- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- magnetic separators

Results for

Magnetic separators - Import export

GHM MESSTECHNIK GMBH

Germany

Filter inserts 250 to 600 Media temperature up to 150 C Nominal widths DN 15 to DN 80 Red brass/brass materials

Request for a quoteFAUDI GMBH

Germany

Advantages Parallel alignment of multiple magnetic separators enables a large flow-rate Extrem durable construction Magnetic rotor up to 1.600 mm width High filtration degree due to optimized design Area of application For the separation of ferritic impurities out of coolants with low requirements on the purity degree, as well as a pre-cleaning step in front of filter systems. Flow rate Various filter sizes and the modular design enable any required flow rate. classification number - Filter aid without Filtration degree - Medium oil and emulsion Filter material magnetic rotor

Request for a quote

STRONG MAGNETS GMBH

Germany

Magnetic separator is one of the most widely used and versatile machines in the industry. It is used to remove iron powder from the reused powder granules. Magnetic separators are widely used in resource recovery, wood industry, mining, kiln industry, chemistry, food and other workshops. The magnetic separator is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with particle size less than 3mm. It is also used for iron removal of coal, nonmetallic ore, building materials and other materials. The magnetic system of the magnetic separator is made of high quality ferrite material or rare earth magnets. The average magnetic induction intensity of the barrel surface is 100600 mT.

Request for a quote

GOUDSMIT MAGNETICS

Netherlands

Magnetic separators filter ferrous and paramagnetic metals from product flows. These contaminations can remain in your end product and cause rejection, but can also damage your process machines. Examples of ferrous contamination in your production line: rivets, nails and screws of packaging, loosened bolts and nuts, wear of moving parts, rust or corrosion. We offer you a wide range of magnetic separation systems, that are suitable for removing large loosened parts, up to very fine wear particles. And with manually to fully automatic cleaning systems.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

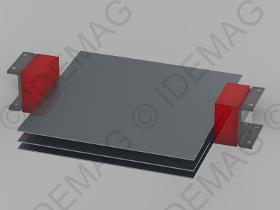

Plate-spreading-magnets are used for separating of stacked iron and steel sheets. The sheet separators are laterally grown from the sheet stack, they magnetize the sheets with the same poles, which repel them from each other. Plate-spreading-magnets apply both in automated systems where plates with vacuum or transshipped are magnetic, and the manual work, where the gripping sheet is greatly facilitated by their help. Our Plate-spreading-magnets consist of a reinforced magnet system, which is installed in a stable sheet steel housing.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Aluminum and copper recycling eccentric eddy current separator China Non ferrous

Request for a quote

TROTEC GMBH

Germany

WATER SEPARATOR WA 4I MULTIQUBEWater separator WA 4i for combination with MultiQube insulation layer dryers The new WA 4i is provided with an integrated micro filter system with low-maintenance magnetic lock filter compartment to take in micro filter cartridges with a threefold filter element. This makes the WA 4i a versatile integral solution with all pre-HEPA filter stages in only one device. Advantage: improved flow-optimized filter technology, quicker setup, decreased material and space requirements – no separate additional micro filter housings required. With respect to insulation drying of surfaces sized up to 40 m², no other model is quite fit to hold a candle to this separator, for despite its ultra-compact dimensions the WA 4i comes fully equipped with numerous practice-oriented detailed solutions, such as a construction yet easier to maintain, TTKwic quick couplings, cable holder, residual water drainage and much more.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

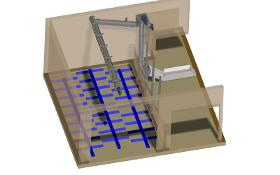

used horizontal machining center – year of construction: 2007-2008 Product name: MFZ 2-3 Update Used 3-spindle horizontal 4-axis machining center Year of manufacture: 2007-2008 Painted in RAL1002 (sand yellow) or red-white Sinumerik 840D Powerline control Machine dimensions without coolant system and chip conveyor L x W x H approx. 5.10m x 3.05m x 2.8m Weight approx. 20,000 kg (per machine without coolant system and accessories) X-axis travel: 300 mm Y-axis travel: 500 mm Z-axis travel: 450 mm Spindle distance: 300 mm Rapid traverse XY Z axis 60,000 mm/min 3 x motor milling spindle GMN, version with HSK63 tool holder Drive power (S1/S6) 28 KW (constant) Torque (S1/S6) 63/83 Nm max. speed 16,000 rpm Chip conveyor Knoll (scratch belt conveyor in positioning variant across the machine) Knoll KSS system with paper belt filter and magnetic separator Flush gun Complete enclosure Tool storage (3 x 30 tools)

