- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- part cleaning

Results for

Part cleaning - Import export

PERO AG

Germany

The ROTIMAT 3U is a universal machine for the cleaning of a wide range of parts. It guarantees maximum technical cleanliness, irrespective of the degree of contamination of the parts. It is equipped with two baths for cleaning, and subsequent iron phosphatising/rinsing, wherby each bath has its own pump cycle. The ROTIMAT 3U can be operated with standard baskets or customised parts carriers. Cleaning with aqueous media (acidic, neutral or alkaline) 660 x 480 x 300 mm 4 x 480 x 320 x 200 mm Spray cleaning for extra demanding applications Catering for wide range of parts Suitable for any cleanliness level from light dirt removal to high technical cleanliness Available as 2bath unit with loading of the unit via Manual loading table Manual charging unit Automatic charging unit

Request for a quote

PERO AG

Germany

After cleaning, parts are normally dried. Efficient drying keeps cleaning medium consumption low, and thus helps protect the environment. In addition, drying effectively prevents recontamination and corrosion. When drying tightly packed or porous parts, drying at atmospheric pressure might not be effective, so that drying under vacuum is the only option.

Request for a quote

PERO AG

Germany

The parts are immersed in the wet medium. Dirt is dissolved from the surface by the heated wet medium. By moving the parts while immersed, cleaning is assisted by a mechanical effect. In industrial parts cleaning, the surfaces are then normally rinsed and dried.

Request for a quote

PERO AG

Germany

The wet medium is sprayed through nozzles onto the surfaces of the parts. Particles are removed from the parts by kinetic energy, and then washed away. The cleaning result is primarily determined by the position and shape of the nozzles, the spray pressure and the volume of media applied to the parts. In industrial parts cleaning, the surfaces are then normally rinsed and dried.

Request for a quote

PERO AG

Germany

The R0 has been specifically designed for intermediate and final cleaning of small and extra small parts. Thanks to its universal process technology, the R0 offers operators unrivalled cleaning performance in an extra compact machine. The R0 can be transported through door clearances of as little as 1,000 x 2,000 mm. Depending on the model, the cleaning unit can be loaded from the long or from the short side. Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit Top quality cleaning in compact unit Short cycle times High throughput Available as 1 and 2bath unit with loading of the unit via Manual charging unit Automatic charging unit

Request for a quote

KORRODIN GMBH & CO. KG

Germany

Pre-assembled assemblies for the clean room A kit consisting of parts that we have cleaned very finely is put together appropriately for clean room conditions and packed airtight. In this way, the assemblies can be brought directly to the appropriate production site without having to be unpacked or cleaned beforehand.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

ViscoTec 1C dispenser vipro-PUMP ▪ Volumetric dispensing, regardless of viscosity ▪ For low to high viscosity materials ▪ Particularly suitable for highly abrasive, filled or shear sensitive materials ▪ Modular scalability of volume flow within the model range ▪ Programmable suck-back prevents dripping or stringing of product ▪ Material entry with Tri-Clamp DN 20 connection for optimized material flow and fast coupling of material supply ▪ Locking ring for easy and fast disassembling of drive unit ▪ Drive unit connection with optimized power transmission free from clearance ▪ Optimized dispenser bracket for easy adjustable mounting ▪ Long lifetime due to low wear ▪ Different rotor and stator materials available ▪ Continuous dosing, pulsation free ▪ Interior non-stick coated ▪ Dividable rotor assembly for easy & fast replacement and low spare part costs ▪ Easy cleaning and maintenance due to quick assembly and disassembly options

