CO. KG

Germany

Cotton Applicator 150 mm Wood, Small Head

Request for a quote

PAUL BOETTGER GMBH & CO. KG

Germany

Cotton Applicator 150 mm PP, Small Head, sterile individually

Request for a quoteResults for

Applicators - Import exportNumber of results

62 ProductsCompany type