- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- program controllers

Results for

Program controllers - Import export

RIEDEL COMMUNICATIONS GMBH & CO. KG

Germany

Riedel puts the world on the air over Skype. Riedel’s STX-200 broadcast-grade professional Skype interface brings any Skype user worldwide into professional broadcast workflows. The reliable, 1 RU, single-box solution allows broadcasters to engage with both reporters and viewers in live programming. The Skype TX Control software provides customers with the ability to manage multiple Skype TX channels from a single user interface. Other parameters that the software manages include stream resolution, aspect ratios, FPS, logo overlays, and various audio options. Riedel’s STX-200 also offers unique device monitoring functions, such as temperature measurement and system status, that can be monitored by means of Simple Network Management Protocol (SNMP). Licensed by Microsoft, the STX-200 offers broadcast-quality HD- SDI and balanced XLR audio I/Os. Previously, users relied on consumer PCs running common Skype clients that then needed to be integrated with scan and HDMI-to-SDI...

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

This feeder consists of a completely overhauled rotary feeder from CMC, a new pressure/vacuum pump made by Becker, and a self-programmed control system. All components are mounted on a stable frame made of aluminum construction profiles, which can be placed as a compact unit autonomously at any desired position in the production. The machine can either be operated continuously or controlled by an external signal. This allows inserts to be placed with pinpoint accuracy in a collecting section or at high speed on a conveyor belt to be addressed via inkjet, for example. We offer a 6-month warranty on parts and service for this machine. Our systems can be freely configured according to your needs. Tell us your requirements so that we can present a concrete solution proposal.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

Kendrion Kuhnke Automation relies on CODESYS as a software platform for a wide variety of applications in the automation industry. For all Kuhnke platforms, this software is available as release CODESYS V3. The IEC 61131-3 programming system offers IEC 61131-3 editors (FBD, LD, IL, ST, SFC), comprehensive debugging and online functions to optimise the application code, as well as fieldbus configurators and editors to generate visualisations. Single and multi-axis motion control all the way to the writing of curves can be projected within the well-known IEC 61131-3 development platform together with all related logic applications. Summing it up it can be said that the tool offers the user an integrated solution to support him in his everyday work and is tailored to offer real-life support to accomplish his tasks. ; EC 61131-3 programming tool for industrial control and automation technology; Integrated visualisation editor; Numerous security features (source code, communication, ...)

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

max. size 33 x 100 cm age 2000 scoring and perforating machine program control 1 tool for ruling / creasing 1 tool for perforating Delivery time: shortly Ref: NA230068A Please ask for price. We ship and install worldwide!

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The preeflow® controllers simplify every dispensing process. They are perfectly matched for all dispensers within the eco-PEN, eco-DUO and eco-SPRAY series. The eco-CONTROL EC200 2.0 serves primarily to control and parameterize the preeflow® dispensers. In addition, pressure monitoring is carried out by the controller for a reliable process with precise dispensing results. The control unit can be easily integrated into fully automatic systems and meets all requirements of modern dispensing processes. The eco-CONTROL EC200 2.0 offers a compact solution with an integrated power supply unit. The control unit also offers options for pressure and temperature monitoring, 100 program memory locations and enables fast and clean storage of programs. The control unit can also be integrated with PLC systems.

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

You would like to get to know the performance options of the µMIC.200? Our starter kit facilitates a quick start into programming the control unit µMIC.200. Just unpack, get connected and start programming with Node-RED or in C/C++.Control unit µMIC.200 Mains adapter Digital CANopen I/O module Connecting cable Quickstart

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

The CAN driver CANpie FD (Controller Area Network Programming Interface Environment) is an open interface for the development of CAN-based applications. The CAN driver forms the basis for higher layer protocols (CANopen / J1939) and may be used for manufacturer-specific CAN communication between embedded systems. CANpie FD is avaliable for a wide range of microcontrollers (more than 160 at the moment). A variety of configuration options facilitates adjustment to individual target systems. The CAN physical layer (data link layer) comprises two protocols: the classical CAN standard and CAN FD. The protocols are described in the ISO 11898-1:2015 specification. The CANpie FD API defines 19 functions to allow manufacturer independend access to the CAN controller to entirely support ISO specifications. The API is based on the concept of dedicated message buffers (mailboxes) in combination with acceptance masks to minimize the application

