- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision sensors

Results for

Precision sensors - Import export

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

The dimensionCONTROL TMWI 8302.LC system is suitable for the inline weight inspection of continuous running rubber profiles (tread pattern or sidewalls) for passenger and truck tires. Based on the force measurement principle, the inspection system uses two load cells which measure the deflection of the measurement conveyor. These sensor elements are attached to a massive construction, which ensures a long-term mechanical stability of the system. The measurement conveyor uses precise and balanced aluminum rollers with special surface treatment. This ensures a low deadweight, avoids influence of unbalance and eliminates material sticking. Data obtained from the load cells are processed in the implemented PLC cards which determine the measured weight mathematically.The software included offers a variety of measurement data processing, definition of design profiles, statistical analysis of measured profiles and diagnostic tools.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

The rubber processing industry, as well as the tire production process is supported by Micro-Epsilon with a range of systems for inspection, monitoring and control of miscellaneous processes.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

The thicknessGAUGE O.IMS is used for stable thickness measurement of coating on separator film. The system is designed as a compact O-frame and uses a white light interferometer that traverses over the battery film. Thanks to the innovative technology, the thickness measurement is contactless from only one side. Two transport rollers stabilize the film belt.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

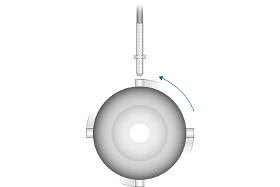

The capaNCDT CST6110 is a capacitive rotation speed sensor system for counting tasks and rotational speed measurements of any type. The industrial measuring system consists of a dust proof, water tight controller and a compact sensors which can be integrated in confined spaces. The rotation speed sensor is used in centrifugal test benches, balancing machines, generators and engines, as well as shafts and drives. The CST6110 detects and counts blades, gearwheels and nubs with the highest precision and stability even in dusty, oily environments.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

White light interferometers use infrared light in the non-visible range (approx. 840 nm wavelength), which means that the measurement position cannot be seen. To visualize the measuring position, Micro-Epsilon systems are equipped with a pilot laser which projects a light spot onto the measuring position. In addition, the pilot laser uses a patented method to provide feedback on the distance in addition to the measurement position. If the measuring object is at the correct distance and within the measuring range, a constant glow is emitted by the pilot laser. If the measuring object is outside the measuring range, the pilot laser flashes.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

P-series draw-wire sensors are designed for industrial measurement tasks. A compact and robust aluminum housing protects the sensor from mechanical influences. As well as analog versions with potentiometer, current or voltage output, digital versions with incremental or absolute encoders are available, providing measuring ranges up to 50 m.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

The optoNCDT 1320 is a new laser triangulation sensor with compact size for displacement, distance and position measurements. Due to its extremely compact size including integrated controller, the sensor can also be integrated into restricted installation space. Its low weight make the optoNCDT 1320 ideally suitable for applications where high accelerations occur, e.g., on the robot arm or in pick-and-place machines. The optoNCDT 1320 offers high accuracy and adjustable measuring rates up to 4kHz. The Active Surface Compensation (ASC) provides stable distance signal control regardless of target color or brightness. Very small objects can be detected reliably due to the small measurement spot size.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The 8661 precision torque sensor is the ideal choice for reliable measurement of static and dynamic clockwise and counter-clockwise torques. Thanks to its high measurement quality and low linearity error, the sensor is equally at home in quality control or research & development. Designed for non-contact operation and zero-maintenance, the 8661 is also ideally suited to the production environment, whether on shift-based production lines, test benches or end-of-line test systems. The 8661 torque sensor is the specialist device for constant torque measurements during continuous operation and for test-bench measurements of holding, friction, break-away or tightening torques. An optional built-in incremental encoder disk with up to 2000 increments makes the sensor the perfect alternative where space or budget rule out an additional angle or speed sensor. For mobile use and for instant digital access to measurement data, the 8661 torque sensor is also available with a USB interface.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This high precision torque sensor is designed for both static and dynamic measurements on non-rotating applications. It is particularly suitable for torque measurements on, for instance, extremely small electrical actuating drives and micro-mechanical actuator elements, or for measuring reaction torques e.g. on micro-motors. The high accuracy of measurement also makes this sensor ideal for use as a reference in many fields of industrial manufacture as well as laboratory research and development projects. Not containing any rotating parts, it requires no maintenance if properly used. The strain-gage based sensor’s modular design allows precise configuration for the desired application. With the integrated amplifier option, the sensor directly supplies a voltage signal of 0 ... ±10 V that is proportional to the torque. The sensor can be configured via the micro-USB interface, providing access to, for example, a filter frequency setting, averaging, and a tare function.

