- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- chemicals for the pharmaceutical industry

Results for

Chemicals for the pharmaceutical industry - Import export

BÜRKLE GMBH

Germany

With the thread adapter made of high-quality stainless steel 1.4301 (304) a pump, a drain cock or any other connection with thread G 2" (Whitworth pipe thread) can be screwed onto a container with G 1 1/2" thread. The thread adapter adapts and thus compensates for different thread shapes. The drum adapter ensures that decanting is liquid-tight; a seal made of ePTFE reliably seals the connection. The thread adapter made of stainless steel is electrically conductive and highly chemically resistant. It can therefore be used for filling solvents and other flammable liquids (e.g. alcohols, petrol, diesel etc.) as well as for weak alkalis and acids.

Request for a quote

BÜRKLE GMBH

Germany

With Novartos Multi double sampling, a double multi-point sample can be taken from multiple predefined sample zones. Depending on the lenght, four, seven or nine sample chambers are each fitted with two sample inserts for the double sampling.

Request for a quote

BÜRKLE GMBH

Germany

With Novartos Multi triple sampling, a triple multi-point sample can be taken from multiple predefined sample zones. Depending on the length, four, seven or nine sample chambers are each fitted with three sample inserts fot the triple sampling.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Probably the most hygienic way of controlling a flow of media is for the valve not to touch the media at all. The endless tube pinch valve operates according to this principle. The medium is channelled through a tube and the valve compresses the tube pneumatically. This constriction of the hose adjusts the flow. This principle means the valve is suitable for lots of critical applications in the chemicals, food and pharmaceuticals industries.

Request for a quote

RUDOLF GUTBROD GMBH

Germany

Seamless protection against corrosion EDLONTM PFA is used everywhere where high requirements are placed on corrosion protection. Challenging solutions for ensuring operational reliability as well as for technical equipment are required particularly in modern industry. Apparatus, pipes and containers have to be equipped with a noncorrosive finish. This factor is particularly important, among other things, in the areas: - Chemical and pharmaceutical industry - Semiconductor technology - Machine and apparatus engineering - Emission protection

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This transducer can be used anywhere thanks to its small size. Designed to work without a measuring chamber (uses a flush front diaphragm instead), this transducer is ideal for any measurements where the material to be measured may leave problematic residues. The range of suitable applications is even greater thanks to a choice of screw-on or weld-on adapters. Areas of use: Bottling plants, food industry Mixing facilities for the chemicals industry Pharmaceuticals Cosmetics industry Bioengineering These miniature pressure transducers are made entirely of titanium and therefore have outstanding resistance to corrosion. These convert the pressure-induced deflection of the diaphragm into a change in electrical resistance, which can be amplified, measured and processed by external electronic circuitry.

Request for a quote

RUDOLF GUTBROD GMBH

Germany

Flexible and versatile Due to the many outstanding characteristics both in a technical and economic respect, E-CTFE – used in coatings from Gutbrod – can be used very flexibly in many fields of industry. Particularly for the semiconductor, micro-electronics, solar panel and chemical industry, the pharmaceutical sector as well as for plant and mechanical engineering, Rudolf Gutbrod GmbH offers with coatings made with E-CTFE excellent corrosion protection for working equipment used in these fields.

Request for a quote

BÜRKLE GMBH

Germany

The bucket is made entirely of high-gloss polished stainless steel. The smooth surface of the stainless steel bucket makes it easy to clean. The rounded, movable handle makes it comfortable to move the bucket. The laboratory bucket is suitable for moving liquids and bulk materials properly, especially in the chemical, pharmaceutical or cosmetic industries, and in the food and animal feed industries.

