- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- meat processing

Results for

Meat processing - Import export

BIZERBA SE & CO. KG

Germany

Multi-functional device for strip cutting and tenderizing of meat for trade and industrial continuous operation Multi-functional device can be used as a strip cutter additionally used with tenderising of meat for trade and industrial operations where continuous operation is required. It stands out in terms of performance and precision, reliability and flexibility. Tenderiser and strip cutter for turning fresh meat and cold cuts as well as fruit and vegetables into fine salads and pan-fried meals. With the unique Emotion® drive concept this multi-functional device is energy efficient and easy to handle. It is suitable for continuous operation for automatic product feed lines. Further highlights of the strip cutter are as follows Strip cutting, tenderising and knitting - all using a single device Compact, tilt-proof IP33 protection Cutting sets can be removed with ease for cleaning without the need for tools or threaded connectors Two-part, detachable cutting set for perfect...

Request for a quote

BIZERBA SE & CO. KG

Germany

Multi-functional device for strip cutting and tenderizing of meat for the trade The commercial meat tenderizer and strip cutter for turning fresh meat and cold cuts as well as fruit and vegetables into fine salads and pan-fried meals. It stands out in terms of performance and precision, reliability and flexibility. Ideally suited to Butchers shops, Restaurants and Hotels. Furthermore this unit is perfectly suitable for cutting all manner of products safely, efficiently and quickly. With the unique, compact drive concept and its compact design this multi-functional commercial meat tenderizer is not only flexible and easy to handle but also stands out in terms of hygiene and safety. Built with food production in mind for busy areas the unit accommodates gastro norm trays naturally. Additional highlights of this compact unit are as follows: Multi-functional device for use in trade kitchens and back of house Strip cutting, commercial meat tenderizer and knitting - all using a...

Request for a quote

BIZERBA SE & CO. KG

Germany

Compact commercial meat mincer for sales counter and preparation area The Carneoline FW N22/82 commercial meat mincer, minces raw, cooked or smoked meat. Even marbled meat – in hot or cold form – bacon, offal, rind and vegetables can be minced. Food processing facilities will achieve perfect results and the machines can be cleaned quickly and efficiently. This heavy duty meat mincer is one of the favourites amongst butchers globally. The robust and easy clean design are not the only benefits to this fantastic piece of machinery. The Bizerba commercial meat mincers incorporate unique technology with a gentle cutting process due to the unique worm solution. Gently mincing the meat as oppose to forcing and and stretching the product. This is how you get the perfect mince every time. Even though the cutting process is gentle, it can still produce up to 350 kilograms of mince per hour. A completely solid stainless steel constructed commercial meat mincer with seamless welding. No...

Request for a quote

BIZERBA SE & CO. KG

Germany

Ideal for commercial meat production environments The FW-N 32/98 Heavy Duty Commercial Meat Mincer minces raw, cooked or smoked meat. Even marbled meat – in hot or cold form – bacon, offal, rind and vegetables can be minced. For us, mincing means commutation or controlled processing of meat instead of squashing it. FW-N 32/98 Heavy Duty Commercial Meat Mincer produces a loose and fluffy volume. The mixture retains its red colour due to increased oxygen enrichment. Food processing facilities will achieve perfect results and the machines can be cleaned quickly and efficiently. With a throughput of up to 1100 kg/h, the FW-N 32/98 Heavy Duty Commercial Meat Mincer is the right solution for preparation rooms, large kitchens or as a manual solution for production. Fast and precise mincemeat production with an impressive output per hour. Some exciting features of the Heavy Duty Commercial Meat Mincer are as follows, Clearance-free fit for gentle commutation without warming up and...