Request for a quote

PACA GMBH

Germany

The Paca Component Cleaner is a professional, fast cleaner. Versatile and effective, it is universally usable and largely biodegradable. It removes oil and grease, hardened residues and brake fluid. It degreases glued surfaces and sealing surfaces, cleans com- ponents efficiently and safely, dries quickly and leaves no residue. CO2 propellant AOX-free Fields of application The automotive industry, construction machinery, agricultural machinery, tools, sport, hobbies, home and garden, office Usage Check the rubber and plastic parts for compatibility beforehand, as Paca Component Cleaner may cause lacquers to corrode. Spray Paca Component Cleaner at close range onto the part which needs cleaning, repeating this step if there is excessive contamination. Allow the solution to dry, then wipe over with a clean cloth. Always shake Component Cleaner well before use! Batch quantity/Packaging units Batch quantity: 150ml and 500ml spray cans Packaging units: 24 150ml cans or 12 500ml...

Request for a quote

PERO AG

Germany

The R5 units from PERO are able to clean large quantities as well as large workpieces in a highly efficient manner with short cycle times. Thanks to its large-capacity processing chamber, the R5 is particularly popular with companies in the automotive and aerospace industries, as well as those of forming plants, heat treatment specialists and contract cleaners where high cleaning capacity is a must. Suitably dimensioned tanks guarantee excellent degreasing and cleaning results in single-shift and multiple-shift operation, even at high throughput rates. Cleaning Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit Highlights - High flexibility - Maximum throughput - Unrivalled cleaning quality Availability Available as 1- and 2-bath unit with loading of the unit via - Hall trolley - Pallet truck - Automatic charging unit

Request for a quote

PERO AG

Germany

The R4 from PERO is able to clean large quantities of parts as well as large workpieces in a hgihly efficient manner with short cycle times. With its high cleaning capacity, the R4 meets the needs of companies in the automotive and aerospace industries, as well as those forming plants, heat treatment specialists and contract cleaners. Thanks to customised parts carriers and logistics concepts, the R4 offers reliable degreasing and cleaning results for emobility suppliers. Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit Suitable for 1/2 EURO wire mesh boxes Suitable for largesize workpieces Efficient cleaning to high cleanliness standard Available as 1 and 2bath unit with loading of the unit via Hall trolley Pallet truck Automatic charging unit

Request for a quote

PERO AG

Germany

PERO Centre of Competence in Königsbrunn in a dedicated area measuring 1,100 m², there are more than 15 separate units available for parts cleaning tests. PERO Centre of Competence in Königsbrunn in a dedicated area measuring 1,100 m², there are more than 15 separate units available for parts cleaning tests. In manufacturing plants, parts cleaning is one of the key activities along the production line. The productivity of a manufacturing plant is determined by the availability of the cleaning technology. At the PERO Centre of Competence, PERO specialists work together with operators to develop the cleaning method that best suits their needs.

Request for a quote

PERO AG

Germany

Bring your dirty parts to the PERO Centre of Competence. The cleaning experts of PERO will advise you in how these parts can best be cleaned. You can then perform a series of tests in order to identify the optimised cleaning process for your parts. Cleaning tests free of charge, using your own parts; including documentation Evaluation of cleanliness analyses Gaining new insights into own cleaning processes

Request for a quote

PERO AG

Germany

The less space between the parts, the more difficult it is to remove particles and contaminants with a wet medium. The handling of the parts and the design of the parts carriers are therefore important aspects for optimised cleaning. Wet media are used in units with 1, 2, 3 or even more baths where the parts are cleaned and rinsed, and, if required, treated with preservation agents.

Request for a quote

PERO AG

Germany

In industrial parts cleaning, wet media are used in 70 to 90 % of all cleaning processes. Wet media include aqueous solutions – similar to detergents we use to wash our dishes or laundry – as well as nonaqueous solvents. For each cleaning task, project engineers must choose the best wet medium, taking into account ecological and economic considerations. Workpieces and parts are produced in finetuned production processes that often require the use of special consumables and process chemicals. Parts are generally made from specific materials, and their contamination after machining is determined by the processes they have undergone. When assessing the environmental impact of cleaning media, one sometimes comes to surprising conclusions. First of all, the energy input and use of resources must be assessed.