Request for a quote

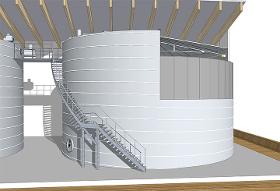

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP® Liquid Storage Tanks are fabricated with best material, as this is the most important quality factor. Municipal/industrial waste water and sludge or certain processing, intermediate and end products from the chemical, pharmaceutical and food processing industries set high requirements regarding the tank material, for example. LIPP offers a variety of materials, ranging from galvanised steel through the combination material Verinox to highalloy stainless steels. Variants waste water tanks sewage sludge tanks process water tanks storage tanks firefighting water tanks Mixing and compensation tanks buffer tanks stockable sludge tanks rainwater reservoirs Filtrate water tanks activation tanks Percolating filter tanks Landfill leachate tanks & Special tanks on request

Request for a quote

BÜRKLE GMBH

Germany

The all-layer drill is a special zone collector specifically designed for heavily compacted substances. Often it is very difficult or impossible with conventional zone collectors to penetrate media of this type and take a sample extending through all layers. By contrast, the drilling blades of the all-layer drill burrow easily and quickly to the required depth without expending any great force. This makes it easy to take samples of media, even those with high density, and every type of highly compacted powders and granulates. The all-layer drill thus allows you to take a representative sample through all the layers, even with greatly compressed media.It is ideal for larger containers, mixed containers, big bags, etc. in the building materials, chemical, pharmaceutical, food and luxury items industries.

Request for a quote

TROTEC GMBH

Germany

INDUSTRIAL DESICCANT DEHUMIDIFIER TTR 800Flexible all-rounder with 86 kg / 24h dehumidification performance for a variety of industrial fields of application Keeping humidity perfectly under control The maintenance-friendly desiccant dehumidifier TTR 800 not only guarantees high dehumidification levels even at very low dew points – with its stainless steel housing and an electrical control box in IP53 design, the corrosion-resistant TTR 800 even withstands adverse operational environments and is therefore ideally suited for a variety of dry keeping tasks or the production of dry air in the chemical, pharmaceutical and food industry as well as in the sector of mechanical engineering, but also to protect machines, inventory and buildings from corrosion, condensation and mould formation, for example in water processing facilities or electrical control centres. High Performance made in Germany

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

MADE FROM VERINOX STAINLESS STEEL OR GALVANISED STEEL WITH VOLUMES RANGING FROM 40 M3 TO 10,000 M3 Both industry and communities require professional solutions for plant and tank construction and for the storage and treatment of liquids, as well as flexibility in terms of size, choice of material and equipment. When constructing liquid storage tanks, the selection of the best material is an important quality factor. Municipal/industrial waste water and sludge or certain processing, intermediate and end products from the chemical, pharmaceutical and food processing industries set high requirements regarding the tank material, for example. LIPP offers a variety of materials, ranging from galvanised steel through the combination material Verinox to high alloy stainless steels. APPLICATIONS Waste water tanks Sewage sludge tanks Process water tanks Storage tanks Firefighting water tanks Mixing and compensation tanks Buffer Tanks Stackable sludge tanks Storage containers

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The core of the technology is the automated welding process, where the tank is simultaneously welded on the inside and the outside. Similar to the Lipp double fold technology the material will be pre formed by Lipp special forming machines and reinforcement ribs are applied for additional stability. By doing so, the wall thickness can be reduced which will have an economic effect on the overall material costs, without compromising structural stability. The process also enables the installation of roofs and other accessories at ground level, which reduces the risk of working at heights. The main application for the new Lipp welding technology is the drinking water sector. However, there is lots of market potential in the food and beverage industry, chemicals and pharmaceuticals as well as other industries. The black steel welding technology enables the installation of bulk silos with huge diameters and volumes, which is a significant improvement compared to today.

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Spiral conveyor are used wherever bulk solids have to be conveyed in a vertical direction. These robust spiral conveyors are suitable for conveying a host of bulk solids from various production processes. These can be fine to coarse-grained, as well as fragmentary bulk solids. Our spiral conveyors are used in the chemical, pharmaceutical and food industries, and also in the raw material industry. The use of additional fixtures enables products to be treated by thermal (cooling/heating) or technical (drying) processes. The bulk solids can be transported both upwards or downwards. The spiral conveyor, which offers large heat exchange surfaces from a small footprint through its coils, is an especially cost-effective solution. A laser-welded version, which offers maximum density in return for minimum heat admission during manufacturing operations (no welding stresses to cause delays), is playing an increasingly important role for these special units. Advantages & benefits energ

