- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal tubes

Results for

Metal tubes - Import export

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis is the global leader in rolled aluminum products and aluminum beverage can recycling. Our technical competence and innovation have made us a development partner chosen by leading companies from the automotive, building, printing and packaging industries, among others. With its customer orientation and strong industrial performance, Novelis plays a crucial part in shaping products for the future. The aluminium content means that there is only slight thermal length variation, just like with metal tubes. In addition, the tubes become completely oxygen-impermeable, which is indispensable when connecting radiators, for example. Using state-of-art production facilities and experienced specialists, Novelis ensures top quality in the manufacture of its products – across the entire production process, from casting and processing the ingots via hot and cold rolling, to packaging.

Request for a quote

ENDO MANUFACTURING CO., LTD.

Japan

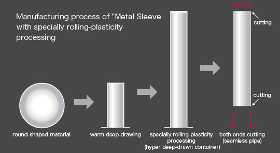

Manufacturing process of Metal Sleeve with specially rolling-plasticity processing.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Tube Components Manufacturer Custom Metal Tube Handles Of Aluminum Alloy, Carbon & Stainless Steel Tubes Tube end forming: A forming process used to create a specific end, usually to allow the tube to connect to another media. Cutting: The cutting process allows for metal tubes to be cut into specific shapes and sizes. Examples include tube laser cutting and mechanical cutting. Notching: This process creates notches at the end of the tube to simplify welding processes or to attach the tube to another part. Swaging: Swaging uses a die to manipulate the size of the tube diameter using force. Custom Metal Tube Forming Components, Seat Frame, Tube Handle, Yacht barrier... sales@mxmparts.com

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Tube end forming: A forming process used to create a specific end, usually to allow the tube to connect to another media. Cutting: The cutting process allows for metal tubes to be cut into specific shapes and sizes. Examples include tube laser cutting and mechanical cutting. Notching: This process creates notches at the end of the tube to simplify welding processes or to attach the tube to another part. Swaging: Swaging uses a die to manipulate the size of the tube diameter using force. Custom Metal Tube Forming Components, Seat Frame, Tube Handle, Yacht barrier... sales@mxmparts.com

Request for a quote

RIEGLER & CO.KG

Germany

Our assortment of threaded screw fittings ranges from connectors, double threaded nipples, counter nuts and bushings to reducing nipples, pipe double nipples, hose sleeves and pivoting bushings and up to bulkhead fittings, union nuts, extension pieces, end caps and locking screws. We also offer various fittings made of steel and malleable cast iron as well as assortment boxes with a chosen selection of screw fittings.

Request for a quote

TECNOCOSMETICA - COSMETIC PRODUCTS MANUFACTURER

Portugal

Tecnocosmética has automatic filling lines for liquids and pastes with a capacity of approximately 10,000 units per day. Tecnocosmética has automatic lines for filling plastic and metal tubes with a capacity of approximately 20,000 units per day.

Request for a quote

FATIH WROUGHT IRON

Turkey

Ø30 - 0,017 kg - 1mm Ø40 - 0,019 kg - 1mm Ø50 - 0,023 kg - 1mm Ø70 - 0,030 kg - 1mm Ø60 - 0,050 kg - 1mm Ø80 - 0,060 kg - 1mm Ø90 - 0,100 kg - 1mm Ø100 - 0,133 kg - 1mm Ø120 - 0,166 kg - 1mm Ø150 - 0,268 kg - 1mm

Request for a quote

FATIH WROUGHT IRON

Turkey

Weight: 0,84 kg Height : 57 cm Width : 38,5 cm Material: 0,8 mm

Request for a quote

TAIHAN FIBEROPTICS

South Korea

# Description Taihan Fiberoptics offers an extensive selection of metallic fiber optic cables designed to protect overhead transmission lines from lightning strikes and to prevent fault currents (over voltages) and to created a path for communication through its optical fibers. We have a wide range of OPGW cables and we can accommodate specific requirements of various clients and projects in order to provide customized bespoke design to suit customers' needs. # Features - Crush Resistance (Shield Wire) - Electrical Performance (Aluminum Pipe) - Cost Saving (Fast Splicing) # Products - OPGW Steel Tube - OPGW AL Tube - OPGW non-Metal

Request for a quote

J.D. GECK GMBH

Germany

Double hooks are suitable for the presentation of goods in clear and blister packaging. The top bar and cross pin can carry scanning pockets, price labels or electronic price labelling as required. The snap lock is designed for perforated walls with euro holes. Goods carriers are our core competence and are available in many variants length, wire and material thickness, back wall system and surface can be selected almost freely.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

