- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- spindle bearings

Results for

Spindle bearings - Import export

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN offers a complete range of sizes, types and designs with its spindle ball bearings in standard sizes S, SM and KH. In conventionally oil-lubricated spindle bearings, lubricant is supplied through a lateral oil supply. GMN spindle bearing designs +A, +AB, +L and +LB provide direct oil supplies to the lubrication point through a bore in the outer ring. GMN spindle bearing designs +AG ensure the highest possible machine running times without complex oil supply systems. These feed the lubricant directly into the lubricating point through holes in the outer ring. The developed high-performance, separable BNT and BHT designs ensure fast and uncomplicated handling, especially with regard to assembly and maintenance.

Request for a quote

NORELEM FRANCE

France

Body and rotary table Al alloy, anodised. Spindle steel, casehardened. Spindle bearing maintenancefree. Version Radial play of rotation axis < 0.015 mm. Axial play of rotation axis < 0.02 mm. Repeat accuracy < 0.05°. Spindle selflocking. Note 360° adjustment, no end stop. Scale graduation is 10 increments. Transmission ratio 2116008 = 501 2116012 = 551 2116025 = 501 The rotary stage can be easily combined with other modules of the same size. Drawing reference All counterbores to DIN 74Bm (D6)

Request for a quote

DALIAN YOUMAI MECHANICAL AND ELECTRICAL PRODUCTS CO., LTD.

China

Dalian Youmai Mechanical and Electrical ProductS Co., Ltd. has been supplying bearings for PRECISION BEARINGS for many years and has helped our customers save a lot of costs. If you are interested in our products, please feel free to contact us.

Request for a quote

SPINDEL- UND LAGERUNGSTECHNIK FRAUREUTH GMBH

Germany

Spindle bearings are in SLF’s DNA. When it comes to Spindle Bearings we manufacture and design only the very highest quality in large renage of Options. are particularly applicable in scenarios involving machine tool building, as well as scenarios in which the bearing is subject to the most stringent requirements pertaining to precision or permissible speeds contact angle of 15° or 25° available Other contact angle and materials are available e DLR bearings are also available

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

EWS quality now available for Swiss-type lathes. This new development in driven tools is EWS's response to many customers' requests. The tool systems may appear straightforward at first sight, but their simplicity belies their performance. The design concentrates on the mounting and the spindle concentricity. The requirement profile was developed jointly with an American medical technology company which uses very small drill bits and requires extreme concentricity properties. The spindle bearing technology used with labyrinth seals sets new standards in this field, and is associated with a long service life. Provision has already been made for service. The service centres in Germany, China, Korea and the USA have already been trained in the system and are ready to respond without delay. Third-party brands can also be serviced there at any time. Download catalogue: PDF

Request for a quote

IGUS® GMBH

Germany

DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv DryLin® N - Technical data DryLin® linear guide systems in the cleanroom DryLin® N - Applications DryLin® N - Design rules System selection & service life calculation NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. DryLin® N - Low profile linear guide system NK-02-17 DryLin® N - Low profile linear guide system NK-22-17-40 drylin® N - Low profile linear guide system NK-22-17-30 NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor DryLin® N low profile guide systems offer you low profiles in various widths. Like in all drylin® products, the carriage runs without lubrication in anodized aluminum profiles. The material used and the unique design make DryLin® N a cost-efficient and flexible guide system. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Rail made of anodized aluminum 2 Gliding elements made of iglidur® J or J200 3 Carriage made of chromated zinc or plastic 4 Carriage with threaded hole or through hole Advantages: Small installation height between 6 and 12 mm Lightweight Numerous carriage options – also with pretension Maintenance-free, self lubricating Corrossion-resistant Low wear with low coefficient of friction Rails in silver or black anodized When not to use ? When precision below 50 μ is required In high loads over 50 kg drylin® T drylin® R drylin® W When high resistance to chemicals is required drylin® W drylin® R DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv Standard, preload and floating bearing NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. 1. NW-01-27 standard 01 with through hole g 2. NW-02-27 standard 02 with threaded hole 3. Preload with through-hole or threaded hole 4. uinjection-molded with through-hole or threaded hole 5. NW-21-27-60P Vollkunststoffschlitten mit Durchgangsbohrung 6. NW-22-27-60P solid polymer carriage with through hole 7. NW-11-27-80 double carriage with through hole NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 1. Standard 02 with threaded hole 2. Injection-molded with threaded hole 3. Standard 01 with through hole NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P 1. Standard 02 with mounting nuts 2. Injection-molded with mounting nuts NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For lubrication points of all kinds as slide ways, spindles, geared parts of the electronic, precision engineering and optical equipment, temporarily or permanently exposed to extreme low temperatures like in arctic climates or cold storages Roller bearing lubrication of high-speed bearings, e.g. spindle bearings, miniature or precision bearings in machine-tools or textile machines, measuring equipment, electric motors of control technology and precision mechanics Advantages and benefits Dynamic light noise proofed long-term lubrication grease Best use at arctic conditions and very high speed High efficiency through optimal formulation Multifunctional application beside the regular range of performance for greases Efficient through economical application No nameable change of consistency at low temperatures or high speeds and accordingly temperatures

