- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressure tanks

Results for

Pressure tanks - Import export

NOVELTY STEEL

Turkey

A pressure vessel is defined as a container with a pressure differential between inside and outside. The inside pressure is usually higher than the outside, except for some isolated situations. The fluid inside the vessel may undergo a change in state as in the case of steam boilers, or may combine with other reagents as in the case of a chemical reactor. Pressure vessels often have a combination of high pressures together with high temperatures, and in some cases flammable fluids or highly radioactive materials. Pressure vessels are used in a number of industries; for example, the power generation industry for fossil and nuclear power, the petrochemical industry for storing and processing crude petroleum oil in tank farms as well as storing gasoline in service stations, and the chemical industry (in chemical reactors) to name but a few.

Request for a quote

BLASQEM, LDA.

Portugal

Developed to meet the highest quality parameters, its high quality components and a simple assembly system, allow it to operate in complete safety and ensure easy maintenance. With different capacities, this equipment is suitable for small interventions, or for operations that require a long working autonomy. Available with one or two chambers, with one or more outlets, the available models allow simple loading of the abrasive, as well as a smooth and uniform flow. Compact in design for easy handling and transport, the rugged valves and rubber coated fittings ensure operations with low maintenance costs. The pickling tanks allow different configurations, namely the use of different valves, suitable for different abrasives, as well as the inclusion in the supply of all the protective equipment necessary for the operation.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Mobile, compact and multifunctional. Whether as manual spraying equipment or as compact solution for experiments. The compact pressure vessels with up to 18 litres useful volume are suitable for all tasks. The particularly easy handling makes these containers a popular entry-level solution.

Request for a quote

GEO TEKNO LTD. CO.

Turkey

These tanks, which have wide application areas in different industries, can increase efficiency and ensure operational safety with the right choices. When purchasing a pressure tank, you should carefully consider your process requirements, paying attention to material quality, design features and safety standards. As GEO Tekno, with over 25 years of experience, we can help you select the pressure tanks you need and provide you with the most suitable solutions through our experienced design and manufacturing departments. If you need a pressure tank for your process, all you have to do is to contact us. Do not hesitate to contact us for your questions. Choose our certified pressure tanks to maximize your process performance!

Request for a quote

KASPAR SCHULZ BRAUEREIMASCHINENFABRIK & APPARATEBAUANSTALT GMBH

Germany

You can expect only the highest quality pressure and bright beer tanks from Kaspar Schulz. The new Pressure Equipment Directive 97/23/EC has been in effect since May 5th, 2002. Surveillance of the QS-System is carried out by TÜV-Süddeutschland (0036). Every pressure tank built by Kaspar Schulz complies with the AD-2000 technical guidelines, which ensures that the customer is spared of any long test intervals, in comparison to other European standards. Please look into our competitors’ rates —higher costs for future inspections could arise. Let the impressive appearance of our tanks and their numerous features do the convincing: Suitable for all types of beer, plus carbonated non-alcoholic and mixed beverages given that they are principally manufactured for a 3 bar operating pressure Welded and ground surfaces create a sleek appearance Finished model is fully calibrated Easy-to-clean contents display

Request for a quote

2K WELDING TECHNOLOGY MACHINE MANUFACTURING

Turkey

The 2Kwelding CBS series of column & Boom Manipulators are specially designed and produced for harsh and rugged area circumstances. Column-Boom Systems are manufactured to ensure ergonomics during weld jointing processes, reaching to hard to access areas while welding large pieces and to perform welding with minimal error.. Column-Boom systems approach to the most suitable area on the piece for performing the required welding process under control of the operatör and welding operation is performed with the command sent to the automatic unit on the boom While Column-Boom systems can perform welding independently for any part, it may also perform circular or lengthwise welding using rotator or positioner. Welding types that can be performed by the system are SUBMERGED, MIG, MAG, TIG. Also, Column-Boom systems can be fixed or with automatic travel on rail.

Request for a quote

LEMVIG GAS DISTRIBUTION A/S

Denmark

NOVELTY STEEL

Turkey

Stainless steel is an alloy of steel with chromium content that is a better resistant to rusting and corrosion compared to carbon steel. For storing corrosive chemicals and liquids, often traditional coatings of carbon steel does not offer enough protection. For such material, stainless steel tanks offer more durable and long lasting storage. Novelty Steel is an experienced fabricator of steel tanks. With our modern CNC Machinery Park and experienced engineering team, Novelty Steel produces bespoke steel frames according to the EN 1090-2 European Norms. Some examples of the stainless steel tanks are: * Fixed-roof tanks * External floating roof tanks * Internal floating roof tanks * Domed external floating roof tanks * Horizontal tanks * Pressure tanks * Variable vapor space tanks * LNG (Liquefied Natural Gas) tanks

