- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tube clamps

Results for

Tube clamps - Import export

CARL FRIEDRICH USBECK KG

Germany

stainless steel*band width 11 mm

Request for a quote

BÜRKLE GMBH

Germany

The materials steel and aluminium ensure that the tubing clamp stop-it metal is extremly heat resistant and sturdy. The tubing clamp is available in four different sizes, for hose diameters up to max. 30 mm. The tubing clamp can be used wherever the flow in hoses with liquids or gases needs to be regulated or stopped. Stepless flow regulation: With the tubing clamp stop-it's knurled screw, a stepless, delicate flow regulation or complete stop of the flow are possible, even for existing hose connections. The hose is compressed over a wide area against the sturdy steel hook in order to prevent it from being damaged.

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

nickel plated brass*hinged jaw

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

nickel plated brass*hinged jaw

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

RK tube connector – unbeatable variety Thanks to their simple clamping principle, the aluminium tube connectors enable the fast assembly of both round and square precision tubes. The huge diversity of this system is what makes it an attractive and cost-effective alternative to conventional welded connections. Our application expertise and the experience we have gained over several decades as a manufacturer of clamp connectors give you security for individual handling of RK tube connection systems. Connecting tubes with different diameters and cross sections to one another The cast aluminium or extruded aluminium tube connectors impress with good mechanical properties, a wide range of variants and optimum value for money. The Solid Clamps product range currently comprises clamp connectors with a diameter of 8-80 mm for round tubes and of 20-80 mm for square tubes. More than 170 basic types in over 400 different variations are available.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

A flexible and cost-effective way of connecting tubes to each other reliably and stably. RK Rose+Krieger developed the precision-cast stainless steel tube connectors specially for heavy loads and impact-resistance. The high-strength tube connectors are resistant to high temperatures and corrosion, and are engineered for dynamic loads. An electrochemical passivation – the tube connectors are electropolished in a final working step – makes them more resilient and resistant to acids than elements made of untreated stainless steel. As a result they are particularly resistant to cleaning with aggressive cleaning agents or hot water from high-pressure cleaners, and ideally suitable for use in packaging machines or for feeding technology in plants in the chemicals industry. Stainless steel clamp connectors are tough. Stainless steel clamps are particularly important for users working in the fields of chemical and food technology.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Tube clamps are best suited for a quick and safe connection of two tubes that can be plugged into one another.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

Electromagnetically operated pinch valve PPV 7 (NC) with high flow rates and precise control. The 2/2-way NC pinch valve clamps tubes with a Diameter up to 7mm and depending on the used material (PVC / Silicone) up to 1.5mm wall thickness. It has a clamping force of 42N.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

Electromagnetically operated pinch valve PPV 7 (NO) with high flow rates and precise control. The 2/2-way NO pinch valve clamps tubes with a Diameter up to 7mm and depending on the used material (PVC / Silicone) up to 1.5mm wall thickness. It has a clamping force of 42N.

Request for a quote

SAMSYS GMBH

Germany

SAMSYS offers Spindle Liner for draw tube diameters from 38mm to 100mm. The length of the reduction tube depends on the length of the draw tube, as well as the clamping device and the type of clamping cylinder. The reduction tube consists of a precision steel tube as support tube (1). In order to ensure optimum guidance, the rear (2) and the front (3) guide are adapted to the lathe. Mounting as well as dismounting can be done in a very short time with a few simple steps, as the reduction tube is only attached to the clamping cylinder with two screws. The POM bushings (4) can be flexibly adapted to the material diameter. Since you do not need to store a reduction tube for every diameter, you save valuable storage space. A Water pan extension (5) is also available as an option for safe covering and splash protection.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Light Clamps – the clever plastic series: With the plastic tube connectors from the "Light Clamps" series, RK Rose+Krieger has developed a cost-effective and versatile range of tube connectors for the positive connection of tubes in the light load range. This design enables the clamping of the most various tube sections and –diameters. Besides their attractive design and the intelligent system of reducing bushes the clamping elements are characterised especially by their resistance to chemicals. They are particularly appropriate for sensitive applications under laboratory conditions and for industrial applications as, for instance, in the beverage or packing industry.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Four new models for even more flexibility The product family of aluminium Solid Clamp tube connectors has a new addition: size 30 base clamps, sleeve clamps and hinge clamps are now also available for delivery with integrated ball joint. A sleeve clamp with double ball also adds to the range. The ball joints are designed for loads of up to 40 Nm (static). Connected applications can be pivoted freely by 60° and rotated freely by 360°. This way, the new tube connectors with ball joint provide a significantly higher degree of freedom for construction than conventional hinged connectors. An appropriate surface coating on the ball joint makes for a high-strength clamping connection. The clamps feature a universal connecting plate for flexible integration. Features: can be combined with size 30 tube connectors the clamps feature a universal connecting plate (KGFS 30, KGM 30, KGGPZ 30) for flexible integration high-strength clamping thanks to special finishes

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

RK tube connectors – the flexible alternative to welded connections The clampable tube connectors from RK Rose+Krieger are a cost-efficient solution for the positive and ready detachable connection of a diverse variety of systems – without the need for drilling and welding. Depending on the field of application and the expected load, RK Rose+Krieger offers tube connectors made of plastic (Light Clamps), aluminium (Solid Clamps) or stainless steel (Robust Clamps). The Solid Clamps tube connector system also includes the RK monitor mounting for the fixation and ergonomic adjustment of monitors and touch screens used in industrial applications. Say goodbye to welding – that could be the motto of the clampable RK tube connectors The simple assembly technology of the clamping elements eliminates the need for time-consuming and cost-intensive drilling and welding work.

