- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coatings- plastic

Results for

Coatings- plastic - Import export

KIRSCH KUNSTSTOFFTECHNIK GMBH

Germany

We have developed into a leading provider, specialised in various processes for surface coating of transparent plastics. Main focus lies on our abrasion resistant coatings, manufactured under cleanroom conditions. Thermosetting coating systems Using the flooding method a thin layer is being applied or rather “flooded“ on the plate. As a result a flushing effect removing existing dust particles occurs. We can coat plate ware as well as ready deformed parts. Considering provision of material we gladly give you any advice needed. We are familiar in using currently known scratch resistant paint systems, like PHC587, AS4000, AS4700 but also recent paints e.g. XH100, MP100. The plastics used are mainly PMMA or PC. Through these coatings the most transparent plates obtain a higher abrasion resistance, an additional uv protection as well as a higher durability against chemicals or an anti-fog-characteristic. Not only in the sectors of mechanical engineering and automotive, but also in medical

Request for a quote

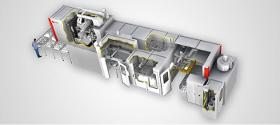

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

precise coating of flat parts

Request for a quote

KIRSCH KUNSTSTOFFTECHNIK GMBH

Germany

We are specialised in varnishing transparent plastics, which are being painted from behind to achieve a profound depth effect. In our specially customised painting booth the plastics are being sprayed with wet paint creating various structures and degrees of gloss. Here we have the possibility to process large-sized parts. KIRSCH Kunststofftechnik has decided to process even the most demanding parts in-house. High expertise and skillful handling with plastics is significant to accomplish our customers` requirements. Highest cleanness standards are our guideline.

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

These systems can only be fastened by adhering (glue or double-sided tape). Adequate adhesive is available from specialised trade. The following materials can be found at the rear: A18B-Ks: Polyamide (PA) A22B-Ks: Polyamide (PA) A31B-Ks: Galvanised steel AS031NdB-00s-03: Polyamide (PA) A43B-Ks: Polyamide (PA)

Request for a quote

SIKO GMBH

Germany

Various sizes. Plastic-coated or bright-finished surface. Various hub versions.

Request for a quote

SIKO GMBH

Germany

Premium knurled aluminum handwheel. Compact design. Various sizes. Surface plastic-coated, anodized or bright-finished. Various hub versions.

Request for a quote

SIKO GMBH

Germany

Robust handwheel made of aluminum casting. Rounded design with dirt corners minimized. Various sizes. Plastic-coated or bright-finished surface. Various hub versions. Turning handle as an option (see accessories).

Request for a quote

SIKO GMBH

Germany

Classical handwheel made of aluminum casting. Various sizes. Plastic-coated or bright-finished surface. Various hub versions. Turning handle as an option (see accessories).

Request for a quote

LUTZ PUMPEN GMBH

Germany

Suitable for neutral and aggressive liquids as well as liquids containing solids Application: Centrifugal pump for dry-well installation featuring a bearing-less cantilever design with direct-coupled IEC motor. Specially designed for plant engineering and confined spaces. The B80 HME Series can be operated beside the container in a dry-well installation. Liquid flowing up inside the shaft guide tube returns to the container via an overflow line. Pumps in dry-well installations allow an easier access to carry out maintenance and repair work. Features: Directly-coupled in bearing-less cantilever design Radial and axial fixed drive elements in two-piece bearing shell Pump housing in glass-fibre or carbon-fibre reinforced plastic (PP or PVDF) Gas seal for protecting the motor bearing Plastic-coated drive shaft Driven by IEC standardised motors Benefits: Compact dimensions Service-friendly dry-well installation Self-centring alignment in the bearing shell Vibration-free and...

Request for a quote

KULLEN-KOTI GMBH

Germany

The roller brush type 964 is made of single section brushes mounted together on a core up to the required face width. This roller brush type can be mounted on cores made from stainless steel, plastic coated steel, or mild steel. Kullen-Koti recommends especially this brush type for heavy-duty operations with a high dense brush surface, e. g. by using our single section brushes with twisted steel knots (Type Z-SH). But we can manufacure the single section in almost all other fill material types. For mounting the single section brushes on the core or by the operator himself on the existing primary shaft, we use our fixing ring (FRB / scew nut (MB) system. The single section brushes are available in 10 particular series-diameter (KD.) The single section brushes can be supplied as roller brushes type 964 with the following core systems: - system WK 1/WK 2 with journals. - tubular core with reduction bushes (WK 3). - "Throw-Away" system with thin-walked tube with arbor hole fitting on...

Request for a quote

KULLEN-KOTI GMBH

Germany

The STS-spiral roller brush range from Kullen-Koti contains all measurements from small to extra large and this unbeatable selection of diameters makes this brush a totally reliable tool for light brushing tasks. Due to the high fill density and precisely ground surface it achieves outstanding results. A flawless radial true runing is a requirement in most cases to achieve the desired brush effect. Therefore the brush cores are electrodynamically pre-balanced and re-balanced according to the required RPM after assembly of the spiral brushes. The balancing quality refers to quality grade G 2.5 as per ISO 1940. As core material we have available: mild steel, stainless steel, non-ferrous metal or plastic coated steel. Fixing of the spiral coils The coils are generally mounted onto the roller cores with pressure rings (PRB) in order to prevent the brush from roating on the core. Depending on the work and the rotation speed of the brush the coils can also be spot-welded or screwed...