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-speed spindles of the HS, HSX, HV-X and UHS series are irreplaceable for grinding work. Whether you must work with holes or frames, with these spindles you always make the right choice. The HV-X and HV-P series are optionally available with a rotational angle sensor, and therefore outstandingly suitable for 4Q operation. The types in the HV-P, HSP and HSP..g series are equipped with an HSK-C holder and furthermore suited for milling and drilling applications. GMN high-speed spindles of the HC, HCS, UHS, HCT series are an essential component of highly-effective machining of various materials. Whether aluminum, steel or titanium, these spindles are optimally designed for all machining tasks which require performance, torque and speed. Using an oil-air or grease permanent lubrication, the spindle bearings operate in a secure fashion.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-speed spindles of the HC, HCS, UHS, HCT series are an essential component of highly-effective machining of various materials. Whether aluminum, steel or titanium, these spindles are optimally designed for all machining tasks which require performance, torque and speed. Using an oil-air or grease permanent lubrication, the spindle bearings operate in a secure fashion.

Request for a quote

NORELEM FRANCE

France

The axis height of the spindle bearings matches the fixed bearing unit 2407801. The floating bearing units consist of a housing with deep groove ball bearing, which adapts axially to the linear expansion of the spindle.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

The use of high-precision radial groove ball bearings is especially recommended when axial forces are supported in two directions, but the installation space makes the use of a spindle bearing pair impossible; plus when the best-possible guide for rotating components is needed, but the RPM requirements are less important. Depending upon the load capability and the installation space available, GMN provides deep groove ball bearings in sizes 60 and 62 as per DIN 625. A large selection of various cages, lubricants and covers make it possible to adapt GMN deep groove ball bearings to any application.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

Based on our many years of experience in developing and manufacturing high-quality machine components, GMN has specialized in the area of high-precision ball bearings as well as the production of high-performance and long-lived deep groove and spindle ball bearings to meet – or even exceed – the highest precision classes P4 and ABEC 7. Certification under international standards ensures the highest precision in the development and manufacturing of GMN ball bearings and guarantees constant, outstanding qualities related to speed suitability, stability and longevity. The broad product range includes a large selection of standard solutions as well as requirements-tailored special designs.

Request for a quote

NORELEM FRANCE

France

Bearing block and carriage aluminium alloy. Guide column and threaded spindle stainless steel. Plain bearing for guide columns and spindle nut highquality special plastic. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Stainless steel hardened and ground. Threaded spindle with ball bearing. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Positioning stages for motorised adjustment and positioning tasks. The plain bearings and spindle nuts are suitable for dry running, however lubrication with a grease for plastic plain bearings is recommended. The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

NORELEM FRANCE

France

Body and rotary table Al alloy, anodised. Spindle steel, casehardened. Spindle bearing maintenancefree. Position indicator plastic. Version Radial play of rotation axis < 0.015 mm. Axial play of rotation axis < 0.02 mm. Repeat accuracy < 0.05°. Spindle selflocking. Note 360° adjustment with no end stop. The position indicator displays in 0.1° increments clockwise. The angle of rotation is indicated directly on the large LCD display. The rotary stage rotates anticlockwise. Reset, chain dimension and offset settings can be made via the keypad. 2 years battery life. The battery is quick and easy to replace. The mounting position of the position indicator is set in 4 positions using one screw. Transmission ratio 211611008 = 501 211611012 = 551 211611025 = 501 The modular design enables the rotary stage to be easily combined with other items of the same size. Drawing reference Assembly position of position indicator a) top (standard) b) right c) bottom