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

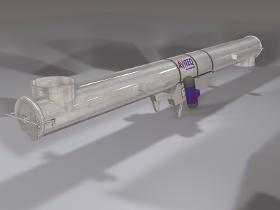

AViTEQ-Tubular feeders are suitable for handling and dosing of free flowing bulk material with a max. grain size of 1/3 of the tube diameter. Especially when the conveying process has to be dust free, tubular feeders are suitable through their closed design; which is needed also with high standards of hygiene and cleanliness. For feeding poisonous and hazardous substances, tube conveyors are used preferred. Advantages & benefits Wide range of applications: dustproof food suitable construction driven by magnetic vibrator/s or unbalanced motor/s long distances possible due to serial connection of feeders possible (conveyor lines) multiple drive possible (magnetic vibrators) variants available for reversing machines separate replacement of tube body or drive traverse (clamp version) made of mild steel or stainless steel Construction Tube feeders are characterized by their simple design. The main components are: feeding tube with a drive beam, either welded or connected by clamping s

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• The classic elbow pipe wrench • Serration against direction of rotation • Slim, S-shaped jaws • With 45° angled jaw • Three-point contact on tube, self-clamping • Infinitely variable • Red powder coated • Made of chrome vanadium steel, forged, oil-hardened

Request for a quote

ORBITEC GMBH

Germany

Tube squaring machines are necessary to achieve burr-free and right-angled seam preparation for orbital welding. That‘s why Orbitec offers two machines, from the small handy Planfix 40 S to the large Planfix 115 S. The Planfix 115 S is a high-performance tube squaring and chamfering device with angle gear for mobile or stationary use with a mains drive. It has a large viewing window, a chip collector and a feed with 0.1mm scale graduation. Optionally, the device can be equipped with a tool carrier and a double-sided indexable insert holder or the well-known Orbitec L facing tool bits. Package includes exemplary for Planfix 115 S Power 230 V: — Tube clamping attachment — Drive — Tool set — Transport box

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTER STAUFFENBERG GMBH & CO. KG

Germany

The type SFO-F tube forming machine facilitates the economical and most reliable production of tube ends made of steel, stainless steel and other materials with a contour typical for the STAUFF Form tube forming system. The machine is designed as a robust table-top device for continuous operation in the workshop. It is used in connection with FI-FST tube shapers and FI-FB clamping jaws. Tube shapers with FI-ID internal tube supports are used with selected tube dimensions, which prevent the tube from being constricted in the shaping area. Tube shapers, clamping jaws and internal tube supports have been specifically designed for the mechanical forming process and can be quickly and simply replaced without the need for any tools, if required. The resulting short tool change and set-up times contribute to the high efficiency of the system as well as ensuring low cycle times. All the tools needed for the forming process are clearly labelled with the tube dimensions so that assembly...

Request for a quote

HUGO BRENNENSTUHL GMBH & CO. KG

Germany

Ideal for in- and outdoor, IP 54. LED-Spot with 28 super bright SMD-LEDs. Low heat generation, no danger of injury. SMD LEDs have a very long lifespan, are shock-proof and maintenance-free. Die-cast aluminium casing. Spotlight mechanism can be swilled and locked. Extra stable and robust tripod. Strong tubular steel, powder-coated. Telescopic from 0.9 - 2 m. Handy and reliable tube clamping nuts. Three sturdy legs. 3 m oil-resistant rubber-neoprene cable with grounding-type plug. With ON/OFF switch. In colourful display-packaging. This luminaire contains built-in LED lamps. Light unit not replaceable. Cable length: 3 m Cable: H05RN-F 3G1,0 LEDs: 28 x 0,6 W Power: 20 W Luminous flux: 1720 lm Lamp efficacy: 86 lm/W Colour temperature: 5700 K Energy efficiency class: A

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

In many areas, stud welding is considered to be the most economic fastening method for components and is sometimes even the only technically feasible solution. Because the stud is joined with the substructure over the entire surface of the stud without any hollow areas, a high strength can be achieved. STAUFF is now using this proven principle for the installation of pipe, tube, hose and cable clamps in the Standard and Twin Series (according to DIN 3015, parts 1 and 3) with M6 mounting thread, where female threaded weld studs replace the regular weld plates; distance plates made from plastic provide the necessary spacing between the clamp bodies and the substructure. If required, the system can also be adopted for alternative fastening methods, e.g. for clamping belts, cable ties or corrugated cable protection hoses. In addition to the individual components – weld studs, distance plates, clamp bodies and metal hardware required – the company also provides the correspondingly...

