- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- seaming

Results for

Seaming - Import export

4CR INTERNATIONAL GMBH

Germany

Sprayable seam sealer for sealing overlapping and welded seams in OEM texture. Fast drying and paintable.

4CR INTERNATIONAL GMBH

Germany

Sprayable seam sealer for sealing overlapping and welded seams in OEM texture. Fast drying and paintable.

QUELLTECH GMBH

Germany

QuellTech Solution For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position. The QuellTech 2D-Laserline Sensor is specially prepared to the highly disturbing ambient light from the weld process. It can be cooled and protected from weld spatter, so this model proves to be particularly adequate for operation in the harsh environment of the welding process.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC controlled machine for belt grinding and polishing stainless steel weld seams. Belt grinding on the contact wheel or slack belt unit is possible for edge profiling.

Request for a quote

ALUMINAL YAPI

Turkey

The system, which is created by clamping flat seam profiles with clips in roof covering, is applied without screw connection. It allows one-piece application from the stream to the ridge. Roof covering consisting of flat standing seam profiles, rock wool sheets and trapezoidal sheets offers dimensions and solutions suitable for all roof forms.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Plastic Extrusion profiles Factory produce Door Seam Protection Strips, we are orignal manufacturer, can provide lowest prices. Material: New PVC, Sturdy & Durable Function: Baby Safety Door Seam Protection Strip Anti-pinch Hand. Structure: Folding design does not affect the opening and closing The characteristics: Sticky, easy to clean foam rubber Length:45cm, also can custom length according to customer's requirement. Children often put their hands into the crack of the door, but they are not aware of the danger. The door seal can effectively prevent the baby from hurting his fingers by the crack of the door. We are Plastic extrusion profiles manufacturer from China Ningbo, we custom produce all kinds of plastic extruded strips, such as door & window sealing strips, seam protection strips. Collision avoidance Strips.... If you need any plastic extruded strips, pls feel free contact with us.

Request for a quote

IMETA SRL

Italy

This tablet comes with a preinstalled application that allows for ontheground checks of critical seaming parameters and keeps a record of previous measurements. As a tablet, it also has many features that may be useful at the time of inspection (camera, integrated email, etc.)

Request for a quote

IMETA SRL

Italy

This micrometer is used for measuring the height and the thickness of the seam.

Request for a quote

IMETA SRL

Italy

Thanks to our experience in this industry, Imeta has developed new assemblies for some older seaming rolls. These include the “Easy System” type roll for the Angelus P Series, and the “Super Seal” type roll for any seaming machines. These can reduce roll maintenance time and costs.

Request for a quote

IMETA SRL

Italy

Ceramic seaming rolls can increase production efficiencies and reduce machine downtimes by eliminating or significantly reducing many problems deriving from wear, corrosion and superficial damage. There is a low friction coefficient and they are approved by the USFDA.

Request for a quote

DOREY

France

Miller Weldmaster T 600 Extreme combines versatility and precisely controlled operating parameters within an ergonomic design and interface for easy operation, speed, accuracy, and productivity. FEATURES, FUNCTIONS, & BENEFITS Easy operation with our touch screen and 25 memory settings. Weld rollers are independent, controlled witch helps produce an expanded range of products and materials. Guides and accessories to weld hems, overlaps, hem with rope... Equipped with dual arms The “Table Arm” takes care of straight seams for applications like tarps, awning and tents; while the curve arm manages curves and unique shapes for applications like boats and inflatables. Inboard puller to help to feed heavy and wide material. Built with one person operation in mind. It comes with a speed of up to 15 meters per minute. Welds PVC, PE, PU and many more. Can weld acrylic with our special Extreme Seam TapeTM. Comes furnished with the new “Seam Screen.”

Request for a quote

DOREY

France

From the innovators of welding automation, Miller Weldmaster presents the DH7600. Designed to finish the outside edges of almost any size product, the DH7600 is an economical solution to finish 2 sides at one time. Available with almost any seam type, the DH7600 is available with an optional conveyor table for additional fabric handling. Double your finishing production The model DH7600 FEATURES, FUNCTIONS, & BENEFITS Throat capacity available in 4.5M or 7.6M (14.76t or 24.93ft) Dual hot air and hot wedge heat systems for seaming any any type of industrial fabric Independent cool down cycle Operator foot pedal to initiate welding process Miller Weldmaster PLC smart screen

Request for a quote

WORKPLANET, LDA

Portugal

Center zip and button Reflective stripes on lower legs Contrast threaded seams Elastic waistband Double safety stitching 2 french pockets 2 bellows pockets, with center double bellows, flap, velcro and pullers 2 rear patch pockets, with flap and velcro.