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Spiral conveyor are used wherever bulk solids have to be conveyed in a vertical direction. These robust spiral conveyors are suitable for conveying a host of bulk solids from various production processes. These can be fine to coarse-grained, as well as fragmentary bulk solids. Our spiral conveyors are used in the chemical, pharmaceutical and food industries, and also in the raw material industry. The use of additional fixtures enables products to be treated by thermal (cooling/heating) or technical (drying) processes. The bulk solids can be transported both upwards or downwards. Advantages & benefits energy and space-saving vertical conveying that's gentle on the material low-maintenance continuous operation easy-to-clean, hygienic design natural cooling of the bulk solid during the conveying process thanks to long dwell times bulk solids cooled either directly by air or indirectly by water through the use of double bottom or laser-welded Thermplate® bottoms as the spirals

Request for a quote

N&H TECHNOLOGY GMBH

Germany

Powder technology has a long history in various sectors such as the chemical, food, pharmaceutical and metal industries. Measuring the physical properties of powder is very difficult and each industry uses different assessment methods. The PD-600 powder measuring system is the further development of the PD-51. It can determine the physical properties of powder via resistivity. Powder materials of carbon products: Materials used for rechargeable battery electrodes, condensers and resistance material and insulating electronics / cokes / graphite / carbon black / carbon fiber / nano carbon, etc. Metal powder: Materials used for battery electrodes, thin film materials such as copper powder or ITO powder, for circuit board materials, for example conductive paste and electro conductive paint. Others: Thermoplastic powder, Printer toner, Magnetic material such as ferrite, food material, pharmaceutical related and automobile parts.

Request for a quote

EMPAC GMBH

Germany

Pactainer ED® offers a safe protection against electrostatic hazards. They can be used for bulk goods which contain or are located in areas where electrostatic hazards are at present. For example for the chemical industry. The conductive fabric of a Pactainer ED® conducts the charge of the bulk products to the hoist in connection with the grounded straps and prevents reliable every kind of discharge which displays a risk of fire. A micro-perforation of all coated components of the inside and outside of the container which are connected with each other, guarantees that they are able to discharge the electrostatic energy. This process has already been patented. Pactainer ED® offers further safety: If there is not direct grounding of the lifting loops, the carriers of the charge will be handed over locally and defined to the hoist. This is realized by a Carona-Effect. The Surrounding area is not subject to static charging. Fields of application: Transport and storage container for products produced by the chemical as well as paint industry for bulk goods of every kind – which own low minimum ignition energy. Main industries: Products for the chemical and pharmaceutical industry, wood and synthetic products, food, detergents

