- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- installation of tanks

Results for

Installation of tanks - Import export

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

With such flexibility, the sales team at Lipp can enable any customer to specify exactly what is needed for their installation. From complete, turnkey systems to individual components and accessories – Lipp can support customers whatever their requirements. Consultation is a primary objective for Lipp before any work is undertaken. Lipp provides diagnostic tests, efficiency calculators and flow sheets to visualise a tank system and inform the customer of the performance they can expect. This is especially useful for anaerobic digestion – where Lipp experience supports the efficiency and safety of the system from design through to construction. Particular attention is always paid to the content to be stored within the storage system, which allows Lipp to offer customers the chemically stable materials and accessories to get the most from their storage tanks and digesters. Fundamentally, Lipp’s focus on the customer allows consultation and sales to be perfectly integrated

Request for a quote

SFA ENVIRO

France

Slow speed aerators used for aeration and mixing of urban and industrial wastewater in various processes Provided in either fixed bridge or floating designs Ideal for Aerating most types of wastewater or industrial euents The TLF® Turbine Aerator is one of the most ecient aeration products in the marketplace Produces High Mixing and Homogenous Solutions in large lagoons and ASP tanks. IP55 geared motor with IE3 highly efficient rating Coupling sleeve and based materials coated with high grade Epoxy Paint Float can me supplied in various materials including HDPE Rotor made of glass fibre reinforced polyester. The GRP has a low density which allows installation without having to empty the tank and the design also reduces the axial loads on the gearbox.

Request for a quote

SFA ENVIRO

France

Designed to be installed in many circular clarifier tanks with flat or slightly sloping bases. Generally used for the treatment of urban or industrial wastewater containing solids that settle quickly and where it is important to be able to remove the sludge as it forms. Aluminium support beams Stainless steel feed well: at the bottom, which dissipates the effluent inlet and at the top, and assists in the sludge being raked towards the sludge discharge cone Sludge cone: collects the sludge transferring from the base of the tank through the suction tubes Suction tubes equipped with extended control valves Stainless steel weir plate and arm for the transfer to the overflow of clarified water

Request for a quote

SFA ENVIRO

France

Submerged turbine operating at low speeds combined with an air blower for oxygen input. The Sofie® Submersible Aerator/Agitator is a mixing unit for extremely challenging applications. The units minimise blocking or clogging, the Sofie® can be used as an aerator or an agitator for wastewater treatment. Sofie® is designed to be installed at the base of tanks and to operate either in aeration or in a mixing mode. Sofie® is a good alternative to mechanical fine bubble aerators and is suitable for ponds with oxygen or mixing requirements.

Request for a quote

SFA ENVIRO

France

Sludge settling Equipment designed for primary and secondary settling tanks in urban or industrial wastewater treatment plants that contain solids and can then be extracted for sludge processing. Scraper bridge made entirely of aluminium and stainless steel for extremely long durability (compared to galvanised steel solutions in particular). Robust and reliable solution. The Scraper bridge is designed to be installed in circular settling tanks. Hundreds of scraper bridges installed over the last 60 years.

Request for a quote

BS BODENSTECKDOSEN SYSTEMTECHNIK GMBH

Germany

Round CEE floor tank 7022A with lockable lid made of saltwater-resistant aluminum. The CEE floor tank is installed at floor level and can be driven on by car due to its solid construction. Waterproof when closed. Protection class IP 67. Standard surface in natural anodized aluminum. Further configurations and colors on request.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

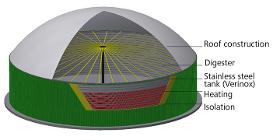

The range of material grades available and individually customisable pumping and stirring technologies provide optimum boundary conditions for any substrate composition. Pre or post treatment of the substrate can be carried out by installing additional tanks (e.g. hydrolysis, sugar beet silos and post digesters). With Lipp tanks for biogas plants which are built and used all over the world, you will benefit from 50 years of experience in plant and tank construction. They are constructed using VERINOX stainless steel which is characterised by maximum leak tightness and high quality. Stainless steel digester with a digester chamber volume of 100 to 10,000 m3 Wide range of tank roofs With or without optional gas accumulator Flexible stirring technology which can be adapted to the digester and substrate Smooth internal walls and uniform temperature distribution