Request for a quote

KULLEN-KOTI GMBH

Germany

Our roller brush coil designed as welded package system will also pack the tiger in your tank! Why is it reasonable and advantageous to purchase a welded package system type 231? Each face width of a roller brush needed can be divided in a corresponding number of single, compact segments, called packages, that are not only loosley coiled spirals. What we produce are light and easy-to-handle packages with a constant high density which facilitates and accelerates the equipping of a brush core or shaft carried out by yourself.The welded package system is not only easy to mount but it also makes you independent of any transportation of the core to the supplier for refilling, packing, delivery times etc. and helps you out of emergency situations.For the core constructions the following materials are available: plastic-coated steel, steel, stainless steel (1.4301; 1.4571; 2.4879). The twin tape mounting is designed as a concave backing system where the coil widths (WB) ranges between...

Request for a quote

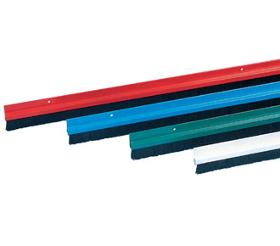

KULLEN-KOTI GMBH

Germany

Additional to the versatility of 11 particular types of aluminium profiles they can be supplied anodised resp. plastic coated in all RAL colours. We call as special types our 11 types of sealing brushes which we can produce in a big range of variations on your request. You can choose: - all fill types, e.g. natural fibres and bristles, plant fibres, wires and synthetic bristles- different trim heights (BH) (free bristle length)- the overall length from a few centimeters to the maximum length which can be transported. We also can supply all sealing brush types with fixing holes in the holding flanges, e.g. 22 available sizes of round holes and 13 sizes of elongated holes. Don't hesitate to ask us for other dimensions of fixing holes, too.

Request for a quote

HUGO BRENNENSTUHL GMBH & CO. KG

Germany

For universal outdoor use and permanent use on sites, IP 44. Robust, plastic-coated steel-tube frame for steady position and additional protection for housing. With an ergonomic carrying handle for comfortable carrying. Oil resistant rubber cable for permanent outside use. With RCD circuit breaker 30 mA for extra safety. Earthed sockets in pairs with different phases. Protective cover for fuses, lockable. Cable length: 2 m Cable: H07RN-F 5G4,0 Plug: CEE 400 V/32 A, 5-pin Socket: 1 x CEE 400 V/32 A, 2 x CEE 400 V/16 A, 4 x 230 V/16 A Protection: 1 x FI 40 A 4-pin, 30 mA 1 x LS 400 V/16 A 2 x LS 230 V/16 A Plug-in system: DE

Request for a quote

HERBERT WALDMANN GMBH & CO. KG

Germany

RING LED is the solution for tasks involving miniature parts. When miniature parts need to be inspected or precisely processed at an industrial workplace, attention to detail is vital. RING LED has the perfect lens – and with its 63 LEDs also the optimum light to meet these requirements. Additional advantage: The luminaire also has an attractive appearance. • Maintenance-free LED technology • Low-distortion magnification right to the edge • Continuous dimming • Hard-coated plastic lens • Exactly adjustable flexible tube • Low space requirements

Request for a quote

HERBERT WALDMANN GMBH & CO. KG

Germany

Thanks to the combination of optimum near vision and high light quality, the MLD magnifying luminaire can be used wherever the human eye comes up against its limits. A field of view perfectly that is adapted to suit your viewing distance provides distortion-free visibility and the ability to work ergonomically. Thanks to the smooth-running linkage technology and the infinitely variable dimmer function, the MLD magnifying luminaire is an indispensable tool in many industrial applications where the human eye is required to perform challenging tasks. — Colour temperature neutral white 5000 K — Colour rendering Ra > 80 — Glare-free thanks to satinised screen — Hard-coated plastic lens Ø 160 mm with 3.5 dioptres — Housing made of colourless anodised aluminium and grey plastic — Polycarbonate plastic screen — Ergonomic linkage technology with 2D head joint — Membrane key integrated into the luminaire head — for On/Off and dimming — Degree of protection IP20; protection class II

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

A prerequisite for the adhesion of an adhesive or coating to a surface is wetting. For wetting to take place, the surface energy of the substrate must be greater than that of the coating. In particular, very many plastics have a very small surface energy and are correspondingly difficult to bond. Often the aim of a plasma treatment is to make a surface wettable and bondable. The wettability can easily be tested with test inks. Diener electronic supplies a test ink set with 8 liquids with surface tensions between 30 and 73 (105) mN/m suitable for most practical applications. There is also a set of 23 test inks, with additional gradations between 30 and 73 (105) mN/m.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Coatings- plastic - Import exportNumber of results

17 ProductsCompany type