Request for a quote

BIZERBA SE & CO. KG

Germany

Flexible sawing system for industrial food production The FK 32 Heavy Duty Meat and Bone Saw is made entirely from stainless steel with high IP protection and with top quality construction all round. Depending on production environment and the food to be processed, this saw is available with a variable work area or can be mobile by adding optional stainless steel wheels. Ergonomic and effective Heavy Duty Meat and Bone Saw cutting and portioning of fresh and frozen foods. This unit will easily cut through fresh and frozen fish as well as heavy cuts of frozen meat including the bones. The Heavy Duty Meat and Bone Saw is ideal for industrial use and has a number of optional extras that you may want to consider to include a Sliding table with removable remnant holder additionally a Stainless steel bench type stand with feet a Mobile CE compliant version, Special saw blades depending on the material that needs to be cut. Safety features. Safety In designing the Heavy Duty Meat and...

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

MACHINE TECHNICAL SPECIFICATIONS: Chassis: Designed with a focus on strength, durability, and aesthetics. Chassis Material: Entire chassis is made of 304 CrNi material. Boiler: Our machine features a double-walled stainless steel boiler. Boiler Plates: The boiler plates are entirely made of 304 quality CrNi material. Boiler Body Plate Thickness: Front Dome: 4 mm Rear Dome: 4 mm Drum Capacity: 1000 liters Meat Carrying Capacity: 350 kg Vacuum System Hydraulic System Maximum Safety Automatic Ready Recipe Easy Operation with Digital Touch Screen Drum Bearing Rollers: FAG or SKF brand bearings are used. ETDYSH - 1000 Mixer Gearbox: 2.2 KW The reducers used are YILMAZ brand, KR series. ETDYSH - 1000 Meat Mixing Tulmbler: Equipped with one 0.70 KW vacuum pump. Electrical Components: Utilizing SCHNIDER or DELTA electrical components.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

MACHINE TECHNICAL SPECIFICATIONS Chassis: Designed with a focus on strength, durability, and aesthetics. Chassis Material: Entire chassis is made of 304 CrNi material. Boiler: Our machine features a double-walled stainless steel boiler. Cooling System Vacuum System Maximum Safety Automatic Recipe System Grinding and Mixing Capability Boiler Plates: The boiler plates are entirely made of 304 quality CrNi material. Boiler Body Plate Thickness: 4 mm Rear Dome Plate Thickness: 4 mm ETDSK Mixer Gearbox: 80 RPM 2.2 KW Electrical Components: Utilizing SCHNIDER or DELTA electrical components. Ensures thorough blending of added spices. Ensures optimal binding of added proteins. Prepares the product for further processing. Warranty: The ETDSK Vertical Meat Tumbler is covered for manufacturing defects. Chassis and boiler construction are guaranteed for 2 years. Electrical components are covered for 1 year under the manufacturers' warranty.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

Chassis: Designed with a focus on strength, durability, and aesthetics. Chassis Material: Entire chassis is made of 304 CrNi material. Boiler: Our machine features a double-walled stainless steel boiler. Cooling System Vacuum System Maximum Safety Automatic Recipe System Grinding and Mixing Capability Boiler Plates: The boiler plates are entirely made of 304 quality CrNi material. Boiler Body Plate Thickness: 4 mm Rear Dome Plate Thickness: 4 mm ETDSK Mixer Gearbox: 80 RPM 2.2 KW Electrical Components: Utilizing SCHNIDER or DELTA electrical components. Ensures thorough blending of added spices. Ensures optimal binding of added proteins. Prepares the product for further processing. Warranty: The ETDSK Vertical Meat Drum is covered for manufacturing defects. Chassis and boiler construction are guaranteed for 2 years. Electrical components are covered for 1 year under the manufacturers' warranty.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

ETDK 60 LT MACHINE TECHNICAL SPECIFICATIONS Chassis: Designed for strength and aesthetics. Chassis Material: Entire chassis made of 304 CrNi material. Boiler: Equipped with a single-walled stainless steel boiler. Vacuum System Maximum Safety Easy Manual Panel Operation Boiler Plates: Made entirely from 304 quality CrNi material. Boiler Body Plate Thickness: 3 mm Rear Dome Plate Thickness: 3 mm ETDK Mixer Gearbox: 25 RPM 1.1 KW Ensures thorough blending of added spices. Facilitates optimal binding of added proteins. Prepares the product for processing.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