Request for a quote

AVM AUTOMATION

France

Handling pneumatic gripper with parallel clamping with 2 concentric fingers. The guide is prismatic and mechanism is completely protected. Benefits of 2finger parallel tightening The clamping of these parallel grippers is the most polyvalent clamping it allows to take pieces of slightly different sizes with the same jaws, to grab a piece in a limited space at opening, to seize the part by the inside or the outside … For very different sizes of parts, it’s possible to grip them without changing jaws with Type 25 parallel long stroke grippers. Reliability and robustness of Type 24 parallel grippers With a hard anodized body and cylinder, prismatic steel guide, fully protected mechanism, these pneumatic parallel grippers are robust and reliable. The positions are detected by magnetic detectors (delivered separately) thanks to 2 Tgrooves on the upper face of the cylinder. This groove is compatible with many detectors on the market to facilitate maintenance.

Request for a quote

AVM AUTOMATION

France

Handling pneumatic gripper with parallel clamping with 3 concentric fingers. The guide is prismatic and mechanism is completely protected Benefits of 3finger parallel tightening Although most handling applications are using parallel grippers with 2 fingers, because even in the case of cylindrical parts, Vshaped jaws allow a good grip. The use of a gripper with 3 fingers is preferred in 2 case – refocusing of the part along 2 axes during tightening – stability of a long cylindrical part clamped by its end In the particular case of screwing, we have a range of 3jaw grippers specifically dedicated to screwing Type 2913 grippers. Reliability and robustness of Type 24 parallel grippers With a hard anodized body and cylinder, prismatic steel guide, fully protected mechanism, these pneumatic parallel grippers are robust and reliable. The positions are detected by magnetic detectors (delivered separately) thanks to 2 Tgrooves on the upper face of the cylinder.

Request for a quote

BLASQEM, LDA.

Portugal

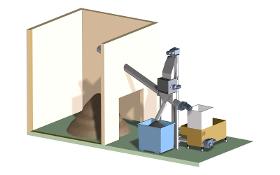

We offer high quality and reliable paint stripping rooms, with different configurations adapted to the requirements of each client. In collaboration with partners with more than 30 years of experience, with engineering and their own manufacturing resources, we study the best technical solutions to meet the expectations of our customers. The blasting rooms supplied by Blasqem can meet different requirements and have different configurations, namely: Shot blasting with several operators Automation of the operation (e.g. robots) Workpiece lifting systems High brightness Double pressure tanks Large capacity depots Different systems and levels of recirculation Magnetic separation ATEX systems No space required We also offer mobile stripping rooms. These solutions can include a complete and compact system for blasting, filtration and recirculation of abrasives.

Request for a quote

OMECHA UAB

Lithuania

Overbelt magnet separator for ferrous metals from bulk materials flow. Separation of ferrous scrap, removing iron impurities at production stages. Recycling waste cleaning from ferrous impurities.

Request for a quote

SILOS SPAIN INSTALACIONES, S.L.

Spain

Efficient post-harvest handling of rice ensures food security. Keep rice clean, dry, and undamaged during storage. Factors to consider: -Moisture content: Aim for ≈ 25% at harvest. -Temperature: High temps promote fungi growth and oxidation. -Storage period: Shorter is better; clean grain before storage. -General condition: Check for broken seeds, impurities, and more. Post-harvest processes include reception, cleaning, drying, and storage. To maintain quality: -Reception: Analyze heat, moisture, and impurities. Use insect control measures and an aspiration system. -Cleaning: Install an integrated system with a magnet separator, drum sieve, grain precleaner, grain cleaner, and buffer silos. Ventilation and exhaust fans are crucial. -Drying: Reduce moisture to safe levels. Prevent discoloration, loss of germination, freshness, and breakage. -Storage: Popular options are steel silos, concrete silos, warehouses, and bag silos. Optimize storage with proper management.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Permanent magnet transporters are used where switchable lifting magnets cannot be used due to insufficient material thickness. They are suitable for thin sheets from 2 mm and are less expensive than lifting magnets, but must be separated from the workpiece under tension by means of a forcing-off device. They are suitable for use in sheet metal storage, on flame or laser cutting equipment, on shears or punching machines, and in steel and container construction. Magnetic transporters of types SH and MK are not compatible with the latest European standard for lifting magnets. We recommend their use only in protected areas.