Request for a quote

DOREY

France

Plastic card cutting, collecting, stacking and skeleton web removal system for card manufacturing industries. Available for any sheet size or printed card layout. Available for PVC, PC, ABC, PET a,d paper materials. Cutting credit card assembly, stacking and skeleton storage system for manufacturing ISO cards, available for any size sheet or PCB layout. PRODUCT DESCRIPTION High volume production rate Hihj speed and accuracy Low noise, low vibrations 100% servo motor driven Shear type male & female die sets for clean and quality cards edge Inboard & outboard ball screw servo driven gripper unit with +/ 0.1mm accuracy and precision Laser sensor registration mark tracking system with +/ 0.1mm accuracy Card collecting & stacking units with 2 interchangeable magazines for continuous operation Automatic skeleton web removal system User friendly touch screen monitor and operator interface systems CE approved safety standards

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG PW RTD sensor has been developed as an alternative to the traditional wire-wound sensors. The PW sensor combines the advantages of high accuracy and precision of the wire-wound sensors with the advantages of thin-film sensors that offer robustness, small dimensions and very low hysteresis at an optimal price level. Compared to a standard thin-film sensor measuring up to +300 °C in IEC 60751 F0.15 (IST AG reference class A), the IST AG PW sensor measures with high accuracy up to IEC 60751 F0.15 (IST AG reference class A) within a wide operating temperature range from -200 °C to +600 °C. Due to the special construction and stable characteristics curve, the IST AG PW sensor is also suitable for low temperature applications. As an additional feature, the PW sensor is available in round ceramic housing with the same dimensions as a traditional wire wound sensor, meaning easy interchangeability into existing temperature applications.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This high-precision torque sensor is designed for both static and dynamic measurements on non-rotating parts. The 10mm diameter throughhole can be used to feed parts such as cables or Bowden cables through the sensor. The mounting flanges contain threaded holes and through-holes so that the sensor can be fitted at either end. With no rotating parts, this sensor needs no maintenance when used correctly. The modular design of this strain-gage sensor allows precise configuration for the desired application. With the integrated amplifier option, the sensor directly supplies a voltage signal of 0 ... ± 10 V that is proportional to the torque. The sensor can be configured via the micro-USB interface, providing access to, for example, a filter frequency setting, averaging, and a tare function. With the USB option, in addition to the voltage output, the measurement function is available via USB as well.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This high-precision torque sensor can be used to perform both static and dynamic measurements on non-rotating parts. The internal and external square drive design make this sensor especially easy to fit in existing or new screw-fitting applications. Quality assurance and monitoring of screw-fastening tools are just two applications that can take full advantage of sensor features such as USB port, built-in amplifier and side-load absorbing bearings. With no rotating parts, this sensor needs no maintenance when used correctly. Available accessories include mounting brackets and flange adapters, which enable quick, easy and practical integration of the sensor into existing or newly developed setups and test benches. The strain-gauge based sensor’s modular design allows precise configuration for the desired application. With the integrated amplifier option, the sensor directly supplies a voltage signal of 0 ... ± 10 V that is proportional to the torque.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The very short torque sensor model 8656 is contactless constructed. The torque is recorded by the torsion of the shaft using the strain gauge principle. Thanks to the inductive and optical transmission of the signals, the sensor is maintenance-free, the signals are digitized directly on the shaft and made available by the evaluation electronics as a voltage signal or via USB. Thanks to the high-quality, up to 10,000 rpm is possible. The direction of rotation can be seen from the potential of the output voltage, clockwise rotation corresponds to positive output voltage, counterclockwise rotation the voltage level is negative. The shaft is equipped with keyways in every measuring range, matching keys are included. If a key connection is not required, the key can be omitted. The torque is matched with suitable couplings, we recommend model 8690, safely transmitted.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

thicknessGAUGE sensor systems are used for precise thickness measurements of strip materials, plates and sheets up to 50 mm. Several models with different sensor types, measuring ranges and measuring widths enable inline thickness measurements of different materials and surfaces based on an unmatched price/performance ratio. This fully assembled system comprises a stable frame on which two optical distance sensors are fixed, which detect the thickness of the measuring object according to the difference principle. The sensors are perfectly aligned to each other in terms of their mounting condition. Furthermore, thickness calibration at the factory enables high precision thickness measurements.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

