- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vacuuming

Results for

Vacuuming - Import export

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

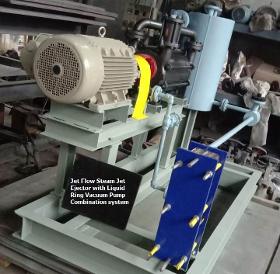

Jet Flow Steam Jet Ejector and Liquid Ring Pump Combination type Hybrid Ejectors Systems are getting popular in major Chemical, Soap, Food, Edible oil sectors. A typical combination of steam jet ejector system followed by inter-condenser and liquid ring vacuum pump. This type of combination system can achieve vacuum as high as 0.05 Torr. It can be configured as single or multistage ejectors, single or two stage liquid ring vacuum pumps and inter-condenser. It is designed to operate at the same capacities and suction pressures as conventional steam jet ejector systems. Jet Flow Hybrid Ejectors provide a solution for high vacuum operations. They are versatile in handling both wet and dry loads, can be supplied with low level skid mounted packages with instrumentation and with closed loop seal water recycle system for vacuum pumps for the total reduction of effluent. Jet Flow combination type vacuum systems major applications in distillation, evacuation, drying, evaporation, cooling etc.

Request for a quote

KNIGHT OPTICAL (UK) LTD

United Kingdom

Knight Optical can offer UV Fused Silica Windows for Vacuum Applications. UV Fused Silica is a relatively hard optical glass with a very low coefficient of thermal expansion. This means that it is a good choice for us in Vacuum applications, as any difference in temperature will not affect the optical performance. In addition to the above, UV FS has high transmission from UV to NIR meaning that there is little loss of image when it is used for a Vacuum Window/viewport and therefore the quality of the optical system is not compromised. All our UV Fused Silica Lenses are fully inspected on their quality in our ISO 9001 certified, state-of-the-art Metrology laboratory, using our Trioptics Optispheric, and Starrett AV300 and Zygo Verifire XPZ. This allows us to work to the highest QA standards and meet the tolerance specifications on these precision components Read PDF for more info

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

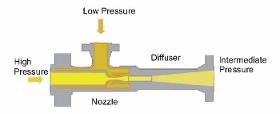

Water jet ejector uses water as motive force. Liquid Jet Eductors use the kinetic energy of a motive liquid to entrain another liquid,completely mix the two, and then discharge the mixture against a counter pressure and are used in large numbers throughout industry for pumping and mixing operations. Water Jet Eductors consist of three basic components, namely a converging nozzle, a diffuser (or venturi), and a body to hold these parts in their relative positions and to provide a suction (or mixing) chamber. In addition, they can be equipped with accessories such as regulating spindles. Water Jet Eductors can also be staged with higher vacuum steam ejectors. In this case, the eductor serves both as the final pumping stage as well as a fairly good direct contact condenser, condensing the motive steam from the high vacuum steam ejectors.

Request for a quote

RUSSELL FINEX LTD

United Kingdom

Vacuum conveying sieve for air-tight sieving and conveying of fine and dusty materials in one operation to improve production capacity. For more details, please send us a message or click on the website link.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Large industrial plants often vent significant quantities of low pressure steam to the atmosphere, wasting energy, water, and watertreatment chemicals. Recovery of the latent heat content of lowpressure steam reduces the boiler load, resulting in energy and fuel cost savings. Lowpressure steam's potential uses include driving evaporation and distillation processes, producing hot water, space heating, producing a vacuum, or chilling water. If the steam pressure is too low for the intended application, a steam jet thermocompressor can boost the pressure and temperature to the required level. Operating Principles - Thermocompressors and ejectors operate on the same thermodynamic and physical principle energy contained in high pressure steam can be transferred to a lower pressure vapor or gas to produce a mixed discharge stream of intermediate pressure.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

The efficiency of a Steam turbine is mainly determined by the pressure of the steam at its outlet. The Turbine Surface Condenser is therefore maintained under vacuum. To enable this, the Steam Jet Ejector Vacuum System must be capable of removing all non condensable and associated water vapour from the Surface Condenser to produce the minimum steam condensing pressure consistent with physical dimensions and heat transfer and to provide for deaeration of the condensate. The sources of non condensables include air leakage through all system components operating below atmospheric pressure, gases released from feedwater drains and vents admitted to the condenser, gases released for makeup admitted to the condenser, condensate surge tank when utilized in a closed cycle and disassociation of feedwater into oxygen, hydrogen and non condensables.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