Request for a quote

IDEMAG

Spain

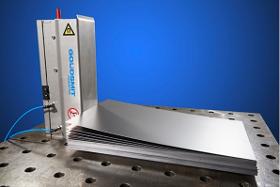

The magnetic sheet floaters are designed for separation of magnetic steel sheets, clean , oily or sticky sheets. They help boost press and press brake production by eliminating the need to fumble with thin oily sheets. It also operates in automated systems. For a good selection of magnetic floater in the separation of plates, first of all we should know the thickness of the sheets, since it is a critical input to do a good job. One thing to bear in mind is that the magnetic float IDG.FS.RB shall be 90 mm higher than the stack of sheets to be separated. Construction features: * Stainless steel case. * Construction of the magnetic circuit with powerful permanent magnet, which can not be demagnetized. * High resistance welded box. * Threaded holes in the mounting base for a quick assembly * Ceramic or Rare Earths magnets. * Non-standard size. * Sizes and configurations according to customer characteristics. * Available in various magnetic forces.

Request for a quote

IDEMAG

Spain

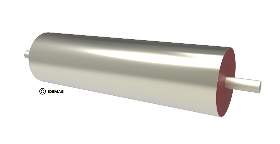

Eddy Current separation system consists of a conveyor belt and a rotor with a magnetic circuit built in 14 or 24 poles; to adapt to the grain-size distribution of the product. All within a steel case and covered by a counter drum . Being separates, the drum and the rotor inductor, allows operation at different frequencies. When the rotor turns at high speed it generates an electric current in the conductive metals (nonferrous), this inductive voltage produces a magnetic field opposite to the rotor, causing the non-ferrous metals being repelled. The rejected metal falls into the hopper by gravity, being separated from the other material. Eddy Current separators are indicated for the separation of non-ferrous metals: aluminum, brass, copper, etc., from inert materials. Used by recyclers in various sectors, production of semimanufactured and other processes. Separation of nonferrous metals in: car crushers, foundry slag, foundry sand, debris in domestic and industrial recycling companies

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IDEMAG

Spain

The electromagnetic separators suspended on conveyor belts are the most effective equipment for removal of ferrous contamination from other nonferrous materials. Consist of an electromagnet which creates powerful magnetic fields that are generated by electrical coils which provide the required attractive force to separate the iron pieces. The self-cleaning of the equipment is performed by a resistant rubber belt and provided with transverse projections.This facilitates the transport of material and separation of the captured contamination throwing it to one side of the conveyor. The belt is mounted on a metal frame with pulleys that rotate with its bearings and is driven by an electric motor with a speed reducer; belt tensioning is done through a deflection drum. Its main mission is the protection of crushing and grinding equipment against damage and wear caused by the presence of iron pieces.The electromagnetic overbands separate ferrous particles from other materials in recycling pr.

Request for a quote

IDEMAG

Spain

mainly used for the purification of materials and the protection of crushing or grinding machines before the next production step. - Widely used in the cement industry, chemicals, plastics, coal, refractory materials, construction or food

Request for a quote

IDEMAG

Spain

The magnetic field of the pulley attracts the ferrous fines which are held to the belt until it reaches the underside. The separated ferrous materials pass out of the the magnetic field and are collected separately into a chute or bin. The cleaned material is discharged normally over the pulley in a vertical drop. The magnetic conveyor head pulleys are available in various sizes to meet requirements of most conveyor system applications. Applications: Waste recovery Feed & grain Mining Recycling applications

Request for a quote

STRONG MAGNETS GMBH

Germany

Neodymium block magnet, also known as rectangular magnet, square magnet or bar magnet, compared with disc magnet, block magnet is not as commonly used as disc magnet, but their straight line and clean edge offer a pleasing and different visual appearance, what's more, it provides a bigger surface area than disc magnet of same diameter. Block magnet is usually magnetized with north and south pole on opposite square faces, also a multi poles magnetized block is possible with a new magnetizer machine. Block magnet is widely favoured for clamping applications, magnetic sweeper applications, magnetic separators in the food industry, wind turbine generators, flow control systems & water conditioning application and other related industrial applications.

Request for a quote

BESTACT SOLUTIONS INC.