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of roller and plain bearings as well as of threaded spindles, gearwheels, worms and similar components Lubrication of spindle bearings in machine tools Advantages and benefits Allows high machine service lives due to low-wear operation and low lubrication frequencies Outstanding resistance in a wide temperature range, at high stresses and surface slide speeds as well as at vibrations Resistant to cold and hot water Excellent wear protection For highest effectiveness carefully clean the lubrication point, for example with OKS 2610/OKS 2611 universal cleaner. Before filling a bearing for first time, remove anti-corrosion agent. Fill the bearing such that all functional surfaces are certain of being greased. Fill normal bearings up to about 1/3 of the free space inside the bearing, high-speed bearings (DN value above 400,000) up to about 1/4. Low-speed bearings (DN value below 50,000) and their housings should be filled completely.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of open toothing, friction and rolling bearings, threaded spindles, hinges, guides on windlasses, ship´s cranes, underwater devices, offshore components or in wet areas of the textile industry Corrosion protection of moving parts subject to seawater in coastal and marine areas or constant influence of water Advantages and benefits Excellently suited as a waterproof special grease above and under water Highly effective due to optimum wear and outstanding corrosion protection Economical due to combined protective effect Lubrication of open toothing, friction and rolling bearings, threaded spindles, hinges, guides on windlasses, ship´s cranes, underwater devices, offshore components or in wet areas of the textile industry Corrosion protection of moving parts subject to seawater in coastal and marine areas or constant influence of water Advantages and benefits Excellently suited as a waterproof special grease above and under water

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Incremental length probe with magnetic detection principle. Very high accuracy and repeatability Extremely insensitive to contamination such as oil mist, moisture and dust Ball spline bearing of the spindle for long life time Perfectly suited for automated measured value acquisition in measuring devices, assembly and manufacturing lines

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of parts subject to high levels of stress such as plain, roller and rod-end bearings, spindles and guideways Advantages and benefits Highly suitable for high-stressed lubrication points Highly effective caused by optimal combination of components Saving of maintenance and lubrication costs by reducing downtimes and corrective maintenance Reduction of down times due to wearFor highest effectiveness, carefully clean the lubrication point, for example with OKS 2610 or OKS 2611 universal cleaner. Before filling for first time, remove anticorrosion agent. Fill bearing such that all functional surfaces are certain of being greased. Fill normal bearings up to about 1/3 of the free space inside the bearing. Low-speed bearings (DN value below 50 000) and their housings should be filled completely. The bearing and machine manufacturer´s instructions should be observed. Subsequent lubrication at the lubrication nipples by grease gun or by automatic lubrication system.

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Incremental length probe with magnetic detection principle for high reliability. with USB interface. Very high accuracy and repeatability. Resolution 0,1µm or 0,5µm Extremely insensitive to contamination such as oil mist, moisture and dust Ball spline bearing of the spindle for long life time Perfectly suited for automated measured value acquisition in measuring devices, assembly and manufacturing lines. Basic measuring software included

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Incremental length probe with magnetic detection principle for high reliability. Very high accuracy and repeatability Extremely insensitive to contamination such as oil mist, moisture and dust Ball spline bearing of the spindle for long life time Perfectly suited for automated measured value acquisition in measuring devices, assembly and manufacturing lines

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of normal-load friction, rolling and pivoting bearings Lubrication of spindles and guides at machines Lubrication of moving parts at fine-mechanical devices as well as household appliances Advantages and benefits Lubrication when dark-coloured lubricants cannot be used Saving of maintenance and lubricant costs by reducing downtimes and corrective maintenance Waterproof Clean the lubricating points well for optimal effect. Before filling for first time, remove anti-corrosion agent. Fill the bearing such that all functional surfaces are certain of being greased. Fill normal bearings up to about 1/3 of the free space inside the bearing. Low-speed bearings (DN value below 50,000) and their housings should be filled completely. In as far as available, the bearing and machine manufacturer's instructions should be observed.

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Incremental length probe with magnetic detection principle for high reliability. Very high accuracy and repeatability Extremely insensitive to contamination such as oil mist, moisture and dust Ball spline bearing of the spindle for long life time Perfectly suited for automated measured value acquisition in measuring devices, assembly and manufacturing lines

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of normal-load friction, rolling and pivoting bearings Lubrication of spindles and guides at machines Lubrication of moving parts at fine-mechanical devices as well as household appliances Advantages and benefits Lubrication when dark-coloured lubricants cannot be used Saving of maintenance and lubricant costs by reducing downtimes and corrective maintenance Waterproof NSF H2 registered Also available as spray version OKS 471 (without NSF certification)