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GEPPERT RÜHRTECHNIK GMBH

Germany

Geppert Ruhrtechnik offers you a modern working environment with extensive additional services, individual training and further education opportunities as well as health offers. Whether you are a pupil, student, graduate or experienced professional: with us you can contribute your knowledge and skills in a targeted manner. We look forward to committed and passionate people who want to work together towards our goals.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRW series is suited for a wide range of applications thanks to shaft lengths of up to 3,000 mm and drive ratings of up to 5.5 kW. It has a standard output speed of between 10 and 200 rpm. Low installation height thanks to horizontal position of the drive. The agitator shaft of the GRW series geared agitator is directly mounted in the hollow shaft of the worm geared drive. Additional flanged or clamp couplings can be implemented upon request. The agitator shafts are balanced for concentric run after assembly of the mixer. According to the specific mixing task, the GRW can be supplied with matching mixing elements and various seals. Upon request, we supply the GRW series with frequency controlled drives.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The LRD series top-entry sealed agitator can be used for mixing in closed containers with a mechanical seal. It is designed with a coupling housing. The agitator shaft is borne in the bearing housing and the mechanical seal (single- or double-acting). The seal can be exchanged without dismantling the mixer from the tank (also in case of a side entry). Drives with shaft journals for LRD series: Three-phase motor Helical geared drive unit Parallel shaft geared drive unit Variable speed geared drive unit Helical bevel geared drive unit According to the tank size, the LRD series agitator is available in four different frame sizes. Shaft diameters of 30 mm to 90 mm and shaft lengths of up to 10,500 mm are feasible. Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3). Pharmaceutical version with FDA and GMP feasible.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GLP is a pneumatic top-entry series agitator that is used for homogenizing, dispersing, emulsifying and suspending in vessels and for viscosities up to 500 mPas for instance in wastewater treatment, chemical and cosmetics as well as in food industries. The agitator speed adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight. Power transmission via elastic coupling in the bearing housing. The agitator shaft has a double bearing in an aluminum housing separated from the drive. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air, expanding in the air engine cools the agitator drive. Includes filters, pressure reducers with pressure gauge that indicates the secondary pressure. Available with a vessel clamp to fix the GLP on a drum.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Side-entry agitator for mixing below liquid surface. The PDR is a simple side-entry-agitator for mixing below the liquid surface. The PDR is recommended for applications where low viscous liquids are mixed turbulently in high tanks and where a top-entry mixer would be too heavy due to its shaft length and –diameter. The sealing between the agitator and the vessel is done by means of a single-acting, internal mechanical seal which is lubricated by the mixing product or an additional fluid The agitator shaft is connected to the drive directly with a flange coupling inside the seal housing. By default, this agitator series is supplied with marine type propellers. Other mixing elements according to the mixing task upon request. Solutions correspond to those of the SPR, additionally mechanical seal in sealing housing. Other solutions for this series upon request.

Request for a quote

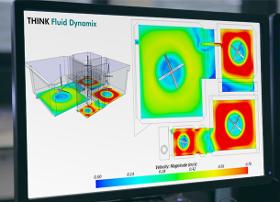

GEPPERT RÜHRTECHNIK GMBH

Germany

Challenging, customer-specific mixing technology solutions can be numerically simulated as early as during the planning phase, and the results analyzed. This means increased design confidence, high-quality solutions and, as a result, reduced project durations and costs. Our experts from THINK Fluid Dynamix® are specialists in the application of numerical techniques such as flow simulation in real time and artificial intelligence methods for automated optimization. This enables processes, such as stirring and homogenization, to be analyzed more accurately under consideration of all applicable process parameters, and complex tasks to be processed far more efficiently. These methods set entirely new standards in terms of design reliability and efficiency. Allow us to contribute to your success!

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Mixing technology is particularly wide-ranging in the food and drinks industry. From simple suspension and homogenization tasks in storage or transport containers, right through to complex reduction tasks, during which mixtures can be exposed to only the lowest of shear forces – you will find it all in the food and beverages industry. High food sensitivity and the multitude of fields of application for agitators require close process coordination with the customer, in order to design, construct, and finish the agitators in the optimal manner with the widest variety of mixing elements. In addition to its popular standard mixers, Geppert also has special stirring elements within its portfolio, capable of being extremely gentle on the product while remaining highly efficient. All agitators have the relevant food approvals and can also be supplied with clean room drives and special sealing systems.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

In the treatment of drinking water, whether done conventionally or via seawater desalination, agitators are used for rapid mix, precipitation and flocculation processes. Precipitation and flocculation processes require low shear, slow-running agitators. For pH adjustments and rapid mixing faster running agitators that can blend reactor content in a flash are required. Wastewater treatment also requires a multitude of application options for agitators. In anaerobic and anoxic tanks for nitrogen removal, slow-running agitators are used to suspend and homogenize activated sludge flocs. In aeration tanks, mixer/aerators can be used for efficient oxygenation and mixing. Where waste water is purified, sludge is generated. This sludge is generally conditioned using polymers, dewatered, and then digested in anaerobic sludge digesters to generate biogas. Special agitators are required for both polymer introduction and for digested sludge mixing.