Japan

A separate type proximity switch that uses Bestact for the built-in contact. It is less susceptible to environmental influences such as dust, gas, and high humidity, and has outstanding contact reliability. Non-contact drive using magnets eliminates mechanical wear and has a long service life. No power supply is required for driving.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Eclipse’s patented magnetic filtration or magnetic separation systems are the ultimate in filtration technology, providing, quality and environmental benefits. The Filtramag is the ultimate in filtration technology, its’ high intensity magnetic cores make it 1005 effective for use with materials which have lower magnetic permeability such as tungsten carbide and cast iron. With a stainless steel construction it is ideal for use in harsh chemical environments and wash systems. Patented design. Easy installation. Unique dual flow technology™ maximises collection capability. Operates at up to 20 bar. Removes both magnetic and non-magnetic contamination. Minimal pressure drop. In-line connections. Ideal for use in harsh chemical environments. The dual chambered design means that fluid is exposed to the high intensity magnets for the maximum time thus ensuring almost 100% of contamination is removed on first pass through the filter. High intensity magnetic cores ensure particle

Request for a quote

VIRA ISI

Turkey

Magnetic Deaerator and Dirt Separator are used with a single device to dissolve microbubbles, dirt, and air in high performance in heating and cooling installations. Micro smart filter design is the most important element of the system design. Optimum air and microbubble separation and very low flow resistance are available. It also has a high degree of dirt handling. With its magnetic Separator feature, ViraPlus separates the moving metal particles in the installation more effectively and ensures faster cleaning of the installation. It also extends the life of your pump and other connecting equipment by minimizing the damage caused by metal parts to high-efficiency pumps that provide low energy consumption.

Request for a quote

GOUDSMIT MAGNETICS

Netherlands

Magnetic separators filter ferrous and weakly magnetic metals from your product flow. These contaminants can remain in your end product and cause rejection, but can also damage your process machines. Examples of ferrous metals in your production line: rivets, nails and screws of packaging, loosened bolts and nuts, wear of moving parts, rust or corrosion. We offer you a wide range of magnetic separation systems, that are suitable for removing large loosened parts, up to very fine wear particles. And with manually to fully automatic cleaning systems.

Request for a quote

GOUDSMIT MAGNETICS

Netherlands

Magnetic sheet separators separate sticky or oiled steel sheets and prevent two sheets from being picked up at the same time. They ensure a smoothly running production process by ensuring that you pick up the steel sheets one at a time. The permanent magnetic force remains constant throughout the years. Sheet separators separate steel sheets up to 4 mm thick of almost any shape, length or width. Round or asymmetrical shapes are also possible. They can be switchable or permanent magnetic.

Request for a quote

STEINER GMBH & CO. KG

Germany

Impurities of your transported goods are often problematic and can be also guilty of disorders. They may even cause damage. But do not desperate! Our tried and tested magnetic separators will help you. These magnetic separators take care to filter out foreign substances. Simply and reliably.

Request for a quote

STEINER GMBH & CO. KG

Germany

The planning and development of our systems are always made according to customer requirements. Whether in combination with container, drying equipment, conveyors, pellet production, saw mills, particle board / furniture industry or in other areas of application. Conveying vertical Low rotational speeds Standard execution Low noise Planning according to the customer

Request for a quote

GOUDSMIT MAGNETICS

Netherlands

Magnets for recycling separate ferrous and non ferrous metals from waste streams or bulk streams. For the elimination of impurities from raw materials or recovery of valuable metals from product streams. An overband magnet effectively and quickly separates high volumes of iron or steel and hangs above a flat or trough-shaped conveyor belt. This type of magnet is self-cleaning and continuously draws Ferro parts from a material flow. he iron removal efficiency of overband magnets ranges from 70 to 90%. This depends on magnet design, product flow and placement. We also manufacture Eddy current separators which remove non-ferrous metal particles, such as copper and aluminium, in a continuous process. For the recovery, recycling or removal of metals.

Request for a quoteResults for

Magnetic separators - Import exportNumber of results

48 ProductsCountries

Company type

Category

- Magnets (16)

- Magnetic equipment (10)

- Metal detectors (2)

- Metallurgy - machinery and installations (2)

- Pneumatic systems and tools (2)

- Wood veneer - machinery and equipment (2)

- Central heating systems (1)

- Concrete forms (1)

- Extraction machinery and equipment - minerals and ores (1)

- Industrial design (1)

- Industrial sheet metal work (1)

- Mechanical engineering - custom work (1)

- Screen filters (1)

- Silos, metal (1)

- Surface treatment - machinery and equipment (1)

- Switches (1)

- Tumble dryers and spin dryers, industrial (1)

- Waste sorting - machines and equipment (1)