- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filling

Results for

Filling - Import export

INDUSTRIA NAVARRA DE CONFITERÍA

Spain

Ingredients WHEAT flour*, Nonhydrogenated vegetable oils and fats* (sunflower*, cocoa*), cane sugar*, Chocolate cream and PEANUTS* 15% (cane sugar*, nonhydrogenated vegetable oils and fats* PEANUTS 5%, fat free cocoa powder*, emulsifier (sunflower lecithin), natural vanilla extract*), BARLEY malt extract*, SOY flour*, OAT bran*, Leavening agent (ammonium bicarbonate). SPELT Ingredients SPELT WHEAT flour*, Nonhydrogenated vegetable oils and fats* (sunflower*, cocoa*), cane sugar*, Chocolate cream and PEANUTS* 15% (cane sugar*, nonhydrogenated vegetable oils and fats* PEANUTS 5%, fat free cocoa powder*, emulsifier (sunflower lecithin), natural vanilla extract*), BARLEY malt extract*, SOY flour*, OAT bran*, Leavening agent (ammonium bicarbonate).

Request for a quote

CANALETAS

Spain

Superior quality, made entirely from stainless steel. Touchless water activation by large and robust stainless steel pedal/s or automatic activation by sensor/s. Elegant and robust fully integrated faucet in the dispensing area. Hygienic faucet design hidden water jet, separated from faucet walls, difficult to reach. Flat top plate enables bottles to stand properly. Vandal resistant model, the top plate can not be removed,allen screws. Easily regulated cold water temperature (thermostat). The installation of a purification filter is recommended for better water quality. A8OP Sensor for cold water. Ideal solution to fill bottles. A88 2OP Sensor for cold water. Sensor for room temperature water. Ideal solution to fill bottles. A8PE Pedal for cold water. Ideal solution to fill bottles. A88 2PE Pedal for cold water. Pedal for room temperature water. Both pedals simultaneously mixed water. Ideal solution to fill bottles.

Request for a quote

FORMEX MAQUINARIA

Spain

•Machine adapted for coupling to the conveyor belt of a line already in operation. •The dosing head is cantilevered, and given the absence of its own conveyor, the structure of the chassis is reduced. •In this way we can move the machine, which has wheels, directly to the production line, so that the dosing head remains on the conveyor belt. •This is a benefit not only in terms of functionality and cleanliness, but also modularity, as the machine can be added to or removed from the production line as required and does not have to remain stationary.

Request for a quote

FORMEX MAQUINARIA

Spain

•You can dispense: bonbon, liqueur bonbon and praline bonbon. •The chocolate can have solid particles up to 3 mm thick. •Model manufactured according to production needs and adapted to the customer's moulds. •The dosing area, both the tank and the dosing nozzles, are heated to facilitate the hot dosing of the chocolate at an adjustable temperature, ensuring an ideal condition of the product. •Volumetric dosing. •The conveyor belt incorporates a vibration system at the product outlet to eliminate any bubbles that may have originated in the product during dosing. •Removable head for easy cleaning and with the possibility of being interchangeable. •A tray loader can be added at the beginning of the belt or a topping unit after dosing.

Request for a quote

FORMEX MAQUINARIA

Spain

•Dosing machine for making muffins, muffins and other food products with two-coloured dough. •Machine made for the dosing of two different doughs in the same capsule or mould. •The tank is divided into two parts to place each mixture in one of them. •The dosing outlet has off-centre nozzles to be able to adjust the depositing point of the mass. •The dosing parameters for each product can be changed independently via the touch screen. •Approximate production of 170-230 trays/hour approx.

Request for a quote

FORMEX MAQUINARIA

Spain

-Conveyor with manual guides at the beginning of the belt that adjust the width of the trays. -For correct dosing, depending on the tray format, the dosing nozzles have adapters to be able to dose at the desired point or plugs inside the tank in case it is necessary to cancel an outlet.