ETD - 400 LT MACHINE TECHNICAL SPECIFICATIONS Designed with durability, strength, and aesthetics in mind. The chassis is made entirely of 304 CrNi material. Our machine features a single-wall stainless steel boiler. Vacuum System Maximum Safety Automatic Recipe System Easy Operation with Digital Touch Screen Boiler sheets are made entirely of 304 quality CrNi material. Boiler Body Sheet: 4 mm Boiler Rear Dome: 4 mm ETD Mixer Reducer 80 Revolutions 1.5 KW Ensures thorough mixing of added spices. Ensures optimal binding of added proteins. Prepares the product for processing.

Request for a quote

ERDEMLER COOLING COMPANY

Turkey

As Erdemler Soğutma, we provide design, manufacturing, installation, aftersales service and maintenance services for our customers slaughterhouse and meat processing systems. We provide turnkey solutions in automation level. Modern cutting and meat processing systems are combining cold room systems for cattle, sheep, and chickens with automation technology. Our company gives importance to animal welfare, quality, safety, hygiene, and ergonomy by providing the highquality services. Our efficiency guarantees for competitive power to our customers.

Request for a quote

EACTECH®

Portugal

The HF-250 Burger Maker is state-of-the-art equipment for producing a wide range of hamburger shapes and sizes. The mold filling system is automatic, ensuring uniformity and quality of the final product. It combines the diversity of available molds - multiple formats and thicknesses - with an ultra-fast changeover system for greater production speed. It can be upgraded to integrate an interleaved paper system and/or cellophane cut from a single roll into your machine. Electro-pneumatic operation.

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

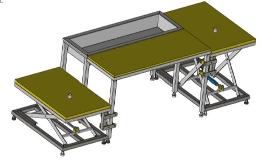

Chassis: Designed with a focus on strength, durability, and aesthetics. Chassis Material: Entire chassis is made of 304 CrNi material. Height adjustment for rotating attachment tables can be made with a pneumatic system. Equipped with a precise weighing system. Table Dimensions: Width: 850 cm Length: 232 cm Height: 76 cm Warranty: The Horizontal Meat Loading Elevator manufactured by us; (Including manufacturing and fabrication defects) Chassis and boiler construction are guaranteed for 2 years. Electrical components are covered for 1 year under the manufacturers' warranty.

Request for a quote

PRO COUPE INDUSTRIES

France

Knives and blades for food processing fish, meat, chicken, vegetables and fruits

Request for a quote

ROHA EUROPE SL

Spain

Paprika E160c Paprika is a popular spice and an important ingredient in many recipes, especially across the Indian sub-continent. Major pigments extracted are the oil soluble Carotenoids, Capsanthin and Capsorubin. Points to note: All Paprika products supplied by Roha are sold with a guarantee of HPLC testing for illegal dyes (Sudan I, II, III & IV etc), whereby only those products with a complete absence of non-permitted dyes are supplied. Roha offers special quality of Paprika with high stability to light&- Applications: Spice blends, Confectionery, Cheese, Processed Meat, Snack Foods, Cereal, Baked goods, dressing

Request for a quote

BIZERBA SE & CO. KG

Germany

Flexible sawing system for industrial food production The FK 32 is made entirely from stainless steel and with top quality construction all round. Depending on production environment and food to be processed this saw is available with a variable work area or can be mobile. Ergonomic and effective comminution and portioning of fresh and frozen foods. Area of Use Suitable for fresh fish as well as for frozen meat Products with bones such as shanks / osso buco and soup bones Production of same weight portions such as cutlets Due to its design and numerous variants it is the perfect tool for industrial use