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

FLEXIBLE POST DIGESTERS FOR INCREASING BIOGAS YIELD LIPP offers three flexible Post Digesters for ensuring the effective utilisation of residual gases and improving efficiency which can be tailored to the requirements of each individual biogas plant. LIPP Universal Digester LIPP KomBio Reactor LIPP Eco Post DigesterCan be integrated in existing plants Flexible diameter and height Minimal installation space required Short installation time Durable tanks and covers Consistent quality worldwide Individually customisable based on customer’s requirements ROOFS AND COVERS PRODUCT SPECIFICATIONS LIPP POST DIGESTER THE RIGHT POST DIGESTER FOR ANY TASK The LIPP Universal Post Digester (with digester chamber volumes from 200 to 5,000 m3) comes with the high quality LIPP stainless steel diaphragm cover and is designed for use with an external gas accumulator. It is particularly suitable for the collection of residual gases and for improving efficiency.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP® Tank Accessories special attention is paid to ensure quality, safety, longevity and cost efficiency. Solid, well thoughtout finishing in every detail. Particular attention is paid to leaktightness. Openings or leadthroughs can also easily be made after attachment/installation. A broad range of technical tank accessories is available for all containers. Some are produced inhouse and some are purchased via partners or carefully selected suppliers with whom Lipp has established longterm relationships based on trust. Accessories tank bottom, tank insulation, pumping and stirring technology, overflow gutters, tank heating, steps, platforms, operating bridges, overpressure and underpressure protection devices, pipeline construction, sensors, etc.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The reference information is then applied during service and inspection visits to ensure that the expected performance levels are being met. All inspections are carried out by fully qualified Lipp professionals, who utilise the latest analytics equipment. Efficiency tests can be run on each system and cross referenced – helping highlight any operational issues that may have occurred. This comprehensive analysis further notifies Lipp and the end user which parts of the system may need particular attention or replacement. Qualified Lipp technicians also have the skills needed to deal with more specialised installations, such as anaerobic digestion tanks for biogas production. By providing the same level of technical proficiency as the original installation team, Lipp safeguards the quality level of maintenance activity and the tank itself. Lipp technicians also impart knowledge and training to the end users, so that everyone can become familiar with their system

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

INDIVIDUAL SERVICE FOR EVERY CUSTOMER After installation of a Lipp tank system, the primary concern is safeguarding the market leading performance of all the associated parts. This process begins from the very first consultation – as Lipp produces efficiency estimates and process diagrams as a comparison point. Lipp understands the particulars of every system that it installs, helping to bring a personalised service and a one stop shop to every customer

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

HIGH QUALITY AND SAFETY STANDARDS LIPP brings over 55 years of experience in the field to every project, helping to meet the most demanding safety and quality standards that will deliver profitability and reliability. Proven technologies, such as the spiral LIPP Double Seam System and Verinox material, have been developed and proven to deliver both flexible and efficient storage systems. Tanks are erected via a construction method exclusively employed and developed by LIPP, delivering customizable tanks for any application with a volume of 10,000m3 or more. Perfectly matched to the purpose of each installation, each tank incorporates large volume with a customized interior. LIPP understands that adaptability provides solutions for various applications and requirements – so customers can even specify their own services to lower the total cost of investment.