Request for a quote

FORMEX MAQUINARIA

Spain

CHARACTERISTICS OF THE MACHINE -The characteristic of the product, a doughnut with a hole in the centre, requires a distributed dosage in the mould. Each nozzle has a shower-shaped adapter, so that the dose is distributed in the mould. -The dosing nozzles are adapted to the mould dimensions. -Six doughnuts are dosed into each tray. -Smooth conveyor belt on which the silicone trays are manually placed. Guides place the trays in the correct position. -The belt must be kept clean during production, so a scraper is included at the end of the belt to clean any remaining dough. ADVANTAGES -Speed and increase in production, up to six times more. -Uniformity in dosing. -Removable head for complete cleaning and disinfection. We also avoid the staining of the trays and their subsequent cleaning. -The operator places the trays at the beginning of the conveyor and collects them full at the end.

Request for a quote

FORMEX MAQUINARIA

Spain

-INJECTOR MACHINE FOR FILLING cream, chocolate, jam, marmalade, dulce de leche, etc. into muffins, muffins, croissants and other bakery products in the same baking tray, avoiding unnecessary handling of the product. -For medium and large productions depending on the degree of automation of the bakery. 170-230 trays/h, approx. -Fully automatic: tray advancement, positioning for filling and tray outfeed. -The volumetric dosing of the product is exact and guarantees the same dose in all the injector needles. -The dosing control allows a very accurate weight regulation and the ease of working with a wide variety of fillings. -Different configuration elements of the machine can be modified according to the customer's needs: number of injection nozzles and distance between them, special injection needles, width of special trays, etc.

Request for a quote

FORMEX MAQUINARIA

Spain

-Automatic DA dosing machine for 40 cm wide trays. -Due to lack of space in the bakery, one end of the conveyor can be folded down.

Request for a quote

FORMEX MAQUINARIA

Spain

PRODUCT •The filler is injected hot. MACHINE CHARACTERISTICS: •Machine for filling chocolate and/or jam into elongated buns. •The injection head has 8 nozzles. The needles are placed horizontally, they prick the buns and the product is injected at the same time as they are being withdrawn, thus achieving a uniform injection along the whole length of the bun. •The quantity and speed of injection are configured on the screen, allowing a more precise adjustment. •The tank is heated to keep the product warm and facilitate injection. •The conveyor has guides that facilitate the manual placement of the buns for greater operator comfort. •At the end of the belt there is an ejector so that it is much easier to remove the product. ADVANTAGES •Speed and increased production. •Uniformity in the quantity of doses injected and in the distribution of the filling. •Easy cleaning.

Request for a quote

FORMEX MAQUINARIA

Spain

PRODUCT: -Panettone 18cm in diameter and 22cm high. -The dulce de leche is injected hot. CHARACTERISTICS OF THE MACHINE: -Injector adapted to the dimensions of the product with precise injection regulation. -The whole injector block, including the tank, nozzles and needles, is located inside a heated tank that keeps the product at a constant temperature of 40ºC. -Smooth belt conveyor with markings to place the panettones by hand and a scraper at the end to clean any remaining dough. -The machine injects four panettones at the same time and the injection is driven by a servomotor. ADVANTAGES: -Ease of use. The operator places the panettones on the marked belt and collects them at the end of the process. -Quick and easy cleaning thanks to the scraper and the removable head for complete cleaning and disinfection. -Safety in the working process. -Production increase: 400% depending on working conditions and parameters.

Request for a quote

FORMEX MAQUINARIA

Spain

MACHINE CHARACTERISTICS: -Production line consisting of three stations: oInjector with three rows of nozzles to inject 27 croissants simultaneously, and with three needles per nozzle so that the product is well distributed. oGelatine station that impregnates the croissants with gelatine. oTopping unit with ribbon for the chocolate chips to fall onto the product and get stuck in the gelatine layer. -Injection quantity and injection speed are set on the screen, allowing a more precise adjustment. -Between the injection belt and the gelatine belt, which is made up of cords, there is a transfer belt so that the croissants fall correctly in position and without turning, and are stacked for the gelatine shower. ADVANTAGES -Automated production for high volume production. -Three processes are completed in a reduced space.

Request for a quote

FORMEX MAQUINARIA

Spain

THE MIXING MAY INCLUDE INCORPORATED SOLID PARTICLES such as chocolate chips, nuts, candied fruit, etc. -For medium and large productions depending on the degree of automation of the bakery. -The volumetric dosing of the product is exact and guarantees the same dose in all the nozzles. -The dosing control is managed by a servo motor system. -Through the touch screen the user can control the quantity of doses as well as the speeds of both loading and unloading of the product. Different elements of the dosing machine can be custom-configured: number of nozzles, tray width, heated tank, conveyor belt, to adapt to the characteristics of the product to be dosed. FOR MAKING muffins, muffins, cakes, shortbread, sponge cakes, ponquets, brownies, plum-cake, sobaos, pancake, marble cake, creams, yoghurt, tarts, sauces, soup, flan, brandade, mousse, croquette paste...YOUR PRODUCT.

