- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- turning - steels and metals

Results for

Turning - steels and metals - Import export

SCHULZ STANZTECHNIK GMBH

Germany

We take the right turn! In the area of turning technology we can offer you a spectrum of prototypes, zero series and small series as well as the production of large series as a powerful partner. We process all materials, e.g. Such as automatics, tempering, stainless steels, aluminum, brass, copper and more! Max. Diameter when working rod and / or coil: Ø 65 mm Max. Diameter when machining sections: Ø 380 mm Max. Working length: 500 mm All common heat- and surface- treatments possible Assembling and more…

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The ultraprecision turning machine (UP-Turning machine) MTC 350 (Micro Turning Center) combines dynamic use with an increased work space, thus resulting in a wide range of products to be manufactured. The travelling distances of the X- and Z-axis are 350 mm and provide the machining of workpieces up to 700 mm in diameter. The MTC 350 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. In addition to the X- and Z-axis there is the option to have an additional linear axis. This A-axis allows to do micro milling or raster flycutting operations on the machine. Besides many other accessories, that make the MTC 350 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The ultraprecision turning machine (UP-Turning machine) MTC 250 (Micro Turning Center) has a lightweight construction of the moving parts and thus enables the machine axes to be used in a dynamic mode (Slow Tool). This machine is our standard machine with the smallest footprint. The travelling distances of the X- and Z-axis are 250 mm and provide the machining of workpieces up to 500 mm in diameter. The MTC 250 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. Besides many other accessories, that make the MTC 250 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quote

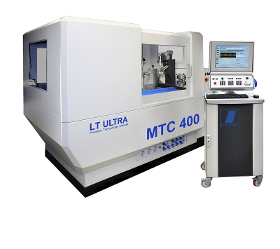

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The ultraprecision turning machine (UP-Turning machine) MTC 400 (Micro Turning Center) is designed to hold heavy weight workpieces up to 100 kg. The travelling distances of the X- and Z-axis are 400 mm and provide the machining of workpieces up to 800 mm in diameter. The MTC 400 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. Different vacuum chucks for workpieces of up to 800 mm (31.5’’) in diameter are available. Besides many other accessories, that make the MTC 250 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The ultraprecision turning machine (UP-Turning machine) MTC 650 is currently our largest series machine. Our customers can machine workpieces up to 200 kg in UP quality. The travelling distances are 400 mm in the Z-axis and 650 mm in the X-axis. Workpieces with a diameter of up to 800 mm in diameter (optionally 1000 mm) can be machined. The extended X travel offers more space for additional accessories, further tool holders or special bodies/ constructions. The MTC 6500 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. Different vacuum chucks for workpieces of up to 800 mm (31.5’’) in diameter are available.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Turned parts Long turned partes, small turned parts Turned, milled and grinded parts Thread inserts in brass, steel and stainless steel Possible materials: Alloy AlCuMgPb, AlZn5,5MgCu etc. Brass CuZn39Pb3, CuZn40Pb2 etc. Stainless steel 1.4301, 1.4305, 1.4571, 1.4401, 1.4101 etc. Steel Machining steel, St52, St37, C45, etc. Special steels Titan, Hastelloy, Copper, Bronze etc. Surface treatments may be done as follows: Galvanizing, nickel, brown, hot-dip galvanizing, phosphating, anodizing, chrome plating, painting, powder coating, plasma coating, sandblasting, Tuflok coatings. All common surfaces as VDA standard are possible (zinc-nickel, zinc flake). Heat treatments such as Plasma / gas nitriding, carbonitriding, hardening, carburizing, vacuum hardening, tempering etc.

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

Turned parts, CNC turned parts, long turned parts Part diameter: 0.3 to 200 mm Parts Length: 1000 mm Materials: steel, stainless steel, brass, aluminum and plastic In association with our high qualified partners the supply of hardened and coated standard parts is self-evident. Our products are galvanized on request, painted, anodised, phosphated, zinc flake coated (e.g. GEOMET) etc.