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

IAI's new controller series: R-Unit R-Unit is the new generation of controllers that are coupled via module connections and are modularly interchangeable. These include the RSEL program controller for connecting up to 8 actuators (in combination with the REC EC control up to 16 actuators), the RCON position controller for up to 16 electric cylinders and the REC EC controller for motion control of up to 16 EleCylinder axes. Common to all of them are the linkable control units with identical connections, which allow a free selection and combination of connected electric actuators and their control methods. Mixed control of electric cylinders with 24 volt and 230 volt motors is also easily feasible.

Request for a quoteMPT DOSING GMBH

Germany

WBL 400 All standard features are included, plus optional information management tools that enable water treatment professionals to deliver more effective service to their customers. The WBL/WDB/WCM/WDC400 Controllers have the ability to store conductivity and temperature values, water usage, relay status, and user settings. With a USB memory stick the information can be extracted. Download logs from the USB stick to a PC, or copy your preferred treatment program settings to another controller to speed start-up. WDB400 Product features: Efficiency Precise control of conductivity and chemical feed inhibits corrosion, solids precipitation and scale build-up. The time proportional blowdown feature saves energy by reducing water consumption. Monthly Reports Download stored data from the controller to a USB flash stick. Use the data to develop reports that show actual water usage, system conductivity, temperature and more. Customer Service Identify system upsets by knowing exactly w

Request for a quoteMPT DOSING GMBH

Germany

Conductive Cooling Water Controllers / Toroidal Cooling Water Controllers Conductive Cooling Water Controllers WCD410 All standard features are included, plus information management tools that enable you to deliver more effective service to your customers. The WCT/WDT controllers can store conductivity, pH/ ORP, and temperature values, water usage, relay and flow switch status, and user settings. With a USB memory stick the information can be extracted. Then download logs from the USB stick to a PC, or copy your preferred treatment program settings to another controller to speed start-up. Product features: Efficiency Precise control of conductivity and chemical feed reduces water consumption and inhibits corrosion, solids precipitation, scale build-up, and growth of algae or dangerous bacteria. WDT 410 Monthly Reports Download stored data from the controller to a USB flash stick. Use the data to develop reports that show actual water usage, system conductivity, temperatur

Request for a quoteMPT DOSING GMBH

Germany

Measurement and control In this sector, MPT represents the interests and products of WALCHEM Corporation in Holliston, Massachusetts (USA). WALCHEM is a leading manufacturer of sensor technology and controllers for the surface technology and for the water treatment technology, including pH-, redox and conductivity controllers as well as special controllers for the cooling-water and boiler water conditioning. Besides the measuring transducer, these controllers include also a control program, adapted to the respective application. Monitoring, alarming – control and telecontrol systems By default, WALCHEM’s WebMaster has available sensors and data amplifiers for various physical parameters. Using the integrated program the parameters can be linked to each other and to control parameters. Via telephone modem and Ethernet board the user is provided with information such as alarm messages and off-limit conditions worldwide. Measuring and control technology for dosing liquid media in

Request for a quote

ZANDER GMBH

Germany

Almost all automation solutions are provided with electronic or electronic computer-aided control. An important element in the implementation of your requirements are Programmable Logic Controllers (PLCs). Automation Technology / Electronics: We manufacture the necessary control for your application from project planning, production, programming to service. Configuration: Analysis of the control process Working out the tax concept Drawing and documentation creation by certified electrical engineers with EPlan P8 Optimal component selection Programming: Programmable logic controllers Industrial PC / bus and network systems Operating and visualization systems Remote maintenance systems cabinet mechanical machining Structure / wiring Testing and measurement Machine installation: wiring Connection of sensors and actuators commissioning Handover and service Service: overhaul software change revision