Request for a quote

QUELLTECH GMBH

Germany

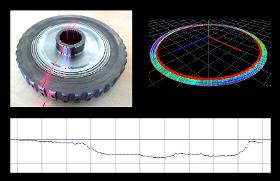

Initial Situation: Inspection of a laser weld seam for pores and geometrical anomalies The production of a client in automotive industry is subjected to extremely stringent quality requirements. This is valid particularly also for the precision of laser weld seam of fine mechanical work. 100% inline supervision is required for the following task: A laser weld beam (width ca. 200µm) has to be verified with respect to the presence of pores and geometrical anomalies. Camera inspection performed until now turned out to be not stable. Therefore the client is forced to implement an improved monitoring process. The challenge The resolution required amounts to 4µm. The high gloss finished material and glossy laser weld seam may give rise to reflections, and the space for installation is restricted. A low form factor for the monitoring equipment is imperative.

Request for a quote

QUELLTECH GMBH

Germany

Particular challenges To correct the effect of the tolerances of the parts, the welding robots path in conventional applications is usually adjusted, by means of a time consuming manual correction (teaching). The warping effect caused by the thermal expansion however cannot be compensated this way. For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position.

Request for a quote

ENOL FOLIEN GMBH

Germany

Our seal edge bags are suitable: when needing high barrier and leak-proof properties when needing high strength of the seams for the packaging of solids, powders, pastes and fluids especially as coffee bag (side fold bag with or without quad-seam), as tobacco bag as well as for pet food. Our seal edge bags are available according to your specification regarding sizes and composition of the laminate – also in combination with PET / ALU / PA as flat bag as side fold bag with normal bottom and backside seam optionally bottom with k-seam as side fold bag with 4-side quad seam. This bag type has good standing properties and can take up high volumes as Doypack as flat bag or Doypack with or without zipper as flat bag also with glue strip with/without Eurohole or carrying punch-out optionally with ventilation valve as very stable header bag unprinted or printed up to 10 colours in flexo or gravure printing

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PEKU FOLIEN GMBH

Germany

Side-seam bags are used for transportation and protection of light contents. Solid welding seams and easy confectioning turn the side-seam bags into an economically priced all-round solution. We look forward to your inquiry by mail or by phone: +49 (0)9181/2960-0!

Request for a quote

PEKU FOLIEN GMBH

Germany

Bottom-seam bags are perfect for heavy weights. The extremely strong bottom-seam guarantees safe filling and transportation, even under high stress conditions. Bottom-seam bags are used, among other, in the building materials industry, chemical industry or in the gardening industry. We would be pleased to give you advice about our bottom-seam bags. We look forward to your inquiry by mail or by phone: +49 (0)9181/2960-0!

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Settling and floating layers are avoided by horizontal and vertical mixing. Before plant construction, coordination takes place with the future plant operator to determine the optimum stirring technology based on the respective substrates. Operational safety is ensured by the closed reaction chamber, the external drive for the agitator and the externally mounted electric drives. Variable dimensions and substrate flexible stirring technology also allow the use of difficult substrates. The wall heating system, externally mounted on the fermenter wall, ensures optimum fermentation conditions and a high gas yield. FAST ASSEMBLY – LESS COST Low installation costs are possible by using the Lipp dual seam system and on site production. If the foundation slab is provided along with assistance during assembly, costs fall still further.

Request for a quote

LACERS GMBH

Germany

Product information "Cross bottom bag made of OPP with sealed seam, highly transparent, 30-40µ in different sizes" Cross bottom bag made of OPP with sealed seam, highly transparent, 30-40µ, in different sizes Features: highly transparent material OPP (polypropylene) sealed seam thickness 0.03mm (30µ) Material: This high quality and food grade cross bottom bag is made of OPP, stable and highly transparent. Our cross-bottom bags made of polypropylene have a sealed seam welded on the back and are perfect for filling flavored, ground products such as salt, spices, decorative sand, etc. or confectionery.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR MUNICIPAL WASTE WATER TREATMENT Lipp has for many decades been an established partner of municipal waste water treatment plants, engineers and general contractors in the field of tank and system solutions for municipal waste water treatment. Due to their method of construction as well as flexibility in the choice of materials and ideal diameter – height ratios, Lipp tank and system solutions are especially suitable for the needs of small to large sewage treatment plants. They are ideally tailored to one another, but may also be embedded as individual island solutions into existing systems and are therefore equally popular with planners and end users alike. The stainless steels used and the double seaming guarantee maximum water tightness and durability with low maintenance for a wide variety of waste waters, slurries, process liquids and gases. The versatility in terms of the system solutions offered for municipal waste water treatment plants

