- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heat recovery systems

Results for

Heat recovery systems - Import export

ANTHERMO GMBH

Germany

Heat recovery with the help of heat exchangers In industry, waste heat occurs at many points in the production process, which is often released into the environment without being used. In many cases, energy is even used to cool the waste heat flows from production so that they can be released into the environment. Heat exchangers (also called heat exchangers) are used for heat recovery so that the waste heat generated in the production process can be used again in the company. Gaseous or liquid media Waste heat can be in the form of gaseous media (e.g. warm exhaust air, steam, exhaust gases, etc.) or in the form of liquid media (e.g. hot water or other liquids). With the help of heat exchangers, the waste heat can be recovered from both gaseous and liquid media and then made available to the production process at a suitable point as energy in gaseous or liquid media. This process is known as energy recovery or also as heat recovery.

Request for a quote

ALNOR VENTILATION SYSTEMS LTD

Poland

The heat recovery ventilation unit HRU-PremAIR has an air flow capacity of 350 m3/h at 100 PA. Designed to use aluminum heat exchangers and EPP self-supporting casing. Heat exchangers that are used depend on the model, such as counterflow aluminium heat exchanger (HRV) or counterflow enthalpy exchanger (ERV).

Request for a quote

ALNOR VENTILATION SYSTEMS LTD

Poland

Heat recovery ventilation unit HRUPremAIR is a modern device with 350 / 450 or 500 m3/h air flow @ 100 Pa. Unit is made from cutting edge materials aluminim heat exchanger and EPP selfsupporting casing. Depending on the model, following heat exchangers are used counterflow aluminium heat exchanger (HRV) or counterflow enthalpy exchanger (ERV). Enthalpy exchangers in HRUPremAIRE series have a polymer membrane that effectively recovers heat and moisture from the extract air. Such membrane works like a membrane in waterproof trekking clothing i.e. it allows water vapour to pass through, but not liquid water and air. The enthalpy exchanger also blocks the transfer of odours, bacteria and spores. The exchanger material, is needless to say, primarily optimized for maximum heat recovery efficiency. PremAIR air handling units optionally can be equipped with the Constant Flow system, whose task is to maintain a constant air flow in the installation.

Request for a quote

ALNOR VENTILATION SYSTEMS LTD

Poland

The FLX-PLO-EPP-F plenum boxes are part of the FLX-REKU air distribution system designed for domestic mechanical ventilation systems, so-called the MVHR system, to which an air valve and FLX-HDPE / FLX-HDPE-A ducts with a diameter of Ø75 are mounted.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

With heat recovery systems in industrial environments, the heat contained in the exhaust air is efficiently used to heat air or water. A very efficient use of this energy is the preheating of dryer supply air. The heat can be used continuously here. This warm exhaust air is also suitable for heating buildings. Depending on the local conditions, both airtoair heat exchangers and airtowater heat exchangers can be used for this purpose. The heated air, in turn, is fed into production and factory halls or other areas of the building. This type of supply air heating is particularly costefficient. Such recovery systems also have a positive effect in terms of environmental compatibility. Waste heat from industry that is harmful to the climate is no longer released into the environment but remains in the cycle of the production process or building heating. The systems are also suitable for cooling rooms when outside temperatures are hot, for example.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Our heatrecovery systems heat fresh air with the thermal energy of exhaust air and can be placed directly on top of a stenter frame. This system can also be retrofitted for older dryers. The benefits are high energy savings which allow payback periods of less than two years, depending on the layout and process, highly efficient platetype heat exchangers with nonstick coating, optimum ease of maintenance by removable drawersized heat exchanger modules, external cleaning of the heatexchangers in a hot water bath with ultrasonic cleaning equipment, high power density, higher than with usual tubetype heatexchangers.

Request for a quote

LIQUOSYSTEMS GMBH

Germany

Cooling tube for fast and flexible cooling. Made out of high quality V4A stainless steel spiral tubing for efficient heat transfer. Unlike conventional corrugated pipes, the smoother shape of the (spirally-shaped) surface improves heat transfer and cleaning.