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

STUD BOLTS THREADED BOLTS CLEVIS PINS DIN 1438 DIN 1445 SPLINT-PIN BOLTS, HEAD BOLTS: DIN 1433 (without head) DIN 1434 (with head) DIN 1435 (with head) DIN 1436 (with head) DIN 1443 ISO 2340 (without head) DIN 1444 ISO 2341 (with head) All bolts based on DIN / EN / ISO or by drawing (modified standard) bolt clevis pin DIN 1445 Material: Machining steel e.g. 9SMn(Pb)28k, 11SMn(Pb)30+C... Carbon Steel e.g. C15, C35, C45... Stainless Steel e.g. 1.4305, 1.4301, 1.4571, 1.4104... Aluminum e.g. AlMgPb, AlMgSi0,5, AlMgSi1... In association with our high qualified partners the supply of hardened and coated standard parts is self-evident. Our products are galvanized on request, painted, anodised, phosphated, zinc flake coated (e.g. GEOMET) etc

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

STUD BOLTS THREADED BOLTS CLEVIS PINS DIN 1438 DIN 1445 SPLINT-PIN BOLTS, HEAD BOLTS: DIN 1433 (without head) DIN 1434 (with head) DIN 1435 (with head) DIN 1436 (with head) DIN 1443 ISO 2340 (without head) DIN 1444 ISO 2341 (with head) All bolts based on DIN / EN / ISO or by drawing (modified standard) bolt clevis pin DIN 1445 Material: Machining steel e.g. 9SMn(Pb)28k, 11SMn(Pb)30+C... Carbon Steel e.g. C15, C35, C45... Stainless Steel e.g. 1.4305, 1.4301, 1.4571, 1.4104... Aluminum e.g. AlMgPb, AlMgSi0,5, AlMgSi1... In association with our high qualified partners the supply of hardened and coated standard parts is self-evident. Our products are galvanized on request, painted, anodised, phosphated, zinc flake coated (e.g. GEOMET) etc.

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

SPLINT-PIN BOLTS, HEAD BOLTS: DIN 1433 (without head) DIN 1434 (with head) DIN 1435 (with head) DIN 1436 (with head) DIN 1443 ISO 2340 (without head) DIN 1444 ISO 2341 (with head) All bolts based on DIN / EN / ISO or by drawing (modified standard) bolt clevis pin DIN 1445 Material: Machining steel e.g. 9SMn(Pb)28k, 11SMn(Pb)30+C... Carbon Steel e.g. C15, C35, C45... Stainless Steel e.g. 1.4305, 1.4301, 1.4571, 1.4104... Aluminum e.g. AlMgPb, AlMgSi0,5, AlMgSi1... In association with our high qualified partners the supply of hardened and coated standard parts is self-evident. Our products are galvanized on request, painted, anodised, phosphated, zinc flake coated (e.g. GEOMET) etc.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Advantages - Very short refacing time! - No dust! - No noise! - Powered by low operating voltage! Features The machine is fitted with two motors providing a smooth cutting action. The operating voltage supplied to the motors by a compact power supply unit is of the low voltage type to eliminate electric hazards. The exchangeable adapter head with the built-in slideway for cutting tool travel ensures a precise seat angle eliminating faulty setting operations. Roundness, concentricity and surface finish of the refaced valve seat are within manufacturers’ specifications or even better. Handling Setup is fast and easy. First, lock the pilot with mounted centering spider in the valve guide. Then, lower the machine over the pilot and position the cutting tool in front of the inner edge of the valve seat. Turn micrometer downfeed to set the desired depth of cut. Refacing is automatic. Pressing one button is enough to start the refacing pass.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Advantages - Very short refacing time! - No dust! - No noise! - Powered by low operating voltage! Features: The machine is fitted with two motors providing a smooth cutting action. The operating voltage supplied to the motors by a compact power supply unit is of the low voltage type to eliminate electric hazards. The exchangeable adapter head with the built-in slideway for cutting tool travel ensures a precise seat angle eliminating faulty setting operations. Roundness, concentricity and surface finish of the refaced valve seat are within manufacturers’ specifications or even better. Handling Setup is fast and easy. First, lock the pilot with mounted centering spider in the valve guide. Then, lower the machine over the pilot and position the cutting tool in front of the inner edge of the valve seat. Turn micrometer downfeed to set the desired depth of cut. Refacing is automatic. Pressing one button is enough to start the refacing pass.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The VD4HD-RC is designed for refacing • the landing surface for the cylinder liner on the engine block, • the landing surface for the cylinder head on the cylinder liner and • the landing surface for the cylinder liner on the cylinder head. Features Drive unit and gear head of the VD4HD-RC are identical with the drive unit and gear head of the VD4HD Valve Seat Refacing Machine. If you have already a VD4E machine and you want to use it with our new face turning heads, we can convert it into the new high performance VD4HD System. The three available face turning heads should be used according to our recommendation with the VD4HD drive unit and the related power supply type 4HD. We would be glad to advise you about our new VD4HD system and send you an offer for this. The D4/0° adapter head is bolted to the gear head in place of the valve seat refacing head. The VD4HD-RC is centered by a pilot assembly which is designed to fit to the engine component to be serviced.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Advantages - Very short refacing time - Easy to use - Modular add-on components - Powered by low operating voltage Features The machine is fitted with two motors providing a smooth cutting action. The operating voltage supplied to the motors by a compact power supply unit is of the low voltage type to eliminate electric hazards. The exchangeable adapter head with the built-in slideway for cutting tool travel ensures a precise seat angle eliminating faulty setting operations. Roundness, concentricity and surface finish of the refaced valve seat are within manufacturers’ specifications or even better. Handling Setup is fast and easy. First, lock the pilot with mounted centering spider in the valve guide. Then, lower the machine over the pilot and position the cutting tool in front of the inner edge of the valve seat. Turn micrometer downfeed to set the desired depth of cut. Refacing is automatic. Pressing one button is enough to start the refacing pass.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