Request for a quote

ACCRAPLY EUROPE LTD

United Kingdom

Improve output, reduce downtime and enhance productivity with Accraply's next generation seaming solution - the Accraply Revolve. The Revolve has an intuitive design that reduces operator dependency and enables you to streamline and improve your operations. Accraply's modular and configurable seaming solution, and operator-friendly design offers unparalleled flexibility, customization, and scalability.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The central agitator has a low energy requirement to ensure mixing and ensures optimum biological digestion. This is helped by the smooth internal walls (largely without any internal attachments) which prevent substrate deposits. As an option, an external heating system can be added to the digester, ensuring an even temperature distribution thanks to the good heat transfer properties of the steel. The central agitator has a low energy requirement to ensure mixing and ensures optimum biological digestion. This is helped by the smooth internal walls (largely without any internal attachments) which prevent substrate deposits. As an option, an external heating system can be added to the digester, ensuring an even temperature distribution thanks to the good heat transfer properties of the steel. MAXIMUM LEAK TIGHTNESS AND PRACTICAL ON SITE CONSTRUCTION With Lipp digesters you will benefit from over 50 years experience in plant and tank construction.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

High quality, productive longitudinal seam welding calls for the utilisation of advanced, superior technology. This enables us to us to protect and expand our market position despite increasingly fierce competition. Our ELENA® longitudinal seam welders provide unsurpassed technology for welding of longitudinal metallic seams.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

CORMIFLEX® tubes are folded spiral-seam pipes made of high-grade steel precision strip. Reaching up to 350°C, their high temperature resistance is predominantly used for exhaust gas routing in passenger car, utility vehicle, RV and marine heating units. CORMIFLEX® PLUS bears additional resistance against corrosion due to salt and other aggressive agents.

Request for a quote

GORDOPACK GMBH

Germany

For protecting and preserving your goods, PE bags of Gordopack is your best option. PE bags have become an indispensable part of everyday life. PE bags from Gordopack have proven themselves in many ways as packaging and means of transport and are therefore preferred by customers from industry, trade and commerce. It goes without saying that we manufacture all PE bags according to the special specifications of our customers, for example with technical additives such as antistatic agents, UV stabilisers, UV absorbers and much more. And of course, our products meet the legal requirements, such as those stipulated in the food industry. Product can range from HDPE/ MDPE/ LDPE/ PCR with seam interruption, perforated on roll or loose in cartons, needled, with antistatic agent, UV-stabilizer/absorber, symbol marking, Corona treatment and in various colours.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

ROTAWELD is our platform to cover a wide range of applications requiring circumferential seam welding. The precision servomotor rotation axis combined with our advanced control system form the basis for the production of accurate and repeatable circumferential seam welds. Machine sizes, part holders, welding equipment, torch holders and any additional positional axes are designed specific to the customer and their products.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

Schnelldorfer CORNERWELD seam welding machines have been designed to weld sheet metal plates in a 90° joint. The precision clamping system with inert gas coverage and advanced OEM control package precisely controls the welding sequence and weld parameters, resulting in the perfect weld for your corners. CORNERWELD applications include welded corners for food, medical equipment, HVAC drip pans, electrical enclosures, and laboratory furniture. Complex inward and outward flanges can be accommodated with custom made tooling pieces. A wide range of materials can be welded, including Stainless Steel, Carbon Steel and Aluminium. Complete welded parts do not require any costly grinding, polishing or blending thus greatly saving on manufacturing costs.

Request for a quoteResults for

Seaming - Import exportNumber of results

116 ProductsCountries

Company type

Category

- Measurement and control instruments (11)

- SMALL METAL PARTS (10)

- Socks and stockings (9)

- Folding machine tools (7)

- Steels and metals - welding and brazing (5)

- Industrial cutting machine tools (4)

- Machine tools, metal machining - parts and accessories (4)

- Tanks, metal (4)

- Packing and packaging - machinery and equipment (3)

- Paper & Cardboard - Raw Materials (3)

- Bags, plastic (2)

- Bottling and filling - machinery and equipment (2)

- Food industry packaging machinery (2)

- Laser - cutting and welding machines (2)

- Paints, synthetic resin (2)

- Sweaters (2)

- Textiles - Machines & Equipment (2)

- Casting, steel (1)

- Chamois leather - cleaning supplies (1)

- Coatings, insulating (1)