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner has developed a fully automatic processing machine with outstanding cutting quality and great length accuracy for steel cable wires of up to 20 mm diameter. The steel cable wires are fed by a motorised feeding device in combination with a contact-free loop control. Then, program-controlled and positionally accurate marking tapes are applied to the steel cable – with a cycle time of less than two seconds. In addition, a wax printer marks all the fastening and processing points that will be required for subsequent processing. This labelling method is carried out in a continuous process. The cut is then made using a special cutting process. Precise length accuracy is achieved by a special laser measuring system. A material stacker with a storage area of up to 12 metres ensures that the steel cable wires are deposited in an orderly manner. All cut steel rope can be stored and sorted according to length to allow it to be removed at a later point.

Request for a quote

STARRAG GMBH

Germany

Finishing centers for the jewelry industries, the machines range s210/ s220 combine several processes such as Milling, Engraving, Drilling and Faceting to produce parts for the most demanding key players of the jewelry crafts worldwide. His legendary finishing qualities best fit the requirements in terms of accuracy and ease of use. Features 6 to 8Axis Faceting, engraving, drilling, milling 2 spindles with changer and tool magazine High frequency 45.000min1 spindle Easy changeover of the programs CNC control unit Siemens 840Di

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

United Process Controls' probe certification program is designed to maximize the life of a probe and ensure the most accurate readings possible. All probes are tested in a certified atmosphere against a probe standard and must meet deviation criteria.

Request for a quote

NORIS GROUP GMBH

Germany

NORISTAR 4 - The flexible remote control system for all propulsion drives The NORISTAR 4 is our powerful remote control system (RCS) for all types of ship, whether tugboats, cargo ships, passenger ships or super yachts. It is based on our NORISYS 4 open automation platform and is suitable for all propulsion drives. The system can be configured for multiple control consoles and offers many useful functions, such as load distribution, preprogrammed control programs, "electric shaft" function, start/stop logic, DP and joystick function. Configuration and monitoring are performed in a simple and user-friendly way via an integrated touchscreen display. Optional web access makes service easier and facilitates remote maintenance and the transfer of data to fleet management.

Request for a quote

KLN ULTRASCHALL AG

Germany

The new generation of plastic welding machines of the OMEGA 4 series combines technical standards at the highest level with ease of use. The modular arrangement of the machine components, consisting of press, control and generator, enables easy adaptation to the respective plastic part and the respective location. Simple system operation is guaranteed with the multilingual touchscreen With this standard machine, even the most difficult welding tasks can be mastered reliably thanks to their performance and control and monitoring options. The S series is the standard version of the Omega. An ultrasonic high-performance generator and and a separate control with a larger touch panel are available. There are also 12 program memories available. The separate control also enables the process data to be read, the travel distance to be measured and greater connectivity.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DR. JOHANNES HEIDENHAIN GMBH

Germany

For more than 35 years, TNC controls from HEIDENHAIN have been proving themselves in daily use on milling, drilling and boring machines, as well as machining centers. While the controls have undergone continuous development during this period, the basic operational technique has remained the same. You will find also these principles implemented in the TNC 640, the HEIDENHAIN contouring control for milling and milling/turning operations: shop-oriented programmability with graphic support, many field-proven cycles and an operational design you'll recognize from other HEIDENHAIN controls. Shop-oriented programming You program conventional milling and drilling operations, and with the TNC 640 also turning operations, yourself at the machine, in plain language dialog—the workshop-oriented programming language from HEIDENHAIN. The TNC 640 provides you with optimum support with practical prompts, questions and expressive graphical aids—for turning operations, too.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Thanks to its flexible operating concept – workshop-oriented programmability with HEIDENHAIN conversational programming or external programming – and its scope of features, it is especially suited for use on universal milling, drilling and boring machines for series and single-part production tool and die making manufacture of machines research and development prototype production and testing facilities repair departments educational and training institutes The TFT 15-inch color monitor shows a clear overview of all relevant information for programming, operating and inspecting the machine tool and control such as program blocks, comments and error messages. More information is provided through graphic support during program entry, test run and actual machining. The selectable split-screen display shows the part program blocks in one half of the screen and the graphics or the status display in the other half.

