- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel stamps

Results for

Steel stamps - Import export

NINGBO FRIMA INDUSTRY CO. LTD.

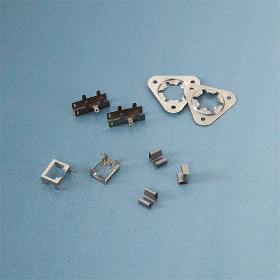

China

We are the Stainless Steel Stamping Parts manufacturer. At FRIMA PARTS, we offer the custom sheet metal fabrication services .The metal manufacturing process contains Stainless Steel Stamping Parts, Deep drawing stamping,CNC punching, CNC bending. The 2000+ projects we have done for our clients from the overworld. Our skilled mold designer will take customer requirement of the parts into consideration during the mold design and manufacturing. Stainless Steel Stamping Parts (Tolerance range +/-0.02mm) We understand that our customers need exceptional products that are consistent with quality, design and build specification. Our company has invested heavily in advanced stamping, bending, deep drawing equipment, enabling us to quickly deliver components in the volume you need. For more information, please contact us at info@frimaparts.com

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

process: stamping surface treatment: customized material: brass tolerance:+/-0.02

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used for precision machine parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The process of sheet metal processing: Select the appropriate sheet metal, and carry out the necessary treatment and preparation, such as cutting, bending, stamping, etc Processing stage: forming the metal sheet, including cutting, bending, stamping, welding and other process operations Inspection stage: Conduct comprehensive quality inspection and evaluation of the final product, including appearance inspection, size inspection, performance testing, etc

Request for a quote

BORNEMANN GMBH

Germany

Steel types, also called type stamps, can be produced in all dimensions. The design is flexible: type stamps with or without groove, with labelling groove, in T shape (T type) and L shape (L type) as well as conical or segment types, which are put together as a ring. Cylindrical steel types can also be produced. The font size is guided by your drawing. The type stamps are hardened and annealed in accordance with the purpose and can be used immediately. Labelling is also possible in unmistakable fonts or with rounded-off engraving in addition to standard designs. Also possible are point font or low stress to avoid cracks in the stamping material.

Request for a quote

BORNEMANN GMBH

Germany

Manual stamping presses for steel, tool and machine engineering for simply labelling of multi-digit texts. For standard stamping presses we offer font sizes of 1 to 10 mm with 11 labelling fields on the wheel circumference. By removing the pin stop, the wheels can be easily rotated, which allows setting the desired combination. The striking cap can also be replaced.

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

The effective protection against self loosening and unscrewing. The "NSK" LOCK WASHER is the improved design of the "SK" LOCK WASHER. It also prevents self-loosening of screwed joints and damage to the bearing surfaces and consequent variations in the tightening torques, as they occur in threadlockers with teeth are avoided with lock washers through the special geometrical shape of the locking edges even better than the proven "SK" LOCK WASHER.

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

The effective protection against self loosening and unscrewing. The "SK" Serrated Locking Washer prevents self-loosening of screwed joints. Damage to the bearing surfaces and consequent variations in the tightening torques, as they occur in threadlockers with teeth are avoided with lock washers through the special geometrical shape of the locking edges. shape S (small) shape M (middle) shape B (wide) shape Z (for screws with cylindrical head shape) shape K (for electrical contacts)

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

We are specialized in the production of precision parts and assemblies for the medical technology, automotive, telecommunications, metrology and renewable energy industries. We use our own equipment and technologies and undertake in-house fixture construction. Laser machining, electrochemical metalworking and mechanical manufacturing are our core competencies. We manufacture quantities from 50,000 up to several million per year. You will find further information in brochure at our homepage.

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

The contact lock washer to NFE 25-511 and SN 70093 with grooved surface provides the designer the ability to secure wobble-prone screw effectively. It is particularly suitable for use on slot fasteners, dynamic cross-loaded to the screw connections and applications that require high biasing forces. Operational: The contact wheel ensures positively spring and a form-fitting locking. Form S = narrow - for small headrests Form M = average - for normal headrests Form B = wide - for large pressure transmission surfaces and slot fasteners Form K = serrated - for electrically conductive connections with contact teeth (SN 70093)

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Stamped parts / contract manufacture Your products delivered punctually As a flexible stamping business, Schulz Stanztechnik manufactures various stamped and stamped bent parts for the most diverse areas of application from conveyance technology components, the automotive industry to mechanical components such as washers and angle connectors or entire assemblies. We place particular emphasis on high-quality and punctual manufacture and delivery of the ordered products and services. We are also in a position to meet special requests of our customers at short notice. Alongside the actual stamping process, Schulz Stanztechnik carries out numerous additional tasks, such as the creation of threads, use of installation parts or the installation of several components to the stamped parts. These activities can be carried out during stamping as well as in a separate work process.