We have developed these t bend machine solutions strong> for fast and efficient processing times. They are specifically tailored to the challenges of individual bends. Whether the system is manual or automated, they will deliver the best possible results. Highly efficient This manufacturing accelerator offers the profitable efficiency of our high performance bending machines for the manufacturing of hydraulics fittings together with Top Speed that is what the "AB" series stands for. For individual bends from 1xD to 1,500 mm bending radius for small and large radii, for demanding materials with thin walls, the high performance (HP) machine series guarantees the perfect bending result.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Hose cover against radiant heat maximum 450 ° C. Outside with aluminum foil and inside with glass silk or Kevlar fabric. Closed or with Velcro for quick installation and removal.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Protective hose, flame retardant and insulating against heat and flying sparks for cables

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Protection against heat and flames up to approx. 1100 ° C for approx. 15 minutes and can withstand ambient temperatures of 73 ° C 260 ° C without limit. Inner life made of calcium silicate yarns, textured and twisted, good insulation properties.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Elbows and connections made of steel and stainless steel for oil, gasoline and air hose lines. The connections are pressed onto the assembled hose.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Super lightweight reusable dash aluminum fittings. Manufactured according to aviation standards, suitable for petrol, oil, methanol, water and air. The first choice when it comes to reliable and flexible hose lines.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Compact and very efficient. Our fully hydraulic mandrel bending machine delivers outstanding bend quality and very simple handling, with SPS control for preselection and storage of bending angles via a touch panel.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NOVELTY STEEL

Turkey

Piping includes a pipe or system of pipes, pipe spools, tubing, fittings, expansion joints, hoses, or other pressure bearing components as appropriate. Pressure piping systems transport fluids under pressure. Components of pressure piping include: a. Pipes: The main conduits for fluid transport. b. Fittings: Connectors, elbows, and tees that join pipes together. c. Valves: Used to control and regulate the flow of fluids. d. Flanges: Connect pipes to other components like valves, pumps, or tanks. Novelty Steel is an experienced fabricator of pressure vessels for power, oil and gas, chemical, food and mining industries. With vast CNC Machinery Park and experienced engineering team, Novelty Steel produces bespoke CNC Machined parts according to the European Norms. Our fabrication portfolio covers: * Pressure Vessels * Boilers * HRSGs * Heat Exchangers * Pipe Spools * Piping Components * Pipe Supports * Process Skids

Request for a quote

EC PLAZA

South Korea

Ferro-Mon Sensor measures the concentration of iron by detecting the change in magnetic flux when magnetic particles such as Fe, Ni,.. etc are collected in the sensor probe. This sensor outputs the amount of magnetic material as “Fe saturation %” so that it detects and evaluates abnormal wear conditions of rotating machines. Two output channels for fine particles and large particles can detect normal wear and abnormal wear. ▪ Real-time monitoring of iron concentration % ▪ Easy installation ▪ Sensor probe and control panel are integrated in one sensor ▪ Integrated Ferro-Mon Sensor can be applied for all equipment. ▪ Particularly, user can get the best effect when applying to gearboxes, engines, transmissions, pumps, bearings, etc., which are vulnerable to wear.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Fewer steps to the finished workpiece With t project you can see all the variables of the bending process before you start the production. Adapted to the material and collisionfree, it makes it possible to plan and execute complex bending geometries. The virtual bending simulation determines exact bending timings and cutting lengths; it also tests tube geometries in advance for feasibility. Tube data and bending results are documented with accuracy and they can then be replicated 100% . All the most common interfaces are available for the import and export of data and connection to BDE or ERP over the network.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Labelling systems can be integrated, whether it is laser, needle or inkjet, to mark and identify the tubes. Other options that can be integrated are welding seam detection, length control or measurement of processed tubes. The corresponding sensor and camera technology can be implemented for the specific product. The following step can be carried out without any problems, whether it is cutting, punching, deburring of holes or seal testing with external systems. Smart data evaluation All the systems can be equipped with different control and IPC panels. Interfaces to data caption systems for consumption and operation make the digitalization and evaluation of the data. Marking system, Welding seam detection, Camera control system, Internal and external cleaning processes, Cleaning and suction, Hole punching, Deburring – chamfering

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The right system for every need There is a great variety of handling systems available, dependent on the length of the workpiece. For short tubes there are systems gripping from below with insertion axis and for long tubes there are systems handling from above. Both options can be used in our combination systems. They guarantee ideal access for the operator, so they can complete the setup and any maintenance operations in the best possible way. Transfer stations, turning modules for processing the tube in both directions within an installation and multiple grippers are available for optimized processes. Handling robots from many different manufacturers can also be integrated. The robots are used to move tubes/workpieces. A preassembly of different workpieces is also feasible in this case. The various components can be sorted using sensors and robots.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