Request for a quote

TROTEC GMBH

Germany

OIL HEATER FAN IDE 20Flexible all-rounder for a wide range of heating applications: the ultramobile oil fan heater IDE 20 Hot air in a trice at a low price: The smallest oil heater fan of the IDE series from Trotec comes up trumps if you are looking for a compact and low-priced yet reliable oil heating solution for flexible heating applications. Whether in workshops, warehouses, production zones or on construction sites – with a heating capacity of 20 kW the IDE 20 confidently generates clean and dry hot air in quantities of up to 600 m³/h. Even longer outdoor applications present no obstacle to the oil heater fan IDE 20, because it is provided with a durable housing made of doubly coated material, borne by a smooth-running carriage construction with cable holders and installed fuel tank. When employing the optionally available flue gas discharge, this heating device can also be flexibly used for the fully automatic heating of closed rooms.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Hazardous area „L" immersion heater ATEX EEx e + EEx d T1 – T6 The “ISES-L” and “FP/BFP-L” series of hazardous area immersion heaters are ideally suited for installation within process tanks, sited in zone 1 or 2 hazardous areas. The design of the heater provides horizontal mounting of the elements, beneficial for low liquid level applications but allowing vertical installation which facilitates withdrawal from the vessel top. This design of heater is particularly for heating for heating the contents of underground storage tanks.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Immersion heater ATEX II 2 G Ex d IIC T3 – T6 ATEX EN60079-0 und EN60079-1 The Exheat „RFA” range of flameproof rod-type immersion heaters is suitable for installation in process tanks, safety showers, engine sumps, pressure vessels and similar plant, located in zone 1 and 2 Hazardous Areas where flammable atmosphere is a group IIA, IIB or IIC gas. They are suitable for heating all process liquids or gases which are non-corrosive to the materials of construction.

Request for a quote

TROTEC GMBH

Germany

OIL HEATER FAN IDE 50The indirectly fired oil fan heater IDE 50 ensures clean, dry hot air Indirectly fired air heaters such as the oil heater fan IDE 50 are an ideal solution to provide large amounts of clean and dry hot air, as it is required for the heating of construction sites, marquees, exhibition halls, workshops or stables. Longer outdoor applications are no problem for the oil heater fan IDE 50, because it is provided with a durable housing made of doubly coated material, borne by a smooth-running carriage construction with cable holders and installed fuel tank. When employing the optionally available flue gas discharge, this heating device can also be flexibly used for the fully automatic heating of closed rooms.

Request for a quote

HARRER UND KASSEN GMBH

Germany

NIR– InLine measurement device, For continues measurement of organic components Description The HK4 is an NIR (Near Infrared) In Line measurement device with state of the art technology. Which can measure all organic components in solids like meat and in liquids with different viscosities like milk, oil. The HK4 can be installed at pipelines, tanks / vessels, cutters, mincer, etc.. With only one measurement you can measure simultaneously valuable components like fat, protein, lactose, solids content, etc. for the dairy industry and fat, protein, collagen, water, etc. for the meat industry. Through the modular construction (Sensor and evaluation unit are separate), the sensorcalibrations.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIEDR. FREEK GMBH

Germany

Screw-in Tubular Heaters are the standard solution for all heating processes with liquids or gas. The heater is installed in a tank or a tube system by the G1½" screw fitting. The IP54 connection head, fitting and tubular heater consists of stainless steel. The tube sheath material 1.4529 is resistant to sulphite, phosphors and hydrochloride media.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 HME series is a design with bearingless cantilever construction that is directly coupled to the IEC Motor. Specially designed for plant engineering and confined installation conditions. It can be operated in dry installation next to the tank, thus facilitating access for maintenance and repair work. The pump is suitable for pumping /circulating neutral, corrosive and mechanically contaminated liquids. However, it can also be used in stationary installation in the chemical industry and process engineering, in surface and electroplating technology and in gas scrubbers. * temporarily also possible in dry running * directly coupled in bearingless cantilever design * available in immersion depths from 275 - 450 mm Features & Advantages * Service friendly dry running installation * Extremely low vibration and wear operation * Self-centering alignment in the bearing shell * All wetted parts made of corrosion resistant plastic

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

FR-HX - Highly viscous media Electric drum mixer for highly viscous media. The FR-HX is Geppert Rührtechnik’s drum mixer for highly viscous media of up to 5,000 mPas. The foldable mixing elements with a diameter of 200 mm demand a non-vertical installation in the tank. This installation is realized due to a traverse with a welded 2”-socket. Additionally the traverse allows the use of the agitator when the drum is open. The mobile mixer FR-HX is by default equipped with an on-/off-switch with low voltage breaker and – upon request – with a connection cable. . The FR-HX could also be equipped with a frequency inverter upon request. Explosion-proof design after ATEX (2014/34/EU) for operation in ex-zones 0-2 for gases and zones 20-22 for dusts (Device group II, category 1-3).