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel fabricates carbon steel and stainless steel tanks; Fixed-roof tanks External floating roof tanks Internal floating roof tanks Horizontal tanks Pressure tanks Variable vapour space tanks Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

GSW SCHWABE AG

Germany

electric compact control with one or two 10l pressure tanks pressurized dispensation made especially for high viscosity lubricants pulsedependent flow control (0 – 99 pulses/min) dispensation time and delay after the incoming signal electrically adjustable via initiator

Request for a quote

ELKON GMBH

Germany

In some countries, cement is widely delivered by railway. The cement carried in wagons can be transferred to the cement silos with special pneumatic cement feeding system developed by ELKON. ELKON Cement Delivery System from Railway consists of wagon feeding hopper, intermediary feeding screw, material holding tank, pressure tank, compressor and control panel. The system which has a cement feeding capacity of 50 tons / hour can also be used to feed a large number of cement silos.

Request for a quote

CMPLAST

Poland

Is the second most frequently used metal after iron. It has high corrosion resistance in marine and industrial environments. It is characterized by high fatigue strength, it is susceptible to welding and anodizing. Aluminum is used in many industries mainly in shipbuilding, chemical, food, household appliances, architecture, construction and the automotive industry. It is used for elements of transport, for welded constructions, pressure tanks, piping elements, pneumatic and hydraulic lines. Details made of aluminum can be anodized and powder coated at your request

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Tank gauges, oil pressure gauges, oil temperature gauges, boost pressure gauges, ammeters and voltmeters for additional installation. All items are from wellknown manufacturers in the field of display instruments

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Efficiency and quality of this innovative cleaning system are impressive, from the three-dimensional small parts to large format workpieces in large batch sizes. The performance of the CO2 ice jet is especially convincing when cleaning plastic workpieces. The shown surface plant offers optimum noise emission values of approx. 80dB(A) due to the patented noise protection system comprising follower-type bulkhead partitions. A cleaning jet consisting of a mix of compressed air, CO 2 and CO 2 ice particles causes the soiling on the surface to become brittle. The thermal tension loosens cohesion and detaches the soiling from the workpiece surface. The cleaning jet guarantees the removal of soiling without residue. The DUST FREE and PERFECT applications optimally meet the requirements of the subsequent downstream surface quality, offering maximum thoroughness from dust removal through to cleaning. This process allows gentle cleaning of virtually all components, therefore, it is an alternative to aqueous power washing. Patented detail solutions form the basis for this mature system technology. Small workpieces are reliably held in place by the special hold-down system. The Venjakob pump station developed for this task guarantees the process reliable supply of liquid CO 2 from a low pressure tank system to the cleaning module. A clear advantage of the CO 2 cleaning system over the conventional aqueous cleaning process is its relatively small space requirement.

Request for a quote

ELKON GMBH

Germany

Cement material supplied with big bags or bags can be transferred into cement silos by means of ELKON Big Bag/Bag Pneumatic Cement Feeding System. ELKON Big Bag/Bag Pneumatic Cement Feeding System consists of cement feeding hopper, intermediary feeding screw, pressure tank, compressor, loading crane and control panel. This feeding system, which has a capacity of 15 tons/hour, is equipped with 2 tons crane to lift the big bags and dispatch into the feeding hopper. The complete set of ELKON Big Bag/Bag Pneumatic Cement Feeding System fits into 1 unit 40’OT container and thus it can be easily transported to overseas countries.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The application of CO 2 ice jet spraying is convincing. Ranging between CO 2 cleaning and high-performance dust removal with regard to quality, optimum pretreatment can be accomplished with this system variant, only requiring simple workpiece fixing and little noise protection measures. DUST FREE can be flexibly integrated in existing equipment. A cleaning jet consisting of a mix of compressed air, CO2 and CO2 ice particles causes the soiling on the surface to become brittle. The thermal tension loosens cohesion and detaches the soiling from the workpiece surface. The cleaning jet guarantees the removal of soiling without residue. The DUST FREE and PERFECT applications optimally meet the requirements of the subsequent downstream surface quality, offering maximum thoroughness from dust removal through to cleaning. This process allows gentle cleaning of virtually all components, therefore, it is an alternative to aqueous power washing. Patented detail solutions form the basis for this mature system technology. Small workpieces are reliably held in place by the special hold-down system. The Venjakob pump station developed for this task guarantees the process reliable supply of liquid CO 2 from a low pressure tank system to the cleaning module. A clear advantage of the CO2 cleaning system over the conventional aqueous cleaning process is its relatively small space requirement. Additional decisive advantages of this system are:

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Pressure sensor for analogue filling level measurement Supply voltage 24 V DC Output of an analogue measuring signal 4 – 20 mA Pressure ranges depending on tank height 0 – 50 / 200 or 400 mbar Safe at several times over-pressure Explosion protection according to ATEX

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KASAG SWISS AG

Switzerland

Pressure vessels, reactors, Pharmaceutical and biotech pressure vessles, Process containers, storage tanks, Modules, components, plants, High-pressure apparatuses,Heat exchangers, vaporisers, condensers, Cryo pressure vessels, technologies Nuclear technology, Vacuum chambers, vacuum apparatuses, Columns, according to PED (EN13445 / AD-2000), ASME (U-Stamp), China Stamp (A1), TP TC 032/2013 (EAC) Pharmaceutical and biotech apparatuses are calculated and manufactured according to your requirements. Stainless steel and special materials are used in the production. After that, the products are grinded, electropolished and tested using non-destructive testing methods, such as ferrite measurements, used for the determination of the ferrite content, or by using the riboflavin test to measure total discharge and CIP/SIP capability. All materials, methods and processes used have been documented in full in detailed QA documents and can be tracked at any time. You can depend on KASAG.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

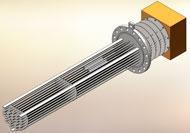

Electrical flange type immersion heaters The range of immersion heaters type FHK offers an economic heating solution for process tanks, pressure vessels and similar plant. The standard heater consists of a number of rod elements TIG welded into a process flange. A robust terminal box protects the electrical connections. The number of elements fitted depends upon the media to be heated and the kilowatt rating required. Dependent on application, the heater can be provided with temperature control by contactor or thyristor.

Request for a quote

FERPLAST SNC

Italy

Series of rugged and professional compressors with dry mechanical. They work without the need for lubricating oil and are equipped with double control manometer for tank pressure and air output, manual pressure regulator of outlet air and ON-OFF button. The FPGE dry compressors are developed exclusively for professional applications and deliver high reliability and continuous operation. Thanks to the self-lubricating mechanical, patented worldwide, FPGE compressors provide approximately up to 5000 hours of use without maintenance, guaranteed even below freezing. Application-oriented use The design of FPGE compressors has been conceptualized keeping in mind principally the work requirements of the user. Frequently, work conditions can be difficult and less than optimal. The ease in which these compressors can be moved and transported is a fundamental product development feature for FPGE.

Request for a quote

FERPLAST SNC

Italy

Series of rugged and professional compressors with dry mechanical. They work without the need for lubricating oil and are equipped with double control manometer for tank pressure and air output, manual pressure regulator of outlet air and ON-OFF button. The FPGE dry compressors are developed exclusively for professional applications and deliver high reliability and continuous operation. Thanks to the self-lubricating mechanical, worldwide patented, FPGE compressors provide approximately up to 5000 hours of use without maintenance, guaranteed even below freezing. Application-oriented use The design of FPGE compressors has been conceptualized keeping in mind principally the work requirements of the user. Frequently, work conditions can be difficult and less than optimal. The ease in which these compressors can be moved and transported is a fundamental product development feature for FPGE.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Pressure sensor for analogue filling level measurement Especially suitable for STRATE sewage pumping stations for municipal applications Supply voltage 24 V DC Output of an analogue measuring signal 4 – 20 mA Pressure ranges depending on tank height 0 – 200 or 0 – 400 mbar Safe at several times over-pressure Explosion protection according to ATEX

Request for a quote

INTERLINEX B.V.

Netherlands

12V 50 Hz electric driving force 250W pump Bar & PSI pressure gauges 2x 30L tanks 28pcs connector set for various models 1 set of oilpipes

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The NRK series is a compact top-entry agitator that can be used to meet high requirements regarding both surfaces and cleaning inside and outside of the tank. Due to its’ compact design, agitator shafts with diameters of 25 mm and lengths of up to 1,200 mm can be realized, making the NRK the ideal mixer for small tanks in food and drug industry. GMP and FDA conform design. The NRK series agitator has an integrated bearing and coupling housing with flexible coupling to connect drives with shaft journals. The NRK can be supplied with radial shaft seal rings for non-pressurized operation or with liquid-lubricated mechanical seals on pressurized tanks. Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3).

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

NRK - Compact top-entry agitator The NRK series is a compact top-entry agitator that can be used to meet high requirements regarding both surfaces and cleaning inside and outside of the tank. Due to its’ compact design, agitator shafts with diameters of 25 mm and lengths of up to 1,200 mm can be realized, making the NRK the ideal mixer for small tanks in food and drug industry. GMP and FDA conform design. The NRK series agitator has an integrated bearing and coupling housing with flexible coupling to connect drives with shaft journals. The NRK can be supplied with radial shaft seal rings for non-pressurized operation or with liquid-lubricated mechanical seals on pressurized tanks. Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3).