Request for a quote

PERO AG

Germany

The modular, preassembled PERO R1 units are available at short notice for your specific application The cleaning units of the R1 series are renowed for their high performance. They offer short cycle times with reproducible cleaning results. The tried and tested process technology behind the R1 meets the highest quality standards in parts cleaning. Operation under vacuum protects the medium, reduces energy and solvent consumption and allows for short cycle times. Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit 480 x 320 x 200 mm or 530 x 320 x 200 mm (std.) 530 x 365 x 250 mm (A chamber) Fast and economical High performance Reproducible cleaning results Available as 1, 2bath and 3bath unit with loading of the unit via Manual charging unit Automatic charging unit

Request for a quote

PERO AG

Germany

Sound waves generated by an oscillator agitate the wet medium. This leads to cavitation bubbles that implode at a high frequency and result in hydraulic impacts. These impacts combined with microflows flush particles and pigments off the parts. The costs of ultrasonic cleaning are primarily determined by the processing time. Low ultrasonic frequencies remove coarse dirt, while high ultrasonic frequencies are used to eliminate fine dirt from parts.

Request for a quote

PERO AG

Germany

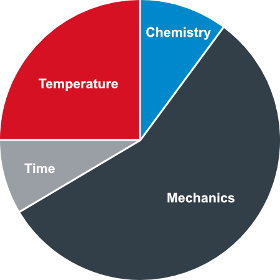

The cleaning process must be designed to eliminate specific contaminants and particles from machined workpieces and parts in order to achieve the required technical cleanliness. For the wet cleaning of parts, the four parameters of the Sinner's Circle need to be combined and adjusted for optimised efficiency. PERO units offer efficient cleaning mechanics and reliable process control. According to the Sinner's Circle, the cleaning result is determined by four basic variables. By adjusting and combining these interrelated variables, it is possible to optimise any cleaning process. Good mechanical design of a cleaning unit optimises the mechanics of the process, which generally means that cleaning is completed in less time and with less resources.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PERO AG

Germany

The TWT combines a number of cleaning methods in a single unit. Through immersion any spray cleaning with alkaline, neutral or slightly acidic aqueous media, it caters for a wide range of parts and meets even the most stringent requirements regarding technical cleanliness. The cleaned parts are dried under vacuum for extra fast processing. All machine components that come into contact with media are made in stainless steel, allowing for the use of fresh and demineralised water.

Request for a quote

PERO AG

Germany

The ROTIMAT 1A has been designed for the spray cleaning of all workpieces that can be placed in the sturdy rotating basket. After production or repair, the workpieces and parts are cleaned with a hot aqueous cleaning medium that is sprayed onto the parts from all sides. The unit can be loaded from the front, or from the top, using lifting gear. The compact machine is equipped with four castors for easy relocation within the factory. Cleaning with aqueous media (acidic, neutral or alkaline) Universell cleaning unit for many different workpieces Compact portable unit with castors Drying without external heat input, or with optional extractor fan Available as 1bath unit with loading of the unit via Manual loading

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Fränkische Industrial Pipes GmbH & Co. KG considers itself an international partner with the automotive industry, the home appliance industry and the machinery industry in developing technically complex corrugated tubes, corrugated tube systems, protective hoses and fluid transport conduit systems. Our custom blow molded parts for air ducts, clean air, recycled air are 3D blow molded and suction blow molded. They are 100 percent leak-proof and guarantee consistent wall thickness. They provide high stiffness combined with high mechanical strength and have been designed to match the different nominal sizes and inside diameters of our corrugated tubes with cuffs. Our corrugated tubes with integrated containers have been designed to reliably collect and store liquids without running the risk of leakage. The product can be custom-tailored in different nominal sizes, types of containers (with and without lid) and cuff sections to meet customers specifications.

Request for a quoteResults for

Part cleaning - Import exportNumber of results

21 ProductsCompany type