Request for a quote

OLIGO LICHTTECHNIK GMBH SURFACE CONTROLS

Germany

The semiautomatic color controller HAFST2.0 can be used to manually control programmed light scenarios with different color temperatures. Light scenarios can be programmed or retrieved on site with the help of the semiautomatic color controller.

Request for a quote

OLIGO LICHTTECHNIK GMBH SURFACE CONTROLS

Germany

OLIGO surface control optics can be controlled using the semiautomatic controller HAST2.0. It enables the coordination of light scenarios and programmed light groups. The controller features function keys that can be specially assigned as well as four-line, alphanumeric display for viewing status information (performance, energy, operating hours).

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Boards requiring good mechanical properties need the glue mix to be evenly metered and the glue to be applied in the best way possible to the particles or bres. Siempelkamp's integrated metering systems help create precise mixes and accurately meter glues and other chemic ow meters to achieve the best possible metering results. Each unit is completely pre-assembled and to a large exte design means that it is easy to add more metering stations for the glue mix. Features, function Metering systems for dierent quantities and components Program-controlled metering using ow meters Metering tanks for each component equipped with pressure-controlled level controls Innovative software Metering containers and stations are completely pre-assembled.

Request for a quote

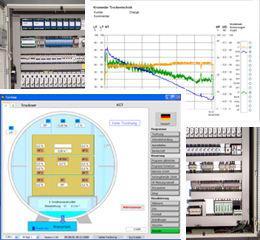

KRONSEDER TROCKENTECHNIK GMBH & CO. KG

Germany

Drying and heat management Kronseder MK 200 control with display The SPC is a robust industrial control. The drying programs for common types of wood are filed in the control. Users can easily create their own programs. The double sensor technology gives you precise measured values to control the programs. This avoids faults in the system. In addition, a visualization program with a No. RS232 interface for PCs with Windows XP is offered. If required, this visualization can also be connected to a wireless LAN network which can be connected according to the interfaces.

Request for a quote

APEX TOOL GROUP GMBH

Germany

Cleco's new CellCore™ Cordless Assembly Tools are smart, durable and designed to withstand the toughest environments. The lightweight ergonomic design reduces operator fatigue while delivering state-of-the-art power, weight and balance. A larger user interface makes it quick and easy to program rundowns on the tool without a controller. - Multi-Color LED for secondary okay/not okay visual feedback - Large User Interface allows easy on-the-tool programming without a controller - Exceptional Low Weight, Balance and Grip for superior ergonomics that increase productivity - Increased Storage - no uploading rundowns for up to one week (15.000 rundowns, 500 traces) - “Stay Alive” Function prevents reboot during battery change, gaining time and efficiency - Forward and backward compatibility with Cleco's entire Global Controller plattform

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The knives of knife-ring akers have to be sharpened and re-set at regular intervals. This can be a very timeconsuming and personnel-intensive job. The quality and precision of these tasks depend strongly on the accuracy and dedication of the individual worker. With the sharpening and setting robot PZSE the knives can be sharpened and set automatically. Features, Function safety housing fully automatic process ow transport to and clamping of the knife ring to the carrier disc determining the wear of all parts automatic readjustment of all wear shoes and knives sharpening of all knives in a wet grinding process cleaning torque control of clamping bolts detection of possible damage to the threads Advantages automatic sharpening and setting process setting of the knives with high accuracy electronic control of tightening torque of the knife xing bolts automatic monitoring of the thread quality of the xing bolts preventative maintenance program thanks to PLC-controlled integrated

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Vacuum degassing / outgassing With the aid of vacuum outgassing, unpleasant tastes or odors can be degassed and thus rendered tasteless. Altitude simulation For aircraft transport, it is essential to perform tests and simulations at a pressure <800 mbar, since in cargo holds, pressure equalization takes place, but cannot compensate for all fluctuations. Vacuum storage systems The safest way to store highly sensitive components is under vacuum. Under the vacuum environment, your components are protected from all external influences. Control and process control Our specially developed control program offers not only the possibility to monitor, but also to program and store various process sequences. High and ultra-high vacuum From the pressure range of rough vacuum to fine vacuum and ultra-high vacuum, we are able to meet your process requirements with our systems.