Based on the process requirement, a Multi Nozzle Ejectors can be designed five or seven nozzles type. Generally, one nozzle in the centre and remaining four or six nozzles are evenly circled around it. Multi Nozzle Ejectors can reduce the steam consumption by 15% to 20% as compared to Single Nozzle Ejectors when designed for the same conditions and it is more efficient to single nozzle ejectors. At times it is also considerably shorter in length when compared with same rated single nozzle ejectors.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

SingleStage Steam Jet Ejectors are based on the ejectorventuri principle. In operation, steam issuing through an expanding nozzle has its pressure energy converted to velocity energy. A vacuum is created and the high velocity of steam entrains air or gas and the mixture of gas and steam enters the converging end of the venturi, passes through the diffuser where its velocity energy is converted into pressure sufficient to discharge against a predetermined back pressure. Single stage steam jet ejectors are used to create vacuum covering 40 mm Hg. Absolute. Two Stage Ejector with Condenser The system is the assembly of two units whose construction is similar to single stage with inter condenser (direct contact type or surface type). Steam of the first stage is expanded through nozzle entrains the air or other gases and discharges them to diffusers at a higher pressure in the condenser.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

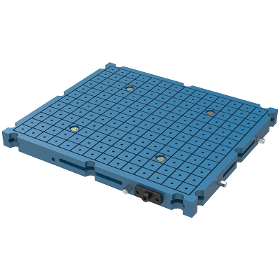

Can be used with or without pallet Can run from vacuum generator or dedicated pump Can be mounted on a magnet for grinding applications Matrix on top surface can be used for traditional clamping or part location DESCRIPTION Possibly the most universal multi-functional vacuum system in today’s market, this system has several unique features to meet your vacuum workholding needs. Each Multi-Power vacuum table has 4 ports to allow for multi component clamping. The top surface is textured for extra holding force and has a matrix of threaded holes to combine vacuum and traditional clamping methods as well as the ability to mount pallets. The bottom surface includes 6 embedded steel washers to allow the unit to be mounted on a magnet for grinding applications. The Multi-Power vacuum table can be equipped with multiple vacuum generators when additional holding force is required and multiple vacuum tables can operate from a single vacuum source.

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

Synthetic high-performance lubricants with a PFPE-base and NSF/H1 food grade approval. The pressure and chemical resistant vacuum pump oils feature excellent lubricating properties at high temperatures and enable long lubrication intervals.

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

Fully synthetic, NSF H1 registered gear and vacuum pump oil with high oxidation resistance across a wide temperature range. Also suitable for the long-term lubrication of chains and spindles.

Request for a quote

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star Vacuum Chamber Sealer The Star vacuum chamber range is used for vacuum sealing products where a high vacuum level is required. The product is placed in an unsealed bag inside the chamber. When the lid is closed the built in vacuum pump evacuates the chamber and seals the bag whilst in a vacuum. On completion of the sealing cycle atmospheric pressure is let back into the chamber and the lid opens automatically. Typical applications include food and electronics packing but special versions have been built for the chemical and medical sectors. Bench top and free standing machines Stainless steel finish Single or multiple sealing bars, single and double heat Gas flushing with multiple cycles available Single program and multiple program versions allowing different vacuum and weld parameters to be preset The chamber lid is released on completion of the cycle

Request for a quote

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star Medical sealers have been developed for applications where ease of cleaning is critical, such as in the food, medical and pharmaceutical industries. The machine body can be built in a number of different designs with the jaws operating vertically (when a product is best sealed laying down) or horizontally (when a product is best sealed standing up). With the cylinders moving the top jaw directly, jaw alignment and pressure are much more controllable. This machine design is available with all the Star controllers. The Star Medical Vacuum sealer allows for the air to be removed from a bag prior to sealing. The machine is available with a range of vacuum pumps or vacuum generators dependant on your application. Gas flushing is available for modified atmosphere packaging. This machine design is available with either our ARTICS or Medical controllers.

Request for a quote

STAR UNIVERSAL (GOSPORT) LTD

United Kingdom

The Star 106 range of vacuum sealing machines are available in a bench mounted of free-standing format. A probe extends into the bag and evacuates the air without the need to place the product inside a vacuum chamber, so there is no limit to the maximum product length. Although predominantly used for sealing food products and electronics, special purpose machines have also been produced for the chemical and agricultural sectors. Seal lengths from 500mm to 900mm. Vacuum pumps from 3cmh to 15cmh. 230V or 115V power supply. An optional gas flush facility is available to allow the product to be packed in an inert atmosphere. Weld and cool cycle times are adjustable. Seal width 6mm as standard, other options including double welds available. With both jaws heated, most modern barrier materials such as foils and nylon laminates can be sealed. A range of control options are available including the Star ARTICS and MkVI C controllers

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

At Lubcon lubricants we have a wide range of Vacuum Grease for all your company demands worldwide using efficient technology.