Request for a quote

GLOBAL GASES GROUP THAI CO LTD

Thailand

Fast Gas Cream Charger Cylinders Introducing the Fast Gas Nitrous Oxide cylinder the new and improved cream charger system which connects easily to your cream dispenser with a pressure adapter. Please note you should only use 500ml Metal Head dispensers or Stainless Steel Cream Dispensers with the Fast Gas system. Each tank contains up to 640g of high-quality food grade nitrous oxide, with purity of up to 99.9%. The Fast Gas system makes creating innovative food and beverages easy with the click of the connector hose to your dispenser whip up a treat in no time at all with no waste from each capsule. The cylinders are suitable for recycling once fully empty. You will receive a pressure release nozzle with each tank, the nozzle will allow you to be sure the tank is empty prior to recycling due to safety reasons. Please check with your local recycling authority prior to disposing. OVER 18’s ONLY: This product is not for sale to under 18’s.

Request for a quote

GLOBAL GASES GROUP THAI CO LTD

Thailand

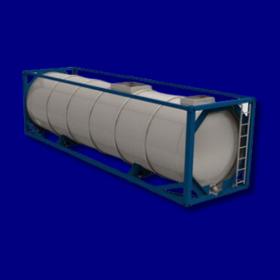

Length: Approximately 20 feet (6.1 meters) Width: Standard ISO container width Height: Standard ISO container height"2. Material: Typically made of stainless steel to ensure resistance to corrosion and durability, which is crucial for transporting hazardous materials like refrigerants.**3. Capacity: The capacity of the ISO tank is designed to accommodate a specific volume of R40<Ja refrigerant based on its density and weight characteristics."t. Pressure Rating: The SO tank would oe designed to handle the pressure associated with storing and transporting R40£a refrigerant. The pressure rating would meet safety standards.'*5. Valves and Fittings: Equipped with appropriate

Request for a quote

NLMK-EUROPE-PLATE

Belgium

Standard : EN 10028-2 / EN 10028-3 / EN 10028-4 / EN 10028-5 ASTM/ASME Our carbon and alloy steels are especially designed to produce large high-pressure vessels. These steel grades are characterized by yield strengths from minimum 235 N/mm² to maximum 460 N/mm² and by good weldability. The fine-grain structural steel grades are suitable for mechanical forming and excellent welding. We deliver these steels as heavy plates or bars, as well hot rolled and forged, so we can cover a wide range of thicknesses and widths. Our specialists can coordinate for you the steel preparation at all stages, to enable you to get your pieces ready to use. Applications : •storage tanks, storage spheres •pressure vessels •boilers •heat exchangers •gas turbines •etc…

Request for a quote

BDSENSORS GMBH

Germany

The differential pressure transmitter DPT 200 has been especially designed for the process industry and can be used for level measurement of closed, pressurized tanks, pump or filter controlling, etc. The possibility passes different pressure seals at the DPT 200 adding with different membrane materials to reach an optimal adaptation to the application. Features: — differential pressure von 1 mbar bis 20 bar — static pressure bis max. 400 bar — turn-down max. 100:1 — accuracy: 0.075 % FSO — HART®-communication — output signal: linear or square root extraction — aluminium housing Optional Features: — IS-version: Ex ia = intrinsically safe Version (group II) EX ia= intrinsically safe Version for firedamp mines (group I) Ex d = flameproof enclosure (group II) — LC-Display — stainless steeel housing

Request for a quoteResults for

Pressure tanks - Import exportNumber of results

156 ProductsCountries

Category

- Tanks, metal (19)

- Measurement - Equipment & Instruments (6)

- Storage tanks (5)

- Wine fermentation tanks (4)

- Vacuum cleaners, domestic (3)

- Air compressors (2)

- Chemical and pharmaceutical industry - machinery and equipment (2)

- Concrete mixers (2)

- Measurement and regulation equipment and instruments - pressure (2)

- Oiling - machines and systems (2)

- Surface treatment - machinery and equipment (2)

- Aluminium coatings (1)

- Autogenous welding machines (1)

- Bakery and confectionery industry - machinery and equipment (1)

- Biotechnologies (1)

- Bottling and filling - machinery and equipment (1)

- Chemical industry - machinery and equipment (1)

- Cleaning, tanks and cisterns (1)

- Construction - Machines & Equipment (1)

- Display boards and screens, electronic (1)