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Electric drum mixer for highly viscous media. The FR-HX is Geppert Ruhrtechnik’s drum mixer for highly viscous media of up to 5,000 mPas. The foldable mixing elements with a diameter of 200 mm demand a non-vertical installation in the tank. This installation is realized due to a traverse with a welded 2”-socket. Additionally the traverse allows the use of the agitator when the drum is open. The mobile mixer FR-HX is by default equipped with an on-/off-switch with low voltage breaker and – upon request – with a connection cable. . The FR-HX could also be equipped with a frequency inverter upon request. Explosion-proof design after ATEX (2014/34/EU) for operation in ex-zones 0-2 for gases and zones 20-22 for dusts (Device group II, category 1-3).

Request for a quote

MITA WATER TECHNOLOGIES

Italy

The best solution for tertiary filtration: high solid removal yields, minimum water and energy consumption. In the TF – TV VM (VM = metal tank) series the cloth support is made of a perforated metal sheet drum. This model is used for wastewater treatment plants of small working capacity (up to 2.000 PE) or as a secondary treatment downstream from immobilized biomass systems. It is available for installation in concrete tanks or metal tanks versions. The equipment is supplied with an electrical switchboard. - Gravity filtration with limited head loss. - Continuous filtration without standby units for the backwash phases. - Cloth filter in polstoff free fibre provided with high mechanical strength. - High filtration rate (concentrations of TSS < 5 mg/l at discharge).

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Horizontal End-Suction Pumps are centrifugal inline pumps with a compact design where the impeller is mounted onto the extended motor shaft. These pumps are not self-priming and must be gravity fed. All pumps are equipped with a single mechanical seal. Upon request a second mechanical seal is available to allow for dry-running (-GD). This pump series is designed for horizontal installations next to a tank and for pumping air entrained coolant fluids, such as water-soluble coolants or cutting oils, as they occur in high speed turning, milling or grinding applications. The SBA pumps are equipped with the user-friendly (SAE) flange connection which allows for either vertical or horizontal pipe connection and the connection of a pressure gauge with G 1/4. Volumetric delivery: up to 2200 l/min Delivery head: up to 62 m Please contact us for delivery quantity.

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Horizontal End-Suction Pumps are centrifugal inline pumps with a compact design where the impeller is mounted onto the extended motor shaft. These pumps are not self-priming and must be gravity fed. All pumps are equipped with double mechanical seal. This pump series is designed for horizontal installations next to a tank and are capable of cutting aluminium chips and similar materials and pumping of these materials along with the coolant fluid. An agitator located at the pump suction helps to break up and separate any large bundles of chips or birds nests which reach the pump suction. The specially made cutting unit (>60 HRC) is cuting chips and the above located semi-open impeller allows with its large clearances to pump the particles along with the coolant fluid from the machine back to the filter. The SBC pumps are capable of handling chip to coolant ratios of up to 1.5% by weight. Volumetric delivery: up to 1400 l/min Delivery head: up to 34 m

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Vertical End Suction Pumps are centrifugal inline pumps with a compact design where the impeller is mounted onto the extended motor shaft. These pumps are not self-priming and must be gravity fed. All pumps are equipped with double mechanical seal. This pump series is designed for vertical installations next to a tank and for pumping highly air entrained coolant and cutting oils, as they occur in high speed grinding applications. The SBG pumps are equipped with the user-friendly 45 degree flange connection which allows for either vertical or horizontal pipe connection and the connection of a pressure gauge with G ¼. Volumetric delivery: up to 2250 l/min Delivery head: up to 62 m Please contact us for delivery quantity