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

At Lubcon lubricants we have a wide range of Vacuum Oil for all your company demands worldwide using efficient technology.

Request for a quote

FILTRATION SERVICES LTD

United Kingdom

Filtration Services offer bespoke manufacture and design to meet both your site specific requirements and the exacting standards of today's industry. Our Rotavac rotary drum vacuum filter (RDVF) is particularly suited for applications where large amounts of liquids and solids need to be separated continuously and with minimal operator input. The Rotavac is available in a variety of sizes, from 0.8m² up to 60m² filtration area, and in a range of solids discharge configurations. Rotary drum vacuum filters operate continuously with the solids and liquid being discharged at steady, predictable rates. The units require little or no manual intervention, being simple to operate and maintain. Contact us now for more details and your individual solution.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

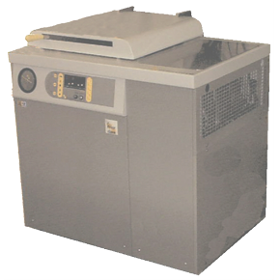

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. 2-Year Warranty Package: with Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price. For heavy or tall loads the Priorclave Loadlite Hoist allows the smaller footprint of a Top Loading Autoclave to be used with safer handling. Load Sensed Process Timing uses an internal probe placed in the load to give guaranteed sterilisation times. If a printer is fitted load temperature is included on the printed record. Waste Containers: for operator safety and protection of your autoclave with waste loads. These contain spillages whilst allowing good steam penetration. Stainless Steel Wire Baskets are also available. ****** ASK FOR A QUOTE *****

Request for a quote

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. 2-Year Warranty Package: Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price. For heavy or tall loads the Priorclave Loadlite Hoist allows the smaller footprint of a Top Loading Autoclave to be used with safer handling. Load Sensed Process Timing uses an internal probe placed in the load to give guaranteed sterilisation times. If a printer is fitted load temperature is included on the printed record. Waste Containers: for operator safety and protection of your autoclave with waste loads. These contain spillages whilst allowing good steam penetration. Stainless Steel Wire Baskets are also available. ***** ASK FOR A QUOTE *****

Request for a quote

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. Load Sensed Process Timing uses an internal probe placed in the load to give guaranteed sterilisation times. If a printer is fitted load temperature is included on the printed record. Process Printer: Temperature and time are printed at key stages of the cycle. Pressure and load temperature printing options are also available. Fitted to all Priorclaves Media Warming keeps sterilised media ‘ready to pour’ at the end of the cycle. An end to early morning starts to melt media! 2-Year Warranty Package: Peace of mind with Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price. ***** ASK FOR A QUOTE *****

Request for a quote

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. Load Sensed Process Timing uses an internal probe placed in the load to give guaranteed sterilisation times. If a printer is fitted load temperature is included on the printed record. Process Printer: Temperature and time are printed at key stages of the cycle. Pressure and load temperature printing options are also available. Loading Trolleys and Loading Cassettes are available for all front loading, RSC and Power Door Models. 2-Year Warranty Package: Peace of mind with Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price. (UK Customers Only) ***** ASK FOR A QUOTE *****

Request for a quote

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. Load Sensed Process Timing uses an internal probe placed in the load to give guaranteed sterilisation times. If a printer is fitted load temperature is included on the printed record. Process Printer: Temperature and time are printed at key stages of the cycle. Pressure and load temperature printing options are also available. Loading Trolleys and Loading Cassettes are available for all front loading, RSC and Power Door Models. 2-Year Warranty Package: Peace of mind with Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price. (UK Customers Only) ***** ASK FOR A QUOTE *****

Request for a quote

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. Load Sensed Process Timing uses an internal probe placed in the load to give guaranteed sterilisation times. If a printer is fitted load temperature is included on the printed record. Process Printer: Temperature and time are printed at key stages of the cycle. Pressure and load temperature printing options are also available. Loading Trolleys and Loading Cassettes are available for all front loading, RSC and Power Door Models. 2-Year Warranty Package: Peace of mind with Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price. (UK Customers Only) ***** ASK FOR A QUOTE *****