The new portable HUNGER universal refacing machine UDM4E is a versatile machine offering a choice of modular components for refacing valves and valve seats as well as counterboring seat ring pockets and resurfacing the sealing surfaces on cylinder heads, cylinder liners and engine blocks of large diesel and gas engines. Key features: - No abrasive dust. A fast clean cut, - Compact and handy design - Modular add-on components provide a flexible solution for multiple projects - Powered by SELV (Safety Extra Low Voltage) to avoid risk of electrical shock - Power supply with universal AC input - Fast set-up time - Easy to use - The economical solution for both field and workshop use »Roundness, concentricity and surface finish of the refaced faces are within manufacturers’ specifications or even better«

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Working Principle: The counterbore is machined to the preset depth by the simultaneous application of both a rotary and vertical or horizontal feed motion to the carbide cutting insert. While the cutting insert rotates in a circle around the counterbore, a feed gear mechanism ensures a continuous feed motion. The lathe-type refacing action provides smooth and closely fitting contact surfaces for oversize valve seat rings. Features: The motor drive unit of the VD4HD-ADM is identical with the motor drive unit of the VD4HD Valve Seat Refacing Machine and, therefore, is only required, if no VD4HD is at hand. Two types of exchangeable boring gear heads are available. The standard AV boring head is provided with a vertical slide for counterboring. The optional AVH boring and facing head is provided with a vertical and a horizontal slide for counterboring and facing the bottom of the bore.

Request for a quote

WILHELM MEIER SPINDELN U. DREHTEILE GMBH + CO. KG

Germany

The customer range of our milled parts stretches from medical and furniture technology to classical mechanical engineering.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WILHELM MEIER SPINDELN U. DREHTEILE GMBH + CO. KG

Germany

We manufacture turned parts such as threaded bushings and nuts for mechanical engineering, power plant technology and for furniture technology. The treatment of the turned parts takes place on our CNC turning machines, conventional lathes, 6-spindle multispindles or automatic lathes. Threaded bushings and thread nuts are usually supplied as a system with matching stems (spindles).

Request for a quote

WILHELM MEIER SPINDELN U. DREHTEILE GMBH + CO. KG

Germany

A stem or spindle with a trapezoidal thread is normally used as a movement stem (spindle). We manufacture stems (spindles) from Tr 12 to Tr 110 for drive and actuator technology, for valve construction as well as for power plant, water, waste water and theater technology.

Request for a quote

WILHELM MEIER SPINDELN U. DREHTEILE GMBH + CO. KG

Germany

Hollow stems (spindles) are pipes with an external thread over the entire length of the tube. They are used for example in telescopic drives for high-quality furniture.

Request for a quote

WILHELM MEIER SPINDELN U. DREHTEILE GMBH + CO. KG

Germany

Threaded stems (spindles) from our serial production are used for example in the actuator technology for medical engineering and for the furniture industry. The fabrication steps used for the serial stems (spindles) usually consist of thread rolling or whirling with a subsequent turning process.

Request for a quote

WILHELM MEIER SPINDELN U. DREHTEILE GMBH + CO. KG

Germany

We manufacture large stems (spindles) up to a length of 6.000 mm with matching threaded bushes and nuts. For example for valve construction as well as for power plant, waste water and stage technology.

Request for a quoteResults for

Turning - steels and metals - Import exportNumber of results

23 ProductsCountries

Company type