- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- winding

Results for

Winding - Import export

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

The key to successful power generation through wind is efficiency, and industrial aluminum is playing a key role in making wind turbines lighter. Working together with our partners, we’ve created a smaller, lighter tower casing behind the rotor blades, as well as an innovative aluminum enclosure for the turbine’s generator that is lighter and more efficient than fiberglass composite housings used previously. This housing reduces fire risk thanks to aluminum’s incombustibility and helps cool the generator due to aluminum’s thermal conductivity, extending the aluminum enclosure’s functional life. It also maximizes the unit’s recyclability and protects the generator from lightning, since the aluminum acts as a Faraday cage and is non-combustible in the event of a lightning strike.

Request for a quote

GSW SCHWABE AG

Germany

Most Winding Lines process one single coil (single-layer winding). There are however also applications where multiple layers are wound: With this process, the rewinding Coil Reel (Rewinder for short) reverses horizontally and orderly puts one layer beside the other, creating one long coil. This will make sense when narrow slit coil materials of small weight and – depending on their thickness – usually short running lengths would require frequent changeovers. Here, a layer-wound coil provides much longer productive time. The “elongation” by the way is done by butt-welding the coil strip ends. We offer this complete technology – including our own end-joining equipment and an adapted servo layering axis for the Rewinder. For thick strips we build vertical straighteners to correct the frequently occurring camber defect.

Request for a quote

GSW SCHWABE AG

Germany

When you deal with industrial surface treatment and your expertise is the cleaning, brushing, polishing or coating of strip steel, you most likely do not want to spend any worries about the run of the material. That’s where our Winding Lines keep your worries away – because they take care of a safe run! They work with high tension and special monitoring and deflectors to do this, with the result of a clean wound beginning to end. The machine design thus calls for especially high drive power and precision expansion systems; even something so simple as the machine base is designed special to cope with the forces… To control the precision of one layer to the next, we utilize external edge controls and servo-drive the Reels for adjustment. This way we meet the typical low tolerances in this industry – after all, the coil is the product!

Request for a quote

TROTEC GMBH

Germany

Correct ventilation is not only an important prerequisite for a pleasant working environment, work protection provisions and regulatory directives make it mandatory in many areas.Proper room ventilation conducts harmful fumes and substances out of the room. The high pressure centrifugal fan TFV 100 is well-equipped for tasks such as transport of up to 4,000 m³/h air, even over longer distances and with back pressure.Owing to its extreme robustness, it is able to handle harsh working environments efficiently.The TFV 100 is available as standard model and additionally as a hire model. Benefits in practice: Extremely robust models with a high flow rate Splash proof type A (IP55) Deployment also possible in very dusty rooms Fan motor situated away from the main air flow Can be connected to suction as well as distribution ducts Stable characteristic curves and constantly high pressure

Request for a quote

GORACON SYSTEMTECHNIK GMBH

Germany

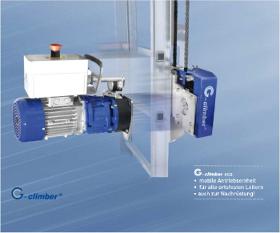

The Gclimber eco minimizes your efforts for the time consuming ascends and descends that come with service works. The advantages are obvious, the lightweight allinone mobile drive unit is easy to transport can be installed/deinstalled in a second to the basic unit comes with included Ebox

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GORACON SYSTEMTECHNIK GMBH

Germany

Save time when ascending to carry out maintenance and repair work to your turbine. With a Gservicelift you can complete a 100 meters ascent in approx. 5 minutes. Without a Gservicelift on the other hand, the arduous climb requires very much more time and demands a lot of strength. But this is not the only argument which clearly speaks for itself. Heavy tools and loads up to 400 kg can be transported comfortably with a Gservicelift, and all this with automatic transport, which does not take up the costly time of your personnel for the ascent. It is well proven, that wind power plants with an integrated ascent system have a higher level of availability and that the quality of your turbine maintenance will increase enormously.

Request for a quote

TAS SCHÄFER GMBH

Germany

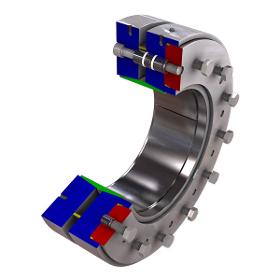

The main function of a shrink disc is the safe connection of a shaft with a hub by means of friction. For example, between a drive shaft and a transmission hollow shaft. The shrink disc generates a backlash-free connection by pressing the hub onto the shaft. This connection is mainly used to transmit torque. The shrink disc only provides the required forces, and transfers no forces or moments between shaft and hub by itself. It is not in the force flow. It is installed by sliding the shrink disc onto the hollow shaft and the subsequent tightening of the hydraulik system. By using conical surfaces the inner diameter reduces and the radial pressure is built up. After clamping the SHS will be locked mechanically and the hydraulic pressure will be removed. Due to this simple approach the SHS is suitable for repetitive clamping operations as they occur on a test bench, for example. Advantages of the SHS: – application-specific design/customization – relatively low pressure – very...

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

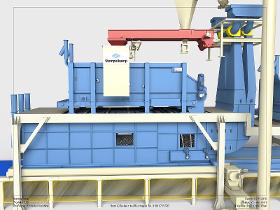

Wind formers convey especially ne particles to the top faces, thus creating ne board surfaces. This is because ner particles are conveyed much farther in an air ow than coarser ones. The forming system of a particleboard line usually comprises two wind formers located at its front and rear ends, as they form the top and the rear board surfaces. The ecoFormer SL by CMC Texpan has been developed from the traditional wind former technology. This was because we wanted to improve the separation of coarse and nes particles to create the optimal board surface. The air ow was simulated using the CFD method (Computational Fluid Dynamics) and optimised with respect to its aerodynamic behaviour thus improving its energy eciency. The ecoFormer SL can also be easily retrotted into existing mat formers, since its outer dimensions are compatible with the conventional wind formers oered by CMC. Features, function

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

System for the impregnation of electomagnetic coils, e.g. of electric motors, transformers, generators Impregnating in electricla engineering means applying an impregnating agent in gaseous or fluid form to a porous body in order to insulate it electrically, i.e. that reliable protection against electrical breakdown is provided even when the thickness of the insulating layer is small. For each application HÜBERS provides appropriate process. HÜBERS offers all relevant process variants including vacuum impregnation, vacuum-pressure impregnation and atmospheric impregnation and of these coupled with the use of the many different impregnating agents such as varnish, resin, oil, wax, gas etc. The processes of evacuating the parts prior to impregnation and if necessary of vacuum-drying the impregnated parts are matched to the properties of the parts and ensure that the agent wets the walls of the pores properly and fills the cavities completely.

Request for a quoteResults for

Winding - Import exportNumber of results

10 ProductsCompany type