Request for a quote

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. Bench top Priorclaves can be manufactured with Leg Extensions to allow cleaning of the bench underneath the Priorclave where this is a critical requirement. 2-Year Warranty Package: Peace of mind with Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price (UK Customers Only). Process Printer: Temperature and time are printed at key stages of the cycle. Pressure and load temperature printing options are also available. Load Sensed Process Timing uses an internal probe placed in the load to give guaranteed sterilisation times. If a printer is fitted load temperature is included on the printed record. ***** ASK FOR A QUOTE *****

Request for a quote

PRIORCLAVE LIMITED

United Kingdom

At the heart of every Priorclave is the TACTROL® microprocessor control system, specially developed for laboratory autoclaves. From simple cycles to fully featured multi-program operation with printed records, this unique control system allows unrivalled flexibility. Bench top Priorclaves can be manufactured with Leg Extensions to allow cleaning of the bench underneath the Priorclave where this is a critical requirement. 2-Year Warranty Package: Peace of mind with Installation, Preventative Maintenance and parts replacement cover for the first 2 years of ownership at a much reduced price (UK Customers Only). Process Printer: Temperature and time are printed at key stages of the cycle. Pressure and load temperature printing options are also available. Load Sensed Process Timing uses an internal probe placed in the load to give guaranteed sterilisation times. If a printer is fitted load temperature is included on the printed record. ***** ASK FOR A QUOTE *****

Request for a quote

JUN-AIR / GAST GROUP LTD

United Kingdom

Gast piston air compressors and vacuum pumps are built to withstand the most rugged of operating conditions. With corrosion-resistant materials used for critical internal parts and Teflon filled rings, the design provides consistent flows throughout the service life of the compressor. All models are oilless and come in motor-mounted or separate drive styles.

Request for a quote

JUN-AIR / GAST GROUP LTD

United Kingdom

Gast diaphragm units require no lubrication making these units the perfect choice of installation for critical applications found in medical facilities, laboratory equipment, air sampling devices, portable gas detectors and dental equipment. With their outstanding performance, durability and flexibility, the varied range of Gast oil-less diaphragm air compressors and vacuum pumps are ideal for industrial applications too.

Request for a quote

J-FLEX RUBBER PRODUCTS

United Kingdom

Our Vac-Sil® Quality Membranes have been specifically designed for use as vacuum membranes for Solar/P.V. module lamination, plus the forming or thermo-pressing of vinyl foil veneers on furniture woodwork, composites in aerospace, F1 cars, marine, and other general products. We also provide a range of precision components, primarily for use in solar panel production. The range includes laminator vacuum seals, PTFE & Glassfabric belts (Stringer, Release, Vision, Transport etc) and also squeegee edge profiles for screen printing. Listening to our valued customers and their experiences, VAC-SIL® Quality Membranes have been polymer engineered to give users excellent thermal and mechanical properties, with good chemical resistance that leads to optimum service life. Visit our website for further information - advantages, benefits, areas of use, datasheets, faq's and installation instructions.

Request for a quote

FORVAC SERVICES LTD

United Kingdom

Forvac Services are experts in Industrial Vacuum andExtraction. We can service, maintain and repair any make, brand and model of industrial vacuum and dust extraction equipment to suit your budget. Servicing and maintaining your vacuum equipment, extends its working life, ensures optimum running efficiency and minimises the risk of a breakdown or mechanical failure. The environments and harsh conditions that Vacuums and extraction systems are subject to, such as damp conditions, low temperatures, high temperatures, long running hours or long periods of non-use, can all effect how the equipment runs. With Forvac performing regular tests & checks, removing and replacing consumable parts, changing vacuum seals, filters and fluids, we can ensure your vacuum equipment is in top shape for when you need it most. Forvac’s engineers are experienced in servicing all makes and models of industrial vacuums and LEV’s regardless of size, age or condition.

Request for a quoteResults for

Vacuuming - Import exportNumber of results

39 ProductsCountries

Company type

Category

- Autoclaves (8)

- Steam turbines (6)

- Vacuum cleaners - industrial (4)

- Lubricants, industrial (4)

- Bag filling machinery and equipment (3)

- Construction - Machines & Equipment (2)

- Custom packaging (1)

- Thermoforming, plastics - machinery (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Filtration, chemical (1)

- Additives, cement and mortar (1)

- Air compressors - Tools and accessories (1)

- Astronomy - instruments and equipment (1)

- Calibration equipment (1)

- Ceramics (1)

- Environmental clean-up - machines and equipment (1)

- Excavation - works (1)