Request for a quote

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

Metal spring, Metal bracket, metal enclosure with high tight tolerance and big volume demand in battery and electronics industries,we design high precision progressive die and production on high speed press machine with at least 150000pcs daily, low production cost and high precision are the characteristic of our small stampings,you can choose stainless steel, 65Mn, and the stampings will be heat treated with salt bath, which minimize the deformation, after heat treatment, the stamping parts will have super good spring.

Request for a quote

DONGGUAN XINHONGYUAN METAL PRODUCTS LIMITED

China

The stamping parts are formed by metal stamping with 2.0mm Steel plate, which can release your hands during watching IPAD, after assembly all components together, put your IPAD on the display support, it is safe ans easy to assemble, the surface finish is powder coated in black, looks elegant, the weight of this unit is around 1.5kg.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Advantages of Heating Plates with Square Cartridge Heaters: -> Simple plate manufacture due to rectangular groove geometry, no deep-hole boring -> Simple heater installation by bending and pressing along the plate surface -> Complex plate geometries with bores and openings -> Optimal heat transfer due to 75% surface contact -> No casting with heat conductive compound -> Uniform temperature profiles due to thermally optimized groove layouts/power distribution and utilization of insulation plates -> high process temperatures (up to 450°C in aluminium, up to 700°C in stainless steel) Example "Heated Stamp": D=100 mm out of tempered tool steel up to max. 700°C continuous temperature. Fitted with 2 Square Cartridge Heaters 1500 W/ 230 V, 4,5 x 4,5 mm x 600 mm, with 50 mm unheated at the termination end. Annealed and formable with a nickel sheath, resistant up to 850°C surface temperature. Connection by fibreglass insulated pure nickel high-temperature leads (max. 500°C)

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

The metal stamping service can be customized during the whole manufacturing process from the mold developing, designing to producing. Every demand from customers like metal stamping, punching, deep pumping and specific angle bending are measured and tested according to the measurement of metal materials then apply to each kind of metal. Features of our products: 1. Material: Steel, Stainless steel, Aluminum sheet, Copper etc. 2. Surface treatment: Zinc plated, Powder coating, Paint, Nickel plated etc. 3. Requirement: based on drawing and quantity. 4. Stamping equipment: 10-500T 5. Packing: we will offer you the standard package which includes plastic film, foam, carton and wooden box which is suitable for transporting 6. Delivery time: Within 20 days after receiving your 30% deposit

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Metal Stamping Parts Supplier Custom Aluminum Stamping Parts According Customer’s Designs Or Samples. Item: Aluminum Stamping Parts Materials: AL 5052, AL 6061, AL 6068… Surface Finish: Anodizing, Black Anodizing Application: Fixing & Mounting Produced by: Metal Stamping Ming Xiao Mfg specialize in sheet metal fabricating services more than 20 years,have been customed many kinds of sheet metal stamping parts & puched parts for different industries. Providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. Have custom many kinds of aluminum stamping parts,such as aluminum stamping clamps, brackets,casings, holders,aluminum console covers,aluminum frames,aluminum punched plates,aluminum stamping Panel pressed-in hole parts by PEM studs, nuts, screws and pins. We are professional metal stamping supplier from China, if you need custom aluminum stamping parts, welcome contact us to discuss your project.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Ming Xiao Mfg is specialize in sheet metal Stamping services more than 20 years,have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching, bending, cutting, shearing, riveting, spinning, welding, deep drawing, etc. We are also have 6 sets different sizes progressive die stamping machines, can produce small metal stampings with high speed and low prices. suitable to high volume metal stamping components. Metal Stamping Parts Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper Finishs: Anodize,painting,powder coating,blackening,electroplatings of chrome/zinc/nickel /tin/silver...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NINGBO FRIMA INDUSTRY CO. LTD.