Request for a quote

REFRA, UAB

Lithuania

Refra buffer tanks with an integrated heat recovery are an innovative and highly cost-effective systems that are rapidly gaining popularity in commercial sector. A special buffer tank with a built-in double wall heat exchangers acts as an intermediary to collect and utilize excess heat. This system is characterized by the fact that it allows the heat generated by the operation of the refrigeration equipment to be used for other heating purposes in the same building. By installing one system, the customer gets heating and cooling at once, as well as huge savings in energy and equipment costs. These tanks are available with an anti-legionella kit, which prevents the spread of bacteria and is therefore particularly important for domestic water systems. A special 6 or 9 kW electric element can be added for additional water heating that will heat the water in the tank to the required temperature.

Request for a quote

ERALP BOILER & ENERGY TECHNOLOGIES

Turkey

Waste heat boilers produced from alloy, high alloy and stainless steel according to physical properties, content, flow and process conditions of gas are designed and produced to be Water Pipe Waste Heat Boilers and Flame Smoke Pipe Waste Heat Boilers. In the gas engines and in the gas turbine, the high-temperature waste gas resulting from the combustion is evaluated by producing waste heat boilers and steam, which increases the overall system efficiency. Waste heat boilers designed and produced for heat recycling are to be heated according to flow and process; Industrial facilities Power Plants In cogeneration plants It is used in organic rankine conversion systems (ORC). These heat recovery steam generators (HRSGs), which are used to convert steam back into electricity from steam turbine back-burning gas, are also called HRSG (Heat Recovery Steam Generator) in the Combined Cycle Power Plant (CCPP).

Request for a quote

NPO ORION LLC

Russia

The module of a warm plinth "Orioten" is created for heating of the room and can be used as the main (consists of several modules), and additional heating of the room. Available colors: white, brown, gray

Request for a quote

HAMON

Belgium

Hamon Deltak’s forty-plus years of engineering experience and advanced mechanical capabilities give us the confidence to tackle any unique customer request. With over 1200 waste heat recovery units to date, HDI has unmistakable expertise in this industry.DI offers a few different types of waste heat boilers, watertube and firetube.Watertube Boilers:Designed similar to our HRSGs, but are refractory lined, and typically have tubes that can handle dirtier gasses than in the power generation industry.Applications that would use a watertube waste heat boiler are typically refinery processes such as: -Fluidized Catalytic Cracking,-Coke Calcining,-Sulphur Recovery

Request for a quote

HAMON

Belgium

Hamon Deltak Inc. has been designing and fabricating Combined Heat and Power (CHP) Waste Heat Boilers (WHB) since 1977.Complex Systems Require Custom Solutions.CHP systems provide their greatest return on investment when energy usage from the waste heat boiler is maximized. CHP waste heat boilers are no longer off the shelf products. It is critical to design a properly sized WHB for the greatest efficiency possible. Let the most experienced team in the industry provide an optimal WHB design for your facility. The value of a properly executed CHP project is dictated by more than price alone.

Request for a quote

HAMON

Belgium

Hamon Deltak, Inc. has had the opportunity to engineer and manufacture more than 500 HRSGs in the last 40 years. From big to small, with different levels of complexity, our engineers have experience with the type of project you need. What sets HDI apart is the level of care that goes into engineering each HRSG project, and since half of our engineers have been at HDI for more than 15 years, it's easy to see why our HRSG standard is synonymous with quality.

Request for a quote

BROX MAKINE SANAYI VE TICARET LTD. STI.