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Low-pressure type rotating nozzle. Solid stream jet provides high cleaning performance. As the nozzle part is movable, it is easy to insert into and eject from a tank or equipment. Compact design allows for installation in a tank with a small inlet. *1) Spray capacity for each model: RJ3-2-Φ7: 103 L/min (at 0.3 MPa, ca. 3 bar)–169 L/min (at 0.8 MPa, ca. 8 bar) RJ3-2-Φ8: 127 L/min (at 0.3 MPa, ca. 3 bar)–207 L/min (at 0.8 MPa, ca. 8 bar) RJ3-4-Φ6: 146 L/min (at 0.3 MPa, ca. 3 bar)–239 L/min (at 0.8 MPa, ca. 8 bar) *2) Reach distance of RJ3-4-Φ6 is approx. 9 meter in radius. Applications Cleaning of tanks, chests, and containers, cleaning inside the chests (material tanks of papermaking)

Request for a quote

ENDURAMAXX

United Kingdom

Enduramaxx rainwater harvesting tanks are available for above and below ground installations. Above ground plastic rainwater tanks are able to store up to 90,000 litres which can be used for agricultural sprayers off a grain store, water for dairy wash down from barns, pressure washers, greywater systems for flushing toilets for commercial factories and office blocks and a number of applications for washing and cooling in industry. If you require more storage, please contact our sales team for a quote. Below-ground tanks are available from 800 litres to 9,500 litres capacity, with the option of plastic or galvanised lid and a range of turret sizes. Rainwater filters are available for removing leaves and moss out of the water coming off the roof to save a build-up of sediment in the tanks.

Request for a quote

APLAST D.O.O.

Slovenia

We produce tanks for rainwater, drinking water (we have a W 270 certificate) and waste water. By installing a tank for rainwater and seepage water, you are free of precipitation water cleaning tax, and the use of collected rainwater also reduces costs for the removal and cleaning of municipal waste water. AQUAstay collectors are distinguished by the following characteristics: high quality (made of polyethylene which is biodegradable, suitable for drinking water and foods - materials are tested for microbe presence development (w270) in a certified laboratory), multiple uses (rainwater, potable water, and waste water), economical (reduction of potable water use -investment returned in two to three years), robust (due to production in a rotational procedure, the collectors up to 12,000 l can be delivered as a monolith - moulded as a single piece), quick installation and simple use (low weight allows for quick and simple transport and installation

Request for a quote

KLN ULTRASCHALL AG

Germany

Ultrasonic cleaning tanks of series SW 12, SW 25 and SW 40 are compact tabletop cleaning devices for industrial purposes. The serial version includes a cover with handle. The cleaning tanks can be equipped alternatively with frequencies of 30 or 40 kHz or in combination 30/40kHz. On the front the ultrasonic operation can be set nonstop or for a limited period. The ultrasonic generators are integrated in the stainless steel housings. The devices are equipped with a heating with thermostatic regulation installed at the outside of the tank. It is set on the front. The tanks are made of stainless steel, here the SW40 – SW90 are built in welded design. On the bottom they have a residual clearance. Heated and cold cleaning tanks complete the program. Only aqueous cleaning agents are permitted in the cleaning tanks.

Request for a quoteResults for

Installation of tanks - Import exportNumber of results

61 ProductsCountries

Company type

Category

- Valves for pneumatic equipment (7)

- Tanks, metal (6)

- Septic tanks - works (4)

- Treatment of industrial waste water (4)

- Cooling and lubrication pumps (3)

- Storage tanks (3)

- Cleaning, tanks and cisterns (2)

- Heating, domestic - installations and equipment (2)

- Pumps (2)

- Tanks, plastic (2)

- Agricultural systems and equipment (1)

- Bronzing - steel and metals (1)

- Central heating systems (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Chemical industry - machinery and equipment (1)

- Cleaning machines, industrial (1)

- Covers for machines (1)

- Electroheat - machines and equipment (1)

- Electronics - import-export (1)

- Engineering - industrial contractors (1)