China

High quality control, no burr and scratch on surface and trimming edge Process Design moulds→ confirm samples→ purchase material→ blanking→ punching→ welding/bending→ forming→ surface treatment→ Inspection→ assemble products→ Package We can produce and process stamping parts (https//www.frimaparts.com/precisionmetalstamping/) according to your requirements. Lead time for samples in 15days. COC, Test Report, RohS , plating report, coating reports, is available !

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

We are the Stainless Steel Stamping Parts (https//www.frimaparts.com/category/precisionmetalstampingparts/)manufacturer. At FRIMA PARTS, we offer the custom sheet metal fabrication services .The metal manufacturing process contains Stainless Steel Stamping Parts, Deep drawing stamping, CNC bending. The 2000+ projects we have done for our clients from the overworld. Our skilled mold designer will take customer requirement of the parts into consideration during the mold design and manufacturing. Stainless Steel Stamping Parts (Tolerance range +/0.02mm) We understand that our customers need exceptional products that are consistent with quality, design and build specification. Our company has invested heavily in advanced stamping, bending, deep drawing equipment, enabling us to quickly deliver components in the volume you need.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

China Stainless steel Stamping Parts We are the China Stainless Steel Stamping Parts (https//www.frimaparts.com/category/precisionmetalstampingparts/)manufacturer.At FRIMA PARTS, we offer the custom sheet metal fabrication services, the metal manufacturing process is including Stainless Steel Stamping Parts, Deep drawing stamping, CNC bending. Trusted by the most famous company in the world, The 2000+ projects we have done for our clients from the overworld, our skilled mold designer will take customer requirement of the parts into consideration during the mold design and manufacturing. China Stainless Steel Stamping Parts We understand that our customers need exceptional products that are consistent with quality, design and build specification. Our company has invested heavily in advanced stamping, bending, deep drawing equipment, enabling us to quickly deliver components in the volume you need. We

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

High Quality Deep Drawn Stainless Steel Parts We FRIMA is a professional manufacturer of deep drawn stainless steel parts and we can produce deep drawn components to suit a diverse range of industries as customer requirements. With our decades of experience, unrivalled approach to customer service and the investment we have made in our people and equipment, you can be sure our parts will give you the best results. Deep Drawn Stampings Advantages Deep drawn stampings will reduce operational costs, assembly costs and reduce waste. This complex process is one that we have simplified here at NINGBO FRIMA and the knowledge with skills that have been passed down to our teams today. If you are looking for deep drawn stainless steel parts of the highest possible standard, advice tailored to your application and industry with unrivalled customer support, speak to the team at Ningbo FRIMA Industry. We would be delighted to tell you more about the many benefits of deep drawn pressing.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Sheet Metal Stamping Parts Factory custom produce Aluminum,Carbon & Stainless Steel,Brass & Copper Stamping Parts as per customers’ drawing or samples. Have custom many kinds of metal stamping parts,such as sheet metal stamping clamps, metal seals, sheet metal brackets, sheet metal holder,console cover,sheet metal frames,spring clip, steel plates,shelf,Square/ Rectangular washers, metal stamped PCBA front Panel, pressed-in hole parts by PEM studs,nuts & fasteners, screw and pin welded stamping housings. Materials can be stainless steel,carbon steel,aluminum alloy,brass & copper,etc Finshing Operations: Forming, Bending,Deburring, Tapping,Riveting,Welding Surface Finish: zinc plating,chromed,nickel plating,oiled,painting,powder coating,hot-galvanizing,heat treatment & blackening,etc Mould Accuracy is 0.01mm-0.05mm We are professional metal stamping supplier from China, we custom sheet metal stamping parts for foreign customers more than 15 years.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Sheet Metal Stamping Parts Factory custom produce Aluminum,Carbon & Stainless Steel,Brass & Copper Stamping Parts as per customers’ drawing or samples. Have custom many kinds of metal stamping parts,such as sheet metal stamping clamps, metal seals, sheet metal brackets, sheet metal holder,console cover,sheet metal frames,spring clip, steel plates,shelf,Square/ Rectangular washers, metal stamped PCBA front Panel, pressed-in hole parts by PEM studs,nuts & fasteners, screw and pin welded stamping housings. Materials can be stainless steel,carbon steel,aluminum alloy,brass & copper,etc Finshing Operations: Forming, Bending,Deburring, Tapping,Riveting,Welding Surface Finish: zinc plating,chromed,nickel plating,oiled,painting,powder coating,hot-galvanizing,heat treatment & blackening,etc Mould Accuracy is 0.01mm-0.05mm We are professional metal stamping supplier from China, we custom sheet metal stamping parts for foreign customers more than 15 years.