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WEBER FOOD TECHNOLOGY GMBH

Germany

Well-rounded: The ASP 460 derinder was designed specifically to process round cuts such as ham, shoulder and haunch. Advantages Clean removal of the rind without remnants Perfect speed regulation in combination with the Weber tension roller Variable adjustment of the rind or cutting thickness Moveable with swivel and fixed castors Space-saving With integrated bucket support and low space requirement User friendly Foot lever as standard Options: Foot switch or body operated lever Special tables Special rollers Special voltage

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The special model ASW 560 for industrial applications offers the latest technology and premium quality: Combine cutting or flattening in conjunction with the Weber automatic initial cut function in one machine. That means that virtually no manual post-processing is required after the processing workflow, even for cheek and very cold material. Can optionally be used with a blade shaft for cutting into the product to be derinded. That leads to an optimal derinding result with a residual rind of less than one percent (temperature dependent) for pork cheek or use with upstream pressure device (roller) instead of the blade roller. Advantages Two work procedures in one machine increase product throughput Almost no more manual post-processing required, even for pork cheeks and highly cooled materials – potential labour savings Options: Operation from left or right Product-specific pressure devices for the derinding process Special sub-frames (height adjustment)

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Perfect fit: Fat remover ASF 560 E for pork belly and loin of pork. Maximum yield with little post-processing. Optimised blade holder profile for exact adaptation to the cross section of the product. Electronically controlled movement along longitudinal profile for exact adjustment to the fat contours. The result: Less fat on the pork belly/loin, less lean meat in the belly/back fat. Advantages Minimal post-processing after the processing workflow Line concept: Perfect integration of the machine in stripping workflows Options: Operating personnel can also remain outside the machine stand Curved blade holder profile for ideal product adaptation Special sub-frames (height adjustment)

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Flexible processing: Highly flexible machine programme for trimmers and splitters for industrial use. The position and number of circular blades can be set individually for the splitter. The variably adjustable cutting width also allows the trimmer to be used as a strip cutter. Advantages Splitting center pieces Variable cutting width Divided discharge belt Modern Hygiene Design

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Combination machine for thick and thin: The AMS 533 TWIN skinning machine is particularly suited to processing cuts with thick tendonsand skin, such as pork loin, pork silverside, beef or veal silverside and boiled beef fillet. Advantages Removal of tendons and skin with one machine TWIN transport rollers and specially coordinated blades providethe highest possible yields Ideal cutting width for powerful skinning and tendon removal inlarge and small cuts Effort-saving work table design due to ergonomicmachine assembly Blade guard in cleaning position Gear brake motor with quick stop Product-specific precision adjustment Options: Quick-clamp blade holder for tool-less blade changing Body lever switch Skinning procedure protection Skinning gloves Special tension rollers

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

One for many purposes: Powerful skinning machine for large and small cuts of beef, veal, pork, turkey, horse and game. The Skinner AMS 533 offers an ideal cutting width for processing large cuts, such as beef topside. Advantages Powerful for the highest yield from the smallest installation area Product-specific optional transport rollers and speciallycoordinated blades provide the highest possible yield Ideal cutting width for powerful skinning of large and small cuts Blade guard in cleaning position Gear brake motor with quick stop Product-specific tension rollers Newly-developed compressed air transport roller cleaning,resulting in consistent skinning results Options: Body lever switch Quick release lock for tool-free blade changes Special rollers Skinning procedure protection Special tension rollers

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The smart solution: Fully-automatic defatting machine ASD 460 enables removal of fat layers from loins and cutlets in predefined strengths. Advantages Fully-automatic recognition of the fat strength using Weber camera technology, with programmable controlled movementalong longitudinal profile Continuous work process Sensor-controlled electronic spring for perfect pressure application Uniform fat layers Considerable minimisation of reworking (trimming) Back bacon instead of small trimming cuts Clearly improved product image for cooking after slicing Product-specific blade holders Combinable with pre-installed derinder Options: Special Weber transport rollers Product-specific blade holders Product-specific pressure devices for products withand without bones Fixed or adjustable guide plates for supply and output belts