Request for a quote

FORMEX MAQUINARIA

Spain

WITH THIS MACHINE YOU WILL BE ABLE TO MAKE: Butter biscuits, almond doughs, curly biscuits, homemade biscuits, polvorones, perrunillas, mantecados, etc. •Uniform and fast production, avoiding punishing the dough or any alteration of its natural characteristics. •For medium and large productions, depending on the product and model. •Easy and quick change of moulds. •Intelligent production management by means of HMI panel, recipe programming. WIRE CUTTING AND MOULDS WITH A GREAT VARIETY OF SHAPES AND SIZES: For dense or hard doughs.

Request for a quote

FORMEX MAQUINARIA

Spain

MACHINE CHARACTERISTICS: •Production line consisting of four stations: - Two automatic injectors. - One automatic dosing machine for chocolate coating. - Unit for spreading the topping on top of the coating. •A single urn keeps the injectors and the dosing machine heated, so that the product is kept at a stable temperature at which the dosing is smooth and trouble-free. •The line is no more than 5 metres long and can be operated by a single person at the start of the conveyor. •A double conveyor belt system moves the trays with the completed product to the start of the line. ADVANTAGES •High degree of automation in a small space, 5 metres. •Handled by a single operator. •Uniformity in the product.

Request for a quote

DISTRIBUCIONES JULMARSA S.L.

Spain

Excellent mechanical and abrasion resistance. Solvent resistant. Compatible and resistant adhesion to oils. UL Aproved 0,185mm thickness Acrylic adhesive

Request for a quote

INTERDERMA - COSMETIC PRODUCTS MANUFACTURER -GMP- MEDITOPIC INTERNATIONAL DISTRIBUTORS WANTED

Spain

Anti-Wrinkle Gel Cream indicated on deep folds and wrinkles, Suitable for all skin types. Regenerating gel cream with anti-wrinkle properties Moisturizes the face Stimulates the synthesis of hyaluronic acid and collagen Effective in areas of deep wrinkles (nasogenian groove)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PACKFEEDER

Spain

The in-Line series from Packfeeder has a wide range of systems and models of machines for unscrambling bottles of different dimensions, characteristics and materials, with speeds that can be adapted to the different production needs. The in-Line Packfeeder bottle sorter system can work efficiently with packages of very different volumes, from small dimensions of 3-4ml to large packages of more than 1L, at a wide range of speeds that can reach 500 u/min. The STD range of the in-Line series is comprised of different sized feeders that adapt to the different volume needs of packages and production speeds. They all provide extraordinary versatility, which allows for them to work with countless products, as they can be configured according to the needs of a wide range of industrial sectors.

Request for a quote

PANACELLA FACTORY S.L.

Spain

We make delicious creams with nuts, chocolates, cookies. Many flavors, you decide the ingredient to add. We manufacture the cream you are looking for, in the format you need.

Request for a quote

SAPLI SOLUTIONS

Spain

Continuous or Intermittent motion highly Accurate Rotary Powder Filler is a suitable solution for a wide range of powdered and granule products to be filled with medium and high production rates. One or more filling stations options, depending on product flow characteristics and a packaging formats. Rotary machines are available with over turrets of 12 to 48 pockets, with outputs up to 400 containers per minute. These can be integrated with gross or tare and gross check-weigher feed-back systems.

Request for a quote

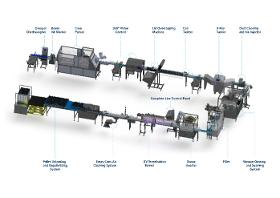

SAPLI SOLUTIONS

Spain

Stand-alone machinery and key turn projects for fully-automatic multiformat filling and packaging lines. Machinery for powdered and solid products, such as Powdered Milk, Infant Formula, Sport Supplements, Coffee, Snacks, Confectionery Products and others in metal tin cans, plastic containers, glass jars and carboard tins.

Request for a quoteResults for

Filling - Import exportNumber of results

22 ProductsCountries

Company type