Turkey

Waste heat recovery boiler, in steam, water or thermal oil, fire-tube or water tube, designed as per exhaust gas parameters, turnkey project flexible solutions.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The thermal incinerator (TI for short) is a system which converts gas or vaporous pollutants found in exhaust gas into non-polluting compounds by way of direct combustion. This machine is characterized by: The thermal incinerator (TI for short) is a proven and robust plant for the conversion of organic pollutants (VOCs, etc.). Today it is used especially for processes which involve high exposure to condensation or dust, or for specialized solutions requiring greater heat recovery potential. An example of this would be exhaust gases containing plasticizers or siloxane. The modular design of the combustion chamber and heat exchanger especially is conducive to servicing and cleaning compared to other designs. The polluted air is forced by means of a centrifugal fan into the tube bundle heat exchanger where it circulates around the tube bundle in a cross-current fashion. The heat exchanger can be designed for an efficiency of up to 70%. The pollutants are converted in the combustion chamber at a temperature of around 760 °C. After extensive heat transfer to the raw noxious gas, the cooled clean gas leaves the plant, where it can be supplied to various heat recovery systems (or a combination of several). The auxiliary burners can be operated with natural gas or propane or light heating oil.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Environmentally friendly generation of steam from available waste heat — The perfect addition to energy concepts involving combined heat and power generation — High efficiency through efficient tubular heat exchanger and thermal insulation — Additional efficiency gain thanks to optional integrated economiser — Matched, modular system for easy planning and fast installation

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Conventional fired heat generator with additionally integrated smoke tube pass for waste heat utilization — Environmentally friendly generation of thermal heat or process heat through the utilisation of waste heat sources — High supply reliability thanks to self-firing function — Robust, reliable and durable — Versatile design for use with different fuel types and as a multi-fuel firing unit (oil, gas, biogas, hydrogen) — Ideal for combination with combined heat and power units or gas turbines

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TECHNOTRANS SOLUTIONS GMBH

Germany

A complete centralised cooling plant, including the required peripherals, can be set up in the absolute shortest possible time at the subsequent place of installation and is immediately ready for use by means of prefabrication and installation in a container. This way, the otherwise high investments for an operating building, the costs for installation and start-up of the plant are reduced. Container cooling plants almost have no limitations in terms of their capacity and variety of possible combinations. They are supplemented by peripheral systems such as water treatment and water preparation systems or compressed air compressors. A series of different cooling systems and the combined systems composed of these units are primarily available: Chiller Heat pump systems for heat recovery Cooling tower combined with a KU system as a closed, clean cooling circuit Air heaters for direct recovery of heat hermeticool-units hermeticool hybrid-units

Request for a quote

AF COMPRESSORS

Belgium

Scope of delivery Heat Recovery System 90°C including : Specific double cooler 2 nd and 3 rd stage. Special design for 1 st stage intercooler. Internally adapted water circuit. The compressor runs with a smaller water pump with frequency inverter,”VSD”. The compressor runs with a smaller separate water cooling system. External Heat Exchanger Kit for easy connection to the customer system. Features & benefits Features based on L 5 model /200 kW. Temperature : 30-35°C water in – between 85-90°c water out. Power : heat recovered @ 40 bar on load is ca.160 kW = ca.80% of the shaft power. Water : Available quantity of water for Heat Recovery is ca. 2 m³/hour water flow for L5 model. Due to HR a smaller separate cooling system is used for the complete compressor system. One year operation, 6000 running hours @ 0.05 € / kW Heat = 48.000 € savings. Scope of delivery Heat Recovery System 40°C including : External skid Heat Recovery System 40°C with stainless steel plate...

Request for a quote

ALNOR VENTILATION SYSTEMS LTD

Poland

The smog filter is designed for effective filtration of the socalled particulate matter. The PM2.5 and PM10 particles are the main component of smog, which have an optical diameter of 2.5 and 10 μm (micrometers). The filtration efficiency (removal) of PM2.5 particles reaches up to 73%, and PM10 particles up to 81% (according to tests carried out with a dust particle measuring device). The smog duct filter consists of a sealed filter box and two filters prefilter and smog filter. It is recommended to install a smog filter on the supply ducts in domestic ventilation and heat recovery systems. In the MOCarzCA version prefilter I3 was replaced by an activated carbon prefilter (or activated charcoal). The main purpose of using such a material is deodorization of air and preliminary cleaning of dust and gaseous pollutants. Activated carbon has a huge adsorption surface, which effectively "binds" on its surface particles of pollutants, bacteria, hydrocarbons.