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

Grinding chips are created by the grinding of metal components. It is a mixture of metal and corundum abrasion in combination with the cutting fl uids being used. By briquetting, the waste is reduced significantly and the briquettes possess a defi ned residual moisture. Thus, the disposal costs are reducedand depending upon the alloy, there is even the opportunity to sell the briquettes with a profit. In most cases, the expensive oil contained in the cutting fl uid can be reused. The briquetting system can already payoff for itself within less than 12 months by processing about 10 to 30 tons of the expensive oil contained in the cutting fl uid per year. Depending on the requirements, our briquetting systems for grinding chips are equipped with hydraulic motors ranging from 4kW to 22kW, and reach a specifi c pressure of up to 3,800 kg/cm². The throughput of the RUF briquetting systems - especially for grinding chips - range from 40 to 350 kg/h.

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

Through the process of briquetting, the value of residual metals can be increased considerably. The value of residual metals can be increased considerably. A further advantage is the recovery of expensive cutting fluids that can be pressed out of wet chips and then reused. When melting briquettes, combustion is significantly lower and results in a higher melting yield than with loose chips. Depending on the need, our briquette systems are equipped with hydraulic motors between 4 and 90 kW. They will achieve a specific pressure of up to 5,000 kg/cm². Suitable for aluminium, steel, cast iron, copper and many other metals Advantages: - Heavy reduction of volume, reducing storage and transportation costs - Recycling of expensive cooling lubricants - Recipients often pay a better price for loose millings - Minimal burn-off and increased glaze recovery thereby For throughput rates between 30 and 4,800 kg/hr.

Request for a quote

CESAL ELEKTRO S.R.O.

Czech Rep.

Allow us to briefly introduce ourselves and at the same time offer the services of our company. we precisely manufacture sheet metal parts, cabinets, covers and control cabinets made of steel, aluminum or copper sheet up to a thickness of 3 mm we treat the surface with powder paints, galvanizing we describe the screen printing method we weld or press bolts, nuts, screws onto sheet metal we have exact connector tools for 100% visual quality we make various moldings, signs (e.g. grounding) or bridges for attaching cables assembly, pre-assembly, packaging we have our own trucking company TIG, MAG and laser beam welding - we produce in small and large series

Request for a quote

KOVINOPLASTIKA LOŽ D.O.O.

Slovenia

Adaptable stamping solutions due to modern machinery- MECHANICAL, ECCENTRIC and HYDRAULIC PRESSES (30-1200t).High quality stamped components for various industries (automotive, electronic, home appliences, garden…). Production limits STAMPING Max width: 310mm Tickness: 0,5mm - 5mm Material: Steel DEEP DRAWING Max dimension: 2000 x 1200mm Tickness: 0,4mm - 3mm Material: steel and aluminium plates, stainless steel

Request for a quote

KINGFONT PRECISION INDUSTRIAL CO., LTD

Taiwan R.O.C.

Customized tool

Request for a quote

KINGFONT PRECISION INDUSTRIAL CO., LTD

Taiwan R.O.C.

Material C5191R

Request for a quoteResults for

Steel stamps - Import exportNumber of results

68 ProductsCountries

Category

- Stamping - steels and metals (45)

- Sheet metals - stamping (8)

- SMALL METAL PARTS (4)

- Steels and metals - forming and cutting (2)

- Agricultural systems and equipment (1)

- Bending - steels and metals (1)

- Electroheat - machines and equipment (1)

- Embossing machine tools (1)

- Forming - steels and metals (1)

- Knives, industrial (1)

- Mechanical engineering - custom work (1)

- Mechanical transmission - components (1)

- Metal engraving - machine tools (1)

- Sensors (1)

- Sheet metal and strips, tinplate (1)

- Swimming pools - equipment and installations for water treatment (1)

- Welding work - steels and metal (1)