The colorSENSOR CFO is a new controller for precise color recognition in industrial measurement tasks. The CFO series is distinguished by high color accuracy, state-of-the-art interfaces and intuitive operation. The controller is connected to CFS sensors with integrated optical fibers, which can be adapted for different measurement tasks. The colorSENSOR CFO is used in color recognition tasks on interior parts such as head supports, in packaging control or in color sorting tasks with crown caps, closures or labels.

Request for a quote

EDDYLAB GMBH

Germany

High-quality eddy current probes: Beside robustness, high dynamics and high resolution the TX-Series also stands out with a wide temperature range from -60 °C up to 180 °C. ■ High precision measurement ■ High resolution (submicrometer) ■ High dynamics (124 kSa/s) ■ Minimal temperature coefficient ■ High noise immunity ■ Custom-made probes

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The 9206 USB sensor interface series is ideally suited to Notebook-based mobile use for high-precision, traceable calibration jobs that must be performed on-site for equipment such as presses, torque measurement facilities and pressure control systems. A factory calibration certificate or German-accredited DAkkS calibration certificate can optionally be provided for the USB interface plus relevant sensors, ensuring compliance even with the stringent traceability requirements of quality assurance standards. Specific characteristics: —Cost effective "Plug&Measure" concept —24-bit resolution —Practical and convenient DigiCal calibration and data acquisition software —Pt100 as option —Free LabView driver DLL for integrating in your own software environment —Multipurpose reference measurement chain with optional factory calibration certificate or Germanaccredited DAkkS calibration certificate —6-wire connection technology

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

The idiamCONTROL sensor system precisely measures the inner diameter of bore holes such as in extruders in order to determine the wear. The idiamCONTROL is guided into the bore hole and determines the bore hole diameter while being pulled out. Wear-based tolerance violations are automatically displayed and can be output via USB.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Incremental rotation sensors are used wherever displacement, positions or speeds have to be measured accurately. They are therefore important interfaces between the mechanical and electronic parts of a machine. Mechanically robust, electrically reliable and resistant to extreme ambient conditions; these are the outstanding properties offered by this sensor. Typical applications include —Machine tools —Wood and plastic machining —Textile machines —Lifts —Door systems —Paper machines —Drive equipment —Assembly and handling equipment —Packaging machines —Scales —Test machines —Conveying equipment —Doors and gates Specific characteristics —Degree of protection IP65, all-around —Robust —High resistance to interference —Rotary speed sensor: 60 pulses/turn (standard) —Angular displacement sensor: up to 3600 pulses/turn —Detection of rotation direction (channels A and B) —Reference pulse (channel N) —Special versions on request

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

High-precision pressure sensors from the 8201 series provide exact measurements while exhibiting very little sensitivity to mechanical stresses. Their application therefore goes well beyond research and development laboratories. They are also outstandingly suited to industrial use in quality assurance or for measurement and control tasks in production. Their robust mechanical and electrical construction guarantees good long-term stability and high reliability, while being resistant to aggressive media – which can be measured in liquid or gaseous states. The structure of the sensors includes no mechanical moving parts, which is why they show so little sensitivity to impact and vibration. The pressure sensors can be configured with options to suit the user. Standard types are available ex-stock, and customized customer versions can also be provided. Aeras of application are: —Research and developmemt —Test rigs —Mechanical engineering —Plant control and monitoring

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Model number 8201 precision pressure sensors are robust, economical, and are available in standard measuring ranges. Their good technical specification and high reliability make them optimum for measuring pressure in all fields of machine construction, process technology, as well as in measurement and control technology. The pressure transducers are easy to handle and immune to shock loads and vibrations as they are designed without moving parts. All pressure transducers without an internal amplifier have a standardized output signal of 1.0 mV/V. This enables the user to change a transducer in a measuring chain as liked without following readjustment of the electronic. Customized designs are available on request. Aeras of application are: —Hydraulic or pneumatic machines —Mechanical engineering —Plant control and monitoring The measuring element of the precision pressure transducer consists of a diaphragm.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