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

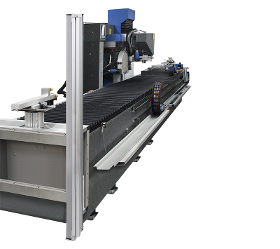

In the basic version the MMC 5000 consists of a main X-axis featuring a linear air bearing (feed axis), a linear roller bearing Z-axis (infeed axis) and the milling spindle (air bearing) mounted on top of the Z-axis. The main application is face milling of optical and mechanical precision components. A Y-axis is available as an option. Another useful accessory is a second milling spindle, used perpendicular to the first one, thus allowing for the machining of two sides of a workpiece to perpendicularity in one setup. Accessories, like vacuum chucks, different milling spindles, touch probes for part thickness measurement, machine interferometers and other sensors for insitu measurement of workpiece shape and roughness, make the MMC 5000 machines an effective tool. In addition, various sensors are available for measuring of the workpiece geometry and surface quality during the manufacturing process.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The MMC 600/900 is the basis for a series of machines that, via several accessories and options, can be fully customized to individual needs. In the basic version the machine consists of a main X-axis featuring a linear air bearing (feed axis), a linear roller bearing Z-axis (infeed axis) and the milling spindle (air bearing) mounted on top of the Z-axis. The main application is face milling of optical and mechanical precision components. Several accessories like a Y-axis, an A-axis and/or C-axis are available, thus expanding the range of machinable parts to microstructures, lenticular structures, spheres, polygons and so on. Accessories, like vacuum chucks, different milling spindles, touch probes for part thickness measurement and even machine interferometers for insitu measurement of workpiece shape, make the MMC 600 and 900 machines an effective tool. Besides further accessories, there is the possibility to make customized solutions, to adapt the machine to your needs.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The ultraprecision turning machine (UP-Turning machine) MTC 650 is currently our largest series machine. Our customers can machine workpieces up to 200 kg in UP quality. The travelling distances are 400 mm in the Z-axis and 650 mm in the X-axis. Workpieces with a diameter of up to 800 mm in diameter (optionally 1000 mm) can be machined. The extended X travel offers more space for additional accessories, further tool holders or special bodies/ constructions. The MTC 6500 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. Different vacuum chucks for workpieces of up to 800 mm (31.5’’) in diameter are available.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

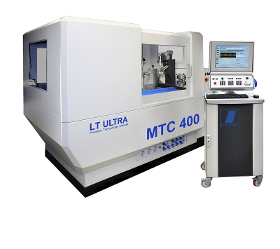

The ultraprecision turning machine (UP-Turning machine) MTC 400 (Micro Turning Center) is designed to hold heavy weight workpieces up to 100 kg. The travelling distances of the X- and Z-axis are 400 mm and provide the machining of workpieces up to 800 mm in diameter. The MTC 400 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. Different vacuum chucks for workpieces of up to 800 mm (31.5’’) in diameter are available. Besides many other accessories, that make the MTC 250 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The ultraprecision turning machine (UP-Turning machine) MTC 250 (Micro Turning Center) has a lightweight construction of the moving parts and thus enables the machine axes to be used in a dynamic mode (Slow Tool). This machine is our standard machine with the smallest footprint. The travelling distances of the X- and Z-axis are 250 mm and provide the machining of workpieces up to 500 mm in diameter. The MTC 250 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. Besides many other accessories, that make the MTC 250 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The ultraprecision turning machine (UP-Turning machine) MTC 350 (Micro Turning Center) combines dynamic use with an increased work space, thus resulting in a wide range of products to be manufactured. The travelling distances of the X- and Z-axis are 350 mm and provide the machining of workpieces up to 700 mm in diameter. The MTC 350 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X-slide. In addition to the X- and Z-axis there is the option to have an additional linear axis. This A-axis allows to do micro milling or raster flycutting operations on the machine. Besides many other accessories, that make the MTC 350 an all-purpose tool, there is the possibility to make customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quoteResults for

Spindle bearings - Import exportNumber of results

43 ProductsCategory

- Silicones (6)

- Turning - steels and metals (4)

- Bearings - ball, needle and roller (3)

- Joints, pneumatic (3)

- Precision measuring instruments (3)

- Lubricants, industrial (2)

- Machine tools, metal machining - parts and accessories (2)

- Measurement - Equipment & Instruments (2)

- Milling - steels and metals (2)

- Cutting - steels and metals (1)

- Electric vehicles (1)

- Embossing machine tools (1)

- Industrial tools (1)

- Mechanical engineering - custom work (1)

- Milling - machine tools (1)

- Tools & Hardware (1)