Request for a quote

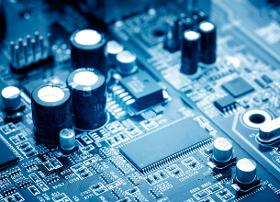

GEPPERT RÜHRTECHNIK GMBH

Germany

In the manufacture of semiconductors, agitators are mainly used in conditioning of polishing and cutting suspensions, etchants and other auxiliary chemicals, cleaning solutions, or in chemicals recycling. Requirements placed on stirring systems are extremely demanding. Almost always, clean room conditions prevail, meaning that drives and seals must be designed with no abrasion or leakage. Parts that come into contact with the medium, such as the shaft and stirring element, often have to be produced with metalfree surfaces due to the aggressiveness of the media and the purity requirements. Also in this area, Geppert Ruhrtechnik can look back on a very successful history. All well-known chip manufacturers belong to our client base, as well as the manufacturers of the specialty chemicals used in this field. In addition, our agitators are used in broad solar cell production areas.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Geppert Ruhrtechnik GmbH has been a certified manufacturer of explosion-proof agitator drives since 2003. This made us one of the first companies to develop and produce ATEX-compliant agitators. Our agitators are certified to ATEX Directive 2014/34/EU (formerly Directive 94/9/EC) in gas or dust explosion-proof designs. In addition, the majority of agitator styles have type test certificates for explosive zone 0, and can be used in applications in which an explosive atmosphere, arising from a mixture of air with flammable substances in the form of gas, vapor, or mist, is present. We offer ATEX-compliant controls for our explosion-proof design agitators. Talk to us and make use of our many years of experience on the topic of explosion protection. We will be happy to assist you! Our services in the field of explosion proof agitators

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

OUR IN-HOUSE TEST PLANT AND LAB In order to ensure the high quality and long service life of our agitators, we have set up an in-house plant for testing our agitators. At the end of the manufacturing process, all of our agitators undergo a specific test procedure with a final test run. Here, we can test agitators with a shaft length of up to twelve meters. When designing our agitators, we use fluid mechanics simulations in our in-house laboratory. All Geppert mixing systems are delivered with O&M Manual and worldwide technical service.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

For over 50 years, Geppert Ruhrtechnik has stood for quality and reliability in agitator construction. We develop, manufacture, and distribute innovative agitators for all applications in the materials processing industries, such as the chemical, pharmaceutical, biotechnology, and food industries, as well as in water and wastewater treatment. Our many years of experience make us the perfect partner for both standard and special applications. When selecting and designing our agitators, we draw on our many years of experience, internal databases, and state-of-the-art tools (such as FEM, Finite Element Method, and CFD, Computational Fluid Dynamics), as well as our own fluid mechanical laboratories. This means we always provide you with the optimal solution. In addition to our agitators, we manufacture suitable containers and stands for stand-alone, wall mounted, and mobile designs. We can implement these in your plants, taking into account any its specific requirements.

Request for a quoteResults for

Chemicals for the pharmaceutical industry - Import exportNumber of results

109 ProductsCountries

- Germany (109)

- Bonn, Düsseldorf and North Rhine and Westphalia (7)

- Frankfurt am Main and Hesse (45)

- Hamburg and region (4)

- Hannover and Lower Saxony (9)

- Kiel and Schleswig-Holstein (3)

- Mainz and Rheinland-Pfalz (1)

- Munich, Nuremberg and Bavaria (7)

- Potsdam and Brandenburg (3)

- Schwerin and Mecklenburg-Vorpommern (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (28)

- Weimar and Thuringia (1)

Company type

Category

- Chemical and pharmaceutical industry - machinery and equipment (61)

- Pharmaceutical industry - machinery and equipment (6)

- Weighing and dosing equipment (3)

- Gear pumps (2)

- De-humidifying equipment (2)

- Tanks, metal (2)

- Air purification - equipment and systems (1)

- Chemicals and pharmaceuticals - packaging machinery (1)

- Storage tanks (1)

- Air filtration equipment (1)

- Aluminium foil for packing (1)

- Bottling and filling - machinery and equipment (1)

- Buckets and grabs, crane (1)

- Chemical industry - machinery and equipment (1)

- Dosing pumps (1)

- Fastening devices - machines for production (1)

- Industrial cabling (1)

- Magnets (1)

- Measurement - Equipment & Instruments (1)

- Pharmaceuticals - basic and auxiliary products (1)