The system RTP 8301.EO operates according to a combination principle consisting of a thru-beam sensor, an eddy current sensor and a measuring roller. The eddy current sensor and the thru-beam sensor are applied on an innovative measuring clamp. Since the sensor measures the distance from the clamp to the roller, the lower side of the material is detected. As the sensor performance is specially aligned with the measuring task a huge measuring gap is possible while offering highest precision. The thru-beam sensor detects the upper side of the material. The thickness of the target is the difference between the two signals. The measuring clamp is equipped with a pneumatically cleaning mechanism and therefore ideal for the application in harsh environment. The profilometer corresponds to the TIP 8301 regarding its functionality. However, it has a different operators´ frontend and evaluation functions.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

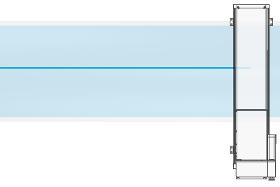

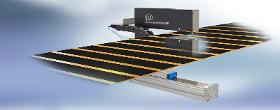

thicknessGAUGE sensor systems are used to measure the thickness of strip materials in-line. Several models with different sensor types, measuring ranges and measuring widths enable inline thickness measurements of different materials and surfaces. The systems uses two confocal distance sensors which detect the strip thickness with high precision. The sensors are precisely aligned to each other and factory-calibrated. By means of a linear axis, the thicknessGAUGE sensor systems can be moved to measure the thickness across the entire strip width. Their extremely compact design enables integration into confined spaces.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

The thicknessGAUGE O.EC is a compact inline measuring system in a stable O-frame design with an aluminum roller and an integrated control cabinet. The system is used for precise thickness measurements of plastic strips and coatings up to 3 mm material thickness and web widths up to max. 1250 mm. To obtain a cross profile of the material thickness, the sensor is traversed over the film. Keeping the sensor fixed at a particular position enables a thickness profile to be generated. Integration takes place in complete production lines, e.g., in plastics production and battery film production. The systems can be integrated into new plants or retrofitted directly into existing plants.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

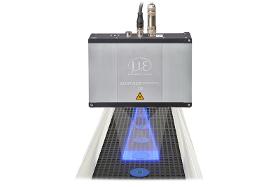

thicknessGAUGE C.LP sensor systems use laser profile scanners for the thickness measurement. These scanners project a laser line onto the surface to be measured. The laser line compensates for strip tilting and enables profile averaging. The laser line measuring technique makes it possible to measure the thickness of structured materials such as embossed surfaces and perforated plates.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

The thicknessGAUGE C.C sensor systems use confocal chromatic displacement sensors for the thickness measurement. The sensors allow for measurements to be performed with outstanding accuracy and high measuring rates. In addition, this innovative measuring technique enables measurements of reflective and shiny surfaces.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

thicknessGAUGE C.LL sensor systems use laser triangulation sensors for the thickness measurement. These laser sensors enable high measuring rates at high speeds. The thicknessGAUGE.laser series impresses with a favorable price/performance ratio and is preferably used for thickness measurements of common surfaces such as plastics, wood and metals.

Request for a quote

MICRO-EPSILON MESSTECHNIK GMBH & CO. KG

Germany

The high-precision surfaceCONTROL 3D 3500 snapshot sensor is used for automated optical inspection of geometry, shape and surfaces on diffusely reflecting surfaces. The surfaceCONTROL 3D 3500 is characterized by its compact design and high measurement accuracy combined with high speed data processing. With a z-axis repeatability of up to 0.4 µm, the sensor sets new standards in high-precision inline 3D measurement technology. It reliably detects the smallest flatness deviations and height differences. Two models cover different measuring fields.

Request for a quoteResults for

Precision sensors - Import exportNumber of results

115 ProductsCountries

Category

- Sensors (77)

- Potentiometers (12)

- Measurement - Equipment & Instruments (5)

- Accelerometers (3)

- Measurement and control instruments (3)

- Electronic components (2)

- Laser - cutting and welding machines (2)

- Liquid film probes - detectors (2)

- Biomass energy - production (1)

- Boxes and trays, storage (1)

- Cameras, cinematographic (1)

- Cooker hoods and extractor fans (1)

- Cutting - machine tools (1)

- Cylinders, pneumatic (1)

- Electronics - import-export (1)

- Flow meters (1)

- Food canning and preserving - machinery and equipment (1)

- Import-export - electrical and electronic equipment (1)

- Industrial maintenance (1)

- Industrial robots (1)