Request for a quote

ESMO AG

Germany

Our specialists in the fields of mechatronics, control engineering, programming, and software development closely cooperate in the development phase. With the support of professional development tools – such as EPLAN P8, SolidWorks, SolidCAM, SolidWorks Simulation – these jointly developed conceptions will then be translated into design and work plans.

Request for a quote

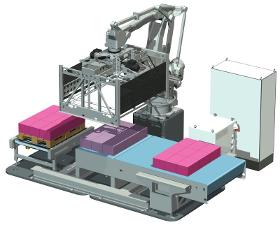

LANGHAMMER GMBH

Germany

Advantages • Easy programming + maintenance via the PLC: no robot programming skills required • Optimal utilization of space + considerable space saving due to compact design • Highly flexible palletizing solution allows for any number of layer patterns • Layer weights of up to 200 kg possible • Gentle product handling of complete layers • Consistent and proven Langhammer operating concept allows for easy configuration In contrast to conventional systems with fork/clamp grippers, this compact design results in an enormous space saving of up to 40%. The new Articulated Arm Robot AR500 in combination with either Siemens or Rockwell controls guarantees easiest programming and maintenance directly via the PLC. By combining the Articulated Arm Robot AR500 with TheWave Langhammer offers a coordinated concept for the complete material flow, characterized by extreme accuracy & high-quality palletizing – and everything according to customer requirements – ready to go from a single source

Request for a quote

JUST-AIR-BERLIN BY T.O.T.S GMBH

Germany

With its modern design and effective filter function, the Air Protector One is designed specifically for large rooms. It features a touchscreen, and a companion app, which can be used for controlling and pre-programming. Description Product NameAir Protector One Voltage220 V – 240 V, 50 Hz Power30 W – 85 W CADR (Clean Air Delivered Rate)800 m3 / h Weight14 kg Product Size400 x 400 x 669 mm Filter1. Pre-filter 2. HEPA 14 filter 3. (activated)Carbon filter Main FunctionAir filtering, Anion release The Air Protector One air purifier filters the air by drawing air into the unit from two sides via an integrated fan. Then the filtered air flows back into the room from above to achieve optimal circulation. Air Protector One uses 4-stage filtration including HEPA 14 double filter on two sides and captures all particles larger than 3 nm from the air with an efficiency of 99.995%.

Request for a quoteResults for

Program controllers - Import exportNumber of results

31 ProductsCountries

- Germany (31)

- Berlin and region (1)

- Bonn, Düsseldorf and North Rhine and Westphalia (5)

- Frankfurt am Main and Hesse (5)

- Hannover and Lower Saxony (1)

- Kiel and Schleswig-Holstein (1)

- Leipzig and Saxony (1)

- Mainz and Rheinland-Pfalz (1)

- Munich, Nuremberg and Bavaria (8)

- Potsdam and Brandenburg (2)

- Stuttgart, Freiburg and Baden-Wurtemberg (5)

- Weimar and Thuringia (1)

Category

- Doors and gates, automatic and access control (2)

- Electronic data processing - microcomputers (2)

- Numerical control systems - minicomputers and mainframes (2)

- Wood veneer - machinery and equipment (2)

- Automation - systems and equipment (1)

- Air conditioning, aeration and ventilation equipment (1)

- Custom packaging (1)

- Dosing pumps (1)

- Electric and electronic components - machines for manufacturing (1)

- Electrical & Electronic Components (1)

- Electronics - ships (1)

- Finishing and binding - machinery and equipment (1)

- High-vacuum photo-cells (1)

- Machine tools, metal machining - parts and accessories (1)

- Mechanical engineering - custom work (1)

- Palletising machinery (1)

- Valves for pneumatic equipment (1)

- Welding, plastics - machinery (1)