Request for a quote

ALNOR VENTILATION SYSTEMS LTD

Poland

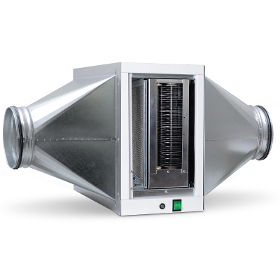

Electrostatic precipitator eMOCarz was design for residential buildings. Compact size and exceptionally low pressure drop makes it suitable for residential heat recovery systems, with little impact on system performance. The filtration efficiency of ePM1 and ePM2.5 particles, the main component of smog, is as high as 95%. Polluted air initially passes through a steel mesh prefilter (which retains larger fractions), then is positively ionized in an electric field due to the “crown discharge” effect. In the last stage, the previously charged particles, are pulled by electrostatic force toward horizontally mounted aluminium plates (electrodes) and build up on their surface. Electrostatic filters (precipitators) have low power consumption (only few Watts), long service life and most of all there’s no need to exchanged dirty (clogged) filters. It is enough to clean in with water and detergent once or twice a year. There is a led status indicator on the casing.

Request for a quote

ALNOR VENTILATION SYSTEMS LTD

Poland

The insulated manifold box is used for mechanical ventilation systems with heat recovery (MVHR). MVHR manifolds do not need to be insulated onsite thanks to the insulating properties of EPP. Manifold boxes are designed for distribution of 75mm semi-rigid ducting around. The number of connectors varies depending on the user's specifications: 6-13 connection spigots.

Request for a quote

ALNOR VENTILATION SYSTEMS LTD

Poland

Round ventilation duct made of expanded polypropylene (EPP). The most important features of the product are rigid construction, low weight, easy assembly and good thermal insulation. EPP ducts, used, for example, as sections of the supply and exhaust ventilation systems with heat recovery, do not require additional insulation. The system eliminates the formation of thermal bridges. Ducts na fittings do not require additional couplings. Lenght EPP ducts 1 m sections Diameters 125, 160 and 200 mm. Wall thickness 43 mm Thermal conductivity 0.039 W / m*K Airtightness class ATC2 (old D) @110Pa acc. to PNEN 17192201901

Request for a quote

ALNOR VENTILATION SYSTEMS LTD

Poland

Round ventilation duct made of expanded polypropylene (EPP). The most important features of the product are rigid construction, low weight, easy assembly (integrated malefemale coupling) and good thermal insulation. EPP ducts, used, for example, as sections of the supply and exhaust ventilation systems with heat recovery, do not require additional insulation. The system eliminates the formation of thermal bridges. Lenght EPP ducts 1 m sections Diameters 125, 160 and 200 mm. Wall thickness 15 mm Thermal conductivity 0.039 W / m*K Airtightness class ATC2 (old D) @ 90Pa acc. to PNEN 17192201901

Request for a quote

EUROPEM

Belgium

Most of the Europem incinerators are equipped with waste heat recovery systems. Europem has supplied a wide range of waste heat recovery installations including steam boilers, thermal oil boilers, gas-liquid heat exchangers, gas-gas heat exchangers, bath heaters and air heaters. All waste heat recovery installations are tailored to the needs of the client and the optimal design of the overall installation. Our range of waste heat recovery systems include: -Fired tube boilers with or without economizer. Single pass and multi-pass systems can be supplied Boilers can be equipped with an on-line cleaning system to allow operation with dust-loaded (flue) gases Boilers up to 30 MW capacity can be supplied with pressures ranging from 10 to 22 bar. - Single pass and multi-pass systems can be supplied -Water tube boiler boilers with or without economizer Superheated or saturated steam Horizontal or vertical boiler arrangements Bundles in refractory lined casing or with membrane walls Capacities up to 40 MWth with pressures ranging from 15 to 65 bar. – Thermal oil boilers – Bath heat exchangers – Air – flue gas tube and shell heat exchangers – Flue gas – liquid tube and shell heat exchangers – Air heaters Heat exchangers can be manufactured in carbon steel or high grade alloys e.g. Duplex, Hasteloy, Inconel, AISI 316, AISI 304.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