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Doubly well-rounded: The Skinner ASP 560 D is an open derinding and defatting machine for round cuts, such as ham, shoulder and haunch. Advantages Clean and fast removal of rind and simultaneous removalof shoulder fat Perfect collection of rind and fat Variable adjustment of the rind and cutting thicknessfor fat removal Two workflows in one machine Toolless removal and assembly of all parts to be cleaned Modern, hygienic design Ergonomic machine design Integrated crate shelf Space-saving Options: Application-specific table for ham/shoulder without bone Extended discharge table Special tension rollers

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The top models for industrial applications offer the latest technology and highest quality: As robust high performers in industry, the derinders ASB 460, 560 and ASB 770 are shining examples of pioneering technology in premium quality. The automatic initial cut control for rinds developed by Weber, combined with the spring-mounted cutting system ensures a clean initial cut and a high product yield. The new hygienic programme ensures quick and simple cleaning and is included as standard. Advantages Cut widths up to 460 mm Maximum output thanks to fully-automatic product process Minimum reworking of derinded cuts Precision thickness setting from 0-4 mm Options: Can be operated from left or right Product specific pressure devices Special sub-frames (height adjustment) Can be suspended over a shredding belt or on a C frame

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Flexible and powerful: the conveyor derinder ASB 600 for artisanal and medium-sized companies with a wide range of applications. The combination machine can be used open with a carriage table or closed with a height-adjustable pressure device and infeed belt. In conveyor operation, all cuts, such as cheek, belly and loin of pork, as well as fat on shoulder and ham are derinded automatically. In open operation, suitable for derinding all round cuts, such as ham, shoulder or knuckle. Advantages Optimal results: clean removal of the rind without residues Infinite adjustment of the rind/cutting thickness Equipped with two operating speeds as standard Compact, movable via fixed and guide rollers Option: Pressure rollers in various hardnesses and air pressing roller Discharge belt Special voltage

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Economical and versatile: the ASB 400 conveyor derinder with a wide range of applications. The entry-level model can be used (open) as combination machine with carriage table or (closed) with pressing unit and conveyor. Automatic derinding of all cuts, such as cheek, belly and loin of pork, as well as fat on shoulder and ham. In open operation, suitable for derinding all round cuts, such as ham, shoulder or knuckle. Advantages Clean removal of rind without residues Infinite adjustment of the rind/cutting thickness Ergonomic machine design: short setup times, simple operation with maximum safety Options: Pressure rollers in various hardnesses Special voltage

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Well-rounded: The ASP 560 derinder was designed specifically to process round cuts such as ham, shoulder and haunch. Advantages Clean removal of the rind without remnants Perfect speed regulation in combination with the Weber tension roller Variable adjustment of the rind or cutting thickness Moveable with swivel and fixed castors Space-saving With integrated bucket support and low space requirement User friendly Foot lever as standard Options: Special tables Special rollers Special voltage

Request for a quoteResults for

Meat processing - Import exportNumber of results

123 ProductsCountries

Company type

Category

- Meat processing machines (41)

- Condiments, extracts and spices (35)

- Spices (15)

- Butchery - machinery and equipment (6)

- Food Processing (4)

- Lifting equipment (4)

- Meats, butchery and delicatessen - machinery and equipment (4)

- Sauces (4)

- Vegetables, fresh (3)

- Cold cuts and prepared meats - machinery and equipment (2)

- Conveyor belts (2)

- Detergents and soaps - professional (2)

- Meats, dried (2)

- Cleaning and maintenance - equipment and supplies (1)

- Meat (1)

- Additives, dyes and pigments - industrial (1)

- Bread, cakes and pastries (1)

- Cold rooms (1)

- Doors, sliding and folding - industrial (1)

- Feeds for animal farming (1)