Request for a quote

PTEC PRESSURE TECHNOLOGY GMBH

Germany

Service pressure: 0-26 Mpa Service temperature: -40°C up to 85°C Reliable in filling and operation direction Small construction Corrosion-resistant All seals are suitable for CNG Certification: ECE R 110 The valve is equivalent of heavy metal regulation Burst pressure: > 100 Mpa, 20° Orfice diameter: 4, 6mm Connection: 6, 8mm tube or 3/8" Tightness: 1x10-5mbar l/s, 20°C, 100% He

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner has developed the mandrel cutting machines of the SR series for cutting off sealing rings from injection-moulded or extruded tubes with different diameters. These machines are characterised by their unique processing method and high cutting quality. First, pre-extended "rubber tubes" are clamped onto mandrels. Due to the special design of the mandrels, the mandrel can be set up and removed quickly and without special previous knowledge. The mandrels are then automatically clamped in the machine between rotating spindles and production is started. A knife carriage travels along the tubes and cuts the flat sealing rings to the desired length with either push-fit or circular knives, depending on the requirements. This cutting method is particularly impressive with its high cutting quality in combination with a high output.

Request for a quote

ABS SAFETY GMBH

Germany

This sealant collar was designed for anchorage points with a diameter of 16 or 42 mm and is cold-bonded onto the subsurface. Special notches allow it to be flexibly shorted. The disc of the collar is 420 mm in diameter. A tube clamp is included in the package. Specially designed for cold-bonding, e.g. on corrugated roofs Not suitable for EPDM sheeting Designed for Ø 16 mm and Ø 42 mm rods Tube clamp included Disc diameter Ø 42 cm

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Removal of adhesive residues on grinding instruments with the Spray cleaning device Clean-o-mat RC 82 Parts cleaning machine for removal of adhesive residues on grinding instruments with approx. 100 bar pressure. The nozzle tube system and the clamping device are adaptable to the grinding wheel diameter.

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

For the abandonment of Offshore structures special legal requirements apply. Tubes have to be deconstructed under the seabed. This requires special technologies. Our Downhole Cutting Heads (DCHs) can be inserted into tubes and casings over an umbilical from the working platform. Arriving at the destination they clamp in the tubes and perform a 360 degrees cut which severs the tube underneath the seabed. The DCH is pulled out and afterwards the pulling of the tube is possible. Cuttings can be performed up to 150 m (500 ft) deep and pipe sizes between 7” and 72” diameter, whereby the wall thickness can be up to 20” thick. For every requirement we offer the appropriate DCH. By extensions nearly every kind of pipe/tubing/casing can be cut.

Request for a quote

FRANZ EISELE & SÖHNE GMBH & CO KG

Germany

Filling and mixing lines: Filling and mixing line, height and laterally adjustable Filling and mixing line, with removable mixing nozzle Mixing tube made of hard PVC, rotatable with 1 pipe clamp Filling and mixing line, galvanised steel, can be rotated using socket spanners, height and laterally adjustable mixing nozzle Mixing tube made of completely from hard PVC with flange connection with 1 pipe clamp Mixing tube made of completely from hard PVC with flange connection, height and laterally adjustable mixing nozzle with 1 pipe clamp Mixing unit completely galvanised, rotatable, height adjustable with clamp bracket and flange connection Mixing tube completely galvanised with flange connection, mixing nozzle, height and depth adjustable Mixing nozzle completely galvanised with flange connection, fixed mixing nozzle Tank filling line completely galvanised, fixed mounting, 360 degrees rotatable with flange connection Coupling parts,...

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

By using REMFORM® screws to join synthetic materials, the cost of the inserts and the associated work step can be omitted in the injection process. The screw simply screws into an existing core hole, forming its own thread as it goes in. The asymmetric thread geometry of the REMFORM® screw ensures that the synthetic material flows towards the load flank as the thread is formed. Thus: low turning torques high vibration resistance low cracking risk high assembly reliability Additionally: The radial force offset to the radius enables a much higher tightening torque simultaneous with a smaller tube geometry. Result: much higher clamping force. Your commercial benefits: The overall cost of fastenings is reduced by up to 72%.

Request for a quoteResults for

Tube clamps - Import exportNumber of results

29 ProductsCountries

Company type

Category

- Screws (3)

- Valves for pneumatic equipment (2)

- Welding, soldering and brazing - equipment and supplies (2)

- Chemical industry - machinery and equipment (1)

- Clamp collars, plastic (1)

- Driveshafts and micro-motors - electric (1)

- Environmental clean-up - machines and equipment (1)

- Extractors, gas and smoke - equipment (1)

- Mechanical engineering - custom work (1)

- Mechanical transmission - components (1)

- Metallurgy - machinery and installations (1)

- Metals - Machines & Equipment (1)

- Metalworking hand tools, non-power (1)

- Package sealing machinery (1)

- Pipes and tubes, aluminium (1)

- Stapling and nailing - machinery and equipment (1)

- Wrapping and outer-wrapping machinery (1)