The correct air budget is an often underestimated quality factor in surface treatment technology. Where heating, cooling, movement and filtration is concerned, a great deal of energy can be saved with innovative solutions. Supply air systems replace extracted air quantities and ensure: Supply and exhaust air systems Supply air systems ensure draught-free and clean ventilation of work rooms, while high-efficiency exhaust air systems with fans and filter systems are responsible for the necessary air exhaust. This takes place with the lowest possible use of energy and with the longest possible intervals between maintenance and cleaning operations. We also offer intelligent air solutions for dryers, pre-treatment plants and cooling zones. Heat recovery A further important point is heat recovery. We can achieve up to a maximum of 80% heat recovery with the most diverse systems. Cross-current, rotary heat exchanger, heating pipe or circulatory systems – they all have their own advantages and efficiencies, which we integrate according to requirements during the planning of the plant.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

The correct air budget is an often underestimated quality factor in surface treatment technology. Where heating, cooling, movement and filtration is concerned, a great deal of energy can be saved with innovative solutions. Supply air systems replace extracted air quantities and ensure: Supply and exhaust air systems Supply air systems ensure draught-free and clean ventilation of work rooms, while high-efficiency exhaust air systems with fans and filter systems are responsible for the necessary air exhaust. This takes place with the lowest possible use of energy and with the longest possible intervals between maintenance and cleaning operations. We also offer intelligent air solutions for dryers, pretreatment plants and cooling zones. Heat recovery A further important point is heat recovery. We can achieve up to a maximum of 80% heat recovery with the most diverse systems. Cross-current, rotary heat exchanger, heating pipe or circulatory systems – they all have their own advantages and efficiencies, which we integrate according to requirements during the planning of the plant.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

Exhaust air purification and heat recovery systems are generally not standard applications, even if individual assemblies are now modular. We have made it our goal to offer our customers the best solution for their task. To do this, we take a step back with our customers in order to gain an overview of the whole. Together we look at how the exhaust air is generated and try to start our concepts right at the point of origin. Only then can we decide which exhaust air system is the most economical when considering the total cost of ownership and compliance with the limit values. Should an extended consideration be necessary, we can accompany you from basic to authority to detail engineering. In addition, it is not uncommon for pilot tests to be offered, which lead to the later real scale of the systems by means of scaleup. With these consulting and engineering services, we offer you a manufacturerindependent package with which you can make the right decision for your company.

Request for a quote

HAMON

Belgium

Besides primary measures, Selective Catalytic Reduction (SCR) is the most effective method for controlling nitrogen oxide emissions (NOx) from combustion sources. It is a commercially proven flue gas treatment technology that has been demonstrated to remove over 98 percent of the NOx contained in combustion system exhaust gas. The catalyst is at the heart of the SCR process. It creates a surface for reacting the NOx and ammonia, and allows for the reaction to occur within typical flue gas temperature ranges.Hamon uses a similar technology to reduce also VOC or CO content.Thorough knowledge in the design of all types of heat recovery systems including heat exchangers made of glass or fluoroplastic tubes to de-saturate the flue gas downstream a wet scrubbing system allows for minimum energy consumption when the flue gas needs to be heated.

Request for a quoteResults for

Heat recovery systems - Import exportNumber of results

50 ProductsCountries

Category

- Heat recovery systems (22)

- Components and parts for small household appliances (8)

- Central heating systems (7)

- Boilers, industrial (4)

- Heating, domestic - installations and equipment (3)

- Induction heating systems (3)

- Air purification - equipment and systems (2)

- Energy - production plants and equipment (2)

- Air conditioning, aeration and ventilation equipment (1)

- Boilermaking, heavy (1)

- Gas filters (1)

- Heat exchangers (1)

- Mechanical engineering - custom work (1)

- Plastics - machines and material for industry (1)

- Refrigeration plants and equipment, commercial and industrial (1)