- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- magnetic separators

Results for

Magnetic separators - Import export

SILOS SPAIN INSTALACIONES, S.L.

Spain

Efficient post-harvest handling of rice ensures food security. Keep rice clean, dry, and undamaged during storage. Factors to consider: -Moisture content: Aim for ≈ 25% at harvest. -Temperature: High temps promote fungi growth and oxidation. -Storage period: Shorter is better; clean grain before storage. -General condition: Check for broken seeds, impurities, and more. Post-harvest processes include reception, cleaning, drying, and storage. To maintain quality: -Reception: Analyze heat, moisture, and impurities. Use insect control measures and an aspiration system. -Cleaning: Install an integrated system with a magnet separator, drum sieve, grain precleaner, grain cleaner, and buffer silos. Ventilation and exhaust fans are crucial. -Drying: Reduce moisture to safe levels. Prevent discoloration, loss of germination, freshness, and breakage. -Storage: Popular options are steel silos, concrete silos, warehouses, and bag silos. Optimize storage with proper management.

Request for a quote

IDEMAG

Spain

Eddy Current separation system consists of a conveyor belt and a rotor with a magnetic circuit built in 14 or 24 poles; to adapt to the grain-size distribution of the product. All within a steel case and covered by a counter drum . Being separates, the drum and the rotor inductor, allows operation at different frequencies. When the rotor turns at high speed it generates an electric current in the conductive metals (nonferrous), this inductive voltage produces a magnetic field opposite to the rotor, causing the non-ferrous metals being repelled. The rejected metal falls into the hopper by gravity, being separated from the other material. Eddy Current separators are indicated for the separation of non-ferrous metals: aluminum, brass, copper, etc., from inert materials. Used by recyclers in various sectors, production of semimanufactured and other processes. Separation of nonferrous metals in: car crushers, foundry slag, foundry sand, debris in domestic and industrial recycling companies

Request for a quote

IDEMAG

Spain

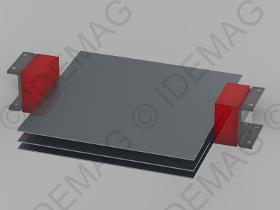

The magnetic sheet floaters are designed for separation of magnetic steel sheets, clean , oily or sticky sheets. They help boost press and press brake production by eliminating the need to fumble with thin oily sheets. It also operates in automated systems. For a good selection of magnetic floater in the separation of plates, first of all we should know the thickness of the sheets, since it is a critical input to do a good job. One thing to bear in mind is that the magnetic float IDG.FS.RB shall be 90 mm higher than the stack of sheets to be separated. Construction features: * Stainless steel case. * Construction of the magnetic circuit with powerful permanent magnet, which can not be demagnetized. * High resistance welded box. * Threaded holes in the mounting base for a quick assembly * Ceramic or Rare Earths magnets. * Non-standard size. * Sizes and configurations according to customer characteristics. * Available in various magnetic forces.

Request for a quote

IDEMAG

Spain

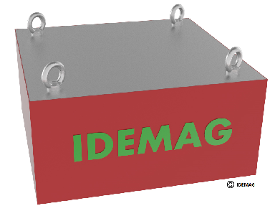

The magnetic plates are used to attract the ferrous contamination that flows freely in the material. We can manufacture them with a slidying tray to help the manual cleaning of the plate.

Request for a quote

IDEMAG

Spain

The electromagnetic separators suspended on conveyor belts are the most effective equipment for removal of ferrous contamination from other nonferrous materials. Consist of an electromagnet which creates powerful magnetic fields that are generated by electrical coils which provide the required attractive force to separate the iron pieces. The self-cleaning of the equipment is performed by a resistant rubber belt and provided with transverse projections.This facilitates the transport of material and separation of the captured contamination throwing it to one side of the conveyor. The belt is mounted on a metal frame with pulleys that rotate with its bearings and is driven by an electric motor with a speed reducer; belt tensioning is done through a deflection drum. Its main mission is the protection of crushing and grinding equipment against damage and wear caused by the presence of iron pieces.The electromagnetic overbands separate ferrous particles from other materials in recycling pr.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IDEMAG

Spain

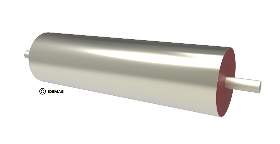

The magnetic field of the pulley attracts the ferrous fines which are held to the belt until it reaches the underside. The separated ferrous materials pass out of the the magnetic field and are collected separately into a chute or bin. The cleaned material is discharged normally over the pulley in a vertical drop. The magnetic conveyor head pulleys are available in various sizes to meet requirements of most conveyor system applications. Applications: Waste recovery Feed & grain Mining Recycling applications

Request for a quote

FELEMAMG,S.L

Spain

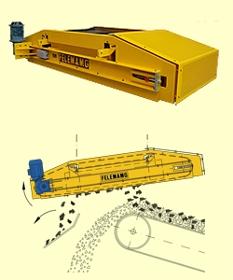

DESCRIPTION Self-cleaning electromagnetic overband separators are designed for extraction and retrieval of ferrous magnetic materials from conveyed material. The overband separator is made of a powerful electromagnet, which supports the small ribbed belt covering the electromagnet. Small frames interlocked to the electromagnet support the drive drum, redelivery drums, and gear motor driving the band. Self-cleaning electromagnetic overband separators are used for automatic extraction of materials, ensuring high recovery of ferrous materials. PRINCIPLE OF OPERATION As the ferrous magnetic materials on the conveyor belt come within the electromagnet’s magnetic field, the ferrous material is attracted and pulled up to belt around the magnet. Ribs clear ferrous materials of the electromagnet’s magnetic field and discharge them freely. Separators may be cross-mounted across the conveyor belt or at the head of the conveyor.

Request for a quoteResults for

Magnetic separators - Import exportNumber of results

8 ProductsCompany type