We offer a great variety of loading systems for all the machines, dependent on the material, tube diameter and tube length. Tubes that have already been formed and with added components can also be loaded without any issues. The appropriate orientation is therefore very important, when loading the tube into the production cell. External workpieces, such as nuts, flanges, supporting sleeves can be added to the system in a controlled manner and included in any subsequent processing steps. A great variety of loading volumes is possible. Step feeder, Conveyor feeder, Chain feeder, Swivel arm feeder, Loading tables, Bowl feeder, Alignment station

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Clean, efficient, versatile. transfluid's knife cutting method is ideal for postbending cuts. Even with extreme geometries it is possible to have perpendicular cuts with sharp edges. In both cases both chips can easily be detected in the process. Extreme requirements are also not a problem, as up to two blades can be used. An internal mandrel can also optimise the process.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Created for precision. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can then be directly processed further and for instance be formed straight afterwards. That saves time and money.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

In form, double strength. For the optimum processing of your individual requirements we simply combine our transfluid forming techniques, as simple as that, in particular the axial forming and the rollforming. The additional clamping unit makes even extreme forming feasible in one work sequence. The cutting before the axial tube forming is also possible, as well as the rollforming of a preformed geometry. That saves you valuable time. A strong partnership axial forming and rollforming. Our t form combination machines is the perfect union of axial and rolling tube processing, with up to 6 axial forming steps, two rollforming stations, two powered tool holders for flange orientation and an additional clamping unit. The horizontal clamping system makes the processing of bent tube geometries possible.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Powerful and fast forming. The type UMR tube forming machine uses smart operating technology with many preset settings that can be retrieved automatically to achieve perfect mirrorlike surfaces. When producing flaring with 20°90° angles, with a clamping length of 1 x D, the machine achieves perfect sealing surfaces. Flaring up to 90° can be produced in a single cycle. Tools can be changed extremely quickly. With the appropriate tools the machine can also close tube ends.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

All the options in one single machine forming, cutting, postbending cutting, threading. Our rotational technology increase the possibilities of forming on tubes with minimal expenditure on tools. All the drives are servoelectric by design and, if needed, CNCoperated. In our SRM typeforming machines, all the settings are preloaded, so there is no longer any need for costly adjustments. Different tool variants further expand the processing possibilities for chipless cutting or postbending cutting. The machines can produce internal and external profiles and can also roll in synchronicity thanks to a special tool head (inside/outside).

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Maximum bending freedom. The robotic bending technology combines the greatest versatility in manufacturing steps and simple handling. The robotic head is equipped with a clockwise and counterclockwise bending head, so that bending can happen in both direction once clamped. The eight synchronized and fully electric axes give maximum versatility when processing tubes. The bending process on tubes, including the processing at the ends and addon component can be done without any problems. The addon components can be positioned automatically, if needed. A radii/plane changer with up to 6 tools per bending system is integrated to give maximum flexibility..

Request for a quoteResults for

Metal tubes - Import exportNumber of results

450 ProductsCountries

- Germany (280)

- Turkey (33)

- China (27)

- France (18)

- India (14)

- Austria (13)

- Italy (10)

- United Kingdom (10)

- Belgium (7)

- Czech Rep. (6)

- Russia (5)

- Netherlands (4)

- Poland (4)

- Portugal (3)

- United States (3)

- South Korea (2)

- Switzerland (2)

- Australia (1)

- Bulgaria (1)

- Hungary (1)

- Japan (1)

- Oman (1)

- Romania (1)

- Serbia (1)

- Slovakia (1)

- Spain (1)

Company type

Category

- Pipe and tube fittings - ferrous metal (181)

- Sheet Metal & Tubes (44)

- Pipe and tube fittings - non-ferrous metal (37)

- Pipes and tubes - ferrous metal (37)

- Copper wires and cables (12)

- Flexible tubes - non-ferrous metal (10)

- Pipes and tubes, stainless steel (7)

- Seamless pipes and tubes - ferrous metal (6)

- Bending - steels and metals (4)

- Ceramics, industrial (4)

- Electricity generators (4)

- Pipes and tubes - non-ferrous metal (4)

- Pipes and tubes, aluminium (3)

- Cleaning and maintenance - equipment and supplies (2)

- Cosmetics (2)

- Cutting - steels and metals (2)

- Die casting moulds (2)

- Flow meters (2)

- Gas fittings (2)

- Industrial piping (2)